Many garage owners try to equip them with maximum functionality ...

|

|

Despite the fact that interior designers do not cease to surprise us ... |

From the point of view of professionals, the facade of a private house is its architectural ... |

How to choose a polycarbonate right

The active development of technologies allows today to create unique building materials that are significantly superior to predecessors in terms of operation, ease of installation and qualitative characteristics. One of these polycarbonate.

Due to its practicality, strength and external aesthetics, polycarbonate is successfully used not only in agriculture and construction, but also in the field of outdoor advertising. The shock resistance of this material exceeds such a glass by more than a hundred times.

Polycarbonate is born by polycondensation of coal acid chlorohydride and definitionelopron.

Table of contents

- Types of polycarbonate

- Cellular polycarbonate - which one to choose and what to pay attention to?

- Choosing a material supplier

Types of polycarbonate

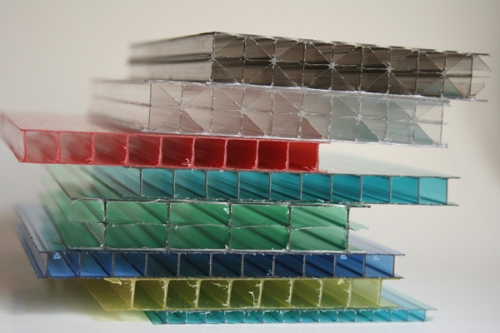

Cellular polycarbonate

It is the most common type of polycarbonate used in the construction industry at the moment. Due to the small specific weight of cellular polycarbonate, the structures from it are light and airy. This material has high plasticity and strength. A large number of voids reduces the weight of the leaf, and, consequently, its cost.

Actively applied:

- in industrial construction (production of corps parts of equipment);

- in urban construction (glazing of stops, telephone rooms, roofs; creation of arched structures);

- in agricultural (glazing greenhouses, construction of agro -industrial objects and complexes)

- in the field of advertising (light boxes, scoreboard, visors, volumetric letters);

- when creating interior design (balconies, suspended ceilings, winter gardens, partitions).

Key advantages of cellular polycarbonate

- Fire resistance (when exposed to high temperatures, the material begins to melt, but the spread of flame does not occur).

- The convenience of installation (all the panels are adapted for light and trouble -free installation using ordinary tools: drills, saws, screwdrivers).

- Transplantability.

- Excellent insulation properties.

- Extreme ease.

- Resistance to weather whims (thanks to a special outer layer, the panel is protected from wear and yellow).

The warranty life of the structure of cell material for ten years. In practice, it can last and thirty depends on how competently the choice of polycarbonate was made.

Monolithic polycarbonate

Due to its decent cost, for the construction of horizontal structures, it is used much less often than cellular. True, his strength characteristics are much higher.

A sheet of monolithic polycarbonate is a whole transparent plate. Its thickness, as a rule, is from 2 to 12 millimeters.

The material has found its application in:

- production of outdoor advertising (stenters, signs)

- production of industrial greenhouses and fences in agricultural;

- construction of gyms, stadiums;

- financial sphere.

Warranty life of 10 years.

Of course, all of the above characteristics and advantages will be inherent in extremely high -quality, certified products. Therefore, it is very important for an ordinary buyer to know how to choose a polycarbonate.

Cellular polycarbonate What to choose and what to pay attention to?

If you have a desire to create a translucent structure within your private estates, then your optimal choice is cellular polycarbonate.

Polycarbonate thickness

The first thing that is worth deciding in the search process is the optimal thickness of the polycarbonate sheet. It is determined taking into account factors such as the snow and wind load on the structure, the bending radius, the step of the crate.

Cellular polycarbonate of minimum thickness cannot be recommended for external structures. Although the misconception that subtle material significant savings continues to overcome the minds of the townsfolk. Look at the question sensibly: what kind of savings are it if sheets of less thickness require a more frequent step of the crate with considerable additional expenses on the profile. But falling into another extreme, choosing the thickest samples is also wrong. Each design is individual calculation.

Compliance with weight standards

Before choosing a polycarbonate, it would not be superfluous to make sure that the sheets offered to you meet world weight standards. Feel free to be corrosive in your interests.

One square meter of a sheet with a thickness of 4 millimeters should weigh 800 grams, 6 millimeters of 1.3 kilograms, 8 millimeters of 1.5 kilograms, 10 millimeters of 1.7 kilograms, etc. Cellular polycarbonate declared by the manufacturer will withstand exclusively with real compliance with these numbers.

A number of manufacturers, pursuing the purpose of reducing the cost of production costs, reduce the weight of a square meter of material. Do you have the consequences of such savings? Undoubtedly. With a reduction in weight by 10 or more percent, automatic proportionate quenching of the horizontal and vertical walls of the sheet occurs. And this entails a significant deterioration in the bearing characteristics of polycarbonate.

In fairness, it is worth noting that in some cases, for some types of design, lightweight sheets can be used quite successfully, but, you see, the buyer has the right to know that this is a light. Civilized manufacturers stipulated by the company's policy by the method marify such samples. It can be:

- word Light (CarboglassLight, Polylight);

- the letter in the title (Makrolon B-Line);

- a somewhat different trade name.

The guarantee for lightweight sheets, as a rule, is no more than five years.

The color of the plates

Which cellular polycarbonate is better - blue, turquoise, milk, bronze, transparent, green? I would like to answer the one that you will like. But this is not so. It is very important to consider the purpose of the design.

The blue, turquoise, green coating will be able to very successfully shade the basin zone, but will be an extremely unsuccessful solution, for example, for a outlet, since the color of all objects located under it will not be recognized.

Transparent polycarbonate is recommended for greenhouses, but we do not want to arrange a recreation area you just go crazy with the heat.

There are many similar examples, therefore, if you doubt the correctness of your judgments, it will not be superfluous to consult about the optimal color scheme for a professional.

Trademark

The quality of the material directly depends on who made it and where. This is an axiom. The external similarity of all products presented on the market is only an illusion; Each manufacturing company is characterized by its chips and intricacies of organizing the production process.

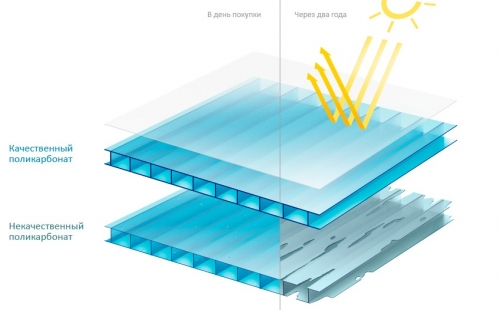

Polycarbonate from leading companies is necessarily equipped with a layer of UV protection applied by the coexstrusia method. Such a layer protects the material itself, as well as what is under it from hard radiation.

Many technological nuances take into account their reputation in their reputation in the manufacture of sheets. One of them does not exceed the amount of secondary raw materials established by the norms. The material from Europe and Israel will definitely serve you for many years, without causing problems and inconvenience. What exactly can not be said about the Chinese fake with such products, you will simply lose money and time.

Choosing a material supplier

The answer to the question of how to choose a cellular polycarbonate, without an algorithm for calculating a conscientious supplier, cannot be considered complete complete. Therefore, we bring to your attention the following criteria for waging:

- An experienced, even seller always follows the principle of an individual approach. Polycarbonate designs of polycarbonate structures cannot be rowing under one comb.

- If the supplier actively claims that there is no difference, except for the price, between the brands, feel free to run away from this outlet with a high degree of probability, it can be assumed that here they will try to slip high -quality goods not very well;

- Do not believe the arguments to buy material more or less thickness than an independent professional advised you to be motivated by attempts to push samples stuck in the warehouse.

- A decent supplier, in addition to the manifested honesty and professionalism, will definitely offer you to purchase components, thermal -haired, end tape necessary for your polycarbonate structure. He is not afraid to push you with additional expenses because this inventory is really necessary for high -quality installation of the structure.

An honest seller will always tell you which polycarbonate is better and at the first request will provide documentation confirming the characteristics and quality of the material.

the article is very useful

the article is very useful

Supply extrusion

We supply extrusion lines for monolithic or cellular polycarbonate http://www.extruder-cn.com