Today, in the construction of country houses, someone uses modern materials and ...

|

|

Of great importance in the construction or decoration of the house is the choice of external coating ... |

The house repair is forced, but some finishing materials give ... |

We reinforce the masonry with a basalt grid with our own hands. Pantry basalt grid - tips from installation professionals

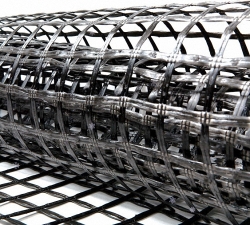

When erecting a building from brick or foam blocks, reinforcement is an obligatory technological moment. A great option in this case will be the masonry basalt mesh. We will talk about the features, advantages and methods of laying this material further.

Table of contents:

- The advantages of basalt grid and the scope of its use

- Features of the use of basalt grid

- Basalt grid reinforcement technology for aerated concrete

- Recommendations for laying a basalt grid on a brick base

- Masonry reinforcement - methods and their description

The advantages of basalt grid and the scope of its use

For the manufacture of a reinforcing mesh, continuous fibers based on basalt are used., In the future, they are saturated with a special substance. The net is characterized by high strength, good performance, the ability to withstand high load.

The scope of use is not limited to masonry of walls made of brick or stone, the material is also widespread during the installation of foam blocks and porcelain blocks. In addition, the grid is used to create adhesive structures based on cement-sand mortar.

From basalt fibers, nets, reinforcing rods, woven and roller materials are produced. The basalt mesh is widely used in the road construction industry to strengthen roadways and asphalt coatings.

Among the advantages of the material we highlight:

- reduction in the appearance of cracks on the surface and strengthening it;

- resistance before moisture, corrosion, temperature fluctuations and stretching;

- Compared to reinforcement, basalt rods do not rust and have a longer service life;

- resistance in front of an aggressive environment and moisture;

- extensive field of use;

- strengthening walls and masonry;

- the possibility of reinforcing stone structures;

- Reducing the level of cracking of concrete products.

The basalt mesh is an excellent alternative to steel reinforcing materials. In places of welding, the nodes of steel nets are corrosion, oxidize and destroy after time, leading to the appearance of cracks and defects on the walls. This occurs due to the exposure to the alkaline pantry on the surface.

In addition, the metal mesh has a large weight compared to basalt. It loads the design of the building and the foundation. The springiness of a steel grid leads to difficulties in the process of its installation on the wall. Sharp rods require special accuracy in work.

The elasticity of the basalt mesh allows you to reinforce multi -level structures that are difficult to configurate, it is difficult to injure about it, and the weight of the material does not complicate its transportation and does not load the overall design of the building.

We offer a comparison of steel reinforcing mesh with basalt:

1. The basalt version is characterized by low thermal conductivity. A steel grid, due to high thermal conductivity, forms cold inside the walls of the bridge.

2. The same diameter of steel and basalt grid, in the second - is distinguished by the best stretching and the ability to withstand a large load.

3. One meter square basalt wool weighs up to 300 grams, the same volume of metal mesh is 2000 grams.

4. The basalt grid is resistant to most aggressive compositions used in the construction of the building, it is not covered with corrosion and is not destroyed under their influence.

5. The cost of basalt grid is an order of magnitude lower than steel. The basalt mesh is more comfortable in work, it easily folds and unfolds. The material is smooth on the wall, easily cut, if necessary, even with ordinary scissors.

6. According to studies, walls with reinforcing the basalt grid are characterized by high supporting abilities, compared with non -reinforced elements.

The scope of use of basalt nets is quite extensive. They are used in low -rise buildings, in the process of building stone, brick or foamed walls. In addition, nets are actively used when plastering, they perfectly reinforce the walls, and prevent cracking.

Features of the use of basalt grid

The basalt mesh is used to connect a two -layer masonry. For example, if the walls are made of foam blocks, but additionally they are faced with brick. The basalt mesh is characterized by high mechanical strength, good chemical anti -corrosion, and low thermal conductivity.

Before laying the grid, calculate the amount of material necessary for work. Next, the grid must be cut in the ratio with the size of the walls on which it is laid. Material cutting is performed with ordinary scissors or scissors for metal. Further actions are determined by the presence or absence of a thermal insulation layer.

For the installation of the grid, at least two people will be required. The joints between certain segments are laid in compliance with the overlap in 3-4 cells. After fixing the grid on the wall, facing brick or cellular blocks is laid on top of it. Keep in mind that the rough displacement of the grid or its deformation is unacceptable. This will lead to a decrease in the supporting abilities of the walls. The basalt mesh is used if the masonry is performed using cement, lime solution or glue.

The grid is laid in such a way as to protrude from the side by 0.5 cm. Installation of the basalt grid is performed through two rows of installations of large -sized stone or foam block. Reinforcement of brickwork implies the fulfillment of such requirements:

- To connect adjacent nets, install a grid with an overlap of 3 mm;

- The thickness of the seam of reinforced masonry is the diameter of the intersection of two rods;

- With the periodic completion of the masonry, equip the penalty, thanks to which reinforcement will continue to continue;

- The corner parts of the house are reinforced using special elements;

- All work is carried out in compliance with safety rules.

Basalt grid reinforcement technology for aerated concrete

Masonry of walls from aerated concrete is performed using special adhesive compositions or cement mortar. The first option is more expensive, but much more effective. The amount of glue, for connecting gas blocks less than cement by 3-4 times, and the cost is two times higher than cement. Therefore, we recommend that you use the adhesive composition when performing masonry.

In addition, glue, compared with cement, has a positive effect on the low thermal conductivity of the basalt grid, additionally improving thermal insulation in the house. If the outer part of the house is made of bricks, then in this case, the reinforcing mesh, connects them to foam blocks. Quite often, a heater or vapor barrier is laid between these layers.

The reference version of the wall consists of such layers:

- reinforcement of foam concrete structures;

- slab or mineral water insulation;

- vapor barrier;

- reinforcement;

- ventilation layer;

- Brick cladding.

Aerated concrete, as a matter of building materials, gives a shrinkage, 2-3 months after installation. The lack of reinforcement leads to the cracking of masonry and the appearance of cracks on the walls, as well as to a decrease in their supporting abilities. Reinforcement with a basalt mesh has a certain functional purpose, namely:

- reduces a decrease in vibration processes on the building;

- protects the waterproofing layer;

- Increases shock strength.

Aerated concrete reinforcement is an individual process, divided into two options;

- full reinforcement;

- Partial reinforcement.

Regardless of which option is relevant for the home. There are compulsory areas that are strengthened by the basalt grid. Among them we note:

- initial masonry on the ground floor;

- lower part of the window openings;

- Rumors and zones of ceiling.

At a distance between the blocks of at least 300 cm, the masonry mesh is installed in two or three places. With a smaller interval, only window openings and areas under them are reinforced. If the masonry is performed, then the net is fixed in the center. Walls that are constantly affecting the wind load or mechanical factors are must be reinforced.

A polymer or basalt -lane for aerated concrete is characterized by the following advantages:

- Long -term operation - more than a hundred years;

- ease of installation - light weight, ease of installation, flexibility and elasticity;

- the ability to withstand a large load;

- lack of cold bridges in the walls reinforced with basalt grid;

- Available cost.

Two options for the basalt mesh for reinforcing are distinguished:

- rolled - used on a smooth surface, the width of the canvas is about 100 cm;

- A narrow grid, it is called a sickle - strengthens the joints between the canvases, fit in the corners, differs in different sizes from 40 to 200 cm.

When choosing a net for reinforcing aerated concrete, purchase a material with a margin of at least 10%. The reinforced canvas makes aerated concrete masonry better, and the lack of increased leads to the formation of cracks.

Recommendations for laying a basalt grid on a brick base

There are three options for reinforcing brickwork:

- perpendicular;

- parrelo;

- longitudinal.

The grid is used for transverse reinforcement. Mesh reinforcement increases the cost of the structure and increases the labor costs of its construction. However, it is transverse reinforcement that increases the bearing abilities of the walls by 50%.

For reinforcing brickwork with your own hands, perform the following actions:

1. Install the grid on the previously laid row of bricks. Connect it with the solution.

2. Lay on the base another layer of solution, so that it completely covers the net.

3. Continue to lay a brick by pressing it into a net and adjusting the position in level. The reinforcing belt has a special clamp, which holds the brick, tightly connecting it to the solution.

Keep in mind that the technology and proper laying of the basalt grid directly depend on the type of brick used. For example, for a silicate -type M150 brick, the mesh is laid every five rows, and for double bricks - after four, for ceramic options - through three.

Masonry reinforcement - methods and their description

The mesh version of reinforcement is used only in the case of using a high brand and solution bricks, which does not provide maximum masonry strength. Mesh reinforcement used in this case is at least 0.1% of the masonry volume.

The installation of the reinforcing mesh is calculated individually and is determined by the load on the building, the material of the walls, the presence of insulation. The minimum value of the diameter of the reinforcing mesh is 0.3 cm. The reinforcement for horizontal seams should be thicker in a diameter of about 0.6 cm.

The transverse version of reinforcement is based on laying the grid between the rows of bricks. The diameter of the rods in this case is from 0.5 to 0.8 cm. The reinforcement interval is from two to five rows.

When choosing a row, consider the height of the bricks, the necessary strength of the walls, their displacement or further deformation. If the grid is replaced by wire, perform reinforcement in two rows at once, laying it perpendicular.

A special solution based on high -quality cement -based cement will help strengthen brickwork. The basalt mesh is laid on the brick so that its edges protrude from the wall to half a centimeter.

The longitudinal reinforcement allows you to strengthen the inter -stratum partitions in the house in front of the bend and lateral loads. In this case, the reinforcement is laid by masonry for additional strengthening. Two options for such reinforcement are distinguished:

- external;

- internal.

To fix the elements, a welding machine, as well as rods and anchor, is used among themselves.

Vertical reinforcement will help strengthen brick buildings. In this case, special elements in the form of corners, transverse jumpers and rods help reinforce brickwork.

The basalt reinforcing mesh is relevant only in case of transverse reinforcement. In addition, this method is most effective when performing brickwork. The quality of the resulting building is also determined by the type of solution, a variant of the selected masonry, the presence or absence of insulation. In any case, reinforcement is a very important component that directly determines the duration of the operation of a brick, stone or aerated concrete building.

Installation of basalt grid video:

My friends advised me here

Friends advised me here https://arh-group.ru/s-fasadnaya-seetka/ Take the grid for filling the floor. What do you think, where to get such products on the Internet or better at the bases?

A very useful article

A very useful article

Road repair in our country

Repair of roads in our country village has not been carried out for a long time. We decided not to wait and repair ourselves, the benefit that there is our own technique. On the website of Nano-SK found a suitable glass-glass mesh product. This company produces a large assortment of building materials for the repair and laying of roads. Available price, quality of execution, and also delivery - added confidence in the work of work. The fiberglass grid provides reliable adhesion to concrete, does not allow moisture to accumulate, which means that the coating will be more wear -resistant, durable.