How to score a nail?

This question, it would seem, should know the answer everyone ...

|

How to score a nail? This question, it would seem, should know the answer everyone ... |

When erecting a building from brick or foam blocks, an obligatory technological point ... |

There are several systems that fall under this definition. This is due to the big ... |

Despite the rapid development of the construction sphere and the emergence of the latest methods for decorating buildings and structures, not one of the alternative methods of decoration is still able to compete with traditional plastering of the walls. This is due to the undoubted advantages of the method and its features, as well as the ability to create a protective finishing layer on the surface of the walls processed walls, which helps to align the surface and create a decorative cover. With the help of plaster, you can fill in the foundation for the building, build a wall or make its finishing finishes, as well as eliminate the existing errors for all these measures you need a solution for plaster. However, for each of these directions, various types of plaster solution are needed during finishing work, a lime solution is required for plaster, to masonry the wall, the masonry solution. And these are far from all existing varieties of plastering solutions. Construction stores offer consumers to purchase a finished mixture for the preparation of plaster, surprising consumers with a variety of these products. In order not to doubt the quality of the solution, it can be prepared independently, while saving a significant amount of money. To delve into the essence of the question and get acquainted with various types of plaster solutions and read our article.

Plaster- This is a rough facing material, with the help of which they align the surfaces of a variety of purpose of walls, ceilings, foundations. Depending on the style you selected for the finish of the processed surface, various components can be included in the plaster, however, regardless of the purpose of the plaster, the following components are necessarily included in its composition:

Depending on the purpose of the plaster, it is customary to add the following components in its composition, each of which plays a certain role and gives the solution additional characteristics:

Lime It is added in cases where it is necessary to give the solution additional viscosity. Lime used to prepare a solution can be extinguished or negative, ground or multi -colored. It is a fragile material with a long drying period, as a result of which calcareous solutions are used for finishing work exclusively in dry rooms;

Gypsum Or alabaster also does not have significant strength, but is characterized by a high hardening rate. This material is advisable to use to carry out minor finishing measures and as an additional component to the limestary solution, which will increase the speed of its drying;

Cementit is a high -strength material that is resistant to atmospheric influences retaining its initial characteristics after contact with water. Resistance to mechanical influences is another important advantage of cement. Stucco based on cement-sand mortar is used for the external decoration of the walls of buildings, as well as surfaces located in the zone of high humidity;

Clay Another component used as an additive to a solution for plaster in order to increase its viscosity. Such compositions are an ideal choice for plastering and masonry of furnaces, due to the fact that after firing, a solution in which clay is present becomes as strong as possible;

Sand As part of a solution for plaster, it is used as a filler, due to which the volume of the mixture increases. For solutions intended for various purposes, various types of sand are used, however, river sand is most effective, which is sorted and sifted before adding to the solution.

In accordance with the predominance of certain components, the following types of plaster solutions are distinguished:

Each of these solutions for plaster is characterized by its own proportions, observing which you can create an optimal working mixture.

One of the most popular mixtures for finishing work is the calcareous solution consisting of bastard lime, which is soaked in water, and sand. The ratio of the mass shares of these components looks like 1: 2, less often by 5;

Cement solution for plaster It consists of cement and sand, with the ratio of mass shares as 1: 3 (4). To prepare the solution, the resulting dry mixture is poured with water;

For cooking cement-license solution Cement and sand, taken in a proportion of 1: 3 (4), as well as a lime suspension, which are a slaked lime diluted with water to the consistency of milk;

Laundice-gypsum solution For plaster, it is an ordinary lime solution, consisting of a mixture of sand and bastard lime, as well as gypsum. The ratio of the mixture of lime and sand to the gypsum is 1: 0.3;

Clay solutions For plaster, they are most often prepared with the addition of secondary ingredients, such as cement, sand, gypsum or lime. The choice of one or another component depends on the subsequent use of the solution. The approximate ratios of the components in clay solutions for plaster are as follows:

To prepare the solution, you need to add to a dry mixture of water, the volume of which depends on the necessary viscosity of the solution.

Important! Before you start preparing the solution, it is necessary to make sure of the need to use this particular mixture. For the greatest reliability, it is necessary to evaluate the physicochemical properties of the solution and the place of their use. In case of incorrect choice of component composition, this can cause a decrease in the operational characteristics of the processed surface.

Thus, the choice of ingredients depends on:

Varieties of plaster depending on the proportion of ingredients:

Given the proportions of the fundamental components, the plaster solution can be divided into three types:

To determine the type of solution, you only need a trowel and a little observation. Lower it into the solution and look:

Important! You can reduce the fat content of the solution by adding a filler to it, while increasing the viscosity of a skinny solution can be increased by adding a binder.

What to pay attention to when choosing a solution of a solution for plaster? First of all, it is important to follow the following provisions:

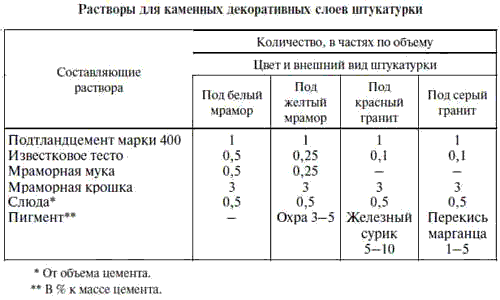

Often, experts recommend paying attention to decorative solutions for plaster, which can be used both for the interior decoration of the walls of the room and for the decoration of the facades. In the process of manufacturing decorative solutions, the following substances are recommended as a binder:

Important!To strengthen the shine of the plastering composition, no more than 10 % of chopped glass and 1 % mica are added to its composition. It is also practiced that the dyes of alkaline -resistant and light -resistant pigments of natural origin, such as chromium oxide, ultramarin, guard, iron and other known substances, are practiced.

First of all, it is necessary to prepare a container for kneading the solution, the volume of which depends on the required amount of the solution. Experts recommend that you prefer such a container, the configuration of which will provide a complete sample of the solution. In the event that the container is characterized by a complex configuration, the solution will freeze in the bottom and in the corners of the container, which will subsequently lead to difficulties in subsequent attempts to knead the solution. Experts recommend choosing containers with a large bottom of the pallet, and therefore, it is not recommended to use a bucket as a container for kneading the solution.

In addition to the container, it is necessary to prepare the following materials and tools:

Before answering the question: how to make a solution for plaster walls?, It is necessary to answer that the preparation of the solution is carried out in several stages, the first of which implies the preparation of a dry working mixture, and the second addition of water to it and the actual kneading the solution. You can prepare a solution for plaster in two ways: manual and mechanized.

It involves mixing a dry binder, during which the following rules must be observed:

Important! If the mixture is not mixed enough, its color will be characterized by heterogeneity and the presence of stripes, while the criterion of high -quality mixing of the composition will be its homogeneity.

To save time and effort, a drill nozzle or the so -called mixer is used to knead the solution. For a mechanized method of preparing a solution for plaster, the consumption of which largely depends on its composition and qualitative characteristics, a bucket or any replacing capacity will also be required. The necessary components are filled into it in the right proportions depending on the selected type of solution and, using a mixer, mix it until a homogeneous consistency.

Most often, the use of cement-license solution is practiced at construction sites. They are intended for the installation of external and internal three -layer plasters. To correctly prepare such a solution, you need to know the requirements for the composition and consistency of each of the three layers, as well as their other specific features.

The first layer of spray plaster.Its application is carried out on a pre -prepared surface so that all pores of the processed surface are filled. The application of this layer is carried out in order to increase the adhesive characteristics of the processed surface, that is, increase the strength of the grip of the base with the layer of plaster;

Important! A solution intended for spraying should be appropriate, creamy consistency. The thickness of the solution on the ceiling does not exceed 4 mm, on the walls of 3-4 mm. The spraying solution can only be prepared with cement without adding lime, however, if you carry out work in rooms with high humidity, you need to prepare precisely the cement-lending solution.

The second layer of plaster is soil. The thickness of this layer should not exceed 15 mm, and its application is carried out only after the first spray layer begins to grasp, but does not finally harden. A solution intended for soil should be an appropriate consistency resembling a cool dough. The middle layer of plaster is aligned with a half -terrible or rail, but, in order to ensure a more comfortable application of the final plaster layer, experts recommend leaving some roughness and irregularity on the ground;

Final finishing layer of covering. To prepare a solution applied at this stage, small sand is used. At the same time, lime is added to it, and in more quantities than at the previous stage. Due to this trick, the solution acquires a more plastic consistency. The covering layer is applied with a thin layer (no more than 3 mm), after which it is thoroughly leveled with a half -terrible or ironer.