DIY mirror ceiling is not as difficult to do as it could ...

|

|

Among the highest artistic methods of decorating metal products remains ... |

The garage, unlike the protected parking lot, will provide the protection of the car not only from ... |

DIY pile foundation: use and construction

Once, when preparing a foundation for a foundation for a foundation for a foundation, you found that the soil becomes weaker as it is deepened, instead of densifying more and more. If, in the end, you have reached a solid base, then the least expensive and simplest is the solution to the placement of the strip foundation. But in the case when the weak soil is located below the reasonable limits, it is more advisable to arrange other types of structures, one of which is a pile foundation.

Table of contents:

- The concept of a pile foundation

- Reasons for the choice of pile foundations

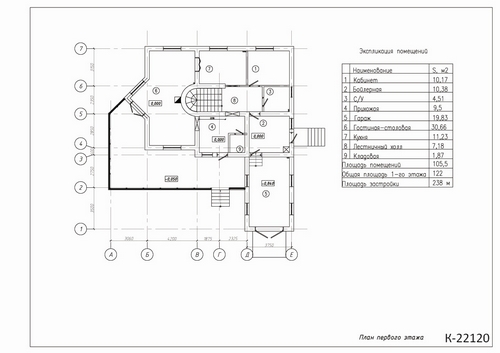

- Design of the pile foundation

- Location and materials of piles

- Technology for the construction of a pile foundation.

- Drilling well

- Concreting and reinforcing piles

- Rosting device

- Restrictions on the use of pile foundation

The concept of a pile foundation

For a long time in the territory that was often subjected to flooding, people erected houses on stilts driven into the ground. The piles were made from logs and manually drove into the soil a similar process, although it took a lot of effort and time from developers, but allowed, nevertheless, to raise the house by a meter or two and save property from water.

The pile foundation is still very popular when it is necessary to build a building on weak soil, low -strength or highly distinguished, that is, on such soil, which is not suitable for an ordinary fine -trimmed foundation.

The pile foundation is characterized by many advantages and among the builders is one of the most reliable structures. If we compare the pile and columnar foundation, the technology of the pile foundation is much easier, because there is no need to tear out the holes, fall asleep sinuses and do the formwork.

When erecting a pile foundation, it is sometimes possible to do without excavation work of the piles with special equipment into the ground, and wells for brownizer piles can be drilled using a hand -made construction drill.

The widest application found the pile foundation in civil and industrial construction. The use of a pile foundation helps to reduce work on the construction of the basement of buildings, or generally excludes the like from construction work. With great success, pile foundations are used in the construction of cottages, country residential and country houses.

Reasons for the choice of pile foundations

What can be the device of the pile foundation during the construction of a country house? The main reason is the weak upper soil layer. Plant soils with peat or humus are ranked to weak soil, les-shaped soils, which lose stability in the presence of water, sand-clay soils of floats, which are strongly saturated with water, loam and clay soils in the current and plastic state.

In the described situations, there is a need to transfer the load from the building to a denser soil, which is located at a depth. The pile foundation also allows you to cope with heaving soils.

Another reason on the other hand is construction in dense soils. Pile foundations can be used to reduce the volume of land work and costs, which can provoke such work, the excretion of the soil after digging the pit, backfill and further concreting.

If you decide with small labor costs and quickly build the foundation, then the construction of a pile foundation with your own hands is suitable for these purposes. To install a pile, which has a length of 3 meters and a diameter of 30 centimeters, you need to dig 0.2 meters of cubic lands. In the case of the choice of a strip foundation, the volume of land work will be significantly larger.

If you choose the foundation based on a variety of a supporting skeleton, for example, if a frame skeleton is used on weak ground, then it is more rational to arrange a tape foundation, but pile bushes for columns.

Design of the pile foundation

There are many varieties of pile foundations depending on the type of piles used and the methods of their manufacture, the location of piles under the structure, the level of immersion of piles in the soil and the design of grillages. It is worth focusing on those designs of the pile foundation that the developer can create with your own hands.

The piles are long rods that are immersed in the soil in the finished form or manufactured directly in the ground. On the one hand, ready -made piles have a pointed end, which is customary to sharpen and protect the steel tip from various damage when immersed in the soil. A steel ring is put on the upper end so that the pile does not split from the hammer blows. Regarding the manufactured piles, such a technique involves drilling wells with reinforcement and the next pouring of concrete mass.

By immersion in the ground, piles are divided into:

- clogging, which are immersed with vibration loaders and similar pressing mechanisms;

- drilling reinforced concrete piles that are installed in drilled wells;

- stuffed concrete piles and piles made of reinforced concrete, which are created by drilling wells and concrete filling;

- screw piles that are installed by twisting piles in the shape of a drill in the soil.

By the method of exposure piles, there are:

- hanging piles that transmit the load by friction of the earth on the walls of the piles;

- the racks that transmit the load on a strong soil, which is under a thick weak soil. This foundation is almost not precipitation.

On the principle of location, there are piles:

- single, which play the role of a separate support;

- combined into pile ribbons, which are located around the perimeter of the walls and distribute the load evenly;

- united in pile bushes, which are placed under the columns of the bearing foundations of buildings.

Location and materials of piles

Regarding the drawing of the pile foundation and the location of the piles, they are usually placed strictly vertically, but there are also options for inclined arrangement of piles. Such solutions are usually used in the soil with horizontal forces, for example, on the site under the influence of long -term precipitation or spring melting, strength may occur, which cause soil movements.

Materials that are used for the manufacture of piles:

- Wood. Woods made of wood are purified even pillars, which have a diameter of up to 34 centimeters and a length of up to 8.5 m. For products, solid conifers are used (larch, pine, spruce and fir). Wooden piles are considered the cheapest way, but they rarely practice it. This is explained by the exposure of wood with rapid decay. However, using the wood preparations available today on the market, such a technique has the right to life.

- Steel. There are many disadvantages of such piles. Firstly, crane equipment is required if the diameter of the pipes is more than 10 centimeters and a length of more than 3 meters. It is also necessary to process the metal in the most thorough way using the anti -corrosion coating. In addition, this method involves large metal costs.

- Reinforced concrete. The advantage of these piles is the possibility of their implementation directly on the spot, if there is an appropriate technique. For the manufacture of such piles, concrete is used not lower than the M200 marking. The useful life of reinforced concrete piles is more than 100 years.

The best options for private suburban construction are reinforced concrete products of continuous section, screw steel and stuffed concrete piles. The most preferred solution to the deepening is called the brownish method.

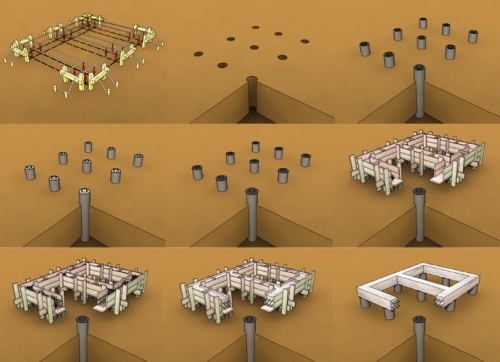

Pile foundation construction technology

If we compare the methodology of erecting a column foundation that requires digging pits with slopes, creating formwork and falling asleep sinuses, then the technology for building a pile foundation is more technological. The foundation in general implies the drilling of a well of a certain diameter, the installation of reinforcement and filling in the created pit of concrete. A big plus of this option lies in the fact that you can perform the drilling of wells with manual construction drill.

Drilling well

The amount of brownish piles, which will be located around the perimeter of the building and are recorded in terms of the pile foundation, should be determined based on the weight of the future residential building along with operational loads. The parameters of the internal piles will be able to determine, taking into account the loads that are created by floor, roof, partitions and operational loads.

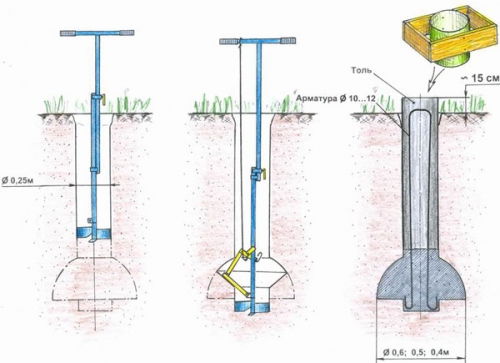

When calculating, you must not forget that the maximum possible value of the diameter of the manual drill, which can be used manually, should reach 300 millimeters, such drills are available in a large assortment. You can adjust the length of the boura rod, and this, in turn, allows wells to perform wells up to 5 meters deep or more.

The cutting blades of the drill are located in such a way that the efforts made during drilling are minimal. Building devices for manual drilling are now produced, which allow you to arrange significant borrowing of the lower part of the well. At the same time, a supporting heel for pile is obtained, which allows you to effectively reduce the number of piles and save concrete.

If you need to drill a well with a diameter of 500-600 millimeters, then it is customary to use motorized and electric drills for work. For example, electric yam-burg, which is used for drilling a well under the installation of high-voltage lines and helps to get a well with a diameter of up to one and up to four meters.

Concreting and reinforcing piles

After the wells were drilled, you need to see the guide about the pile foundation and make pipes from roofing material in diameter of the well, which have a length of 200-300 millimeters more than the depth of the pit. The upper part of the pipe must be made from two or three layers of roofing material, then tighten them with a soft steel wire. This part will become formwork. Then carefully insert the pipe into the well.

If at the bottom there is a small amount of water in a well, then you do not need to pay attention to it. However, if the water is more than 1/4 of the depth of the pit, then before pouring concrete it should be pumped out.

If you do not use the so -called pipe, then this will provoke negative results that affect the strength of the foundation pillars. When the concrete sets and gains strength, the cement milk remains great in the presence of cement milk in the concrete mass, and it can easily go into the soil, and as a result, there will be no design strength.

Frosty forces when freezing the soil will act much stronger on the rough walls of the piles, which were obtained when pouring concrete into a hole without arranging a pipe, the more smooth with the use of the pipe.

When the well is made, to increase the strength of the pillars, you need to make a spatial reinforcing cage. There are enough three vertical rods from the reinforcement of diameters of 6 millimeters, which are fastened to each other every 500-600 millimeters by crossbars.

Vertical rods for connecting the pillars and grillage must be displayed above the poured products to a height, which is equal to the height of the grillage minus two to three centimeters. After installation in the frame of the frame, concrete (40,60 centimeters) is supplied, while its seal using vibrators is carried out.

Rosting device

The groter of the pile -type foundation is the design, which unites the piles and provides uniform distribution of loads on the soil and piles. Grillages are prefabricated, monolithic and prefabricated monolithic, as well as high and low. Low grillages are placed buried in the ground, and part of the vertical loads is transmitted to the soil. Regarding high grillages, their load is completely transferred to the piles.

According to the piles, the grillage is performed with monolithic or from prefabricated reinforced concrete beams. For light houses, the recommended parameters of grillages are the following:

- height - at least 300 millimeters;

- with a single -row placement of piles, the width is taken equal to the width of the basement, if the base is absent - the thickness of the wall of the first floor, but not less than 400 millimeters.

Cutting or crossing the grillage by sanitary pipelines is not allowed. The deviation from the vertical position of the centers of piles after concreting or immersion should not be more than 5 centimeters.

When installing prefabricated elements, you should definitely watch a video about the pile foundation with your own hands and pay special attention to consolidation on the head of the piles. In the process of filling with a concrete mixture of the cavity, the t-shaped reinforcing rod is concrete vertically. On the head of the pile, it is necessary to lay horizontally the following reinforcing rod.

The length of such a rod should be equal to the width of the pile with restraint plates that are welded on both sides. Their heights should be enough to capture the pile and element of the grillage, which is mounted. Then the installation joint is customary to concrete, and the shorty of vertical rods is welded to the mounting loops of the grillage using reinforcing rods of the desired length.

When replacing the national team of the grillage with reinforced concrete supporting jumpers, it is recommended to fix them with combination by welding by reinforcing rods or tied with wire twisting. After the grillage is arranged, all seams and joints must be filled with cement mortar or fine -grained concrete.

Before the construction of the walls of a residential building, you need to check the marks of the upper plane of the grillage and align it, if necessary, a cement mortar under the mounting horizon. To do this, you can use the leveling or water level. Checking the size of the grillage and the rectangularity of the plan finally measure its diagonals and sides.

Restrictions on the use of pile foundation

Despite all the advantages and cost of the pile foundation, these designs have their own disadvantages, and to be more precise - restrictions that prevent their use, and specifically: specifically:

- The pile foundation is bad in horizontal-moving soil, which include subsidence and swelling soils. The characteristics of the Earth can be determined only through laboratory studies, within the framework of which you will need to conduct a detailed geological research due to the insufficient level of resistance to overturning.

- When installing a pile foundation, difficulties arise with the construction of the basement. The space between the piles needs to be filled (perform a bunch) as in the design of the column foundations. And this is additional expenses of money and expenditure.

Thus, you know in which cases it is worth arranging a pile foundation on your land plot, and how to make a pile foundation. When choosing a foundation for your own residential building, you need to think about all possible minuses and pros to make a final decision well. If you do not figure out everything, the pile foundation can not only be the perfect solution in construction, but also become the biggest mistake.

The foundation is a serious business.

The foundation is a serious business. We wanted to completely build a house on our own, having read about the varieties of the soil, the foundations, we realized that they could not cope with this business. The Bogatyr company helped us a lot. Having determined the type of soil, the level of freezing, we were recommended to set the foundation on the screw stilts http://kommtex.ru/dachnye-doma-na-vintovykh-svayakh. Pretty interesting technology and reviews are very reliable.

The article is good, but not

The article is good, but not a positive ending. In my opinion...

Pile foundation

Pile foundation http://www.benikom.ru/svainay_fundament.html

Why don't you give a distance

Why don't you give a distance between the piles, this is the most important size when installing foundations

Hello everyone) if anyone needs

Hello everyone) If anyone needs to score reinforced concrete piles in Ufa for a house, please http://superfundamentufa.ru