The windowsill is not only a mandatory constructive, but also aesthetic, but ...

|

|

What do you think about to make repairs? That it is already scary to enter the apartment ... |

Warm hydraulic -type warm floor is a worthy alternative to the traditional ... |

Penetrating waterproofing of concrete: description, choice of material, features of application

During the repair or restoration of concrete or plaster coatings, penetrating waterproofing of concrete is used. This material helps to improve the quality characteristics of concrete and makes it moisture resistant. We will consider how to choose where to buy penetrating waterproofing concrete.

Table of contents:

- Penetrating waterproofing of concrete: features and characteristics

- Restrictions on the use of concrete waterproofing

- The principle of operation of additive to concrete for waterproofing

- Penetrating waterproofing of concrete: materials, selection process

- Features of the use of penetrating waterproofing

Penetrating waterproofing of concrete: features and characteristics

Penetrating waterproofing is the material that includes Portland cements, fillers and active chemical additives. Salt elements of alkalis, alkaline earth metals or polymers act as additives.

The main feature of penetrating waterproofing is the principle of the solution of the solution: chemical additives applied to the surface fall deep into concrete, while moving through capillary pores filled with water.

The function of protection against moisture consists in the interaction of calcium compounds, which are the main component of cement with penetrating waterproofing, while the pores that are on the cement surface are reduced and do not pass water.

The scope of the waterproofing of the penetrating effect applies to:

- repair and waterproofing of concrete surfaces;

- restoration of reinforced concrete structures;

- Restoring coatings of cement-sand composition.

In addition, the use of the waterproofing of the penetrating action is associated with waterproofing:

- concrete or brick basements;

- cellars;

- foundations;

- pools;

- terraces;

- garages;

- viewing pits;

- object objects;

- water containers;

- Colodeus.

Elements that are the main components of which are foam concrete, expanded clay and other types of porous concrete and asbestos cement materials are unsuitable for applying penetrating waterproofing.

The main difference between penetrating waterproofing and roll materials is that waterproofing acts throughout the area and thickness of the concrete structure, and roller materials protect concrete only at the installation site. In addition, roller materials are not able to make constant contact with water, so their installation in pools, water tanks are ineffective. Penetrating waterproofing has an unlimited validity period, and performs its functions until the concrete coating itself collapses.

Restrictions on the use of concrete waterproofing

The use of penetrating waterproofing becomes a rather popular process, but there are times when, out of ignorance or by lack of experience, these materials are used in cases where their use is inappropriate. Therefore, we propose to consider the cases in which the waterproofing of concrete is necessary.

The use of penetrating compounds is reduced to their use as one of several waterproofing options or the main waterproofing material.

In the process of waterproofing of the foundation that constantly contact with water, the use of roller waterproofing is not always effective. In order to additionally strengthen the waterproofing characteristics of this kind of designs, it is recommended to use penetrating waterproofing, which can provide internal protection against moisture.

The fundamental difference between penetrating waterproofing and its alternative option is its ability to penetrate the thickness of concrete. Some types of penetrating solutions are capable of waterproofing concrete deep into up to forty centimeters.

It is recommended to use penetrating waterproofing materials in order to protect structures made of concrete or reinforced concrete, for waterproofing surfaces that are constantly in contact with moisture, in the process of waterproofing foundations, if the groundwater level is too high.

The main advantages of buying waterproofing materials of penetrating action:

- increasing the water -repellent characteristics of concrete structures;

- the formation of a durable layer of waterproofing along the entire thickness of the concrete product;

- the ability to work on internal and external parts of the structure;

- the possibility of applying on wet surfaces;

- Lack of need to dry concrete.

The main advantage in the purchase of materials of penetrating action is their ability to protect the internal part of the structure from the external influence of moisture. This explains the widespread use of this material in the restoration of premises, such as basements in which there is no opportunity to conduct external waterproofing.

In addition to a large number of advantages, penetrating waterproofing is characterized by the following disadvantages:

- concrete structures that have or are subject to surface cracks will not be protected from moisture, therefore the use of penetrating waterproofing is associated only with crack -resistant structures;

- provides only surface protection of brick buildings, since in the brick there are no substances necessary for the reaction;

- not suitable for waterproofing porous concrete foundations;

- Not applied to the foundation blocks.

The principle of operation of additive to concrete for waterproofing

First of all, the waterproofing mixture is mixed with water, and covers the wet surface of the concrete base. The waterproofing effect occurs due to the fact that the pores of concrete are gradually filled with a waterproofing solution.

Due to the fact that a large number of active chemical additives are present in the material, they begin to interact with elements in the concrete composition, while the process of crystallization is obtained, and a continuous barrier is created, which makes concrete moisture resistant.

The course of the concrete solution compaction process occurs due to the presence of water. If the water in the solution is absent, then the process stops, in the presence of water, its resumption occurs.

The penetration of waterproofing into concrete reaches thirty - forty centimeters. The presence of microports, capillaries and microcracks filled with crystals increases the water resistance of concrete several times. At the end of this process, a concrete base is obtained, in the form of a compacted waterproof coating.

The penetrating waterproofing is rightly attributed to unique materials, since in the process of processing concrete, using these solutions, it interacts between chemically active substances and cement stone. As a result, an insoluble threaded crystal coating is formed, which is stable not only before moisture, but also before the influence of aggressive substances.

The structures that were processed using penetrating waterproofing are stable before the influence of chemical reagents, aggressive stimuli, salty solutions, stock water and other aggressive components, and from the environment.

The use of the waterproofing of the penetrating action positively affects the frost resistance of concrete, provides its protection against wind, mechanical strokes, atmospheric precipitation and prevents the process of oxidation of reinforcing sites of reinforced concrete.

Crystalline compounds are characterized by the presence of the smallest pores through which water does not pass, but at the same time, concrete does not lose the characteristics of air or vapor permeability. Thus, the concrete coating breathes, but does not pass moisture.

To form crystalline compounds on the surface of concrete, the presence of moisture is required, so the ideal option for the work of penetrating waterproofing materials is the recently installed concrete base. When working with dry concrete, it requires preliminary moisture.

In addition, among the main advantages of penetrating waterproofing there is:

- compaction of the structure of concrete;

- Cracks of cracks up to four millimeters;

- lack of need for the processing of a concrete base with a primer;

- stability before a puncture, separation or separation from the surface;

- Lack of need in protection in the process of fulfilling backfill.

The most effective is the use of penetrating waterproofing at the temperature of the use of concrete structures from -30 to +10 degrees.

The use of penetrating waterproofing provides concrete protection from chemical exposure, chlorides, from metal corrosion. At the same time, concrete is not exposed to moisture and ultraviolet radiation. Also, the materials of penetrating action are of good resistance, are stable before loading, compressive strength and resistance before radiation.

Penetrating waterproofing of concrete: materials, selection process

Before the penetrating waterproofing for concrete, you should get acquainted with recommendations that will help you choose the correct type of solution suitable for a certain stage of the waterproofing process.

The use of penetrating waterproofing based on cement is relevant in the processing of external walls, floors, basements, foundations, containers for storing fluids, sewage systems, tanks, tunnels, mines, wells, automobile parking, technical buildings, water dams, pools.

We offer to consider the main manufacturers of penetrating waterproofing:

1. Osmosil - Italian penetrating waterproofing. The material looks like a ready -made mixture that is based on the use of an osmotic waterproofing cement, with a high -strength protective composition and with special filler impurities.

The use of osmosil is associated with internal and external waterproofing works on the processing of the foundation, the bases of the building. It is recommended to use the material in the premises of mines, elevator, when arranging a drainage system and water tanks, when repairing a shower or bathroom. The application of the material is possible both from the inner and the outside. Osmodil is applied on the basis of stone, concrete or brick composition. The main feature is the preliminary plastering of the surface. It is not recommended to use waterproofing on surfaces that are subjected to constant shrinkage or vibration. In this case, it is recommended to add to the solution of latex -based additives. The coating processed using this waterproofing material is recommended to operate in the temperature range from -35 to +85 degrees. The performance of waterproofing work is carried out at a temperature above five degrees of heat. The finished coating is loaded no earlier than after two days.

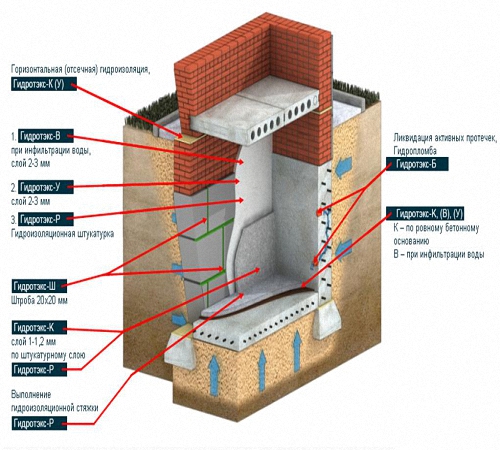

2. Gidrotx - waterproofing of penetrating effects of which includes sand, cement and penetrating additives. There are two types of this waterproofing: Gidrotx B - is used for internal waterproofing, hydrotx y - with external.

Scope of the material:

- concrete and stone structures;

- concrete buried or semi -pounded bases;

- basement, garage premises;

- storage facilities;

- tunnels, mines;

- sewage, water systems;

- Pools, water containers, etc.

Gidrotx products developers say that their materials are able to penetrate into concrete to a thickness of up to one meter. Hydrotx is not used on stone-concrete structures, which are characterized by the absence of capillaries.

Features of the use of penetrating waterproofing

1. The basements.

Protection of the basement from the accumulation of moisture implies not only the use of good waterproofing, but also the correct construction of walls and their support in the form of the foundation. The positive effect of penetrating waterproofing will be achieved if the minimum number of joints is present on the walls, the materials will be introduced directly into the concrete solution, and the application will be both internal and external.

2. Potato storage.

If you do not provide protection against moisture at this facility, then it will be filled with water and potatoes will deteriorate. Therefore, to ensure high -quality waterproofing potato storages, it is necessary to use special concrete slabs in the construction process that have waterproofing characteristics or take care of the organization of water resistance using special water protection materials.

The use of dry mixtures allows you to prevent the formation on the coating of the film, since they are used directly in the solution itself and act along the entire perimeter of concrete. The use of dry mixtures is the most optimal waterproofing option for this kind of designs. The main advantage of such waterproofing is the lack of the need to dry the surface before application. The mixture is applied to a wet coating.

Such waterproofing is applied with a brush, and immediately interacts with the surface of concrete. In addition, the solution helps to fill the microcracks, while the wall does not pass moisture, but passes the air.

3. The foundation.

The waterproofing of the foundation is the necessary part of the construction of the house. Since it is the foundation that is most susceptible to the effects of the environment on it. Therefore, this part of the building requires protection from exposure to water and soil water, as well as from harmful substances that fall from groundwater. At the same time, the materials of penetrating action are absolutely harmless to people, but very effective for the building. It is recommended to use such waterproofing in the construction of buildings of any purpose, ranging from public and industrial, ending with private and social. Since the building has been operated for more than a dozen years, even if, when building its foundation, the groundwater level is low, then after a certain time, changes are possible, which, with poor -quality waterproofing, will significantly affect the entire building and lead to its destruction.

4. Wells.

The use of penetrating waterproofing during work to improve the water -repellent characteristics of concrete in the well allows you to start work without preparing the surface, while there is no need to fine walls, moisturize concrete and waterproofing.