During repair planning in the apartment, we always want to make our nest ...

|

|

Textile wallpaper is an excellent solution for wall decoration, while the joints between the canvases ... |

Despite the rapid development of the construction sphere and the emergence of the latest methods ... |

House from non -removable formwork: construction technology

Wooden or brick houses rightfully have an army of fans. But with all the advantages, they have one very significant minus their construction cannot be called quick. Those who thought about building their own home, but do not have enough time in stock and cannot boast of great knowledge in construction, it remains to choose a monolithic way to build housing. The article will talk about houses from non -removable formwork.

Content:

- House using non -removable formwork technology

- The advantages of the use of non -removable formwork

- What is the non -removable formwork

- Building houses from non -removable formwork with your own hands

- What can you make a fixed formwork for the foundation from yourself?

- The cost of building a house from non -removable formwork

In order to fill the foundation and walls of such a house use formwork. It can be removable (that is, dismantled after the end of work) or non -removable. The second option remains in place after pouring and hardening the solution, and all external finishing work is carried out directly over the formwork.

House using non -removable formwork technology

- Formwork is nothing more than a form. You can recall your children's games in the sandbox or imagine a mistress that fills the cake dough in special baking containers. Only unlike the above examples, the form will remain in place, becoming part of the walls or foundation.

Houses from non -removable formwork photos

- Non -removable formwork is assembled according to the principle of a children's designer from blocks with different compositions. The principle of installation resembles a brickwork. The structural elements have grooves or special locking types.

- If necessary, to fasten the opposite blocks, screeds are used. Be sure to use vertical reinforcement, and in order for the design to withstand the pressure exerted on it from the inside with a solution, the fill is carried out in series. In each of the visits, cement is filled with a height equal to three or four rows of blocks.

- Elements for formwork are made of polystyrene foam or some other materials that contribute to thermal insulation.

The advantages of the use of non -removable formwork

- Monolithic constructions are strong on their own. The left formwork creates an additional frame that enhances the walls of the future house.

- Monolithic walls less crushed on the baseTherefore, when developing projects of houses from non -removable formwork, you can calculate the option with an increase in the number of storeys of the house.

- Sound and thermal insulation of the dwelling. Foamed polystyrene is excellent material for insulation of residential premises, and its characteristics are supplemented by the fact that it extinguishes sounds perfectly. The construction of non -removable formwork is in a kind of simultaneous conduct of insulation and sound insulation.

- Less time less time. It is necessary to save when building your own housing wisely. Renting expensive construction equipment will be deleted from the estimate of a monolithic house. And much voluntary or hired workers are not required. The filling process is fast. This means that it will also not have to be overpaying workers for the extra time at the facility either.

- Saving space. There are never many free space even inside private houses designed by personal projects. The monolithic walls are thinner than the brick, but they protect their owners from the cold no worse, and they save the place inside a large extent.

- Continuing a conversation about saving, I must say that a non -removable formwork will not overpay for heating with further operation of the house.

- Durability. If you adhere to the technology to the smallest detail, then the walls formed by polystyrene blocks and concrete will last at least a century.

- Simplicity of finishing. Blocks create a good even surface of the walls, which allows without effort and unnecessary costs to align the grounds to carry out their finish finish both from the side of the street and inside the house.

What is the non -removable formwork

Foam polystyrene blocks for installation of non -vegetable formwork

- These are hollow elements with walls of various thicknesses. The outer side of the material is much more internal. It is it that will be responsible for maintaining heat in the house. The blocks themselves are strong enough to hold the flooded solution, are non -thresh -pissed and affordable.

- The assembly in the form of brickwork adds the strength of the structure, and the additional rigidity of the wall will give reinforcement. Reinforcement rods located vertically are connected. It is important to choose the right diameter, like a brand of concrete.

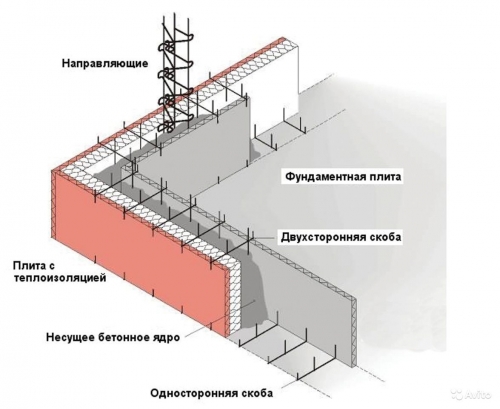

- Communications, including electrical wiring, are laid through the holes pre -carved in the blocks. All work needs to be completed before the start of the fill. At the exit, a kind of sandwich is obtained, where the filling of reinforced concrete is concluded between the insulation layers.

- Opponents of the foam of the polybel focus on the fact that this material is unequological. But this is rather a matter of choosing a manufacturer. The foamed polystyrene made by all standards and rules does not pose a health threat. It is enough to note that the picky European commissions and examinations allowed the use of this synthetic material together with food. Therefore, when making the purchase of the material, it is worth familiarizing yourself with the quality certificates and not chase the dubious monetary benefit.

- But with vapor permeability in the polystyrene, things are really bad. But there will be no problem if you think over the ventilation system well.

Polystyrene concrete This is breathing material

- It is steam -proceeding because it is created on the basis of cement. You will have to lay the blocks on a special glue, tie with reinforcement and then fill it up. In terms of strength, they surpass the formwork of foamed polystyrene.

- Cement -based blocks differ in the same wide variety. So there are masonry blocks for load -bearing walls, produced in several sizes and modifications, you can separately purchase elements for formwork of columns, vertical or bearing beams of ceilings, jumpers or strapping belts.

Mixing-cement blocks

- This is the invention of Dutch developers. They have been known since the 30s of the XX century. For their production, large wood chips are used (it is approximately 80-90% of the total composition of the material). The chips are processed with special additives and fastened with a mixture of gypsum, cement clinker and some other additives (Portland cement).

- Advantages, in addition to environmental friendliness, are obvious:

- high strength against a background of small weight;

- vapor permeability;

- heat and soundproofing properties;

- resistance to atmospheric influences;

- frost resistance.

- Fire safety is achieved due to special processing, and such blocks are also not afraid of decay, mold and pests. They are easy to cut and processed. When constructing the formwork, the plates are placed opposite each other and fastened with wire ties. They not only connect the structural elements, but also do not allow the wall to deviate from the vertical. The dimensions of the material are standard: 2000 500 35 mm.

- They also found another application: often the most intricate cement slabs are used to warm the facades or to build small shield houses in the country, designed for living in the summer.

- You will have to reinforce the structure less. Strenges will require jumpers of window and doorways, columns. And the walls themselves are reinforced with a significant gap of 2.5 or 3 meters (for formwork from polystyrene blocks, the interval is 1 meter). In one approach, the mixture is poured, moving around the perimeter, to a meter height (two rows). Seal flooded concrete by bayonet.

- Since the first version of the material for non -removable formwork is found much more often, as an example it is worth considering the technology of construction from polystyrene blocks.

Building houses from non -removable formwork with your own hands

So, there is a foundation made by the most suitable way for this soil. Most often it is a strip base. In any case, it is first covered with a layer of waterproofing material, and reinforcing rods are driven.

The laying of the first row

- Blocks are neatly strung on the reinforcement, fastened with each other in accordance with the recommendations of the manufacturer (wire screed). Start with corner elements. Between them, it is convenient to pull the cord to run with it when laying out the rest of the blocks in the row. On the ends of the material there are crests and grooves. This type of connection will hold all parts of the formwork in place. The first layer is the basis of the future building. At this stage, the discharge of internal partitions, the openings of input groups occurs. All engineering communications are formed right there. The design feature of the blocks (inner voids) allow you to hide all the necessary wiring inside the walls. We must not forget about ventilation.

The masonry of the second row

- The second row of blocks is laid with a displacement, like bricks. Such a dressing will provide strength and stiffness of the structure. It is important to ensure that the side sides of the laid blocks coincide. Be sure to check with the level so as not to take the wall away from the vertical. Fixation of the blocks of the first and second row is easy. The grooves on the surface of the elements are closed after light pressure.

- The laying of the third row of polystyrene blocks is performed similarly to the installation of the second level.

Pour the solution.

- Concrete is poured around the perimeter of the site with erected formwork. It is important to compact a flooded mixture well. The small depth of filling with the solution allows you to use a piece of reinforcement for these purposes: it acts as a bayonet intensively pierce concrete to get rid of voids, destroying air bubbles. The optimal length is calculated as follows: the height of the block must be multiplied by 3. But the speedy work will contribute to the acquisition (or rental) of the deep vibrator. It will cope much more efficiently with the task of compaction of the solution. For this, the diameter of its working part should not exceed 4 cm.

- Experts advise not to fill the upper layer of blocks to the very end with cement. If you fill out half an extreme row, then the seam will turn out to be hidden inside the polystyrene elements of the formwork. So the wall will turn out more strong. One m will need to be poured from 0.075 to 0.125 m of the solution.

Launching the fourth and subsequent rows

- The laying of blocks in the subsequent rows has the same algorithm that was described. After the sixth row will take its place repeated the operation of pouring concrete. The formwork of ceilings is best done by enlisting the support of specialists. The technology is as follows. In the row of blocks where it is planned to lay the beams of ceilings (or floor lags), the seizure of the desired sizes is made. A cut fragment should not exceed the parts from the formwork element. Now beams are installed in their places, and filling is made.

The final stage

- The finish of the house from non -removable formwork is quite simple. Due to the high adhesion of the blocks to the plaster mix, it will fall evenly and easily. Roofing in monolithic houses is no different from the construction of the roof in buildings built using another technology.

House from non -removable formwork video

What can you make a fixed formwork for the foundation from yourself?

If the home master gets the strength to be precise, neat and consistent in his actions, then he will be able to make a fixed form for the foundation himself. It will be necessary to choose from several options for suitable material:

- moisture -resistant plywood,

- cement-stove,

- flat slate.

All of them are quite strong, resistant to moisture, elastic. The only indicator that these materials do not have heatproof. Therefore, you need to buy something in addition to provide heat (for example, mineral wool). Waterproofing material, reinforcement, components for cement-sand mixture, a set of solid screws and nuts to fix the structural elements between themselves will also be required.

The cost of building a house from non -removable formwork

- The cost of a monolithic house from a non -removable formwork is much lower than a brick or wooden version of housing.

- The price of materials varies depending on the region and the manufacturer, but on average, for m formwork from blocks of polystyrene blocks you will have to pay from 800 to 1000 rubles.

- All manufacturers and sellers calculate the total cost of formwork for free, and on official sites there are calculators for accurate calculations.

I meet a lot of such

I meet a lot of such options

https://www.youtube.com/watch?v\u003dRF5T9Klyp08

https: //www.youtube.com/watch? V \u003d PKZRO3QSR3W & LIST \u003d PLZVHYCT9MVYQ6PEY60JGNV ...