The windows in the form of arches have firmly taken root in the architecture of different styles and dominated ...

|

|

One of the most popular materials for making a gate is corrugated board ... |

The double -glazed window is the most vulnerable window element. Modern wooden ... |

Soft tile

Soft tiles are modern material for the roofing, its main purpose consists in protecting the roof from flowing and freezing, but, in addition, such a tile has high aesthetic qualities and looks excellent on the roof of any configuration. Otherwise, this material is called bituminous, asphalt or flexible tiles, and the resulting coating is called a soft or hound roof. In the article, we consider the cost of a roof from a soft tile and the features of its installation.

Content:

- Features of the production of soft roofs of flexible tiles

- Soft tiled roof technology

- Advantages of soft tiles

- The main manufacturers of soft tiles and its price

- Flexible tile coating

Features of the production of soft roofs of flexible tiles

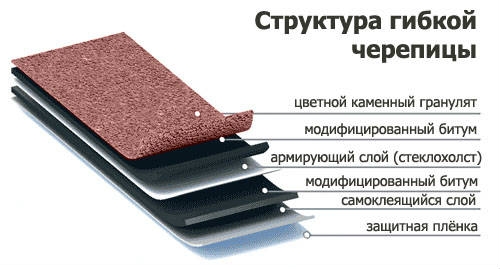

Soft tiles have a unique multilayer structure, thanks to which it receives high operational qualities and is widely used in any climatic conditions. All this became possible due to the latest coating production technology.

The composition of the roof of soft tiles

- The basis for soft tiles is a fiberglass, soaked on both sides with bitumen. It has water -repellent properties and is a product of oil refining. This is partly why the prices of flexible tiles depend on oil prices.

- All the basic characteristics of the flexible tile depend on the quality of the fiberglass used. This reliable substance with a large margin of strength is not torn and resistant to mechanical exposure.

- The fiberglass is made by pressing the fibers, which includes quartz sand, lime, clay and soda. That is why it is considered the most safe, non -combustible material, with high resistance to temperature extremes. The resulting canvas is twisted into large rolls, from which roofing tiles are further produced. In addition to glass and chisel, wood chips of different fractions or cardboard in repeated processing can be used as isolating coating.

- The canvas from the rolls enters the loop former, creating a reserve for unforeseen situations, in order to continue production without interruption in the event of a stop. At the first stage of processing, the base enters the saturator apparatus for applying impregnation. A modified bitumen in a molten state is used as impregnation.

- Modifiers (special polymer substances) in its composition improve plasticity and elasticity during operation in any temperature mode. Such a substance does not pass moisture, which means that the resulting tile becomes moisture -proof. In addition, this bitumen does not melting in the sun, does not have an unpleasant odor and does not crack. In order for the finished product to be bent perfectly, it is covered with another bitumen layer, but now a thicker consistency and with the addition of lime powder.

- Until the bitumen dried up, ceramic granulators are applied to the upper part of the tiles, or shale or basalt crumbs, and the lower layer is protected by plastic film.

- Mineral granules can have various shades, which gives finished products an exclusive appearance, but their main purpose protection against ultraviolet rays. The granulate is perfectly held on the surface and even after decades he perfectly copes with its functions. Many manufacturers add copper to the paint for adding, which prevents the spread of lichen and moss. Those particles that did not stick to the bitumen coating during processing are used to add the subsequent canvas.

- A plastic film is necessary so that the finished tiles are not glued together in a pack, for the same purpose, the lower side is sprinkled with ground limestone. This is the last stage of creating a multilayer structure, after which the material must be cooled. To do this, layers pass through chilled drums with a stream of cold water. The cooled canvas enters the conveyor, where a strip of bitumen is applied to the lower layer of soft tiles, which will melt under the influence of solar heat and fasten the roofing tiles to each other, forming a single strong surface.

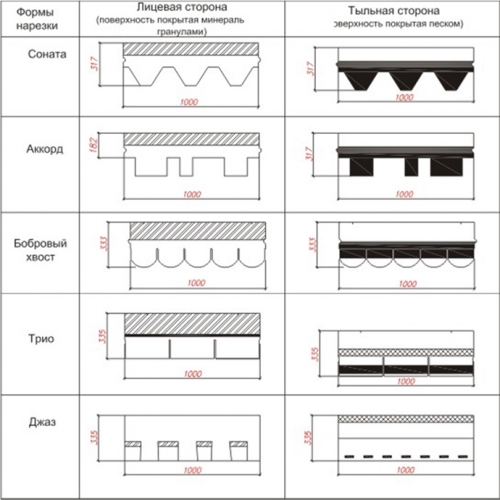

- At the final stage of production, the canvas is cut according to the specified dimensions, while it is necessary to figure out the lower edge figuredly. The standard size of one tile of soft tiles is 1 m long and 33 cm in height. The edge can have the most diverse shape: oval, rectangular, wave -shaped, hexagonal, triangular and others.

- The finished material enters the packaging workshop, where it is folded in boxes of 10-25 pieces. One package is enough to cover 2-3 m2 of the roof. Only tiles made of high-quality glass-chilling will be a reliable protection, which will last a dozen years, cheap material that has not been in the composition of the fiberglass and modified bitumen, will last a maximum of 5-7 years and is suitable only to cover the temporary roof.

Soft tiled roof technology

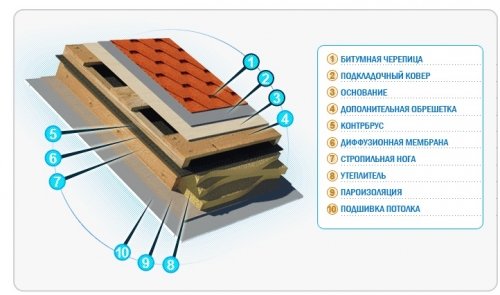

To arrange a reliable and durable roof, not only high -quality tiles are necessary, but also the construction of the correct roofing cake, that is, a complex of elements, each of which has its own function, and all together form a strong roof.

The correct design of the roof of soft tiles involves the presence of the following elements (sequentially from the first layer of the roof on the attic floor):

- internal lining of the attic;

- karcas boards for air gap;

- vapor barrier layer;

- rafter system;

- controller for laying insulation;

- insulation;

- membrane (water protection film);

- control for providing ventilation;

- crate in the form of bars;

- solid base (chipboard, OSP);

- waterproofing layer or special lining carpet;

- soft tile.

Tip: Despite the fact that flexible tiles refers to moisture resistant materials, all wooden roof elements must be treated with special impregnations and protective compounds.

Stages of work

- A vapor barrier film is placed on the installed roof frame, which will protect the design of the roof from vapors penetrating from the room. It is laid without gaps and without sagging, fixing the strips from the inside, on which the internal sheathing will be attached in the future. In places of overlap, the film is glued with double -sided tape

- When erecting a rafter system, it is important to pay special attention to the consolidation of inclined rafter legs. Between the rafters, controls are fixed, which will fix the thermal insulation layer. After everything is securely fixed, you can proceed to laying the insulation that will prevent heat loss. As a warming layer, mineral wool laid in several layers is used, while the seams of each of them should be overlap.

- A windproof film and a hydremembran are laid on a layer of insulation, which will protect all the lower layers of the structure from random water flow. Installation of soft tiles is carried out on a continuous crate. Light materials, for example, moisture-resistant plywood or OSP-plate, which are fixed in the run, for a more reliable roof arrangement, can be used as crate. In addition, it is worth leaving the gaps between the plates of 3-4 mm so that they do not warp with the increase of humidity.

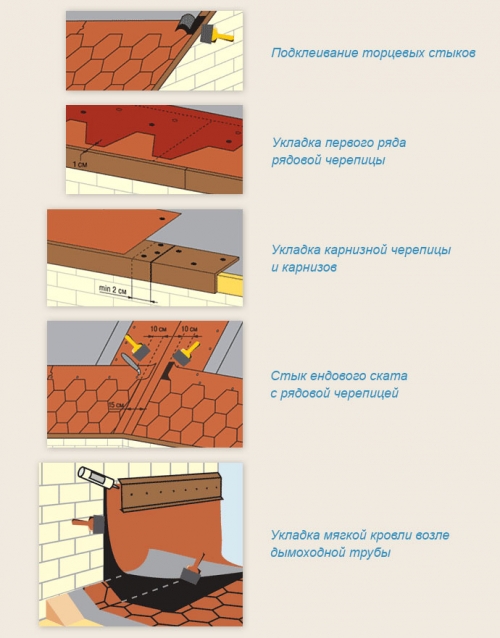

- All work is recommended for dry weather and air temperature of at least +5 degrees. On the basis for attaching the tiles, a lining carpet is laid, which should be placed, starting from the lower part of the roof, gradually moving up. The material is overlapped, and the joints are smeared with bitumen mastic. Before starting the installation of tiles, cornice and end strips are installed.

- Depending on the shape of the tiles, installation is carried out differently. In each pack of tiles, the manufacturer puts detailed instructions, which is important to observe for proper styling.

- In order for the stacked tiled carpet does not have a color imbalance, you should mix tiles of 6-7 packs before work. The first strip is laid on top of the cornice of the bar. It should be either a special skate-carnious tile, or a tile with a cut curly edge. Installation of the first row of curly tiles begins with the center of one of the slopes.

- The next row is also mounted from the center, but with a shift of half a shift in any direction. The tile is nailed so that the lower edge is on the same level with the beginning of the previous row. All the tiles are also fixed gradually. Bitumen tile sheets are attached to the crate using special roofing nails with round large hats.

- Particular attention should be paid to the locations with the main elements of the roof, stove pipes, ventilation, attic windows, skates. In these places with poor -quality installation, leaks are often formed, subject to all the requirements of such problems simply do not arise.

- Tiles, superimposed on each other, are fastened under the strength of their own severity into a single carpet, which provides reliable protection against bad weather. When buying a material for a roof of soft tiles, it should be taken into account by waste that will be no more than 5 %, if there are a large number of decorative elements, yends and fractures, but if the roof is flat, then there are practically no waste.

Advantages of soft tiles

The bitumen roof has several significant advantages over other types of roof coating.

- It has good sound insulation.

- Resistant to adverse weather conditions.

- Moistenous, due to the low porosity of the surface.

- It differs with easy installation that does not require special -design and equipment.

- Economically consumed during styling.

- It has a small share, due to which you can not strengthen the design on which it is mounted.

- It has a long service life.

- Undead in leaving.

- It is resistant to corrosion, decay and the effects of chemicals.

- It has high heat and frost resistance.

- Fireproof and refractory material.

- Creates a sealed surface.

- It has a high wind resistance.

- The roof device does not require snow retention.

- It differs relatively low cost.

- It is made in a large assortment of colors, shapes and sizes.

- It can be laid on the roofs of any configuration, due to its flexibility.

The main manufacturers of soft tiles and its price

| Tilest brand | Country |

Peculiarities

and produced series |

Warranty service life | Price |

| ICOPAL / IKOPAL http://www.icopal.ru |

France, Finland | Products are intended for use in the climate of the northern countries. Has a shale crumb coating

Produced series:

|

20 years | 400-500 rub./M2 |

| Katepal / Katepal http://katepal-russia.ru |

Finland | The multilayer structure has a unique production process. The fiberglass is impregnated with SBS-modified Venezuelan Bituma Bitum. In addition, granules are used in production, ceramicized in a special way, which are applied to tiles with 10% margin.

Produced series:

|

25 years | 340-560 rub./M2 |

| Daflex / Daphlex http://daflex.ru |

Germany | Unique material from the company Holzplast. It has a small share, but is considered one of the durable and reliable materials. Caring for such a roof is minimal, the tile has high indicators of moisture resistance, sound insulation and tightness. The upper layer is covered with shale or basalt granules, which are painted at high temperature, so they do not change the color throughout the entire period of use.

Produced series:

|

35 years | 350 -550 rub./M2 |

| Ruflex / Ruflex http://www.ruflex.ru |

Russia | The production of tiles is carried out at the Russian factory, has popular shapes and various colors of natural shades. This quality material, with a long service life, reliably retains heat and has increased moisture resistance. Due to the use of Bitumen from Venezuelan oil in the production.

Produced series:

|

30-35 years | 335-480 rub./M2 |

| TEGOLA / TOGOLA http://www.tegola.ru |

Italy, Russia | Roofing can be used in any weather, both in the northern and southern regions. In the production of this tile, sprinkling the upper layer of the form of basalt crumbs is used. In the manufacture of this particular tile, a modified bitumen was first used.

Produced series:

|

10-15 years | 215-540 rub./M2 |

| Shinglas / Shinglass http://shinglas.ru |

Russia | The tiles from the Russian company Technonikol, is of high quality, a long service life and a relatively low price.

Produced series:

|

15-50 years | 210-500 rub./M2 |

| Certainteed / Soldantide http://www.c-teed.ru |

USA | This is two or three -layer laminated tiles, which has a wide range of color, shapes and sizes. The produced series differ in the warranty life, resistance to wind and cost

Produced series:

|

25-50 years | 380-1740 rub./M2 |

| BP / Building Products http://www.bpcan.com |

Canada | The tile is a two -layer laminated material painted in bright, contrasting colors

Produced series:

|

500-540 rub./M2 | |

| Docke / Dyok http://www.docke.ru |

Germany | The material produced has 30 different colors and many different forms of produced in 7 collections. Colors can be either homogeneous or have overflows, shadows and many combinations. The roof of this manufacturer is characterized by low cost, a long service life and reliable protection. Within 3-7 days, the finished roof becomes a single coating. Due to the special technology of applying glue, the moisture falling under the tile easily evaporates, and not seized, which avoids the appearance of bubbles during operation.

Produced series:

|

30 years | 300-400 rub./M2 |

| Iko / Iko http://www.ikor.ru |

Belgium, Canada | The tiles are made in factories with a closed production cycle. It has a large range of shapes, sizes and colors.

Produced series:

|

25 years | 500-1000 rubles/m2 |

Flexible tile coating

In order for the roof covered with soft tiles to serve for many years, while reliably protecting the building from the penetration of precipitation, gusts of wind and temperature differences, several simple rules should be observed when caring for it and not forget about regular scheduled inspections twice a year in the beginning Autumn and late spring. If any, even the slightest, defects are found, must be eliminated immediately, avoiding larger problems.

Planned check

- Twice a year, the surface of the roof of the roof of soft tiles is checked. You can choose any cloudy, but not rainy day or do it while the sun is not heated, for example, early in the morning, since you should not step on a soft tile at too high air temperature, when under the influence of heat, the bitumen layer begins to soften , and the canvas becomes vulnerable to mechanical influences. Also, it will not be possible to examine in the winter, due to a layer of snow on the roof.

- Before inspection from the roof, all garbage is removed: branches, leaves, grass and so on. To do this, it is better to use a broom or a soft panicle, but in which case it is impossible to use metal shovels or sharp objects. The entire structure of the roof of the pipe, gutters, gutters and so on is cleaned of the dirt. Then they proceed to a thorough examination of the roof for damage. At the same time, special attention is paid to the joints between the rolls, as well as the places of fit to the pipes and skates.

- The discovered problems should be immediately eliminated. If shallow damage is noticeable on the roof, then such a section must be cleaned and completely sealed. For this procedure, any bitumen mastic is suitable, which is heated to a half -liquid or liquid state and closed the damaged area.

- Technologically correctly laid tiles over time becomes a single canvas, so if small areas are damaged, it is sometimes difficult to remove separate sheets. If there is a need to replace large areas of tiles, then it is better to invite professional roofers.

- When the plot is small, you can cope with your own forces, for this the damage place is cleaned, granulate is removed and a patch of the same tile is placed that would block the removed area by at least 10 cm on each side. Using a gas spray or a special heating pad, the coating is heated, while the material should not be allowed. You can also fix the tile with small cloves with wide hats or with the help of a dowel with a puck.

Departure in the winter period

- The main danger to the roof of soft tiles, in winter, is a large snow cap on the roof and ice, which exert high pressure on the rafter system. With a small snow layer, there is no need to clean the roof. Being snow from the roof, it is best to leave its layer at least 15 cm, while I use only wooden and plastic shovels. Such a measure will help to avoid damage to bitumen tiles. Snow should be thrown to the ground, and not transfer to the lower parts of the roof.

- If the bitumen tile begins to bubble, premature aging is manifested, a flowing bitumen layer is formed, granulates crumble or edges, then, most likely, the technology was disturbed during its installation. If everything is carried out according to the instructions that are supplied with each packaging of the material, then such a roof will last a warranty period and for a long time after it, without causing the owners of any worries.

Roofing tiles belongs to inexpensive, but durable and durable materials. It can have a variety of coloring, shape and texture, the thicker the layer of bitumen and granulatory, the more reliable the soft tile will be. The roof takes on all adverse weather phenomena, whether it rain, hail or snow, so it is so important to have a reliable roof in every house, such as a roof of soft tiles, under which one could feel comfortable and comfortable.