Wallpaper is one of the most popular materials for interior decoration. They distinguish more ...

|

|

One of the most difficult works when repairing housing, according to both masters and ... |

Among the latest developments of universal decorative coatings for decoration ... |

Laying roll roof with your own hands

Rolled materials cannot be called aesthetically attractive. Nevertheless, there are conditions in which the roll roof is almost the only option for coating the roof. This is a flat roof, a single -sloping or multifaceted roof with a small slope of up to 30 degrees. The device of the roll roof provides the tightness and water resistance of such roofs. Garages, storage facilities, hangars, retail premises, enterprises and high -rise buildings are covered with roller materials. The installation technology of roll roof depends on many factors, including the type of material and the slope of the roof. To perform work, you will need at least three people. How is the styling, what should be paid to and what rules to observe, we will tell in this article.

- Types of rolled materials

- Roller roof: technology for arrangement and fasteners

- The technology of laying roll roofs in a fusion method

- The technology of laying roll roofs cold

- Adjoining the roll roof to vertical elements

- Non -rolled roof: installation technology

- Laying roll roofs: video - Example

Types of rolled materials

The days passed when the only roll materials for the roof were roofing and only. Their service life did not exceed 5 7 years, since the cardboard base was quickly destroyed under the influence of water, bitumen crackled under the influence of sunlight and temperature changes. Modern technologies have significantly improved the characteristics of bitumen materials, extend their service life up to 15 25 years and make more universal.

Modern roller materials have a more durable base, complex structure, have increased plasticity and frost resistance and can be attached to the base in various ways.

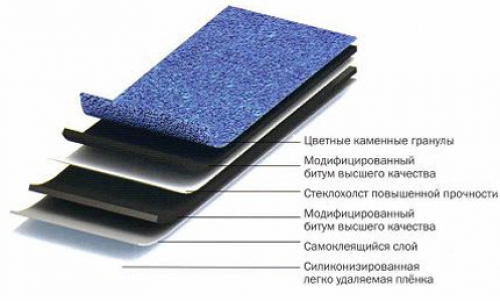

Roll roofing materials are not the same, they differ in the basis of the base, the binding substance and the material and the fraction of sprinkling.

As the basis of roll material are used glasshold, fiberglass and polyester. The most durable, reliable and expensive material on a polyester basis is considered.

As a binder Use oxidized bitumen and polymerized bitumen. Polymeric materials are more resistant to temperature changes, more elastic, which allows them to be used on roofs with a complex relief, and more durable to break efforts. Different substances are used as polymer additives, but stylbutadianstyrol is considered the best.

Sprinking on the surface of rolled materialsit differs not only in the type of material, but also in the size of fractions. Distinguish bright -grained, medium -grained, fine -grained, polvoid and scaly sprinkling.The main function of sprinkling bitumen protection from direct sunlight, increasing its strength and resistance to mechanical loads, therefore, in most roll materials, sprinkling is only on the front side of the material.

Separately, I would like to note materials that do not have a basis. They are called nonsense. Such materials are obtained by heat treatment of polymer binders with various additives and fillers, then the resulting composition is rolled into canvases.

In total, 4 generations of rolled materials can be distinguished:

- Ruberoid. As already written, the material is not durable, but it continues to be used to cover the roofs of uncertain objects.

- Substered roofing material. It differs from the usual roofing material in that on its basis there is already a layer of bitumen, during the melting of which the canvas of the material is glued.

- Glass -rubled. As a basis, fiberglass or polyester is used. The glass -rubleberoid is more durable than the usual roofing material, its service life reaches 12 15 years. Not afraid of temperature changes and frosts, as well as ultraviolet rays. It is considered a more reliable option for arranging roll roofs. It is attached by salary or mechanical fixing.

- Membrane rolled material The most modern at the moment. The service life of membrane material reaches 20 25 years. It uses the most reliable and durable binders, fiberglass as a base, as well as colored granules of sprinkling. The main difference between membrane roller materials is that they are self -adhesive. On the underside there is a special protective film that hides the adhesive layer. It is enough to remove the film, roll out the material, align it and it will stick it itself when the sun's rays heat up the adhesive layer of the base.

When choosing roll material, pay attention to the marking. There are such types of coatings:

- N lining;

- To roofing;

- E elastic.

Material with appropriate marking can only be used in certain conditions. For example, lining roll material can only be used as the first lining layer. Roofing material can be used as the upper layer, and elastic is conveniently used to enlist complex vertical elements.

Roller roof: technology for arrangement and fasteners

The technology of laying roll roofs depends on several factors: first of all, on the slope of the roof slope.

For example, the number of layers of roll material should be:

- 2 layers are enough if the slope is more than 15 %;

- 3 layers if the slope of the roof is 5 15 %;

- 4 layers, if the roof is flat, a slope is 0 5 %.

The maximum allowable slope of the roof, in which you can use rolled materials, is 25 %.

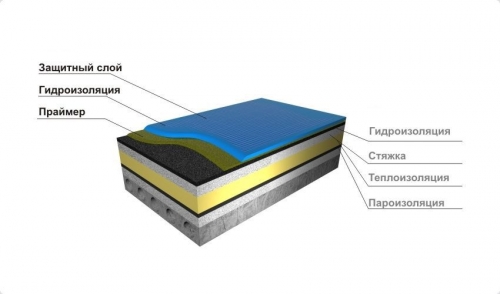

Technology for laying roll roofs on a flat rooflooks like that:

- Base in the form of a concrete floor slab;

- Vapor barrier film to protect the insulation from wet vapors coming from the premises;

- Thermal insulation material. Most often used stone mineral wool in plates and extruded polystyrene foam;

- Screed with a layer of 2 7 cm;

- Rolled roofing material in 2 3 or 4 5 layers.

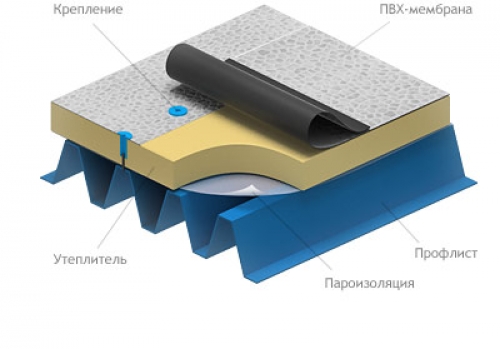

If the roof is made of metal profile, then the layers of the pie look like this:

- Roofing material of corrugated board;

- Thermal insulation material;

- Rolled roofing material.

Basically, this method of laying roll roof is used to cover the hangars and other warehouses. Please note that the base should not let pairs from a heated room. Also, laying the roll material on top of the insulation is not the most successful option, since the resource of the insulation is reduced. But this method is still used, since most often it is not recommended to overload such roofs with screed.

Technology for laying roll roofs on the pitched roof:

- Vapor barrier film inside the attic or attic;

- Thermal insulation material between the rafters;

- Waterproofing superdiffusion membrane;

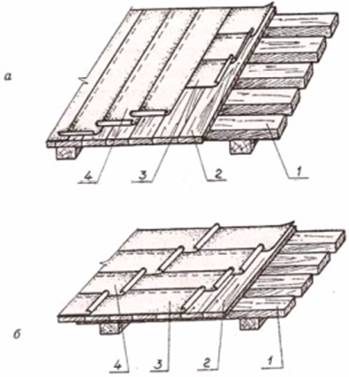

- Continuous crate in the form of sheet sheets or moisture -resistant plywood;

- Rolled roofing material.

All layers of roller material must be laid with a displacement so that the places of joints and overflows do not coincide.

The cost depends not only on the price of the material used to lay the roll roof, but also on the styling technology and on the fasteners method. For example, laying material in 2 layers on a ready -made base will cost 7 cu. For 1 m2, if it is necessary to perform a screed and lay the insulation, then such work will cost 40 cu. for m2. Laying membrane material by mechanically even on a ready -made base will cost 14 cu. for m2.

There are several ways to fasten hard roofing materials:

- Mechanical method With the help of roofing nails. It is usually used to fix the first lining layer.

- Frusting the material. A gas burner is used, with which the lower bitumen layer of the material melts and the canvas is glued to the base.

- Gluing on bitumen mastic. The base is thoroughly coated with adhesive composition with the bitumen mastic of cold application, and then rolled material is glued to it. Thus, all layers of the roof are attached, from the first lining to the roof of the last.

- Self -adhesive materials. As already written, there are materials, the lower layer of which is adhesive. It melts and acquires adhesive properties from heating under the sun's rays. Such materials are simply easy to fix with a roller in places of overlap and joints.

The most common way to attach roller roof material is to pay. The last category of self -adhesive materials belongs to expensive materials, therefore it is used less often. But at retail and residential facilities with a flat roof, membrane materials are increasingly used.

Laying roll roofs: diagram

The location of the paintings of the roll material depends on the slope of the roof.

On a flat roof, laying of roller materials begins in the lowest place.

On the pitched roofs with a slope of less than 15 %laying is performed in parallel to the skate. It is necessary to start from below, from the overhang and move up. After laying the material on the slope of the roof, the canvas is cut off and laid on the roof ridge so that the water drains down.

On the pitched roofs with a slope of more than 15 %laying is performed across the skate. The upper edge must definitely move through the horse, and the bottom is lowered on an overhang by 15 cm. The coating of the second slope is performed in the same way. The upper edge should spread through the horse.

The size of the overlap also depends on the slope of the roof. If the slope is more than 5, then the overlap between the canvases of the inner layers should be 7 8 cm, and between the canvases of the outer layer 10 15 cm. If the slope is less than 5, then the overlap in any layers should be at least 10 cm.

It is forbidden to lay layers in transverse directions. This is especially true for a flat roof. Laying of rolled material in layers should be carried out in only one direction, and overflows should be located with a displacement of 10 cm.

The technology of laying roll roofs in a fusion method

Laying in a fed method is most often used to arrange flat roofs. The styling technology is a certain sequence of actions that must be followed, not excluding any of the stages.

Stages of laying roll roofs:

- The arrangement of the drain.

- Creating a ramp.

- Installation of a storm receiver.

- Laying vapor barrier material.

- Laying thermal insulation material.

- Laying a reinforcing grid.

- Laying a cement-sand screed.

- Laying roofing around the funnels of water and aerators.

- Installation of roofing on parapets and other vertical and complex elements.

- The primer of the screed and all the places of intercourse to the vertical elements of the primer.

- Purvery of roller material 1 layer.

- Setting the material in the places of adjoining.

- Purvery of roller material 2 layers.

- Installation of a clamping bar.

- Installation of the apron on vertical elements of a galvanized.

- Installation of a parapet from galvanizing.

Preparation of the base

The concrete base must first be cleaned of debris, dust and dirt. If there is an old coating on the surface, it must be removed. All chips, cracks, potholes are sealed with a repair composition. All further work should begin after the repair composition is completely dry. At this time, you can engage in the installation of a stomach and gutters.

Laying vapor barrier materials

As vapor barrier, film or membrane materials are used. They must be laid with an overlap of 10 15 cm. All joints are glued with construction tape. The vapor barrier is being developed for all vertical elements to such a height that it eventually turns out to be higher than the location of the future thermal insulation material.

Laying thermal insulation materials

For thermal insulation of flat roofs, mineral wool in plates and extruded polystyrene foam are used. Thermal insulation material is laid in two layers to block the cold bridges formed by the joints of the plates. By the way, the joints between the insulation plates should be located.

Thermal insulation slabs can be glued to the base, or you can fix it using special dowels.

After laying the insulation, the leveling screed is poured with a layer of 2 cm to 7 cm. It is imperative to perform temperature-shrink seams in a screed of 5 mm thick. The linear sizes of the seams should be 6x6 m.

In those meters where the roofing material will be adjacent to vertical elements, sides and 10 cm high should be made. They can be performed using a cement mortar. Just fill out the angle formed by a vertical element and base.

After laying the screed, 4 6 hours wait, and then cover its surface with a primer, which is a bitumen diluted in half with kerosene. You can also buy a ready -made primer.

After drying the screed and primer, you can start laying roller roof material.

Installation of a melted roof

First you should waterproof the temperature and shrinking seams. To do this, stripes 15 cm wide are cut off and glued to the base using bitumen mastic. Next, you can lay the canvases of the roll roof:

- Laying begins at the lowest point. The roll is unwound and fits into the place of future installation. Before you start fixing it, it is necessary to check its integrity.

- First of all, the edge of the roll of the roll is fixed. To do this, the edge is heated by a gas burner and is crushed to the very edge of the site where it will be fixed.

- The canvas is again rolled into a roll to the place of fastening.

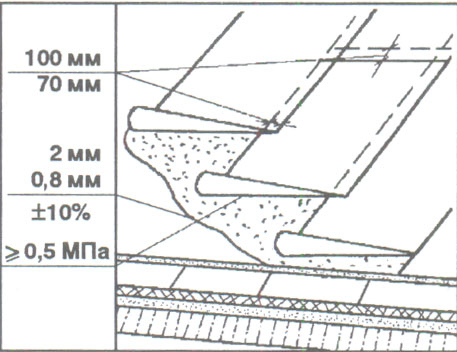

- Now you can heat the burner itself with a burner. The gas burner is kept so that it warms up the surface of the base, where the canvas will be attached, as well as the lower surface of the canvas itself. As a result of heating in front of the canvas, a bitumen roller with a layer of 2 cm should form.

- The technology of work is as follows: one person warms up the fabric with a burner, the second hook turns the canvas along the gluing, and the third rolls it with a rink. In more detail, this can be seen in the photo.

Laying roll roofs: photo example

- If the canvas is heated correctly, then bitumen 2 cm thick should be at the edges.

- Walking through the newly laid roll material is undesirable.

- A man rolling in a roller should carefully remove all air bubbles. After gluing, it is advisable to check the fastening of the edges of the material. The poorly fixed edges must be torn off with a spatula and warm the gas heating pad again and crushed to the base.

- The edges of the roll must be rolled with special care. The movements of the rink along the rolled material should be at some angle, starting from the middle of the canvas and moving to the edges.

- The canvases are glued with an overlap: longitudinal overlap 10 cm, end 15 cm.

- To lay rolled material on the parapets, it is necessary to make the following: cut a piece of the required length, then attach its upper edge to the parapet with a mechanical way, then glue the canvas with fusing to the base.

- To lay the material in the corners of the internal and external, it is necessary to cut off a larger canvas and glue it with an overlap.

- To lay the material around the receiving funnels of the drainage system, it is necessary to cut off pieces of the canvas and glue them so that squares 70x70 cm are formed around the funnels.

- The second and third layer of roller material is attached exactly in the same sequence. Do not forget about the locations of the adjacency to vertical objects, parapets, funnels. After each layer, additional layers are laid in these places.

Remember that it is necessary to lay roll material in only one direction.

The technology of laying roll roofs cold

Cold laying of the roll roof is somewhat different from the hot method. We note the most obvious differences in technology:

- Before laying the roll, it must be rolled out and left in this position for at least a day. If this is not possible, then it is necessary to roll out a roll, and then roll in the opposite direction.

- The laying of the first roll is carried out as follows: the roll is rolled to the middle, the size of the canvas is checked, whether it is enough to the place of laying, then the expanded part of the canvas is again rolling into a roll. As a result, it should turn out like this: a roll divided into two rolls in half.

- Then one person smaches the base with mastic where the roll material will be laid. It is enough to process an area of \u200b\u200bnot more than 1.5 m2 at a time.

- The second person rolls a roll on a base, missed by mastic.

- The overlap of the roll material should be: longitudinal 8 10 cm, end 15 cm.

In addition to laying the roll roof on mastic, there is another way of cold styling. If you use membrane roller materials, then they can be laid either on glue or mechanically.

Laying membrane roller materials for glue is quite expensive, so mechanical styling is more often used. Welding of the membrane roof panels is carried out using special welding equipment.

Thermoplastic panels are well fastened with hot air with a temperature of 600 C The adjacence of the canvas to vertical elements is performed using a construction hairdryer.

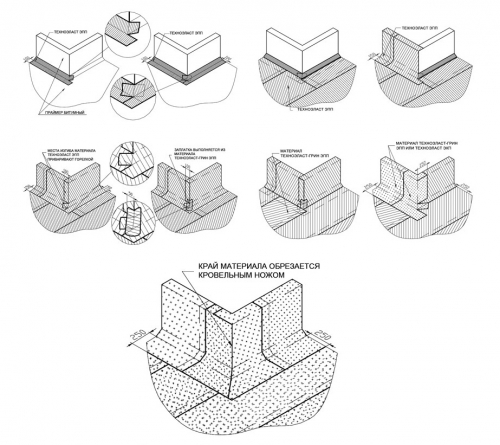

Adjoining the roll roof to vertical elements

The locations of the roll roof to vertical elements are considered the most difficult, since the probability of falling under the material of water is great. Laying of roll material in such places is performed at least 2 layers:

- The first piece of such width is cut off that its upper edge enters the vertical element at least 25 cm.

- The upper edge is fixed by mechanically with nails or self -tapping screws.

- The rest of the canvas is glued to the base.

- The second piece of such width is cut off so that its upper edge enters the vertical element of 35 cm.

- The upper edge of the piece is folded into a small steering wheel of 5 cm, applied to the vertical base and is fixed using the mounting bar.

- The rest of the canvas is heated and glued to the base.

Non -rolled roof: installation technology

A feature of the installation of the roll roof on the pitched roof is that a continuous crate from OSP or plywood is used as the base. It is also worth paying close attention to cornices, overhangs, yendov, vertical elements and skates.

As already written, if the slope of the roof is less than 15 %, then the material must be laid in parallel. The first canvas is in the bottom from the edge, the bypass on the cornice overhang should be at least 12 15 cm. This hanging edge is then fixed using a clamping board. Next, laying is made from the bottom up. All subsequent rows are laid with an overlap of 10 cm. The last canvas is laid with an overlap on a horse at least 25 cm. Then they are laid on the second slope according to the exactly the same technology.

If the slope of the roof is more than 15 %, then you can lay the material across the skate. To do this, rolled tightly from top to bottom, and the overlap on the horse should be at least 30 40 cm.

It is possible to fix the charming material on the pitched roof both in a melting way and gluing on mastic. To lay a mechanical method, a stick machine is used to connect the edges of the paintings.

To cover the yends and m lands, the material is laid in 4 5 layers. The first 3 layers are laid immediately, running 10 cm. The fourth and fifth layer is laid, interspersing them with layers of rolled material on a slope. If the width of the apples is less than 60 cm, then the canvases on them are glued along. If the width is more than 60 cm, then the canvases are cut into pieces and glued across. In this case, it is necessary to ensure that the flow of water is carried out without hindrance. For this, the material begins to lay down from the bottom.

In places of overhangs and cornices, the material is laid with a margin of 10 15 cm. Then the edge is wrapped and fixed with roofing nails. From above, the edges of the cornices on the sides of the building are covered with roofing steel. In places of overhang, gutters are necessarily mounted.

Laying roll roof is considered one of the easiest way to cover the roof. The main thing is to observe the technology, to ensure that there are no air bubbles left under the material, and the edges are firmly fixed.

The technology of work is as follows:

The technology of work is as follows: one person warms up the fabric with a burner, the second hook turns the canvas along the gluing, and the third rolls it with a rink. In more detail, this can be seen in the photo.

Something neither the second nor the third is visible.)))

One person is enough to cope with this matter.