In order to improve the site and make it suitable for living, ...

|

|

The roof is an important element of the construction, from the correct installation and high -quality ... |

Foam is an excellent insulation that is often mounted on the outer walls ... |

The phased filling of the foundation under the house. Advantages of the summer and winter filling of the foundation

Filling the foundation is a very important process, the life of the whole house directly depends on the quality of execution. Several technologies and schemes for filling the foundation are distinguished, each of which has its own advantages and disadvantages. And how to fill the foundation under the house with our hands will talk further.

Table of contents:

- Fill the foundation in the summer of the year: features and advantages

- Features of filling the foundation in winter

- Tips for preparing a solution for filling the foundation

- How to improve the quality of the solution

- Equipment for filling the foundation under the house

- Preparation for the filling of the foundation with your own hands

- Recommendations and instructions for filling the foundation with your own hands

Fill the foundation in the summer of the year: features and advantages

The foundation is the support of the building and its manufacture should be approached with special responsibility. With independent construction of the house, we recommend that you choose the right time of the year to fill the foundation. Since weather conditions play an important role as the resulting structure.

You can fill the foundation at any time of the year. However, each of these fills has its own characteristics:

1. Fill the foundation in the autumn season.

In the fall, the foundation is protected from excessive humidity. For this, the already dried -up coating is covered with a film made of polyethylene. In addition, the inside of the formwork is covered with a cellophane that improves the smoothness of the surface and the waterproofing properties of the foundation.

Work in the cool season has its advantages and disadvantages. During this period, the solution is poorly grasped and dries, but at the same time there is time to install it. In addition, there is no need to arrange additional waterproofing.

2. Features of the summer filling of the foundation - at this time of the year, the main enemy of concrete is direct solar radiation. Under its influence from the foundation, water quickly evaporates, to prevent this process, concrete is constantly moistened for two weeks.

Summer foundation filling is the most ideal option. It is quite easy to build a trench in this year, the concrete does not freeze, as in winter. However, we recommend selecting cloudy weather to perform work.

At high temperatures and reduced humidity, work quickly. In addition, when performing summer filling, follow the recommendations below:

- Use a waterproofing membrane that prevents the care of excess moisture in the ground;

- attract the largest number of employees in order to do the work as soon as possible;

- Make the solution more moist, thus, the service life is extended.

Features of filling the foundation in winter

Pouring the foundation at this time of the year is quite difficult. First of all, difficulties arise with digging a trench. If there is snow on the site, remove it. Next, cover the location of the foundation with a black waterproofing film. Thus, under the influence of sunlight, the soil warms up.

For the manufacture of winter formwork, polystyrene foam is most often used. This material is distinguished by elasticity, is not afraid of frost and additionally insulates the foundation.

Special difficulties in the winter season arise with the manufacture of concrete solution. At a too low temperature, the water freezes to prevent this, the composition is constantly heated. Keep in mind that at a temperature of -15 and below, work on filling the foundation is not carried out. There are several ways to prevent freezing of water in the foundation. We offer to familiarize themselves with them:

- Performing the heating of the site and the foundation - the concrete composition and the foundation, for several days from the date of filling is heated by air guns;

- Using improvised heating products - after filling the foundation, it is covered with a burlap, after poured manure or turf;

- The third method is based on the use of special additives, such as table salt, it is added directly to the water for the solution in the ratio of seven to one, such concrete is called cold, it is not prone to freezing, but also dries longer than usual.

To improve the quality of the solution, plasticizers that prevent freezing of water are added to it. Filling the foundation in winter is a completely real process, however, if it is possible to perform this work at another time of the year, we recommend using it.

Tips for preparing a solution for filling the foundation

To obtain a high -quality solution for filling the foundation, first of all, you need to choose its correct components. The most important components for the concrete mixture are sand with water. In addition, sand and coarse -grained material in the form of crushed stone, gravel, pebbles are used as aggregates. Also, special substances are added to the concrete solution that improve its strength characteristics.

Cement is the main component, the main function of which is the combination of all components into a single composition. We recommend that you purchase cement immediately before pouring, since this material is characterized by high hygroscopicity, easily absorbs moisture and hardens.

To obtain high -quality concrete, we recommend using the cement of the brand 400 or 500. In this case, it is possible to get a high -strength composition. Water - dilutes a concrete solution to the desired consistency. Use only clean water, without additional inclusions and salts.

Pay attention to the proportions of water, with insufficient amounts, concrete is very difficult to fit on the surface, and with excessive - the mass does not have the right strength and cracks over time.

If you connect the water directly with the cement and apply such a composition to the surface, then from excessive stress, it will begin to crack. To prevent this process, increase the strength and reduce the cost of concrete, use fillers in the form of sand and crushed stone.

Use only pure sand without clay inclusions. The ideal option is river sand, previously washed and dried.

Crushed stone is most often used as a large aggregate. This material should also be clean, and all stones are different in size. Thus, the number of voids in the solution is reduced and the strength of the coating increases.

The following is an equally important process - the selection of the proportions of the concrete composition. The standard scheme for the ratio of cement, crushed stone, sand and water is 1 to 2 to 4 to 0.5. In private construction, these proportions are determined by the type of concrete and sand characteristics, when using wet material - the amount of water is reduced.

With an excessive amount of cement in the composition, it turns out to be too hard, a large amount of sand - the solution is poorly grasped, the presence of an excessive amount of water - leads to poor adhesion of the coating and high porosity. Therefore, strictly observe the proportions in the preparation of the solution.

How to improve the quality of the solution

Even with an ideal ratio of proportions, some options for concrete solution need to improve. In order to make the composition more plastic, while reducing the amount of water, various plasticizers are used.

Using hydrophobizers, the solution acquires the properties of bubbles and the time of its setting is reduced. In the winter season, various salts are added to the solution that change the properties of concrete.

In addition, the quality of the resulting coating is also determined by the way to lay it. The most durable composition is obtained when exposed to a solution of vibrational mechanisms. With its help, laying is done as quickly as possible.

Equipment for filling the foundation under the house

The number and type of devices for filling the foundation are determined individually and depend on many factors, such as:

- time of the year for work;

- type of foundation;

- the dimensions of the trench;

- Individual features of the structure.

Most often, in the process of filling the foundation, a grid for reinforcement, gutter, beacons are used.

In addition, with independent manufacture of a solution, a concrete mixer is used for its kneading. You should also take care of the containers by which the solution is supplied directly to the trench.

The use of concrete mixers significantly improves the quality of the solution, making it as homogeneous in consistency. The best option for filling the foundation, concrete mixer, with a capacity of more than 50 liters. To organize the continuity of the process, we recommend that you work at least the three of them.

Mixer is an automatic concrete mixer that brings ready -made factory concrete to the site. It will take no more than a few hours to fill such a foundation. A special gutter is connected to the machine, with which the solution falls directly into the trench.

In the absence of the possibility of entering the site, a device in the form of a concrete pump is used. This unit supplies a solution at a distance of about 50 meters. A special sleeve with a hose distributes the solution as accurately as possible.

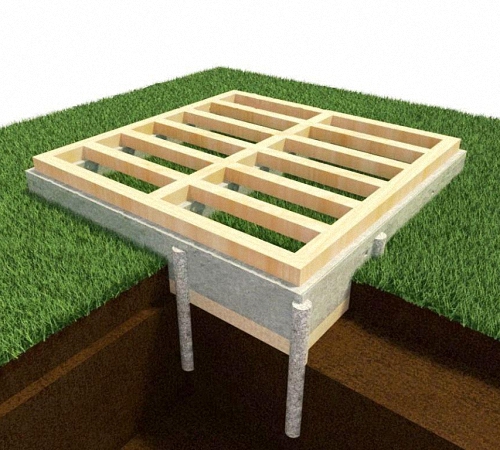

Preparation for the filling of the foundation with your own hands

There are several stages of the construction of the foundation:

1. The study of the geological characteristics of the site. The strip foundation under the house is poured only with dry ground. In the presence of heaving, we recommend that you stop on another option.

2. Marking. The site is pre -aligned and cleaned of garbage and vegetation. Using pegs and cord, make the internal and external location of the foundation. To build partitions, also make markings. Pay attention to the corners of the foundation, the evenness of the future structure depends on the correctness of their location. Check the marking with the level.

3. Digging a pit or trench. The depth of the foundation is determined in advance, which depends on the type of soil, the features of its freezing, the load on the foundation and weight of the building. Most often, the foundation for a one -story house is built with a depth of 50 to 100 cm. The bottom of the trench is checked by a water level. Swear in height are not allowed. To perform work, use an excavator or shovels. When performing work in the winter season, only specialized equipment is used.

4. At the next stage, the foundation pillow is formed. This element is mandatory and performs the function of reducing the load on the foundation when the soil displacement. At the bottom of the trench, sand is laid, at least 15 cm thick. At the same time, every 3 cm of sand is thoroughly tamped with a special tool and aligned along the water level. Next follows a layer of crushed stone that performs the function of moisture. Waterproofing in the form of roofing material or polyethylene film is laid on gravel.

5. The construction of formwork is the next process. For its manufacture, use metal, wood or plastic. In the winter year, the formwork is made only of plastic. The formwork protrudes above the surface at least thirty centimeters. Inside the formwork, a rope is installed, indicating the level of filling the foundation. At this stage, water and sewer pipes are installed.

6. Fulfillment of reinforcement. The strength of the foundation and the duration of operation of the entire building directly depend on the quality of the implementation of this process. Inside the trench, metal rods are laid, connected using a special wire. The type of rods and their number are determined individually for each structure.

Upon completion of reinforcement, the process of filling the foundation with concrete solution should be directly followed.

Recommendations and instructions for filling the foundation with your own hands

Two options for filling the foundation are distinguished:

- partial;

- Complete.

Each of them has certain advantages and disadvantages. There are three types of partial filling:

- horizontal;

- vertical;

- diagonal.

This method in private housing construction is used less often than full filling. This is due to the complexity of its implementation, the need for individual calculations of time intervals.

For a strip foundation, horizontal or vertical filling is used. The strength of the foundation after the filling is primarily affected by the correct reinforcement. And the calculation of the number of layers and the time of their setting.

Before the start of the partial filling, determine the method of performing the work, make a drawing on which each of the layers and the time of their setting is clearly determined. Divide the area into several parts, in relation to the method of filling.

Full filling of the foundation is used more often. As a result, a holistic monolithic coating is obtained, which has excellent operational characteristics. The concrete solution is made immediately before the filling. Distribute the composition evenly along the trench, remove the voids with a special device or a concrete vibrator.

The monolithic of the foundation made by full fill has the following advantages:

- lack of necessity in complex and long -term work;

- resistance before seasonal soil changes;

- High strength level - resistance before deformation.

When choosing between partial and complete filling the foundation for the house, we recommend that you stop on the first version.

Fill the foundation of the video: