The duration of operation of the entire building depends on the quality of the roof. Since it is ...

|

|

When changing the old flooring or when arranging a new floor, a floorboard ... |

To date, the question how to choose a stretch ceiling, can be... |

How to properly cover the roof with a corrugated board with your own hands. Instructions

The roof is an important element of the construction, on the correct installation and high -quality coating, which depends on the safety and durability of the entire structure. A huge selection of roofing products is presented in the building materials market, among which corrugated board occupies a leading position. The article will talk about how to properly cover the roof with a corrugated board with your own hands. It is worth saying that the technology itself is simple if you know the features of this material and follow some installation rules.

Content:

- Characteristics of corrugated board

- The angle of inclination of the roof

- Calculation of roofing material

- Roof structure from corrugated board

- Useful tips for laying corrugated board

- Necessary tools

- Material and additional elements for roofs from corrugated board

- How to cover the roof with corrugated board

- Installation of complex roof structures

- Cover the roof with corrugated board the price of work

Characteristics of corrugated board

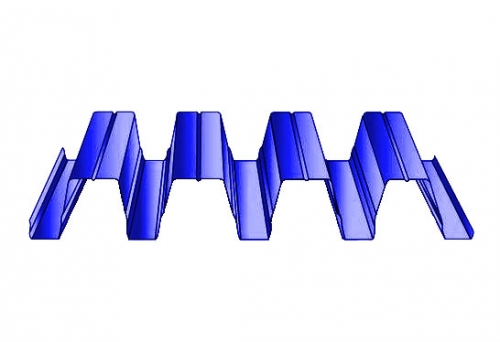

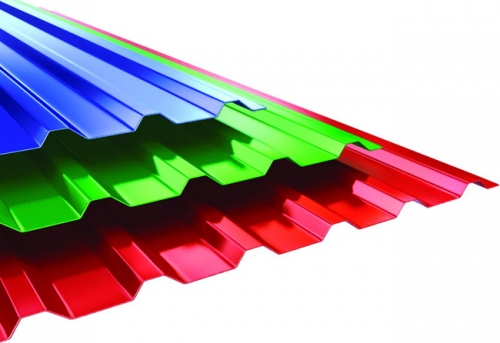

In the manufacture, the metal sheet passes through special rolling equipment, which creates a profile of various heights from 8 mm to 75 mm. Due to the wave -shaped, rectangular and trapezoidal profile, additional rigidity is achieved. Thanks to this, corrugated board easily withstands mechanical damage and high loads.

- The galvanized coating makes this material reliable and durable. He is not afraid of chemically aggressive substances, corrosion, atmospheric precipitation (weather conditions).

- The corrugated board is one of the few materials that is easy to install and is convenient during transportation.

- Roofing using a profiled sheet is performed faster than with other materials. Which significantly saves not only time, but also money.

- In the production process, the profile is covered with a colored polymer, such a coating serves as an additional protective layer and gives an attractive appearance. This allows you to choose this roofing material of any color in accordance with the general type of structure.

The angle of inclination of the roof

The laying of profiled sheets depends on the slope of the roof, the minimum slope is at least 12. At the end of the work, sealing working seams should be carried out using mastic or sealing tape.

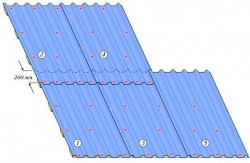

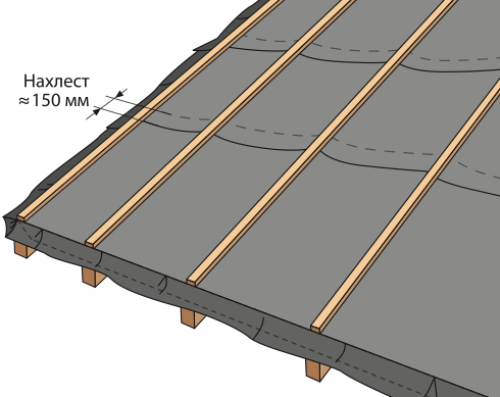

- tilt up to 15 - neighboring sheets are mounted with an overlap of 200 mm;

- the slope up to 30 - the overlap in this case is 150-200 mm;

- the slope is more than 30 - the permissible overlap is 100-150 mm.

Calculation of roofing material

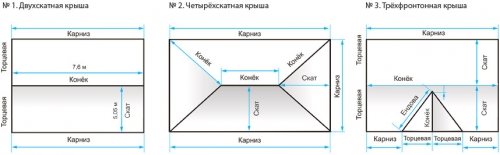

Before calculating the amount of the required material, the roof should be measured. Because, at the stages of the project, roofing slopes can undergo changes.

- To do this, you need to measure the slopes diagonally and compare these values, the discrepancy should not exceed 20 mm. It is also necessary to check the plane of the slopes, such a measurement is performed with a level with a cord, where a deviation of not more than 5 mm is allowed for every 5 m. Otherwise, the sheets are not incorporated.

- The ideal option if the length of the sheet corresponds to the length of the slope, it is necessary to add about 40 mm to this parameter for the overhang overhang. Next, the amount of cornposure is calculated, where the length of the cornice is measured and divided into mounting (taking into account the overlap) sheet width.

- You can calculate the number of sheets in another way, the length of the cornice is divided into a useful (not taken into account) sheet width, and round the resulting value.

- If the roof has a complex configuration, then it should be visually divided into geometric shapes. Each form is calculated, and the final results are summarized. It is important to consider such additional elements as: windows, pipes, ends, skates.

Roof structure from corrugated board

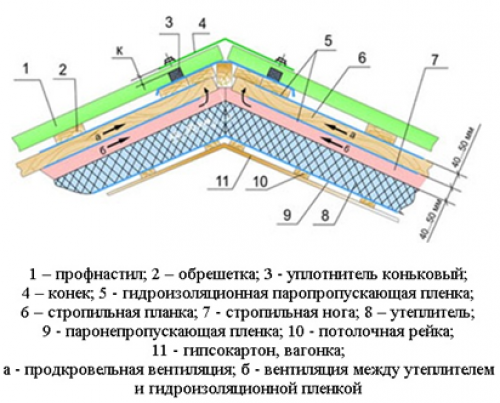

The roofing structure, in addition to the coating itself, consists of a whole complex of structural elements as: heat -hydro -hydro -product and ventilation. Each of them fulfills its role, ensuring the correct operation of the entire roof. In order for the roof to serve for a long time and performs its direct function, it is necessary to provide a competent location of all layers of the pie.

Vapor barrier. Its task is to prevent moisture penetration into the insulation. Special films are used here, the styling of which is performed from the inside of the roof with a construction stapler along a horizontal line. The seams formed during installation are glued with tape or butyle tape.

Insulation. The next layer consists of insulation, which serves as a compensator of the air temperature difference, so it prevents the accumulation of moisture and condensate under the roof during operation of the structure. Its thickness is selected depending on the region of residence, it is recommended to use a heater with a thickness of at least 200 mm. Tile or roll material is laid in the space between the rafters.

Waterproofing. The final stage is the installation of a waterproofing membrane (wind protection). It acts as an additional insulation and, thanks to its waterproof surface, protects the entire structure from condensate, thereby extending the life of the roof.

The membrane is rolled out in the horizontal direction from the cornice to the ridge (from the bottom up). Having it in such a way, so that the joints of the rolls are on the rafters, it must be attached with an overlap of 150 mm.

Material for hydro and thermal insulation is calculated in the same way as the number of profiled sheets.

Useful tips for laying corrugated board

- sheets on the roof rise using lags from one or two boards of the desired length;

- it is not recommended to carry out work in windy weather, as there is a chance to miss the sheet and damage it;

- during the work, move along the professional facilities should be in soft shoes, advancing only in the deflection between the waves in the places of the crate;

- it can be avoided by the formation of corrosion on the material if you treat all sections or other leaf damage to the repairs with repair enamel;

- when working with corrugated board, it is necessary to use dense protective gloves, since the edges of the sheets are quite sharp;

- garbage formed during installation should be removed with a brush or washed with a soap solution;

- the protective film of the material is mandatory removed immediately after installation;

- it is forbidden to use a grinder (grinding machine) in order to avoid the development of the corrosion process.

Necessary tools

- lever scissors or electrician cutting sheets;

- a screwdriver for attaching the material or a hammer if the fasteners are carried out using nails;

- construction stapler for attaching films and insulation;

- drill and drill No. 5, if the profile is attached to a metal structure with a thickness of more than 2.5 mm;

- and such auxiliary instruments as: marker, knife, level, roulette, pistol for sealant.

Material and additional elements for roofs from corrugated board

Corrugated board.To cover a light roof with a slight slope, you can use profiled sheets C35 or C44 sinusoidal or trapezoidal shape.

Their length is from 2 to 6 m, but some manufacturers offer the manufacture of sheets for individual sizes from 0.5 to 12 m and from above.

The arrangement of the pitched roof is recommended to be performed from the corrugated board of the SN35 brand, this model is better for these purposes. Professor of the brand H is used for equipment of supporting structures. The height of its profile can be from 57 to 114 mm.

Self -tapping screws.This mounting element with a polymer coating is selected to the color of the sheet. Thus, it is as invisible as possible in the architectural ensemble. They are chosen depending on the material: wood and metal. Its lurestick allows you to perform fasteners to a metal structure, the thickness of which does not exceed 2 mm. When buying screws, it is necessary to check the presence of a sealing washer (neoprene rubber).

Seal.It is possible to seal sealing of the gaps, for example, between the skate and the roofing, you can use a special seal. It prevents garbage and moisture from entering the subcutaneous space, due to the repetition of all bends of the profiled sheet.

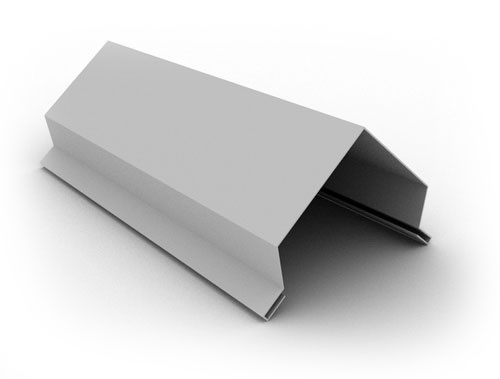

The horse is semicircular or rectangular.It performs both functional (protects joints between profiled sheets) and a decorative role. The ends of the semicircular skate are covered with special plugs.

Wind bar.It does not allow rain to get on the walls of the building and gives the roof a finished look.

Depending on the complexity of the roof design itself, the following additional elements will be needed:

- Upper and lower grades of yends. The lower bar prevents rainwater from entering a subcutaneous space. Upper Endova - serves as the final detail, giving the ended appearance of the roof.

- The corner is external and internal.With the help of them, sheets are combined at external and internal corners.

How to cover the roof with corrugated board

- The crate for laying the corrugated board can be solid or step. The smaller the slope of the roof, the smaller the step of the crate, for example, if the inclination is less than 15, then the wooden or metal strips are mounted at a distance of 300-400 mm, with a roof slope over 15-a step can be 500-600 mm or more.

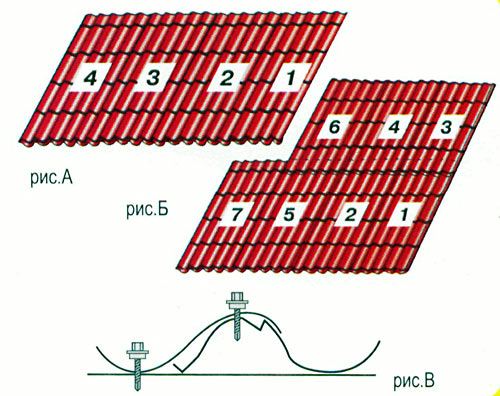

- The profile sheets always begin to mount from the bottom up, while moisture (rain or formed from the melting of snow) will not fall into the space between the sheets. Such wavy material is laid against the direction of the wind prevailing in the area. If the wind is more often blowing on the right side, then the installation of a profiled sheet should be laid from left to right, and vice versa. In what sequence to cover the roof with corrugated board correctly is shown in the photo.

- If the length of the slope allows you to use a whole sheet, then styling begins with the end of the roof. It is necessary to align it according to the cornice, not forgetting about the additional 40 mm (cornice overhang), it is not allowed to align the corrugated board along the edge of the end.

- The first roofing sheet is installed in place and fixed with one screw approximately in the center. The second is laid with an overlap on the previous sheet and is attached in the same way. Having fixed the required number of sheets along the entire length of the roof, they are aligned along the horizontal line of the cornice. Next, it is necessary to connect the corrugated board between the skate in every second deflection of the wave.

Then the final fastener is performed:

- self -tapping screws are screwed through the vertical line through the step of the crate;

- horizontally in each second deflection of the profile sheet;

- it is advisable to strengthen the leaf from the end of the roof in the step of the crate;

- the upper edge of the sheet (at the skate) and the lower (on the cornice) in each deflection of the wave;

- it is recommended to strengthen the joint between the sheets with meters, both on the wave and on the deflection of the sheet.

- Excess material is cut off using electric wizards or electric saws. Similar manipulations are performed from the ends of the building and on the other side of the slope, if we are talking about a gable roof.

- At the next stage, the end bar is installed and the waves are fixed in the crest using the same screws. Its styling begins from below towards the roof skate. When increasing the length of the strips, the overlap should be equal to at least 50 mm, the fastening step up to 1 m.

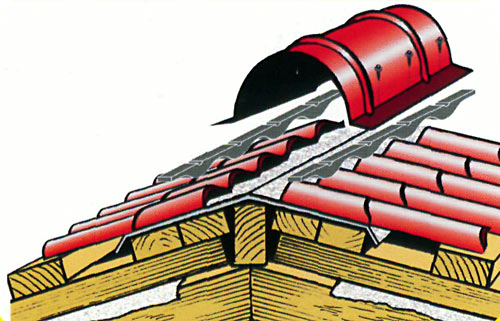

- At the end, fasteners of the skate are performed. Between it and the profiled sheet, it is recommended to lay a self -adhesive seal. Skate strips are increased with an overlap of 100 mm, a fastening step - at least 300 mm.

Installation of complex roof structures

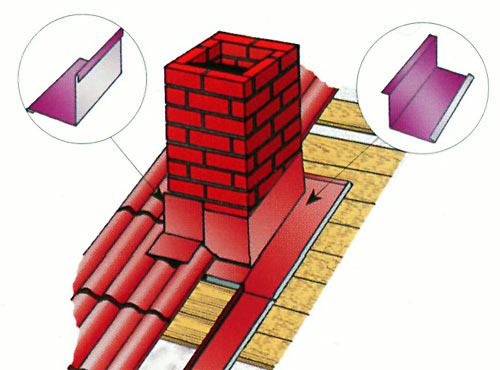

Complex structures often have internal corners (yends), ventilation or furnace pipes, parapets, and so on are located on the roofs. The formed joints must be thoroughly sealing, since moisture in the undercarbon space can fall through such places.

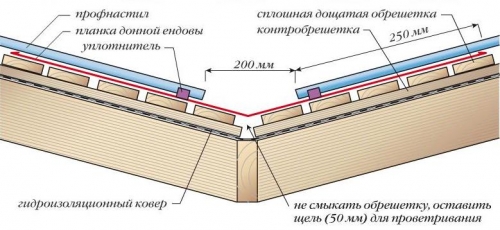

Yends. In these points, a continuous crate is needed on both sides of the fan. The lower (bottom) bar is attached to the edges with self -tapping screws or nails, when it is lengthened, a 200 mm overlap is necessary. From the upper end of the bar, a bend (sewing) is made at the roof skate.

Between the bar and the sheet of corrugated board, it is recommended to install the seal or perform sealing with special mastic. The final fastening of the yends bar occurs simultaneously with the roofing material.

The upper bar is installed on top of the profiled sheet, carrying a decorative role rather, closing the joint between the edges. Its installation is also desirable to perform with the use of sealing materials that protect the mounting joints from possible leaks.

Pipe. The crate around the pipe should be continuous, where the adjoining bar (apron) is attached to the chimney using dowels (a step 200 mm), and to the crate with self -tapping screws.

The installation of the lower apron can be performed and previously lasted the groove on a brick pipe, with mandatory sealing of this joint. On top of it, a roofing with a seal is mounted. The upper bar is installed without stroke, after the installation of the coating around the pipe. In the same way, the installation of both longitudinal and transverse adjustment of the pitched surfaces to the wall is performed.

Many manufacturers are ready to perform additional elements of non -standard shapes, so the difficulties associated with the installation of roofing materials on complex roofs will not arise.

More clearly how to cover the roof with corrugated board, demonstrated in the presented video.

Cover the roof with corrugated board the price of work

Wanting to calculate how much it is worth covering the roof with a corrugated board, it is necessary to take into account the constructive complexity of the roof, the organization of a roof pie and a subcutaneous space. For example:

- the installation of corrugated board will cost about 200 rubles per m;

- performing a walking crate of 120 rubles per m;

- installation of the ridge, wind and cornice of the bar, the adjustment strips 100 rubles per linear meter;

- pipe bypass costs 2000 rubles per element.

The roof of profiled sheets harmoniously fits into modern architecture. And the affordable cost and easy installation makes this material popular among consumers. The roof of profiled sheets has high strength and has aesthetic qualities.

they covered the roof with a profiled sheet

covered the roof with a profiled man.

thanks

thanks