The final stage of construction is work on the roof. Roofing work on decoration ...

|

|

Paul finishing is the first stage of facing work, because of this it is necessary ... |

The development of screw piles in domestic construction began recently. But that ... |

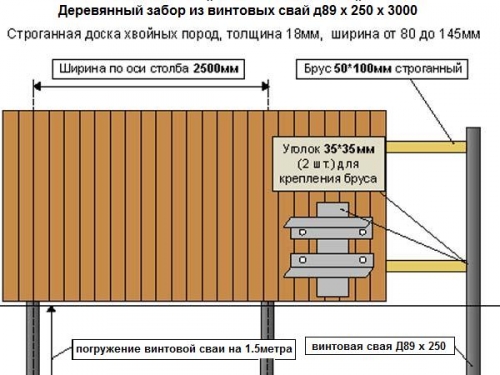

Screw fences - the main advantages and rules of installation

Each owner wants to protect his house or summer cottage from the penetration of unauthorized persons and stray animals, for this purpose, fences are being built. Of course, to fulfill its direct function, the fence should have not only an attractive appearance, although this aspect, of course, is also very important for many homeowners, but also to be truly reliable, durable. Most are interested in these qualities are combined with another economy of the fence being built. The most optimal solution that will satisfy all these requirements is the choice of fence on screw stilts. The history of its use has been there for more than 200 years. In the article, we consider the main advantages of screw piles and the rules for their installation.

Content:

- Single piles for fences

- Advantages of erecting fences on screw piles

- Rules for installing fences on screw piles

- Installing a fence on screw piles with your own hands

Single piles for fences

Rifle fences, as the name implies, are mounted using screw piles, which are either a foundation for fence poles, or perform their function.

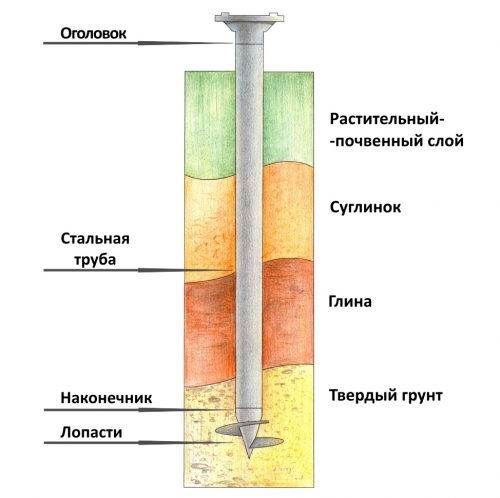

They are metal hollow pipes, one end of which is pointed and has a thread. To protect against corrosion, a special anti -corrosion coating is applied to them.

Piles are customary to distinguish between several parameters.

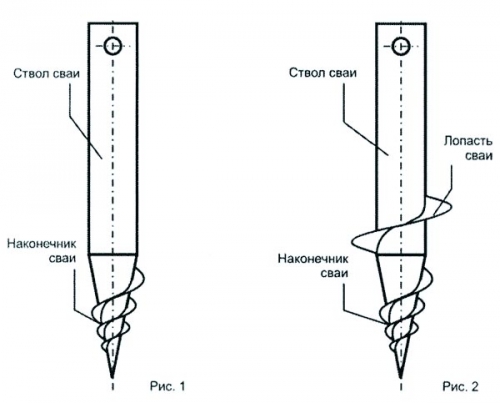

Firstly, they are divided by type of thread:

- having a standard thread (Fig. 1);

- with blades;

- with combined threads (Fig. 2).

Piles with different threads differ not only externally, but also what load they are designed to withstand. The most reliable are considered to be the blades, but are the most expensive. They, as a rule, have two blades, which increases the reliability of the support, because the second is intended to distribute the pressure that is on the pile. Due to this, bearing capacity improves, and in addition, it becomes possible to use them on any type of soil.

Secondly, the piles differ in their diameter.

The most popular sections for installing fences:

- with a diameter of 57 mm;

- with a diameter of 76 mm;

- with a diameter of 89 mm.

But the most common in the construction of fences are piles of pipes, the diameter of which is 76 mm.

Thirdly, they are distinguished by the method of manufacture:

- welded;

- combined;

- cast.

The most popular for the construction of fences welded piles. Castle, capable of withstanding heavy loads, are optimal for the construction of houses.

As for combined piles, they are inferior in quality to the first two types, so they are used much less often.

Welded piles

A welded pile is a metal pipe, one end of which has the appearance of a cone with blades welded to it. It is treated with a special anti -corrosion composition. The blades, like the cone, are formed by plasma harsh, which ensures the accuracy of the product. They are perfect for installing the fence, since in this case they will not be on a serious load, but for the construction of the house they are unsuitable due to low strength.

Rifle piles with a welded tip, in turn, are divided into several types:

- for rocky soil, having double blades, they create a reliable clutch with the soil. Their use for the construction of fences is irrational, due to the lack of serious loads on them;

- with an open -type tip is suitable for any soils;

- with a closed -type tip is also suitable for soil of any type.

Cast screw piles

The cast pile has a screw cone. They are made using casting according to perfectly accurate models, in the form of certain forms. It is with their help that a monolithic tip with blades is created. Their main advantage is high strength during prolonged use, due to the fact that they are performed completely steel.

Casting screw piles are distinguished by what types of soils they are intended. They are:

- standard. For ordinary soils with large blades;

- for areas with high groundwater. With medium blades, guaranteeing that during screwing, the soil will not loosen;

- for eternal -free soils. With small blades that facilitate the installation of piles and exclude the risk of distortion.

Advantages of erecting fences on screw piles

The use of screw piles, when erecting fence pillars, is popular due to the significant advantages that they possess.

- High strength. First of all, it is worth noting such a feature of fences on stilts as a strength of 1 pile can withstand a load of 4 tons.

- Universality. You can install fences on piles on different soils, including complex peat, clay, sandy loam, loam, with a high level of groundwater and the like. The only thing where these fences are not recommended for these areas with a rocky breed, since chips and gatherings can occur here, which call into question the reliability and durability of the entire construct.

- Do not require preparatory work. They are suitable for operation on any territory both on an even area and on the slope. In addition, their installation does not require work on the preparation of the territory. They are perfect if the fence is built between the trees, and near the stumps.

- Easy installation. Another significant plus of screw pillars for the fence is the ease of installation. It does not require professional knowledge, and is carried out in a fairly short time without the use of special equipment all the work can be done manually.

- The possibility of secondary use. Screw piles can be used again, which is very convenient if there is a need to establish temporary fences.

- Environmental friendliness. Installation of screw piles will not spoil the structure of the soil, since harmful substances will not be added to it.

- Reliability. Fences installed using this technology are distinguished by enviable durability and can stand for more than a century, which is confirmed by multiple facts.

- Affordable price. Good ratio price quality.

- Easily repaired. Rifle piles intended for the construction of fences differ in that they are quite easy to repair.

- Simplicity of dismantling.

- The possibility of construction even in winter.

Rules for installing fences on screw piles

Like any installation work, installing fences on screw stilts has its own nuances.

- Before starting installation, you need to perform a trial screw. This is necessary in order to determine the possible level of depth of piles, which directly depends on the composition of the soil.

- The piles can be screwed manually, as already noted above, and mechanical - using special equipment. It allows you to screw them without making any additional holes in the housing.

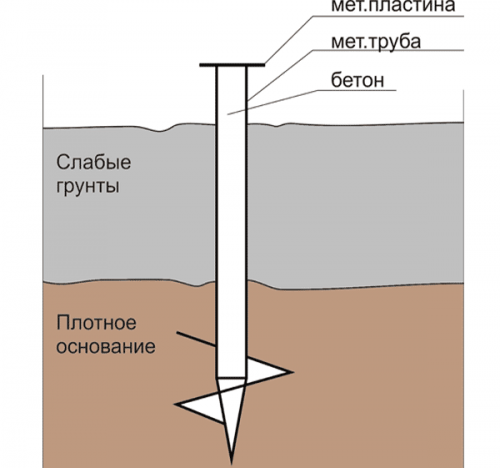

- It is worth noting that with any installation method, it is necessary to lengthen the screw piles until they reach hard soil. This is done using connecting couplings and only after the main pile is fixed.

- When the pile is installed, it is cut to the desired level and filled with a concrete solution of the brand not lower than the M-150. This will increase the supporting ability of the structure and protect against the penetration of moisture into it.

- Also, to protect the piles, the upper part is primed with a special two -component solution and treated with anti -corrosion, wear -resistant mastic.

- If on the site where the installation of the fence is supposed to be, complex soil, then it is enough to lay a pile to a depth of 1.5 m, especially since it will be almost impossible to screw deeper under such conditions.

Installing a fence on screw piles with your own hands

Let us consider in more detail one way to install the fence with your own hands. The following materials can be used for the manufacture of the canvas:

- professor;

- wood;

- grid;

- concrete;

- brick;

- forged segments.

Most often, wood and corrugated board are used to build fences on screw stilts. In this case, the frames, as a rule, are performed according to one scheme, which will take on the basis of further descriptions of work in this article.

Preparatory stage

The first thing to do to make the perimeter markings. It is important to consider that no underground utilities are laid nearby.

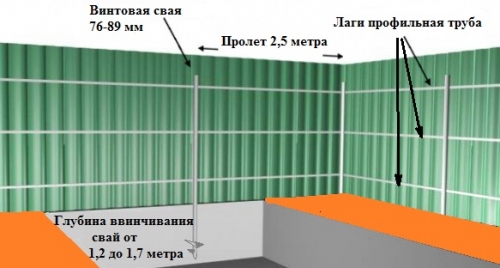

Tip: The distance between the supporting posts is from 2 to 3 meters (depending on the characteristics of the soil), but the optimal step is not more than 2.5 m.

Then there is a trial screw, which will help determine the depth of piles. It should be remembered that according to the rules, the minimum twisting depth is 1.5 m. It is determined by the calculation of the bulging that occurs under the influence of frosty soil abrasion. If this rule is not observed, then you can get serious problems with an already established fence.

Installation of piles

According to the markup, small recesses in the ground are prepared (15-20 cm). A pile is placed in it and twisted.

To do this manually, you will need to build a lever from the pipe. On each side, its length should be at least two meters (the larger it is, the easier it is to deepen the pile in the ground).

Tip: if the soil is too loose, and the pile cannot catch on it, you will need to make an additional load on it.

When screwing a screw pile, it is necessary to immediately monitor its vertical evenness with the help of a plumb line or level, otherwise this will not be corrected in the future (a deviation of not more than 2 degrees is allowed). If the inclination failed to track in time, then I will have to completely get out of the ground and start all over again. The same will have to be done in the case when a pile cannot deepen at a minimum permissible depth of 1.5 meters.

To determine that the pile reached a solid layer of soil is very simple at the junction of the lever and piles when applying forces, the metal will begin to deform.

Cementing

Further, the piles are cut to the required height and concrete. If necessary, small recesses are made around them, which are filled with cement mortar to fix the support in the right position. But these measures are optional, and are more often used in the construction of houses. To install the fence, it is quite enough to tighten the pile to the required depth.

At the same stage, the upper edge of the pile can be treated with protective compounds.

The further sequence of work depends on what height of the pile is left on the surface:

- if 1.5-2 m, then the installation of guide lag begins to them;

- if 30-60 cm, then you need to install fence poles.

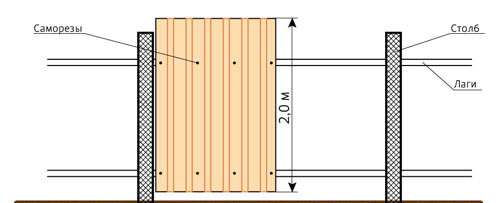

Installation of guides

After that, you should proceed to the installation of the guides. For fences with canvases from corrugated board, they need at least 2 upper and lower. You can attach them in two ways:

- weld directly to the supports;

- turn to the pillars with bolts. In this case, metallic corners are welded to Swai, in the places of passage of the guides, on which there are drilled holes for fasteners.

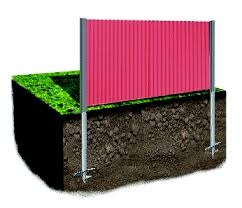

Installation of corrugated board

The method of attaching corrugated board depends on the chosen hedge style. Most often, the panels are installed parallel to the bearing pillars. When fastening the first sheet, it is very important to especially accurately take measurements, otherwise, in the course of further work, such a problem as distortions will appear.

When installing the first panel, it is important to ensure that it is at a height of at least 5 cm from the ground. If the sheet affects the ground, it will quickly lose its operational qualities under the influence of moisture.

The installation of panels must be carried out in the following sequence:

- the height from the ground to the lower boundary of the sheets of corrugated board is determined;

- the construction thread stretches between the columns of the fence exactly in a given height;

- it is attached, focusing on the thread for the correct installation, the first panel;

- it is necessary to make sure that the height and the plumb line are exhibited correctly, and only after the check to fix the sheet;

- the next sheet is aligned according to the previous one, applying it to horizontal lags, after which it is also fixed;

- repetition of the previous stages for all subsequent sheets.

The fence on screw piles with canvases from profiled sheets is ready.

Summing up, we can say that screw supports for the fence allow you to install strong and truly durable fences, and their installation will not interfere with the irregularities on the site, or the cold season. You can carry out the installation manually, without the use of special equipment, and the result, according to numerous reviews, will please for more than one year.