Tiles are a material that has been for several decades for several decades ...

|

|

A neat well -groomed ceiling is the key to a pleasant external appearance of any room. Choice... |

The appearance of the house creates the initial impression of its owners, so very ... |

DIY screw piles

The development of screw piles in domestic construction began recently. But, nevertheless, today they have begun to be used everywhere to arrange supporting structures for individual buildings. The article will discuss what screw piles are, their operational characteristics, for which soil they are intended, as well as many other nuances.

Content:

- Brief description of screw piles

- The device of screw piles

- Application area. Advantages. Flaws

- DIY screw piles

- Calculation of the pile field

- Calculation of screw piles

- Methods of installation of piles

- Violation of construction technology

Brief description of screw piles

- Screw piles are made of high -quality steel. The trunk of a cylindrical shape, with a cone -shaped tip, is equipped with screw blades of a special configuration. They, in turn, provide the bearing capacity of the piles themselves, preventing them from plunging deeper at loads.

- The diameter of the barrel can be from 57 to 159 mm, the diameter of the blade is in the range of 180-550 mm, the bearing capacity of 1 to 15 t/pc.

Screw piles photo

- A square head of 250-300 mm is welded to the upper part of the pipe, which serves as a support for the first rows of structure. The hindling of screw piles with a profile of black rental will help to increase the reliability of the foundation. Also, a reinforced concrete slab or the first crown of a wooden structure can serve as a grillage.

- All steel elements are covered with two -component epoxy paint, which provides exclusive protection against the effects of an aggressive environment. It is worth saying that such paintwork is used to paint the bottoms of vessels of various purposes, which are in constant chemical interaction with various materials and substances (salt water, acids, temperature changes).

- The warranty period set by most manufacturers on this product is at least 70 years. Well, well-made piles with their subsequent competent installation allow you to operate the structure up to 150-170 years.

The device of screw piles

High bearing capacity favorably distinguishes screw piles among analogues. The supports withstand a large weight due to their special design. The blades compact the soil when screwing, thereby transmitting and distributing the load to the vertical layers of the soil.

By manufacturing, screw piles differ in three types:

- Cast. Such piles are made by filling the alloy into forms. They are produced mainly by a certain diameter of 108 mm. There are no seams on the mold, which excludes the separation of various parts from the barrel. The production method creates some difficulties in performing piles according to special ordering, for example, an assortment of non -standard diameter. The manufactured products using this technology are distinguished by a long service life and high reliability. However, if steel of a low brand was used, then pile can deform and talk about the strength of the structure.

- Welded.Production is carried out by steaming the blades to the pipe, one end of which has the shape of a cone truncated under a certain inclination. For the manufacture of blades and the trunk, plasma cutting is used. Which guarantees the accuracy of the specified parameters and high resistance. The welds are carefully cleaned and then treated with a special anti -corrosion coating.

- Combined. Piles of this species are less common. They combine a cast trunk and welded blades made by means of laser cutting. The quality of the seams is made of special requirements, because the reliability of the product and, accordingly, the durability of the foundation, depends on it.

There are several types of tips:

- with a cut under the slope;

- cone -shaped;

- with a symmetrical cut.

The length of the piles is selected taking into account the characteristics of the landscape, for example, the maximum indicator of the soil difference on the construction site, the height of the base and the like nuances are taken into account.

Application area. Advantages. Flaws

Pile parameters are determined depending on the application, for example, you can take lightweight, which are used in the installation of awnings, terraces, advertising structures, or reinforced support elements calculated for a large load.

Pile products have the following distinctive features, thanks to a unique configuration:

- the foundation can be equipped in uneven areas;

- suitable for any type of soil, including peat and filled soils, unsteady rocky rocks;

- actively used in conditions of dense urban development;

- lack of vibration, especially this is important when working near historical and cultural monuments;

- screwing is carried out both in a mechanical and manual way;

- supports amenable to repair, they are distinguished by mobility and the possibility of re -use;

- the arrangement of the base on screw piles can be performed at any time of the year;

- quick installation, in addition, the supports are ready to accept the load immediately after completion of work;

- the low price of screw piles allows you to create the cheapest type of foundation.

From negative points, one can note:

- exposure to corrosion processes;

- the cost of insulation of the basement of the residential structure will be compared with the cost of the foundation itself.

DIY screw piles

It should be noted right away that it will not work to manufacture this product with a artisanal way, corresponding to all the technical and technological parameters. The reliability of the support will be under a big question.

Of course, you can purchase one sample and make all the measurements of the product, but the manufacturers carefully hide the other no less important information.

- Often it happens that I screw up to half, the tip or blades break off the barrel. In such cases, the support is replaced, and the stuck elements of the product at the intended point are necessarily extracted.

- The fact is that the blades that are more responsible for the bearing capacity are welded at a special angle, and the steel itself should be of high quality. It is possible to give the correct form to the tip only if there is special equipment and a thorough study of the technology.

- If there is confidence in one’s own strengths and knowledge, it should be borne in mind that installing homemade screw piles can only be for light designs of an unprecedented purpose: sheds, toilets, wooden fences and the like.

The following materials and tools will be needed for manufacture:

- a metal pipe with a diameter of 100 mm and a wall thickness of at least 3.5 mm;

- steel sheet 5 mm thick;

- bulgarian with a special nozzle or jigsaw.

Stages of work

- 4 triangles are cut from sheet steel, which are welded to the end of the pipe, forming a cone.

- The blades can be made independently by cutting them out of the metal sheet. It is necessary to bend them at a certain angle so that the distance between the turns in the finished product is about 5 cm. This process can be greatly facilitated if the blades are taken from any drill.

- The welds are carefully cleaned.

- On the other side of the pipes, working holes are drilled with such a diameter that scrap can pass through them, which serves as a lever with screwing the pile.

- The support is covered with epoxy, which will provide protection against premature corrosion formation.

http://www.youtube.com/watch?v\u003dq4tbztfokva

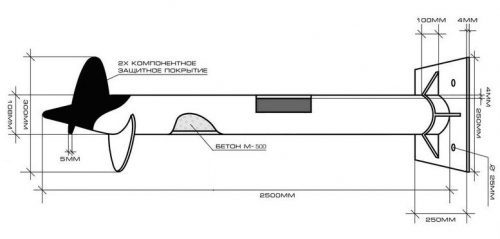

Rifle piles drawing

Calculation of the pile field

A competent arrangement, the required number of supports with the corresponding parameters for the design of any purpose is the key to reliability with a long service life. Before proceeding directly to calculations, you need to know the general principles:

- when erecting light fences, it is not recommended to mount piles with a step of more than 3-3.5 m;

- for more thorough fences, for example, from a profiled sheet, light stones, the distance between the supports should be no more than 3 m. If there is a wind load, then the step should be reduced to 2.5 m;

- frame houses or log cabins are allowed to be installed on piles, screwed at a 3-meter distance from each other;

- if gas blocks, foam, aerated concrete or similar materials are used during construction, then the step between the piles should be no more than 2 m.

Calculation of screw piles

- All calculations of the foundation on screw stilts are based on the plan of the first floor. The supports are indicated at the corners of the structure, at the joints and intersections of external walls with supporting internal partitions. Further, along the length of the walls of the pile location, every 2-3 m are marked, depending on the material used for the construction of the house.

- The rest of the space is filled with supports with the same step along strict lines. Otherwise, during subsequent work, difficulties may arise with the organization of structural elements of the structure.

- If it is planned to lay a furnace or fireplace, then at least 2 supports should be installed in this place. Screw piles are indicated at the outer corners of small terraces, outbuildings or balconies.

Of course, a specialized organization will conduct more accurate calculations, where many other equally important factors will be taken into account and taken into account:

- building weight taking into account the material;

- snow and wind loads;

- features of layout, spans, etc.

Methods of installation of piles

- The process of screwing supports of this kind is not particularly difficult, this manipulation can be carried out both manual and mechanically. Special technique is used for installation of piles, the diameter of which exceeds 108 mm and this is determined not only by the fact that the product is quite heavy, but also by the fact that its large dimensions increase the probability of inclination when screwed.

- Also, the use of equipment and guides is necessary if work is carried out on complex soils. The permissible error with vertical inclination should not exceed 2.

- The massive supports used in the construction of large objects are mounted using special equipment, where control over the vertical lies on the on -board computer.

- The dimensions of piles are not the only reason why the deviation may occur. Often, when screwed, an obstacle occurs in the form of large boulders in the ground.

- Sometimes piles with defects come across, but, unfortunately, this can be found out only in the process of work. The most common marriage is a poor -quality seam, so the lobe can occur, thereby excludes the reliability of the entire structure.

Twisting screw piles with your own hands

- On the marked fields in the marked points using a shovel or drill, holes break out. Their depth should not exceed 40 cm, the pits serve only certain guides. Tip: the piles are screwed, not buried! It is these manipulations that give the necessary strength to the screw product.

- First, corner screw piles are installed, because they will serve as a guide for other supports. They are inserted into prepared holes, and sprinkled with earth. After completion of work, the soil around them is compacted.

- At this stage, it is important to strictly observe the vertical level. The levers are inserted into special holes and after that you can proceed directly to the screwing of the support. 2 people will cope with such manipulations, in the presence of certain skills, the process will take no more than 15-20 minutes.

- A screw sovere is twisted until the blade passes below the freezing level of the soil. In the course of the work, it is regularly checked whether the perpendicular is withstanded.

- It happens that the support rests on any obstacle, here it is necessary to make more efforts. In principle, when deepening piles per 1 meter or more, it is allowed to leave it at this level. If the deepening is less than a meter, then the screwing point is transferred. The worst option to transfer the entire foundation.

- At the end of the installation, the pipes are cut off by a grinder to the desired level. The barrel is poured with a concrete mixture of the M300 for the entire length. If the structure is temporary (worker, trading pavilion) and it is planned to be dismantled in the future, then the last manipulation is not performed.

- It remains to weld the heads to the barrel and mandatory process the surface and working seams with protective anti -corrosion material.

Twisting screw piles video

Violation of construction technology

Failure to comply with certain rules and norms when arranging a pile-screw foundation can lead to rather complex and expensive repair work. Therefore, it is so important to know some basic principles that will help to avoid sad consequences.

- The study of soil. Do not neglect this stage and replace a full -fledged analysis by trial drilling.

| Risk | What to do |

| In the site, heterogeneous soil can lie, which will over time lead to a failure of piles. Accordingly, part of the structure will fall on the soil.

|

In such cases, the house rises to the jacks and the new piles are screwed. Because the extension of the supports is unacceptable, welding seams should not be below the ground level.

|

| When working, it turns out that the depth of immersion of the supports should be deeper. Since only the average freezing of the soil during trial drilling were taken as a basis. | Extension of length or their complete replacement. Which will undoubtedly incur considerable expenses for the purchase and transportation of products. |

- Poor material. Violation or simplification of technology in the production of piles will definitely lead to a short service life of the foundation, due to the deformation of the barrel, separation of the blades and so on. And as a result, the unreliability of the structure as a whole.

| Characteristic. It should be | Otherwise. Effects |

| The thickness of the pipe wall is from 4 mm and above. | Reducing thickness even by 0.5 mm reduces the operational period of the foundation by 25%. |

| The thickness of the protective layer should be at least 200 microns. | A sophisticated layer of coating will not be able to provide reliable and long -term protection of metal elements, thereby reducing the service life of and the foundation itself by 15%. |

| The blades of the wrong configuration.

|

The soil is loosening with screwing, instead of compacting it near itself. In this regard, the bearing capacity of the pile cannot be guaranteed. |

| Undetrically executed welded seams. | Low quality welding work reduce the service life of a screw pillar from 40 to 80%. |

| The absence of a scarf on the headline. | It cannot provide a reliable support for strapping. |

- Load distribution. The illiterate calculation of the pile field will violate the horizontal of the base, which, in turn, will lead to the destruction of the structure. Easier consequences of the overrun of the material.

| Cause | Consequence |

| Incorrect placement of piles, irregular dimensions. | The gesture of the floor or the corner of the structure remains in a hanging state. |

| Exceeding the permissible deviation relative to the vertical axis. | The support will carry a lower load than in design calculations. |

| The piles are screwed into a run. | The complication of subsequent construction processes, an increase in the consumption of material for strapping. |

The pile-screw foundation has recently been selected more and more often in the individual construction segment. High characteristics, ease of installation and very significant savings in its arrangement make it very attractive for most developers. But in order for the base to meet all the requirements for operation, it is necessary to purchase quality products and comply with the relevant requirements when organizing this foundation.

This is who forbade

This is who forbade the gradual extension of the body of the SVS welding? If the bearing layer of 12 m lies, how to twist. If you do not shit - why give people left tips - twisted below a meter and everything is fine. The pile should pass the level of freezing, drop lower to the bearing layer

idiocy, typical summer resident

idiocy, typical summer resident