Abundant rains, as well as the stormy streams of water that fall from the roofs, forced people ...

|

|

The most popular today is a wooden floor, because the tree is ... |

Among several options for insulation of the facade, mineral wool is the greatest ... |

The scope of use of facing ceramic bricks. Characteristics and description of ceramic brick

The scope of ceramic brick is extensive. It is used for laying load -bearing walls, interior partitions, furnaces, pipes, fence pillars, etc. The facing ceramic brick is made according to a special technology, so it has not only an attractive appearance, but also high strength characteristics. They are faced by both new houses and old buildings during the reconstruction, giving them a new life. In addition, it is also popular in the interior decoration of rooms in the modern loft style. The article will talk about a variety of ceramic bricks, their properties and areas of use.

Content:

- The advantages and disadvantages of ceramic brick

- Types of ceramic brick

- Characterization of ceramic brick

- Wall cladding with ceramic brick

The advantages and disadvantages of ceramic brick

- High strength and wear resistance. It has been tested for more than one decade that it easily withstands several cycles of freezing/defrosting, without loss of its functions and external qualities.

- Soundproofing. Ceramic brick fully complies with the requirements for soundproofing in residential premises.

- Moisture resistance. It practically does not absorb water, and after heavy rain quickly dries.

- Environmental friendliness. In addition to the fact that it is made of natural materials and is safe for human health, it also has vapor -permeable properties, which allows you to maintain a favorable microclimate indoor, without the effect of thermos.

- High -strength. It has a density of 2000 kg/m3 and can be used in any climatic conditions.

- A variety of textures and colors. The method of its manufacture allows you to create a beautiful cladding of facades, giving them the appearance of ancient mansions.

Types of ceramic brick

Ceramic brick is available in several versions and is intended for certain purposes.

Private ceramic brick

- Its second name is building. It is full or hollow.

- In the hollow of ceramic brick, voids should not exceed 13%. It is allowed to be used in the construction of walls and structures, which will be provided with a load in addition to its own weight. So, it is suitable for the construction of supporting structures or supporting pillars.

Tip: a hollow brick holds heat better than full -bodied. Therefore, during the construction of a residential building from the latter, you need to take care of additional thermal insulation.

- For the construction of low private houses, it is most optimal to use a hollow version. They are less durable, but initially the project is not provided for large loads. But due to fragility, heavy objects are not recommended to be attached to such walls. During construction, a vertical or horizontal arrangement of cavities inside the brick is allowed. But horizontal voids are less preferable, as they negatively affect the strength characteristics.

Facing ceramic brick

- It is needed for the exterior decoration of buildings, so its second name is facade. Very high requirements are presented to its appearance: a clear geometry, an even plain color, a surface without defects.

- In most cases, facing brick is made hollow, which allows you to reduce the load on the supporting walls and ensure good thermal insulation.

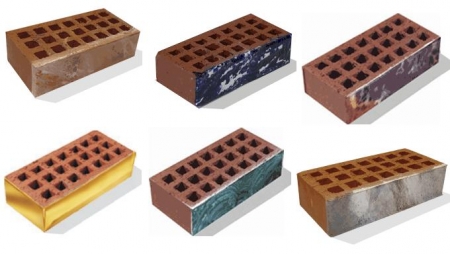

There are several types of facing ceramic bricks on sale:

- ordinary. It has a simple and smooth surface, the shape is strictly rectangular. It is not painted additionally, the color is obtained thanks to a certain temperature of firing and the time that takes it. This method guarantees that cladding will not lose its excellent appearance for many decades. The disadvantage is only a high cost;

- glazed. After the clinker brick passes, it is covered with glaze. The strength of such a coating is achieved by the main component of alloy glass. After repeated firing, the frost -resistant properties of the material increase;

- with Angobe. It looks most spectacular, as it imitates a natural stone. A decorative layer of white clay with the addition of dyes is applied on a base of ceramic brick. The result is a two -layer stone, which is also called Angobused Brick;

- textured. Suitable for finishing certain elements, for example, window openings or door arches. He will burn a different shape and texture. Often imitates wood or aged stone

Ceramic brick video

Characterization of ceramic brick

Due to its unique characteristics, ceramic brick still remains in demand, and sometimes indispensable building material. Strict requirements for the compliance with the GOSTs 7484-78 and 530-2007 are presented to it.

- Full -colored brick must weigh 3 4 kg. Due to the absence of cavities, it has high strength. It also has soundproofing and warm -intensive properties. Therefore, it is recommended for the construction of foundations, basement and first floors, stoves and fireplaces, carrying walls and supports. And when laying on the rib, it forms a thin but strong interior partition.

- Hollow brick. It has voids of rectangular or round shape. The weight of brick is within 2 2.5 kg. And the permissible number of voids in percentage should not exceed 15%. It has higher thermal insulation qualities, but its strength is much lower. Therefore, it is recommended for the construction of only walls of low -rise buildings and internal partitions. It is forbidden to use in zones with a high degree of humidity, such as basements or foundations. Water, getting into the cavity, fills them and leads to the destruction of the material. It is not suitable for laying furnaces. The presence of voids will lead to uneven heating of the material and to its possible destruction.

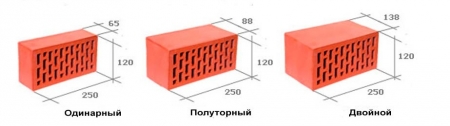

In size, ceramic brick is divided into:

- double with dimensions of 25x12x13 cm. It is made only hollow, when laying is required less than the solution;

- single 25x120x6.5 cm. Its size and weight are calculated for the purpose that it is convenient to take it with one hand, while laying a solution with the second;

- one and a half 25x12x8.8 cm. It can only be hollow, due to a reduction in weight and the required solution, the cost of masonry is reduced.

In the brand of ceramic brick, there is an abbreviation m, which means a characteristic of its compression strength:

- M175 and M150intended, basement floors and foundations;

- M125 suitable for the construction of the load -bearing walls of low houses and arched openings;

- M100 and M75for load -bearing walls and partitions;

- M50 For structures that do not turn out to be a load.

The brand of brick should be indicated in the project of the house. The higher it is, the stronger and denser the material, and therefore higher and its weight.

- Coefficient of thermal conductivity It depends directly on the presence and number of voids. So, for complete material, this value is in the range of 0.5 0.9 W/m x degrees C. And for a hollow from 0.3 to 0.5 W/m x degrees for the middle lane and northern regions, at The thickness of the outer walls up to 100 cm requires additional insulation.

- Frost resistance. This is an indicator that indicates how much the material will withstand the material with a freezing cycle without losing its qualities. Values \u200b\u200bvary greatly depending on the density of brick. For laying external walls, F50 material is used. A particularly strong facing ceramic brick has a F150 value. Material with F25 indicators is used only for internal walls.

- Moisture resistance. The material should have a low waterjack. For full brick, no more than 13-15 % of water should be absorbed relative to the mass of the material after it is 2 days in water.

- Color. It directly indicates the quality of the material. There is a special reference color, which is approved by the plant on which the brick is produced. Bricks obtained from clay are red, but after firing this color is called brick.

Tips for buying ceramic bricks:

- having decided on the project of the house and the desired brand of brick, the seller needs to ask for a certificate of compliance with the product of GOST and the declared brand;

- it is advisable to inspect several bricks from the party for chips, cracks or uneven color. In the case of their detection, you should not buy such material;

- when tapping the brick, which is held with one hand, the sound should turn out to be sonorous.

Wall cladding with ceramic brick

Laying of facing ceramic brick

The facing brick is directly under the influence of the environment. Particular attention is paid to the pantry for him, since it should equally resist the frost, heat and moisture for many decades. Therefore, it is worth highlighting the main important requirements:

- high response qualities. The main condition is a strong adhesion of facing brick with the walls of the house. This is achieved due to the porosity of the material. But clinker facing bricks are highly density, as a result of which a simple solution based on cement and sand becomes unsuitable;

- strength. The finished cladding has a large weight, and in order to avoid cracking of the seams, the grasping solution must have high strength qualities for compression. Even at the masonry stage, the seams should turn out to be uniform and not pushed under the weight of subsequent rows;

- the pantry must be well mixed, during operation, excess water should not be released;

- ready solution must dry evenly, too quick grasp (less than an hour) indicates a technological violation;

- since the finish cladding of the walls of the house is performed, decorative qualities of the seams masonry should be on top;

- seams must remain unchanged At any time of the year and under any weather conditions. It is especially important that it serves an obstacle to education on masonry.

Of course, even given all of the above requirements, you can make such a solution yourself. But in case of failure to redo something, it will be already impossible. Even experienced matters recommend buying special compounds, especially when it comes to clamping with clinker brick.

Is it worth making wall clading with ceramic brick with your own hands

The temptation to do these works and save a decent amount of money is very large. But if you figure it out, the cladding of the house with a brick is the most difficult stage of work. To make the masonry beautiful and durable, a large amount of experience is required. In addition, the cost of facing ceramic brick is high, as is the price of a masonry solution, which meets all technological requirements.

Based on all of the above, it becomes clear why professional construction brigades appoint a high cost for this work.

- It is very important to do everything in one summer, without leaving the masonry unfinished until next year. But this work is slow. For clarity, we give an example. Take the walls of the house, the area under the cladding of which is 300 m2. A professional mason who works with a helping officer bringing bricks and a solution, a day will be able to lay approximately 300 bricks of a standard size. This is a little less than 6 m2. It turns out 300/6 \u003d 50 days. But taking into account that the working days is only 5 in a week, then 50/5 \u003d 10 weeks. In rainy weather, you cannot work with the solution. Therefore, in the most optimistic situation, 20% are laid on rainy days, it turns out 10*1.2 \u003d 12. So, an experienced storehouse with an auxiliary for such a house will take at least 3 months.

- Even having golden hands, the owner of the house without proper practice will not be able to lay more than 100 bricks per day, which means that the work will stretch for 3 seasons. The brick should be purchased immediately, since it may differ in color from different parties. Therefore, you will have to think through the storage conditions for this expensive material two winter.

Therefore, we decide to make the lining of the house with a ceramic brick with your own hands, you need to calculate your strength well so that the construction does not overgrown with a multi -year headache.

Questions and answers about facing brick

- Is it necessary to do wall cladding tedious? Ceramic facing brick is designed not only to improve the external decorative qualities of the building, but also to increase its operational period by protecting the load -bearing walls from negative atmospheric influence.

- Is it possible to masonry ceramic bricks at minus temperature? It is forbidden. The fact is that in the frosts the brick does not have sufficient waterwork and simply does not absorb the required amount of moisture from the tub solution. If, with conventional laying to the solution, salt is simply added, which prevents quick freezing, then in the case of facing material this is excluded. In the future, due to such an additive, no walls of the house may appear in white.

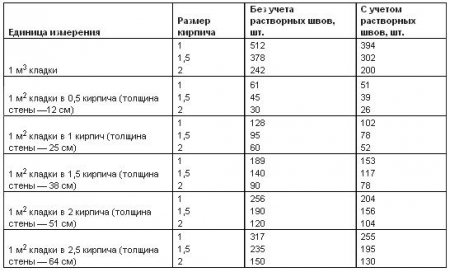

- How to calculate the amount of facing brick? First, each wall of the house is measured separately, its width and height. Window and doorways are subtracted from the resulting area. Separately, they consider the area of \u200b\u200bbiases, verandas or porch. Given the masonry joints, 52 bricks are spent on 1 m2 of walls. Therefore, the resulting area is summarized and multiplied by this number.

Installation of ceramic brick

First, you should decide on the type of masonry. The appearance of the finished walls and the technological process depend on this. If the experience of such work is not enough or at all, then it is better to choose the simplest technology, for example, the front. The most complex is the masonry technique called the stack, it is better to abandon it with independent work.

Necessary tools for facing brickwork

- trowel;

- hammer;

- cord;

- bulgarian;

- for alignment of angles, metal rods with a diameter of 10 cm;

- building level;

- anchor;

- wire for fixing cladding with a bearing wall.

Stages of work

- As the grounds on which the facing brick will be laid, a ledge of the foundation of the house will serve. It needs to be cleaned from garbage and dust. After that, the horizontal level is checked, if there are deviations, they make formwork and align with the solution.

- Prepare a solution. If a special mixture is not purchased, then all proportions will have to be mixed independently using concrete mixers. Use river dark sand, it has a smaller fraction. It is mixed with the cement of the M500 brand in those proportions that the manufacturer indicated on the pack. When the dry components were evenly mixed, they gradually add water without ceasing to knead. They do this until the solution is a homogeneous plastic consistency. Having taken him in his hands, he should not crumble.

- Before the work, it is advisable to place bricks in the water. Then get, put in a row and check its horizontal evenness with the level. The procedure is repeated with each brick.

- The first row is laid directly on the waterproofed foundation. Only vertical seams are fastened with a solution. In most cases, the length of the foundation does not correspond to the size of the masonry row. Therefore, the extreme brick should be cut.

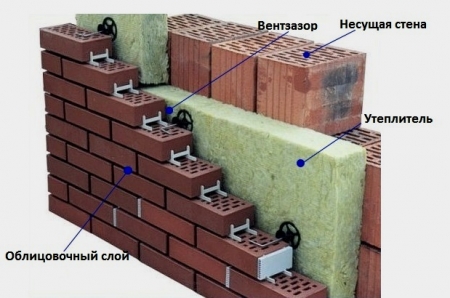

- Between the facing line and the wall of the house, a venture of 3 cm is left.

- When the first row is finished, they begin to lay out the corners at once in several rows up. It is they who will become the guarantor that the masonry will be performed correctly. In case of violation of the geometry of the corners, the entire cladding will have curvature, so this is the most crucial moment.

- To make the ranks even, after the first row, they make a guide for them. The twine is tightly pulled and pressed in the corners so that the brick is located exactly along the twine. They put the solution and begin the laying of facing bricks, if necessary, pressing the hammer to press the brick into the solution so that it rises along the stretched level.

- The cladding is necessarily tied to the house, recently a new or old building. There are 2 technologies in total, how to do it:

- in the first case, the binding is carried out through dowels and knitting wire. This is the most relevant for brick or monolithic houses. At the rate of 5 dowels on M2 masonry in the load -bearing wall, holes are made and mounted are driven. They screw the wire with the calculation so that its ends are firmly attached in the facing laying. But did not show out;

- in the second case, the role of fasteners is played by galvanized anchors. They are driven by the wall and the knitting wire is screwed similarly to the first method. It is optimal to use an anchor with a diameter of 0.6 mm.

- When the masonry reaches the door or window opening, the most crucial moment begins again. These elements immediately attract attention, so they often perform a brick contrasting color. For greater decorativeness, masonry of slopes is performed by pumpkin technology.

- When the solution grabs, the stage of the seams begins. To do this, prepare a special solution consisting of lime, cement and sand in a ratio of 1: 1: 10 parts. Add water until the consistency becomes pasty. The finished solution is applied to the wall pre -moistened with water and neat seams are formed.