Today, a metal grid is a popular material used for any ...

|

|

Wooden or brick houses rightfully have an army of fans. But with all ... |

The labycle grid is widely used both in construction and in landscape design ... |

Foam plaster

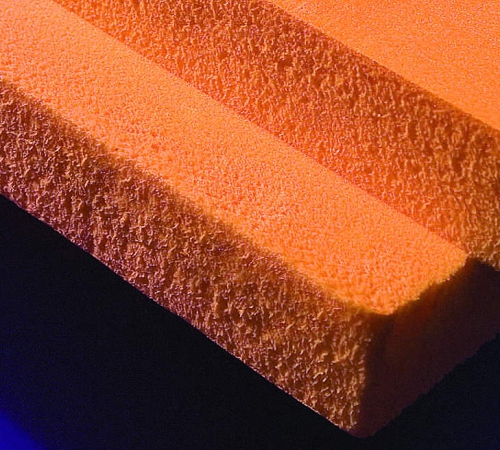

Foamyplex is an excellent insulation that is often mounted on the external walls of the building. However, in order for this material to qualitatively perform its functions, it is necessary to provide its protection against external environmental factors. For these purposes, plaster is most often used. We will consider the features of its application to the foam.

Table of contents:

- Foamyplex: features and advantages of using the material

- Stucked walls by foam: Features of choice of material

- Foam plaster technology

Foamyplex: features and advantages of using the material

Foam and extruded polystyrene foam is quite widely used as a heater. With it, it is possible to ensure thermal insulation of walls both outside and indoors, floor, ceiling, inter -story floors, foundation, roof, etc.

Among the main advantages of the foamyplex, we note:

- low vapor permeability;

- very low thermal conductivity, this characteristic provides a decrease in thermal losses in the room;

- stability before compression, the ability to withstand heavy loads;

- duration of operation;

- convenience and simplicity of installation;

- Available cost, which is fully consistent with its positive characteristics.

However, this insulation has certain shortcomings, namely:

- low vapor permeability;

- high level of fire safety;

- Resistance in front of rodents.

Stucked walls by foam: Features of choice of material

Before starting work, you should decide on the type of plaster composition, which will be used in the process of finishing the foam. There are several varieties of plaster solutions:

1. Mineral -based plaster - for its manufacture, cement and various kinds of polymer additives are used. This variant of plaster is characterized by low moisture absorption, resistance in front of the fungus and mold, ease of applying and working, affordable cost. These characteristics make this option ideal for use as a decoration of thermal insulation materials.

2. Acrylic -based plaster - this material has high elasticity, excellent resistance to atmospheric precipitation, resistance before ultraviolet radiation. The use of this solution is relevant if the place of its application is under constant or periodic exposure to moisture. Cement plaster, in such places can be deformed. The cost of an acrylic basis plastered solution is slightly higher than cement.

3. Silica -based mixtures - this variant of plaster is highly effective, elastic, high antistatic indicators, vapor permeability, and resistance to atmospheric precipitation. This option of plaster is used both indoors and facade finishes.

In addition, when choosing a foam plaster, pay attention to the duration of its operation. Acrylic -based plaster has the best performance characteristics. The second on this basis is silicate type plaster, and less persistent to mechanical influences - plaster on a mineral basis. The operational indicators of the composition also depend on its texture than the textured plaster, the greater its resistance before the external environment.

The construction market has a large number of plaster manufacturers, which is suitable for the foam. At the same time, one manufacturer has several options for plastered solutions. Some of them first glue the slabs, while others protect them from external factors. Universal compositions perform both functions. We offer an overview of popular manufacturers of stucco for foam:

1. The mixture of Cerezite is characterized by a vapor permeable composition, but it has low elasticity, so it needs additional coloring. Acrylic compositions of this manufacturer differ before ultraviolet radiation, but the vapor permeability of this composition is at a low level. The silicone composition has a long service life and tolerates solar radiation well. This manufacturer offers several options for the composition of the foam and all of them are of good quality and a long service life.

2. The compositions of Ecomicus - are used for external and internal work on wall decoration. Among the advantages, we note: moisture resistance, environmental safety. However, finishing work should be carried out exclusively in the warm season, at a temperature of at least 7 degrees of heat. These materials are also used to get rid of cracks, deformations and chips on previously plastered surfaces.

3. Stolny - for the manufacture of this composition, high -quality cement and various kinds of stabilizers and modifiers are used. Therefore, the material is used in a wide temperature range, is characterized by good adhesion, resistance to moisture and frost.

Foam plaster technology

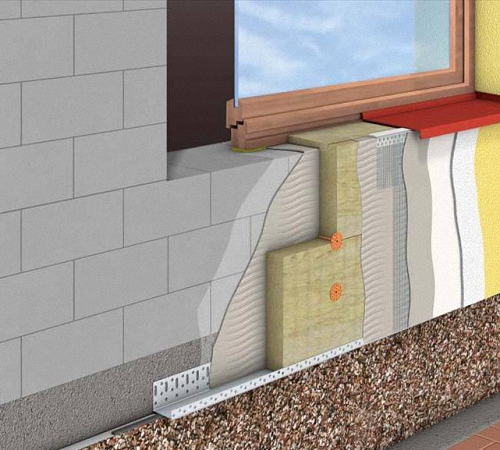

In order to ensure proper protection of the building from moisture, ultraviolet radiation, high temperature, the wall plaster in the foam is performed. This process consists of the following stages:

- performing the preparation of the mixture on a plastering basis;

- installation of a mesh for applying plaster;

- execution of grout on the walls;

- wall covering with a primer;

- Performance of facade plaster according to the foam.

In order to apply a plaster solution to the surface of the insulation, different in composition of the mixture are used. However, all of them are intended to work with materials based on polystyrene foam. Keep in mind that the composition used in the plastering process should be made by one manufacturer. Since some manufacturers create mixtures based on one universal mixture, which only protects the base. Other compounds contain two or more substances, one of which provides proper adhesion of a plaster solution with a foam, and the second creates a protective layer.

Using the universal composition, it is possible to stick a plaster mesh to the surface of the wall. In order to glue the net on one square meter of insulation, it will take about 4 kg of universal composition, if plastering also provides for the alignment of the surface, then this value increases to six kilograms.

In the process of manufacturing a solution for applying to the insulation, without fail, read the instructions from the manufacturer. If the work is carried out with a plaster mesh, then the consistency of the composition should be more liquid than on the instructions of the manufacturer, thus, it is possible to achieve excellent adhesion between the surface and plaster.

The composition with which leveling is performed should be such that it easily flows from the surface of the spatula. After preparing a solution for a foam for plaster, a process of gluing a grid follows, which performs primarily the function of additional reinforcement.

In addition, with the help of this grid, the adhesion between the plaster solution and the insulation improves. When choosing this material, we recommend that you give preference to a grid that is used to work outside buildings. Its density should be from one hundred forty to one hundred and sixty grams per cubic meter. The evenness of the resulting surface depends on the density of the grid. However, too dense the net is unsuitable for pasting angles.

Please note: cement is often included in the composition of plaster solutions, so choosing a mesh for plastering, you should dwell on a material that is resistant to an alkaline environment.

Work should be started by gluing corner areas. In order to stick a grid, the strip should be cut off, the width of which is not more than 35 cm, and the length depends on the length of the angle. Bend the strip through the central part, dividing it into two halves. Apply the composition for fixing the mesh with a spatula to the surface, while observe the optimal thickness of its application. It is about 2-3 mm. Attach the grid to the surface, press it and fix it on it in the correct position.

After gluing the corner areas, the main part of the building should be glued with a grid. To do this, it is most convenient to cut a mesh in size of 1 m. At first, using a spatula, the composition is applied to the wall, the thickness of the layer is about 3 cm. Try to apply the composition not completely on the entire surface, but 90 cm. Step back on each side along 5 cm to compensate for the butt areas. In order to apply the composition, use the average spatula, the width of which is 30-35 cm.

Set the net to the surface and tear it from the central to the upper and lower part. The grid should stick well to the surface and be pressed into it. To completely close the grid, add a little more mixture using a spatula.

After gluing one vertical strip, go to the neighboring area. At the same time, the grid fits in such a way that it turns out to be over at least 6-8 cm. The joints with the corners are also glued in compliance with a certain overlap.

Keep in mind that if at least one section of the wall will have a space on which the grid did not fall, then it will be allocated even after finishing. Therefore, the wall should be completely pasted with a grid.

At the next stage of the work, grid grows. For these purposes, a plastic grater is used, on which there is an sandpaper. The grout is performed only after the composition completely dries. The drying time is indicated in the instructions from the manufacturer. If the weather is warm, then 4-6 hours are enough to dry the solution, and in cold weather, you should wait at least a day.

In order to wipe the composition, make physical efforts. Perform work with circular movements.

Application of plaster on the foam is the following stage of work. The final layer is aligning. In order to level the surface, it is recommended to use the same universal composition as when applying a protective layer. In order to apply a layer to align the wall, perform a number of actions:

- For work, the presence of two spatulas will be required: wide and small, using the first tool, the composition is applied to the wall and leveled on it, and the second spatula helps apply the plaster to the surface of a large spatula;

- Using a large spatula, the composition is applied to the surface with uniform movements;

- A layer of plaster should be about three millimeters thick;

- The solution is carried out fragmented, while trying to ensure that the joints of fragments do not coincide with the joints of the grid installed on the surface earlier.

To wipe the layer, aligning the purpose, as well as the protective layer of plaster.

Please note: the grinding of the leveling layer is performed after 24 hours, after applying a plaster solution. It is forbidden to grout after more than four days. Since the process, firstly, will be very difficult and it will take a lot of time, and secondly, there is a risk of damage to the integrity of the wall.

In order to fix the plaster on the surface of the insulation, a primer is used. Try to choose the composition in which there are quartz grains, if further work is associated with the application of another decorative plaster layer. If, in the future, you will color the facade, then it is enough to use the usual primer intended for external work.

To apply a primer, use a roller that has a short pile. Try to do without fluxes on the surface of the walls. After the primer dries, the process of finishing the walls follows. Its character depends on the individual preferences of the owners of the house. A great option is to apply a decorative outer plaster in the foam. The application technology of which is described below:

1. Apply a plaster solution using a medium or large spatula.

2. Try to apply the plaster evenly, the thickness of its application depends on the size of the grains, which are part of the plaster.

3. In order to form a decorative texture, use a sponge with large pores or a special grater.

4. After plastering the entire surface and after the formation of the texture, leave the plaster until completely dry.

5. Next, the surface is covered with varnish or paint, while the materials that are used for staining should be designed to work outside the room. They will help protect the plaster from moisture, temperature changes and other negative environmental factors.

In order for the coating to serve you as long as possible, choose high -quality materials, for its decoration.