In order to protect your plot or house from extraneous invasion, it is protected ...

|

|

Soft tiles are modern material for the device of the roof, its main ... |

In order to quickly and efficiently make the roof of waterproof and persistent to ... |

Building houses from logs: step -by -step instructions

In the process of choosing what to build a house - a log, is a rather popular material. Since the building, built of logs, differs primarily by environmental friendliness, a healthy microclimate soars inside such a dwelling, and under the technology of erecting a house, it will last its owner for more than a hundred years. We will consider how to build a house from a log.

Table of contents:

- Advantages and disadvantages of erecting houses from a gallected log

- Recommendations for the construction of houses from logs

- How to build a house from a log with your own hands

Advantages and disadvantages of erecting houses from a gallected log

The cost of building a house from a log directly depends on the type of material used in the process of work. That is, if the logs undergo minimal processing, the bark and a small part of the tree are removed from them, then the price of such material is not high, compared with the construction of a concrete building or a stone house. However, the quality of such a log is at a fairly low level. Two types of logs are distinguished, in relation to the method of their manufacture:

- manually cut off;

- Escalled logs.

To begin with, we propose to consider the shortcomings of the log cabin logs, they include:

- a small length of the material, which is a maximum of 600 cm;

- There are many defects on logs, such as cracks, chips, worsening thermal insulation of a wooden surface during its use;

- restriction in the method of connecting logs made by hand;

- the possibility of finishing work indoors, exclusively after one, two years, from the moment of building a house;

- Before installing the finish, to the surface of the walls, it is necessary to apply a crate or frame structure.

Therefore, logs made by manually, although they differ in low cost, but have a large number of disadvantages related primarily to their operation.

If we consider the second version of the logs from which they are built at home, then the method of their manufacture consists primarily in removing the large layer of the bark, so the aesthetic type of log is at the proper level. In addition to the fact that the logo is characterized by an attractive appearance, this material is also easily interconnected, using almost any connection methods. In addition, logs of a rounded nature allow you to create dense, sealed compounds that protect the house from wind and frost. The heat saving of such a building is at the proper level.

Please note, since a very deep layer of the bark is removed from the gallected log, it needs to be thoroughly treated with antiseptics before the installation, which prevent its lesion with a fungus and mold.

Next, the tree should be treated with antipyrens that improve the fireproof characteristics of the tree and special impregnations of a whitening nature. Despite this, the gallected log also has certain shortcomings, namely:

- limited diameter and length;

- The cost of this material is much higher than that of the log cabin logs.

Among the advantages of galled logs are highlighted:

- the presence of the same diameter in each log, so the assembly procedure and their connection are greatly simplified;

- You do not need to wait a lot of time to finish the building, since its shrinkage is made faster than that of the previous option;

- The best technological characteristics in the process of drying and transportation.

The use of a standard beam in the process of building a building differs in a mass of advantages. In the process of choosing between a cheap chopped beam and a looped log, you should weigh all the advantages and disadvantages of each of the materials and compare them with their individual preferences.

For the manufacture of a conventional beam, a standard log is used, the top layer on a grinding machine is removed from it. Thus, the log takes a certain shape: rectangular or square. After that, the log is processed using special compositions that protect it from moisture, fungus, mold and microorganisms.

If we compare the walls erected from the beam and from logs, the second option is characterized by a rather high shrinkage, which is not very convenient when the house is put into operation. Please note, despite the processing of the beam with hydrophobic substances, it still absorbs moisture quite strongly, and under its influence it is deformed. The profiled beam has higher performance characteristics, since it adjacent to a friend to a friend much denser, from a clearly expressed shape. In addition, such walls are more easy to finish, do not need to erect a special frame.

The most modern variant of the beam is its adhesive type. For its manufacture, lamellas interconnected under a hot press are used. The profiling of this material is mandatory, thanks to this, this beam is hermetically interconnected, especially in the corner areas.

In addition, the glued type of beam is highly resistant to mechanical damage, it is able to withstand heavy loads, stable before moisture, high temperature, frost.

This version of the beam is the most optimal when erecting a house. However, its only drawback is too high the cost of the material that justifies itself during the operation of the house.

Recommendations for the construction of houses from logs

1. Treat the choice of wood very seriously.

The most optimal wood option that is suitable for the construction of a residential log house is a pine tree or any coniferous trees. Since it is this type of tree that has a large amount of resin, which is an antiseptic and improves wood resistance in front of external stimuli.

If a bathhouse is built from logs, then it is better to stop at the aspen, which perfectly opposes moisture and does not deform under its influence.

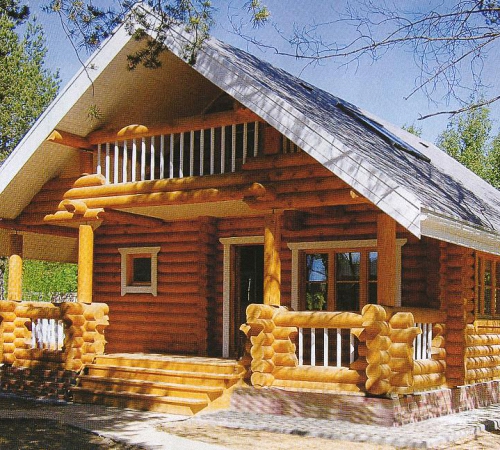

Log house photo:

2. In order to build the floor, it will be necessary to equip its hydro- and thermal insulation.

The floor insulation is a very important process in building a log house. Since the walls of the building are erected from wood, it will additionally help save the heat of the floor. With the help of vapor barrier, it is possible to prevent moisture on the beams and keep them in integrity for many years. Try to mount a vapor barrier overlap to prevent impaired sealing of the joints.

Waterproofing will help protect the layer of insulation from moisture, which leads to its wetting and damage.

3. Design the building in such a way that it is divided into two parts: summer and winter.

The presence of a veranda, porch - will help to evenly distribute heat in the house and prevent additional thermal losses.

4. The choice of high -quality cutting and conjure logs.

The first option is the choice of cutting in a paw, is characterized by cheapness and functionality. The second method - the corner type of cutting is more durable and reliable.

When choosing the first option, consider the fact that the interior wall decoration will become possible after two, three years from the date of construction. The use of the second method is characteristic of the northern regions, since it is characterized by the greater tightness of the joints and preserves the heat in the house better.

5. The presence of dummies will help prevent deformation of the log.

For the manufacture of doughs or dummies, a solid tree is used, for example, birch. These elements are mounted on the central part of the logs, the interval between them is from 150 to 200 cm.

6. Proper masonry of the first crown is the main one and requires special attention. Put the first crown on the liners, but in no case on the usual foundation. The most important condition for high -quality thermal insulation is the absence of a gap between the logs, so between the first of the crowns and the foundation.

On the foundation, roofing material is laid in three, four layers. Next, installation of the submarine is installed. Thus, there will be no cracks between the lower crown and the base.

7. Use the correct material in the process of insulation.

After building a house from a log, in order to insulate the areas located between the crowns, we recommend using moss, packley or jute fiber. These insulation options perfectly seal these areas.

8. Until the house gives the final shrinkage, do not erect floors and ceilings in it.

The time for shrinkage of the house depends on the type of log, which was chosen for its construction. In some cases, it is enough to wait half a year, and sometimes two, three years. If you neglect this rule, then the wood will succumb to rot.

9. Use casing boxes that are mounted in openings for windows and doors.

This error is very popular in the process of building houses made of logs, sometimes its results lead to the fact that the house has to be completely demolished or redone. If you set the windows and doors directly to the openings intended for this, then over time, during the shrinkage of the building, which lasts for almost ten years, the house is deformed due to the presence of hard mounts between the window, the door and the wall.

10. In no case, do not clog the nails into the crown joints.

Nails are prone to corrosion, after a certain time they rust, and this, in turn, leads to spoilage and rotting of the tree, and, accordingly, to the destruction of the house.

How to build a house from a log with your own hands

Before the construction of houses from the log, drawings are developed. They will help to clearly determine the shape of the building, its dimensions, type of connection, etc. There are two options to develop projects from log houses:

- independent drawing up drawings;

- Getting assistance from specialists.

The second option is more expensive, but more reliable. Experts will help calculate such important details as the type of foundation for the structure, wall thickness, the number of additional details, etc.

To begin with, we will figure out how to equip the walls in a log house. The walls of the building include directly logs and thermal insulation material laid between them.

The most difficult process is the connection of corner areas. The walls of the house are best made from needles or pine trees. In addition to the cheap cost of the material, it also has good operational properties.

For the construction of the house, you will need to connect the logs well with each other, bandage the longitudinal and transverse sections of the walls. Each of the logs differs with a thickness of 24-26 cm. Consider that if in winter, in the area, the air temperature is less than twenty degrees of frost, it is advisable to increase the thickness of the logs by 5 cm.

Try to choose the material that was harvested in winter, since it has higher operational characteristics.

Do -it -yourself installation instructions with your own hands:

1. On the previously prepared base on the foundation, lay the logs of the first crown. Keep in mind that in this row, logs should be a tesan by at least 150 mm.

2. Before laying boards on the foundation, process them using a bitumen mastic that improves their hydrophobicity.

3. Next follows the process of installation of thermal insulation.

4. Put two opposite logs on the lower crown.

5. Next, try to alternate the sides of laying logs, in such images erecting the wall to the required height.

6. Using the spikes, make the walls vertical, lay them at a distance of 200 cm from each other.

7. Do not forget about the installation of thermal insulation material, which is located between two crowns.

The technology of a log house is also based on a high -quality connection of logs in the corners. There are two technologies for performing this process in a cup, in a paw. The first option implies a greater flow of wood for building a house from a log with your own hands. In addition, this method takes more time, but it retains heat in the house in the process of its operation.

The use of the method of connecting in the paw implies less both temporary and material costs. However, the use of this method is distinguished by the presence of a larger number of non -tight compounds.

The technology of building a house from a log using the first method involves laying material on two walls opposite to each other. Another log in the perpendicular direction is laid on the logs. With its help, marking is carried out for the connection.

Keep in mind that 400-500 mm should retreat from the extreme site. Depending on the markup, cut the cup in which the next log will be installed.

The second option - the cutting in the paw involves conducting more complex manipulations that are associated with the shinning of the final section of the log in a square shape. Separation of its vertical sections into 8 particles, a section of one of the sides into one eighth of a share, and the second into two eighths.

In the ratio with internal marking, the log is cut into two and three eighth parts as in the previous version. Thus, the external and internal corners of the logs will differ among themselves. This element has the name of the paw.

After laying logs and the construction of the walls, a hemp is carried out. Conduct this process, start from the lower part of the wall, gradually moving to the top.

Houses and baths from logs from

Houses and baths from a log from the manufacturer. Quality, warranty. www.saltusdom.ru

The worst article that

The worst article that I read.

Saltus House. Beautiful houses and

Saltus House. Beautiful houses and banks from logs www.saltusdom.ru

Complete nonsense!

Complete nonsense!

Houses and baths from North

Houses and baths from the northern forest. Quality, guarantee, fair prices. Lesdom.rf

Lesdom.rf House from logs

Lesdom.rf House from logs

lesdom.rf House from logs

lesdom.rf House from logs