How nice to walk barefoot on a warm wooden floor! But what to do if the floor is already ...

|

|

If necessary, in the location of cracks, gluing a certain kind of materials or ... |

The flooring for a children's game room should be safe for health, ... |

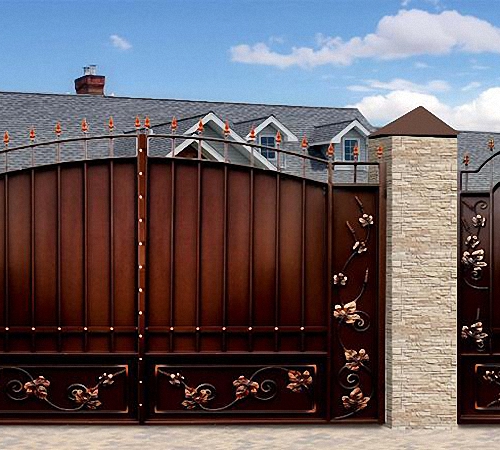

DIY forged gates: choice of choice and installation

Among the highest artistic methods for decorating metal products, bending and forging remains. Since ancient times, openwork metal curls have adorned furniture and interior items, fences and hedges, gates and gates. Metal or wooden gates with forged elements look more elegant and lighter. And as the theater begins with a hanger, so the well -maintained courtyard of private household begins with the patterned gate. Such gates can be made independently so that they become the hallmark of your home.

Table of contents:

- Where to start with the independent manufacture of forged gate?

- 1st option we work with ready-made gates

- The 2nd version we make forged gates on our own

- We master the basics of blacksmithing

- Using ready -made forging elements and other decor

Where to start with the independent manufacture of forged gate?

To master a blacksmithing, bending, forging and getting elementary skills of a welder would be interesting to any home master with an artistic taste. Moreover, it always makes sense to learn, since metal work is profitable and fascinating.

You can start with the manufacture of simple grilles or decorations with ready -made elements of metal products. And then the entire courtyard can be decorated with intricate metal patterns:

- bench and gazebo;

- windows on the windows;

- porch and veranda;

- wickets and garage gates are sworn forged.

All these products can be performed in general design or each time create new, more original, masterpieces. Today, having such skills is very profitable, since the same work on order will cost many times more.

Tip: If you already own part of these skills, do not be afraid to start, learn the rest of the case in the process of doing work. Today in the public domain all master classes and detailed videos at the end of the article.

1st option we work with ready-made gates

If there is a desire to do this business seriously, it is better to start with finished products. For example, it makes sense to get to update your old metal gates with a gate. To work for a while, you will have to remove them from the loops to give metal products a new look.

Before decorating the gate by forging and bending, they are necessarily cleaned of pollution and rust, remove the old paint using special grinder nozzles or universal tools. The drawing of the new gates can be sketched yourself or use ready -made samples set forth on our website photos of forged gate.

Ready -made illustrations are always useful, even if a home master has an art education. This is due to the specific properties of the metal, so not all ideas are easy to embody without familiarization with the best works of people's craftsmen. Experts also recommend watching ready -made forged gate elements:

elements of forging and bending:

- in the construction market;

- in the blacksmith workshop;

- in a construction supermarket;

- on Internet catalogs.

Some of the elements that could be useful can be found in your yard or in the garage, something is suitable in the form of basic or auxiliary elements. For example, large nuts are suitable as central figures for outlets or man -made fantasy colors. Small steel rings and scraps of thick steel rods can also be useful.

The finished gate forged with patterns after completion of work is recommended to be painted to give them a complete look. Therefore, it is worth considering this technique of decorating metal products.

Tip: white, golden and silver openwork elements on a black background of the gate look very exquisitely. The painting will also hide the scale and all the errors of the work. For painting metal, use only specialized primer and paint.

All these ideas are useful to create a preliminary sketch of the gate with a new finish. You can make several sketches of patterns at the gate to approve friends with relatives. There are 3 options for developing a sketch of forged gate:

- take a finished sample and pick up and make all fragments to it;

- make an author's drawing based on improvised materials with the addition of several ready -made elements;

- buy your favorite forging elements and on their basis make 2-3 options for decorating the gate.

Tip: if no sketch is impressive, and it is difficult to evaluate what the finished gate will be posted on the floor with a pattern of ready -made elements to see a natural decor. Probably, something will want to change, and this is much better than after welding to be disappointed and try to redo something.

The ornament on the background of the factory gate, compiled independently, has many options, since human fantasy is limitless. When the final option is approved, it remains to weld the forging elements and bending to the canvas and gratings with point welding. After cooling with a grinder, the welds on the grilles should be adjusted, on the sheet gland, the defects are more difficult to eliminate, they will be painted painting.

The updated gates do not rush to hang on the loops so it is more convenient to treat them with a primer for metal and paint with special paint. It will be possible to paint several elements on plain gates later, after hanging the gate.

A spectacular decoration of swing metal gates with forged elements will be the so -called blacksmithing patination. The use of patina for metal will give the product an exclusive look, will advantageously emphasize home -made or purchased forged parts.

Attention: decorating the gate with forged elements, do not overdo it and excessively weight the product. It is better to make an elegant openwork pattern that visually gives lightness and will not create an additional load on the hinges and support of the gate.

The 2nd version we make forged gates on our own

For those who have elementary skills in working with a welding machine and can cut metal, it is worth deciding to make patterned forged gates with their own hands. Quite complicated stooped-welded gates with bent overlays are quite realistic to do with your own hands. Of the materials will be needed:

- metal corner for the frame structure;

- sheet iron for a closed part of the gate;

- metal blanks of round and square section;

- hinged loops for attaching the gate;

- forged overlays for patterning finishes.

As described in the previous section, they can be made independently or bought ready -made, as well as order in a blacksmith or workshop. In retail sale, they go in a standard set, as in the figure:

All these curls and curly pads will easily decorate the finished product. The independent manufacture of forged gate involves owning certain skills, but there is nothing complicated in this. First, you have to choose a variety of the gate, and it is desirable that they have a gate made in the same way. Metal gates with decoration have their own varieties:

- lattice, completely openwork;

- partially closed (with a metal back) and jewelry;

- lattice (with bent decorations);

- partially metal with wooden inserts;

- metal with forging and wooden back.

The exclusive design of such gates, in which all skill and creative approach is invested, always leave an indelible impression among passers -by and delight with aesthetics. At first glance, it seems that such beauty cannot be repeated, but if you use ready -made illustrations and do everything in stages, patiently observing the technology, everything will turn out.

Yes, designers have more imagination and creative developments, but no one offers to surpass masterpieces, it is enough to borrow good ideas. Or at least try to make the option that is available technologically. You can also use the finished drawings of the forged gate, only a little adapting them to their conditions.

Paradoxically, iron is plastic material that is ideal for the embodiment of many creative ideas. The drawing on the forged gate can be:

- geometric;

- fantasy;

- abstract;

- with plant elements (grapes, flowers);

- with fragments characteristic of some styles (a whip from modern);

- with the image of animals, birds, characters.

Some forged elements can be part of the structure, while others are used as figured linings on the gates forged. You can also use the finished device for artistic bending metal blanks photo:

We master the basics of blacksmithing

You can proceed with the manufacture of forged gate with your own hands after:

- selected sample;

- the sketch of future forged gate with a gate is ready;

- there are drawings with exact dimensions;

- all forging elements and their number are planned;

- material for the manufacture of the base and decoration was purchased.

You will need:

- sheet iron for the backdrop (if it is assumed);

- corner for the gate frame;

- metal rod for bent parts;

- driving blanks.

Cutting sheet iron and segments for decorating the gate and gate is made with the appropriate tool exactly in size.

Attention: it is difficult to accurately determine the length of the segments for bent and twisted parts. Therefore, it makes sense to make control samples from wire, and in their size to make the rest of the figure pads. Next, according to the drawings, they make a frame of the gate and gate.

Attention:

1. The sizes of the corner of the corner should be accurate so that there are no deformations of the overall structure, otherwise there will be problems with their use. If the corner and blanks are thin enough, make sure that the frame does not lead, this defect is then very difficult to fix.

2. Gate and gate should be fixed on the hinges above and below, just vertically, otherwise they will spontaneously open under their own weight under the slope!

Features of cutting metal blanks:

- at home, cut in the yard a grinder with a special disk;

- you can use the services of a workshop or workshop where there is a machine for cutting metal or other tool;

- for sheet gland, a grinder and an electrician with a metal file for curly fragments are used;

- thin sheets (tin) are cut with scissors for metal.

Ready -made elements are welded in the form of a lattice or pattern to the frame of the future gates with a welding machine.

Attention: any product has a front and wrong side, the gate is set to the face on the street! The sutures of welding are cleaned with grinding.

The base on which the gate with the gate will be attached should be very durable. As a vaccine, use metal pipes or pillars that can withstand the large weight of the metal.

For the manufacture of forged parts for the gate at home, a compact blacksmith is used, which can be rented for several days Fig.:

You will also need firmware for holes, vise, anvil and blacksmithing ticks to hold hot parts.

Heated preparations are reduced by the necessary shape with a special hammer on the anvil. You will also need blacksmiths of different sizes.

For artistic bending, a special device is used, which can also be rented. This will help to tighten the prepared segments of the metal into curls.

The blacksmithing is needed to maintain high temperature in order to heat the metal to a plastic state, after which it lends itself to forging. When working with such equipment, special protective clothing is necessarily used. Ready -made parts are connected by welding.

The skills of the work of the blacksmith can be mastered by the video that is at the end of the article.

Using ready -made forging elements and other decor

If your garage gates are quite reliable, but there is a desire to decorate them with forging elements, it is easiest to buy ready -made ones. If there are few carved jewelry, then it makes no sense to remove heavy metal gates from the loops.

In specialized stores you can buy:

- ready -made inserts;

- elegant grilles;

- solid ornaments;

- curls;

- peaks;

- rings;

- ruffles;

- fantasy forging elements.

After all the elements are welded to their place, the gate for a day is left in a closed form for a day. Further, the metal must be protected from corrosion and the destructive effects of weather factors. Painting with special enamels for metal will make the gate more beautiful and hide small defects from welding.

The finished product must be primed before painting, it is better from a spray gun. The gate can be painted in any color, depending on the general design task from white to black. The forging elements can be distinguished by a separate shade, for example, bronze powder is added to the brown paint, and to gray silver, to achieve a certain effect.