Each owner wants to protect his house or summer cottage from penetration ...

|

|

Of course, not every real estate owner can afford to equip the ceiling from ... |

Ceramic tiles are one of the most convenient finishing ... |

System and installation of smoke removal

In the event of a fire, the greatest danger to human life is not fire and high air temperature, but smoke. It could trigger a panic, disorient people and cause poisoning. In order to prevent such problems, the premises are installed in smoke removal, which can localize carbon monoxide, clean the room from small particles of dust and ash.

Content

- Smoke removal system Important fire safety element

- Types of smoke removal systems: static or dynamic ventilation

- Elements of a smoke removal system

- The principle of operation of the smoke removal system

- Calculation of the fire system of ventilation

- Installation and commissioning of a smoke removal system

- Fire ventilation maintenance

Smoke removal system Important fire safety element

The smoke removal system is an emergency complex of supply and exhaust ventilation, creating the conditions for the evacuation of people in a fire. The missile defense system is included in the overall fire safety set.

When fire alarm is triggered, fire ventilation is turned on. The system begins to actively remove combustion products and smoke from the focus of the fire, as well as prevent their distribution to other zones of the room. Lighting fans direct clean air to fire and main outputs, to staircases and elevators.

In accordance with the construction standards, such installations should be equipped with high-rise buildings (more than 10 floors) with a fire safety class, rooms without natural ventilation, underground structures, prisons, hospitals and other institutions in which a large number of people are focused.

The smoke removal system performs the following tasks:

- Prevention of the spread of fire from the place of fire.

- Reducing smoke on the ways of evacuation.

- Providing a normal microclimate outside the fire of a fire - this will allow you to effectively perform the work of fire extinguishing personnel.

- Reduced air temperature in the room. In closed buildings, during a fire, the temperature can reach 1000C, and with the debugged operation of the smoke removal system, the temperature decreases to 400C. According to the standards, such a degree should withstand office and residential buildings risk of collapse significantly reduced and people can leave the danger zone.

- Control and timely notification of the emergence of a source of fire.

- The opening of automatic hatches, windows for removing the products of combustion and ventilation of the building.

- Maintaining the concentration of oxygen in normal condition is necessary for the evacuation and safety of people.

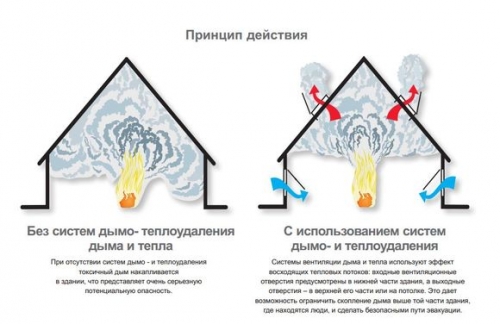

The fire -fighting ventilation system functions according to the laws of physics: cold air drops down the room, and the warm air rises up. Equipment for the removal of warm air will restrain the increase in temperature and reduce the negative effect of smoke on the human body.

The smoke removal system is an expensive complex, its technical characteristics and the appropriate structure require special design.

Types of smoke removal systems: static or dynamic ventilation

To date, all smoke removal systems can be divided into static and dynamic complexes.

At static smoke removal There is an emergency shutdown of ventilation. At the same time, smoke does not go to other zones of the room. Such a system is most primitive and affordable. In fact, smoke removal, as such, does not occur, all smoke is localized in one room.

Dynamic system Designed for the removal of smoke and burning, as well as for the influx of fresh air. The work of the complex is based on the use of fans that pull the combustion products outside the room.

Dynamic complexes can function on one fan that works alternately in different directions (suction of smoke or supplies of fresh air), on separate fans of supply and confusion, or on combinations of two axial fans.

The choice of smoke removal scheme depends on the features of the construction of the building and the possibility of implementing a particular project.

According to the type of control, the Soda is divided into automatic and semi -automatic systems.

Automatic smoke removal is associated with the security system of the object, the installation of automatic fire extinguishing and fire alarm.

Buildings equipped with a large number of equipment and engineering systems are desirable to equip an automatic smoke removal system. The complex fire extinguishing and smoke removal system practically eliminates the risk of fire and spread of fire, giving a signal about the slightest breakdown of equipment

Elements of a smoke removal system

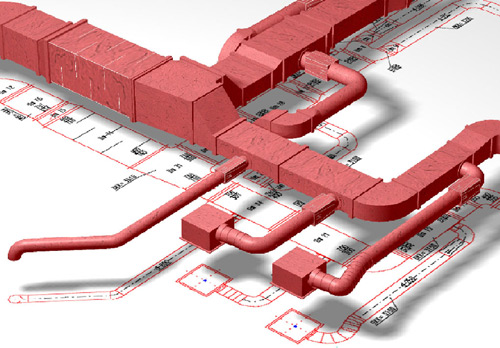

Smokewood is carried out through existing ventilation shafts, the inner surface of which is covered with a fire retardant. However, the use of individual communications with special fans and air ducts is considered more effective.

The dynamic smoke removal system consists of the following main elements:

Fans of smoke removal Large heat -resistant installations of high power. Minimum air flow 20,000 m3/h. Fasters of smoke removal are capable of working at very high temperatures.

The fan pumps smoke, combustion products from the place of fire. Some models of fans perform two functions alternately: the supply of clean air and the removal of smoke. Smokers fans are mounted on the roof of the building.

Air support fans Create excess pressure on the stairwells, in elevator shafts and vestibules of gateways, excluding their smoke.

No less important element of the smoke removal system fire valves. Four categories of fire valves are distinguished:

- Fire -holding valves (normally open valves) are mounted in air conditioning air ducts, air heating and general ventilation. Under normal conditions, the valves are completely open, and if a fire occurs, the valves are closed and the penetration of combustion products into other zones of the room is closed.

- The smoke valves in the anti -drum ventilation system provide smoke and redirect it to smoke mines.

- Normally closed fire valves are mounted in the system of anti -drum supply ventilation. The valves are constantly in a closed state, and only when the fire focus occurs to be opened to remove smoke. If the room is equipped with a powder or gas fire extinguishing system, then the valves will open to remove gas and harmful vapors.

- Double -action valves are installed in the basic ventilation system. During the fire, he acts as a flamping valve, and after the elimination of fire, the valve opens to remove gas and smoke from buildings equipped with powder and gas fire extinguishing.

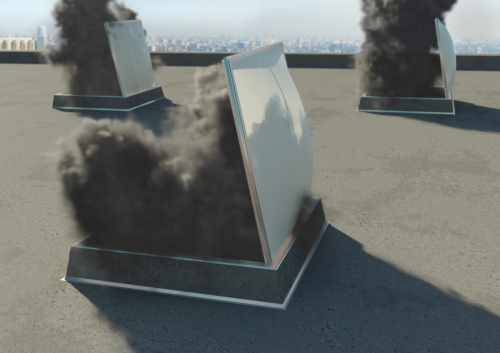

Lukes of smoke removal They are mounted on the roofs of buildings and when a fire occurs automatically open. As such hatches, anti -aircraft lights can be used, which under normal conditions perform the functions of lighting and ventilation.

Ventilation channels of smoke removal (mines) large cross -section ducts made of black steel. The thickness of the material should be at least 1.2 mm, this increases the stability of the ducts of the smoke removal to high temperatures.

The automatic complexes provide smoke sensors that work when the focus of the fire appears, and the signal for inclusion in the operation of fans and fire valves.

The principle of operation of the smoke removal system

Let us consider in a stages the working cycle of a smoke removal system:

- A smoke sensor is triggered in the room.

- The signal from the sensor arrives at the dispatch station.

- The general ventilation system is automatically turned off and all fire -retention valves are closed.

- In the fire zone in the smoke removal system, a valve for removal of smoke opens.

- At the same time, the fan of the smoke exhaust and the air support fan are turned on.

Important! The smoke removal system is designed to pump smoke from one fire of the fire. That is, all smoke is removed from one grate of the system (conditionally one, since each zone may account for several gratings). On the remaining floors and zones of the room, fire valves of the systems will be closed

Calculation of the fire system of ventilation

Designing a smoke removal system

The requirements for the design and maintenance of smoke removal systems are quite high, so engineers designers should be done by this work. The company's specialists will calculate smoke removal, prepare a working project, carry out installation and commissioning of equipment, and also conduct tests of the system.

When calculating and developing a smoke removal scheme, the following room parameters are taken into account:

- building building material;

- the number of storeys of the structure;

- emergency evacuation plan;

- the state of the current ventilation system;

- smoke permeability of the room;

- the presence and location of windows in the building;

- the state and material of the insulation;

- type of internal and facade finishes.

All factors that can affect the rate of distribution and the amount of smoke during the fire are taken into account

The smoke removal project is drawn up on the basis of building codes and rules, where the minimum requirements for the fire ventilation system are clearly spelled out. The main document regulating the design procedure is the calculated determination of the main parameters of antidium ventilation of buildings from 2008.

Normative documents determine the capabilities of the smoke removal system:

- the maximum number of people in the room;

- the area of \u200b\u200bthe serviced building.

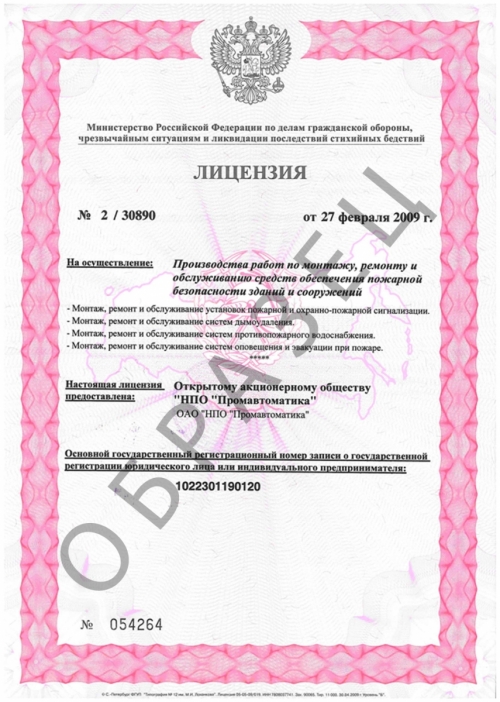

The company performing the development and installation of a smoke removal system must have a license of the Russian Emergencies Ministry for the installation, maintenance and repair of fire safety equipment

The nuances of the design of smoke removal

When developing a project and installing a smoke removal system, experts recommend taking into account a number of fundamentally important points:

- the integrity of smoke permeable structures;

- placement of fire -resistant partitions in the general ventilation scheme;

- the ability to test the smoke exhaust system with cold smoke;

- in the places of passing the ducts through the enclosing structures, it is necessary to mount fireproof valves;

- in certain regions, seismic loads should be taken into account.

The arrangement of fireproof partitions has a significant impact on the wiring of the ducts. Changes in the place of placement of such a partition can lead to a reorganization of air wiring. This is especially true if each room uses a separate supply installation.

The cost of fire ventilation

The development of a smoke exhaust project and the installation of the system will cost approximately 2000 rubles/m2. The price will depend on the complexity of the project and the equipment used.

The smoke removal system costs 2-3 times more expensive than a conventional ventilation system

The calculation of the cost is based on the following components:

- Development of a project 10% of the total cost of a smoke removal system (about 300 rubles/m2).

- Equipment and materials:

- industrial fans (from 100,000 rubles/unit);

- fire valves (from 15,000 rubles/unit);

- reinforced air ducts (from 1000 rubles/m2);

- automation system (cost depends on the scale of the project);

- auxiliary elements and special equipment (drives with a drive, transmets, ventilation chambers, chimneys, gratings, anti -aircraft lanterns, air pressure press strata, etc.).

- Installation work costs of installation are usually 30% of the cost of materials and equipment.

Installation and commissioning of a smoke removal system

The initial stage of installation is the laying of welded ducts in the room according to the developed plan. After that, they start installing fans. Axial, radial or roof fans can be used.

An important stage in the installation of smoke removal processing of mines with a special coating that protects the complex from fire. After the necessary level of fire resistance on the air ducts is reached, the installation of fire valves is installed, they are placed in mines passing under the ceiling.

The mounting of the air ducts and the placement of valves is performed with clear compliance with the requirements of the working documentation

The final stage connection of automation, adjustment and testing of the smoke removal system.

When adjusting the system, it is necessary to check the operation of the valves in manual and automatic mode, perform the calculation of the actual air flow (preferably separately for each zone), check the fan speed.

During the commissioning, it is necessary to give the fans a vacation at least one hour every 30 minutes

When checking the operation of retaining fans, you need to pay attention to the following parameters:

- direction of rotation of the fan blades;

- the work of fire -holding valves (manual and automatic control);

- measurement of pressure in the fan;

- comparison of real pressure indicators with the indicated aerodynamic characteristics of the fan.

Using the measuring device of the dipmanometer, it is necessary to determine the excess pressure in the shafts of the elevators, stairwells and vestibules-blues.

The pressure difference between the street and the room should be at least 20 per this means that the fan's support meets the established standards, and the smoke removal system is calculated correctly

Fire ventilation maintenance

For each smoke removal system, the maintenance schedule is developed. Instructions for planned maintenance are provided by the company manufacturer and installer of the system.

Timely maintenance eliminates the likelihood of failure of fire ventilation at the most crucial moment. During the system check, it is possible to identify problems in time and eliminate them, replace some elements of the complex with more modern equipment.

Maintenance is carried out monthly and quarterly. Once a month they perform such work:

- checking the technical condition and performance of the alarm;

- technical diagnosis of devices;

- checking mounts and external assessment of the state of valves and equipment;

- trouble-shooting.

The quarterly check includes the following measures:

- performing a set of work on a monthly check;

- inspection and cleaning of the devices;

- technical diagnostics of equipment;

- verification of the system’s performance from the backup source of power supply;

- checking cable lines to determine possible hidden failures;

- trouble-shooting.

The results of each audit should be recorded in the journal of the established form.

It is safe to say that the smoke removal system is vital to ensure the safety of people during a fire. The development and equipment of the system is determined at the design stage, the equipment should be certified, and the control and maintenance of the complex comply with the established norms of the Russian Federation.