By purchasing an interior door, it is impossible not to face the problem of choosing a door ...

|

|

The active development of technology allows today to create unique construction ... |

More and more people are thinking about installing stretch ceilings in the apartment. AND... |

We make a solid fuel stove in a private house. Types of solid fuel furnaces and their characteristic

Solid fuel, as the main source of heat, retains its position today. Despite the alternative to heating housing with gas or electric boilers, solid fuel furnaces are still installed in private houses, cottages and summer cottages. Modern modifications appear that provide long -term burning and the safety of the use of furnace equipment.

- Advantages and disadvantages of solid fuel furnaces

- Components and the principle of operation of the furnace

- Classification of solid fuel furnaces

- Making a solid fuel stove DIY with your own hands

Advantages and disadvantages of solid fuel furnaces

For some regions, electric or gas heating remains inaccessible. Electricity tariffs make housing too expensive. In addition, electric heating is completely dependent on the flow of current.

There is no ability to install a gas boiler in many areas, rural flags and summer cottages of the gas distribution network. Heating options using geothermal springs or solar energy for remote regions are little relevant and not always effective in conditions of harsh winter.

In such cases, the most rational and economical solution is the installation of a solid fuel furnace, the work of which requires only coal or firewood.

Advantages of a solid fuel furnace:

- High degree of economy. Solid fuel renewable source of thermal energy.

- The ability to make with your own hands. The simple model of the furnace will be made independently using metal, cylinder or brick.

- Good level of efficiency. In traditional Russian furnaces, efficiency reaches 40%, modern high -tech models show the effectiveness of work up to 70%.

- High heat capacity. After the fuel fuel is attached, the stove cools slowly, continuing to heat the rooms.

- Multifunctionality of furnace equipment. The product can be designed and built with a hob or fireplace.

- Independence of work. The system is autonomous does not require communications.

- The stove heating can be improved and connected to the water, increasing the efficiency.

The disadvantages of solid fuel furnaces include:

- The traditional stove occupies a lot of useful space in the house. However, the modern equipment of the Swedish and Dutch design occupies less space.

- To maintain a stable temperature, you have to constantly control the process of fire combustion.

- The need to build a chimney and its high -quality isolation from rapidly ignited structures.

- The uneven heating.

- Incorrect structure and errors in operation can lead to emission of carbon monoxide.

- When using the furnace, fire hazard increases.

- The need to regularly clean the chimney from ash large accumulation of soot can provoke minor flashes or ignition.

- A large supply of fuel is required. Under the placement of firewood, it is better to highlight a separate small room.

Components and the principle of operation of the furnace

Before proceeding with the construction of heating equipment, you should familiarize yourself with its device and the principle of operation.

To maintain the combustion process, oxygen access is required. At the same time, as a result of combustion of fuel, carbon dioxide is released, which needs to organize free access to the atmosphere.

Based on the features of the process of stove heating, the design should be provided for three main zones:

- Fuel. In this compartment, firewood or coal is burned. The dimensions of this element are selected depending on the area of \u200b\u200bthe heated room.

- Ash. It is placed in the lower part of the structure, the main task of the element of the supply of oxygen and the removal of combustion waste.

- Chimney. Provides the withdrawal of smoke and selection of heat energy. Brick stoves can be equipped with several moves.

Most furnaces operate on the following types of fuel: pellets, wood, sawdust, chips, Euro, stone coal and boura.

Important! For the firebox, you need to use a well -dried tree. Dry wood when burning gives more gas, and therefore more heat

The entire process of the furnace can be divided into the following stages:

- Firewood is tightly laid in the furnace and set on fire.

- Oxygen enters the fuel in a limited amount of combustion process slows down and smolders fuel.

- The burned firewood turns into coal, which during processing releases heat.

Classification of solid fuel furnaces

Safety largely depends on the competent approach to choosing a furnace, the convenience of its use and comfort in the house. It is desirable to determine the type of heating unit at the stage of designing the house not every model of the stove will be integrated into the finished building.

Brick models of solid fuel furnaces

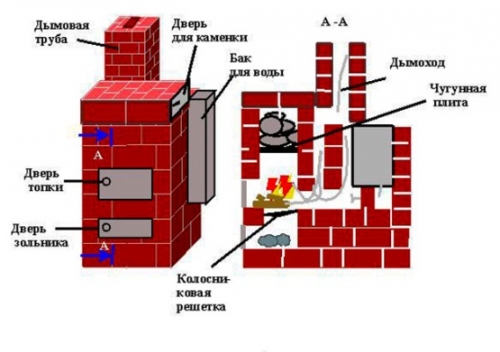

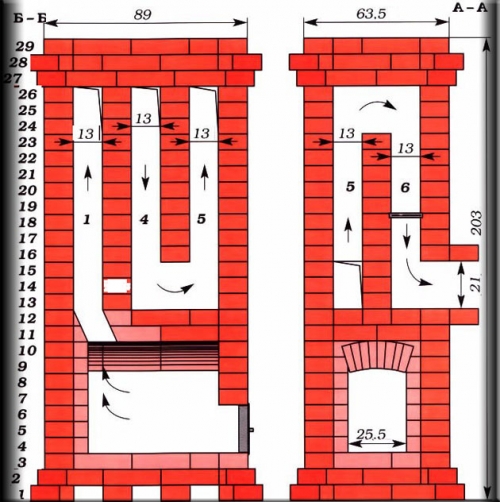

The standard equipment of a brick solid fuel furnace includes a fuel, a blowing chamber, grate, cleaning, doors and valves. Depending on the features of the design, the following types of brick furnace equipment are distinguished:

- direct -flow;

- anti -flow;

- channel;

- cold.

Direct modelsThe most easy installation. Smoke rises along a straight channel up. By this principle, a Russian stove is arranged. The main drawback is low efficiency and the low rate of heating of the room. Most of the heat goes into the environment with combustion products.

Solid fuel furnace for the house - a photo of a direct -flow structure.

Anti -flow furnace It has a more complex design. The air is supplied from below, warms up and rises up the lifting channel. As it cools, it sinks down two chimney channels.

Characteristics of solid fuel furnaces of the anti -flow type:

- the convective heating system determines the high level of efficiency;

- the furnace body warms up quickly enough and evenly;

- the possibility of arranging a hob.

Advice. The manufacture of anti -flow furnace equipment is best entrusted to the professional. The specialist will perform the exact calculation and high -quality installation of the furnace

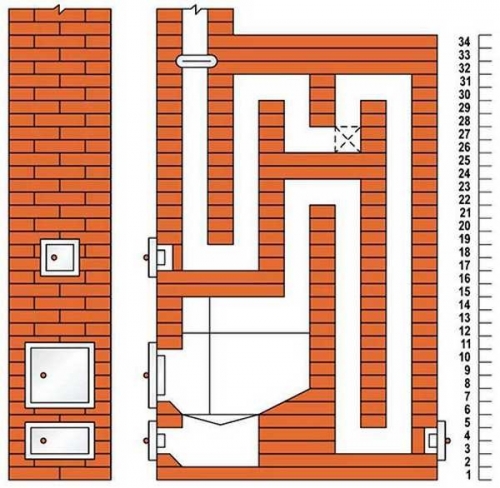

Canal furnaces They are equipped with horizontal and vertical moves along which combustion products circulate. Warm air, passing through the channels, changes its direction and gradually gives the heat to the furnace body. Due to such a system, heating efficiency increases, and the room warms up faster.

Features of the device of different types of channel furnaces:

- Vertical channels. Staging air flow can provoke smokes. To prevent the stove, is equipped with a firebox that works according to the principle of a direct -flow model. Topies regimes are regulated by valves.

- Horizontal channels. In such passages, the air does not accumulate, the risk of smoke is reduced. Horizontal models are easier to maintain.

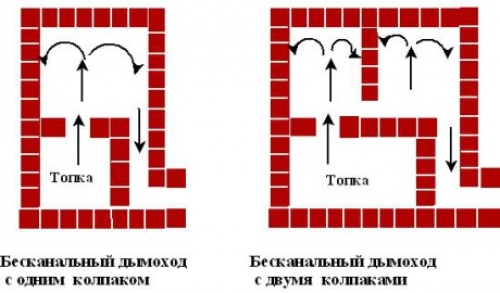

Colling stoves They are considered the most productive. Hot air rises and rests against a brick cap. The cooled air is supplanted into the chimney with newly received combustion products. There are models with one and two caps.

Some refuse to install a cap of a cap, considering it explosive. Theoretically, non -combatant gases can accumulate in the cap of the cap and explode under certain circumstances. In practice, this happens extremely rarely. According to experts, the risk will be able to minimize, abandoning wood heating and switching to the kindling of coke, anthracite and stone coal.

Depending on the dimensions of the structure, they distinguish:

- Thick -walled models (thickness more than 12 cm) large -sized furnaces with high heat capacity. It will take about 3 hours to warm the rooms to a comfortable temperature.

- Thin -walled stoves (up to 7 cm) quickly heat up and begin to give heat for 30 minutes. The efficiency of such models is higher, but the ability to accumulate heat below.

The form is selected taking into account the layout of the house and placement of the furnace. The most in demand: rectangular, polygonal, corner and T-shaped models.

Metal house

Modern metal solid fuel furnaces are equipped with automation system, control levers and sensors. This makes it possible to adjust the heating temperature. An important plus increase in safety.

Types of solid fuel furnaces for the home, depending on the material of the heat exchanger:

- Cast iron models. The main advantages: durability, high heating speed and slow cooling. Lack of material susceptibility to sharp temperature differences.

- Steel furnaces are resistant to thermal passages, but sensitive to the formation of condensate on the case. Over time, corrosion may be subjected to corrosion.

In terms of functionality, metal stoves are divided into two categories:

- Single -circuit. Perform one task of heating the room. The models have the ability to connect a water heating tank.

- Double -circuit. The functionality of the models is expanded: maintaining a comfortable temperature regime in the house and providing hot water supply. The arrangement of the system allows you to do without an electric boiler.

Solid fuel stoves of prolonged burning according to the principle of action are divided into traditional and gas generator. The first option corresponds to the pyrolysis type of work. The second option is characterized by constructive features:

- the presence of two gas -tight chambers located above the other;

- a nozzle is installed between the gas compartments;

- fuel loading into the lower chamber;

- the presence of a built -in fan to accelerate the process of fuel and combustion.

High -tech samples have an automatic supply of solid fuel. The design provides a separate bunker for laying out the supply of fuel.

Important! The furnaces of prolonged burning are more profitable and effective in use. They have a high degree of heat transfer and more economical fuel consumption.

Making a solid fuel stove DIY with your own hands

Preparatory events

Before construction, it is necessary to develop a detailed drawing of a solid fuel furnace, since construction by eye can lead to errors, the correction of which will cost expensive. Experts recommend first to perform dry masonry, check the design of the design.

The necessary materials and tools:

- water, sand, clay;

- refractory bricks;

- roofing material and polyethylene;

- building level;

- metal sheets and pipe;

- building level;

- grate;

- furnace door;

- counstrans, kiyanka and rubber hammer.

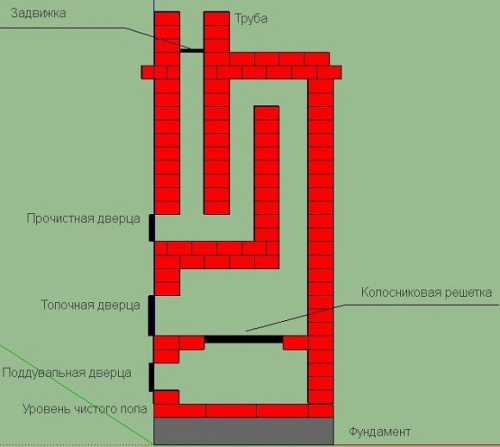

Stages of building a Dutch stove

The sequence of actions for the construction of the furnace:

- Put the roofing material, pour a layer of sand, align it and check the horizontal coating with a level.

- Lay 12 bricks, control evenness, pour a layer of solution of clay and water. Add sand to the mixture.

- Mount the blower door, wrapping it with asbestos cardboard and fixing it with an excessed wire.

- Put the second and third row, place the grate.

- Put the fourth row on the rib.

- Install the stands for the chimney. On the back wall of the structure, lay bricks without using the solution.

- Place the furnace door.

- Put the fifth row by analogy with the fourth, but flat.

- The sixth row is the installation of bricks on the rib. Check the evenness of the corners of the furnaces.

- The seventh row the front bricks are laid out flat, and the rear with installation on the rib. Subsequently, all bricks are exposed to flat.

- The eighth row is located above the firebox.

- The ninth shifts back a little, and asbestos cardboard is laid on top of it. The tightness of the joints is checked.

- To equip a chimney, mount a valve and compact it with an asbestos cord. Form a joint with a metal pipe in a quarter of a brick.

- Close the gap at the base of the furnace with a metal sheet.

- Find the structure.

To verify the operation of the furnace and put it into operation, it is necessary to wait for the complete drying and setting of the solution. After three to four days, you need to put paper in the furnace and check the traction.

Homemade solid fuel stove: video