Solid fuel, as the main source of heat, retains its position today ...

|

We make a solid fuel stove in a private house. Types of solid fuel furnaces and their characteristic

|

The domestic market is saturated with a variety of materials for finishing the ceiling, offering ... |

The scope of ceramic brick is extensive. It is used for laying load -bearing walls ... |

DIY polycarbonate fence

To protect the site, polycarbonate fences are increasingly used. Even a person who does not have the skills of the builder can build such a structure, but knows how to use the necessary tool. Polycarbonate fencing, made on its own, will successfully complement your landscape. In addition, it is easy to care for a polycarbonate fence: it is customary to wash it with a warm soap solution, without using metal brushes and solvents.

Content:

- The concept of polycarbonate

- Advantages of polycarbonate fences

- Disadvantages of polycarbonate fences

- Varieties of polycarbonate fences

- Installation of polycarbonate fences

The concept of polycarbonate

Iron and tree have not been the only suitable materials for all kinds of hedges, fences and fences for a long time. It is worth paying attention to the fragility and fragility of these materials, the properties of the wood over time to crack, break and rot, as well as the characteristics of iron to deform and rust, acquiring a very unaesthetic appearance.

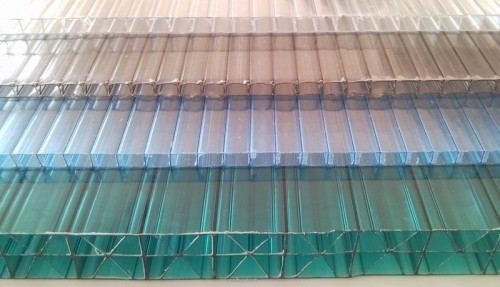

In the modern world of the latest technological discoveries and developments, you can easily find a solution to this problem. Cellular polycarbonate is offered to your attention, which is a synthetic polymer with special properties that make it popular in various fields.

Imagine a material that has a good level of light permeability, is in no way inferior in terms of glass characteristics, has high strength and flexibility. Polycarbonate designs combine the advantages of transparent and deaf buildings. They well hide from prying eyes all the events occurring on the territory, but they pass the sun's rays and look very impressive.

If desired, polycarbonate fence can be given absolutely any shape. One of the most valuable properties of cellular polycarbonate for the fences is its sound permeability: the material that absorbs noise creates a cozy and quiet situation in the house if it is located in the noisy part of the village. Polycarbonate is also useful for gardeners, its high light permeability protects plants from wilting and from the harmful effects of UV rays.

If you plan to independently make a polycarbonate fence, then you will have a lot of positive points: polycarbonate differs with lightweight, which is convenient for transportation, the material is easy to install, you just need to choose the right supports for fastening polycarbonate sheets.

Advantages of polycarbonate fences

The installation of polycarbonate fences has been widely used recently to protect the space of different accessories. You can see such fences in the courtyards of administrative buildings and educational institutions, country houses and private territories. The fence from the polycarbonate canvas is considered relevant at protected objects, parking lots, because transparency of the material allows you to constantly view the territory and control what is happening on it.

It is necessary to immediately make a reservation about the advantages of polycarbonate fences. Here are the main ones:

- do not respond to moisture, mold, corrosion, like iron and wood;

- resistant to daily temperature fluctuations and sharp differences, do not heat up in the sun, do not burst from frost, with reliable fastening of fences for giving polycarbonate they are not terrible for them;

- able to withstand large loads, take the necessary shape, since flexible (to varying degrees, depending on the plasticity, which is indicated in the instructions);

- are translucent and transparent, which allows you to create and not create a shadow for plants;

- do not require painting, all the care of polycarbonate fence is reduced to periodic washing with water;

- they absorb street sounds, acting as noise -protective screens, due to a peculiar cellular structure, therefore are often exhibited along roads and highways, not far from station and airports, protecting the population from excessive technical noise;

- they have different colors, harmoniously combine with wood, metal and artistic forging, converting a regular fence into a work of art.

Disadvantages of polycarbonate fences

Cellular polycarbonate fences have some negative sides:

- the mandatory creation of a metallic fastener from all sides, otherwise the fence will lead or take away the wind;

- there is a certain impact resistance, but polycarbonate, unlike concrete, wooden or brick fence, is not designed to throw bricks and sticks into it, as well as scratching with nails;

- in combination with curly pruning, forging and specific fastenings, beautiful polycarbonate fences often turn out to be more expensive than ordinary fences from corrugated board, wood or brick.

Varieties of polycarbonate fences

Thanks to the greater demand for decorative fences of plots, a significant assortment of different fences is presented on the market today, among which polycarbonate fences also occupy a considerable part.

Set fences

Collectible fences made of polycarbonate canvas are considered welded, since under the installation of a sheet the frame is cooked from a metal pipe or a standard corner. A piece of polycarbonate is installed on the back, using self -tapping screws or special locks. Such fences are often formed as forged fences. The price of polycarbonate fences and forged elements is higher than the standard option.

Stone fences

Another type of unique and original fences that entered the market several years ago is a fence made of polycarbonate and stone (brick). Popularity is determined by the success of polycarbonate and exclusive design ideas with an ideal combination of polycarbonate and stone.

Installation of polycarbonate fences

It is customary to build polycarbonate fences as follows: first, a trench is pushed for profiled pipes, a metal frame is made, it is installed in pits, drilling is made in a polycarbonate, with which cellular polycarbonate is attached to a metal frame. The sheets are of any color you like, then you can give them the look you need. Polycarbonate does not need to be painted or processing with special compositions.

Choosing material for the fence

As you understand, polycarbonate has a huge number of advantages. But the most significant drawback is high price. Therefore, the calculation of the needs in it is recommended to be made as accurately as possible, otherwise the launched construction of a polycarbonate fence will become too expensive. Therefore, pre -measure the perimeter of the site to calculate the length of the fence.

First, it is recommended to determine the thickness of the polycarbonate canvas. It is usually customary to use sheets that have a large thickness. For a country fence, it is worth choosing a cell polymer, which has a maximum thickness, so you can provide high soundproofing properties of the fence.

Finally, carefully study the composition of the material, since the risk of acquiring low -quality polycarbonate with different impurities is great. A monolithic polycarbonate is suitable for a country house, which is best stored away from sunlight to avoid excessive heating.

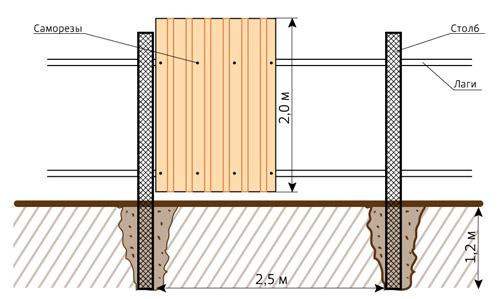

Then look at the photo of polycarbonate fences and a metal frame. It is recommended to use profiled pipes, 60 by 60 millimeters as pillars. Horizontal pipes that will be welded to them, select a rectangular section of 20 by 40 millimeters.

When installing metal pillars from the pipe and installing a polycarbonate fence, it is worth remembering some things that determine the strength of the fence. In the process of work, only certain proportions of the concrete mixture must be used. It is better to take concrete concrete of brand M 200 for the manufacture of concrete mixture.

Preparatory work

For the construction of a polycarbonate fence, prepare the following tools: a manual drill for drilling holes with diameters of 200-250 millimeters, a sledgehammer, which is designed to hammer pillars, a grinder for cutting a pipe, a screwdriver, a nylon thread and a building level.

The installation of a polycarbonate fence with your own hands should start with the marking of the territory. The marking of the site is carried out in two stages. Evaluate, first of all, the perimeter. Calculate the number of paintings and see how even the soil is in this place. If the surface is not even, pits and bugrs are found on the way, then you need to get rid of this problem using additional Earth or the materials replacing it or removal of the soil.

Designate where the foundations will be placed. After that, feel free to tear out the pits with the help of a drill. In any case, the depth of the lower part of the fence foundation should be located below the freezing level of about 200 millimeters. This is the most important requirement to create a pit for a profile pipe.

If your site does not have a suitable closed room for storing a polycarbonate canvas, then it is recommended to cover the material with a dense cloth that does not pass the sun's rays. On the sheets that were on top, it is necessary to put the load in order to protect them from strong winds. It is impossible to use PVC materials for coating, this can harm polycarbonate slabs.

Foundation for polycarbonate fences

When creating the foundation, it is necessary to rely on the indicators of the freezing of the soil. However, not every developer knows exactly what kind of freezing depth is on the site. Typically, the depth of the pit should reach 0.8 - 1.2 meters. The depth of freezing of the soil for most regions that belong to the European part of our mainland is no more than 700 millimeters.

However, it is better to act with a small reserve for reinsurance, which is able to compensate for any incidents with the level of groundwater, which leads to the bulging of the dimple foundation for the fence, the inclination of metal pillars and the destruction of the fence from cellular polycarbonate.

For complex soil, you can use an extremely full -fledged strip foundation, which has a depth of at least 1000 and a width of 300 millimeters. Under each pillar you need to dig up a deeper fossa and make a nest at its place of installation, which has large size, for example, 450 by 450 millimeters.

Reinforcement of a concrete foundation

When installing pillars for a fence from cellular polycarbonate, it is necessary to reinforce that an additional strength will give the concrete foundation. Reinforcement is extremely important when installing racks if you plan to arrange a more complex polycarbonate fence. So the polycarbonate fence can hardly perceive without the destruction of the moving of the soil, without changing the shape and geometry, as well as preventing the formation of cracks in the fence.

It is necessary to reinforce a fencing foundation, like any concrete structure, using the usual construction reinforcement of a suitable diameter of 10 - 16 millimeters. At least not less than 8 millimeters. Make sure that reinforcement is continuous and frame.

It is customary to weld the reinforcement or bind to the lattice boxes, which provide the stiffness of the fence foundation from the polycarbonate canvas and its strength, which is equal to the strength of the concrete structure. When installing reinforcement, it is not advisable to leave gaps or non -targeted fragments.

Installation of a metal frame

Before making a polycarbonate fence, you need to set the poles for fastening the polycarbonate canvas, having previously determined what depth it is necessary to instill them. High construction theory for developers proposes to use a not very complex formula for calculating the depth of the location of the pillars for polycarbonate fences.

However, we will bypass such calculations. Remember that the depth of cells for the installation of fence posts should be more than a similar indicator of the entire strip foundation. For example, for the foundation of a fence from cellular polycarbonate, you swayed a trench with a depth of about 1000 millimeters, and under the poles of the pit you need to deepen to 1200,1500 millimeters. See the photo in which there are appropriate drawings of polycarbonate fences.

Metal poles are customary to install at a distance of about 2 meters. Using the level, align the corner supports strictly vertically and pour a mixture of concrete and sand. After the masses dry completely, weld two or three lags from the pipe to the pillars. The resulting design is the basis for attaching a polycarbonate canvas.

Two corner pipes and two lags set the plane of one part of the fence. Throughout all the work, follow the verticality of the fence. And remember one subtlety. Pillars for polycarbonate fence are pipes, assure the upper part or close with plugs so that water does not get inside.

Drilling holes in the canvas

Polycarbonate sheets should be attached to pillars using conventional screws. You can also install such a fence using glue, bolts, rivets or welding. The distance when drilling holes from the edge should be at least 4 centimeters. The drill can be taken on wood or metal, but it should not be excessively large so as not to lose the structure.

Do all the mounts on the same level. Drill between the stiffeners so that the panels are tightly falling to the base. Plates must be mounted in the direction of the ribs of stiffness, vertically, closing on top with plugs or sealant. Polycarbonate is recommended to press tightly to the pillar so that the canvas does not move.

If the sheets of polycarbonate in size do not coincide with the one that is needed, you can easily cut them with a hand disk tool. Typically, for this, a disc saw with the following characteristics is used: the angle of sharpening - 150 degrees, the angle of inclination of the teeth is about 30-250 degrees, the cutting speed is about 200 meters per minute, the feed rate is close to 1800 meters per minute, the cut thickness is up to 5 millimeters.

Building a fence made of polycarbonate canvas, remember that when cutting polycarbonate and its drilling, this material can expand. But when cooling, the thermal compression is performed, and as a result, the diameter of the holes is reduced. Make holes when drilling 10-15% more planned.

Final work

The most difficult in the docking of the corner joint. Be extremely careful and use the level that the parties are the same in height. Consider some fastening of the polycarbonate canvas when joining and weather conditions must be tightened more.

Cellular polycarbonate for the construction of fences is covered with a protective film. It can only be removed after the installation of the fence in the summer cottage. There is another item that requires your attention sealing. Look at the photos of polycarbonate fences and make sure that the panels are protected from moisture.

You can fix the ends with aluminum tape, which is easily glued. Close the lower part with a perforated ribbon that provides free water flow if necessary and does not allow dirt and dust from entering. That's it, the polycarbonate fence is ready! Wipe the sheets, lubricate the mounts and make sure that these places do not rust. If desired, you can paint the frame.

If you are interested in how to build a polycarbonate fence with your own hands, if you do not have the opportunity to attract workers from the outside, you just need to follow our instructions and rules for installing fences, and also be able to use a certain tool. After all, independent installation of a fence from a polycarbonate canvas does not require special building skills, and almost any summer resident can produce it.