The construction of the house begins with the foundation, and the overhaul is impossible without ...

|

|

Laminate is a fairly popular finishing material that has excellent ... |

The design of the garden on the roof of the house becomes quite popular as among the inhabitants ... |

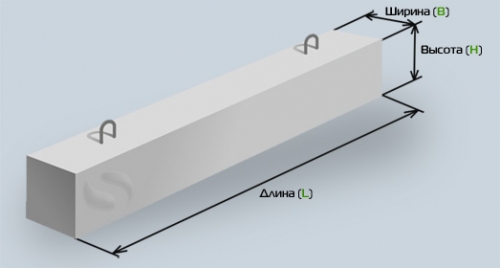

DIY reinforced concrete jumper

In the construction of any house, it becomes necessary to use reinforced concrete jumpers. You can order them or make them yourself. But given the price of reinforced concrete jumpers, it is preferable to choose the second option. Of course, it seems to many that factory products are more convenient or reliable, but making high -quality jumpers with their own hands is quite simple. In addition, you will significantly save your funds, since you will have to pay only for materials. In this article, we will consider the technology of independent manufacture of jumpers.

Content:

- Types of reinforced concrete jumpers

- Methods for the manufacture of reinforced concrete jumpers

- Making formwork for jumper

- Insulation of reinforced concrete jump

- Reinforcing reinforced concrete jumper

- The procedure for strengthening the formwork

- Fill the form with concrete

- Standards for installing jumpers

- Tips for the manufacture of a jumper

Types of reinforced concrete jumpers

Reinforced concrete products are widely used in the construction industry. Due to the strength, durability and diversity, they are in the first places among today's materials for construction. Cattle jumpers occupy a high place among other reinforced concrete products, despite the small size and weight. Without jumpers, you cannot construct a single house from concrete and foam concrete stones, bricks, etc. Reinforced reinforced concrete jumpers are necessary for support and the part that is located above the doorway or window. They are used to block window and doorways in block, stone and brick walls.

Simple technology for the production of reinforced concrete jumpers gives very effective results. This is due to the fact that the concrete composition is poured into the formwork with pre -laid steel reinforcement. Metal reinforcement accepts severity for various bends and stretching, and concrete reinforcement for compression.

Rumors can be arched, steel, brick, armored, etc.

There are several types - bar, prefabricated, window and supporting jumpers. They are made of concrete of a heavy brand and are indicated by the corresponding letters, which indicates the length, calculated load and the size.

Reinforced concrete prefabricated jumpers are the most popular. They are marked by the designation PR and consist of classic bars of reinforced concrete and plates. Such a property as a collection is a huge advantage, since during the masonry you can install a jumper and continue to make masonry. It is not necessary to cut a brick and derive the ranks, due to the modularity of the size of the jumper.

Window jumpers made of concrete are used to block window openings. This species is widely used in brick buildings, but can also be used in buildings made of natural or artificial stone.

Carrying reinforced concrete jumpers are used if it is necessary to close the opening walls. Reinforced reinforced concrete jumpers are needed to take loads from the slabs of the partition. Carrying beams take the load only from the wall located above the opening. Rumors of large sizes are called runs, and by crossbars - horizontally different beams with a shelf, which is necessary as a basis, on which higher structures will rest. Like all other species, they are widely used in the construction of different objects.

There is another type of reinforced concrete jumpers. These are pencils - thin supporting jumpers, which are often used in interior partitions 120 millimeters thick. They are also often involved in the openings for doors. The most popular are jumpers for windows and doors.

Methods for the manufacture of reinforced concrete jumpers

For the manufacture of reinforced concrete jumpers, you will need the following materials - reinforcement, corners, boards, nails, concrete mixer (not necessarily), strapping wire, cement, gravel and sand for the concrete composition. You may need other materials that you can use at will. Before starting work, it is necessary to choose the right type of jumpers.

For small buildings with a light design, you can use ordinary jumpers for additional savings. They should also be used in cases where the sets of floors of all floors focus on reinforced belts, which themselves accept the loads and distribute them evenly.

Let's look at the technologies for the manufacture of reinforced concrete jumper with your own hands. You can fill in the jumper immediately above the opening or manufactured first on the ground, and then mount it in the opening. You can use a more convenient option. If you like the first method more, you will have to tinker with the formwork device, if the second is to raise and mount the already made jumper on your own.

The last option is heavier, you may have to hire a lifting crane. In this case, even two jumpers must be made, the width of which is 150 millimeters. At the same time, the thickness of the zabulak masonry is 300 millimeters - 100 millimeters of insulation and foam block.

Making formwork for jumper

But if you make preference to the first method - pouring a jumper already in the opening, then save your strength, money and time. An additional plus can be called that in this case only one jumper will be needed. Installation of formwork can cause some questions, but we will try to answer them.

The formwork for the reinforced concrete jumper should be reliably attached and kept inside a rather heavy concrete. The shape can be made of wooden boards from which the shields should be created. Their thickness should be 20-25 millimeters. Boards must be fastened with self -tapping screws or nails. It is recommended to use screws and screw them with a screwdriver. After application, you can easily disassemble the formwork, simply twisting self -tapping screws.

To begin with, you should install a horizontal shield in the opening, which will rest on the supports. You can place it in one level with filling masonry or slightly go beyond it. If the shield goes a little beyond the masonry, it must be installed on it from above, and not on the side.

On the horizontal shield in the formwork, it is necessary to put the reinforcing mesh. After that, the vertical shield should be fixed with self -tapping screws. When pouring for the better stability of the shield, it can be tied to a sliding grid using a knitting wire. It must be pulled. This method will not allow the shield to move due to the concrete load, and it will be well attached to the window.

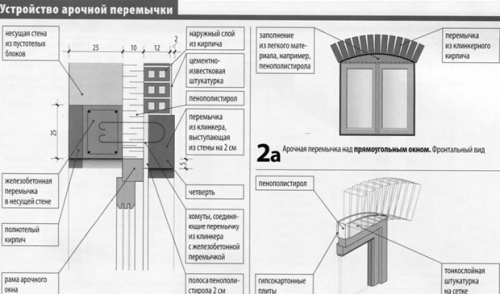

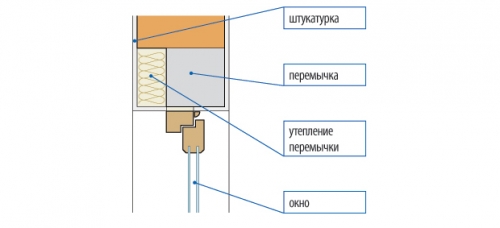

Insulation of reinforced concrete jump

Between the jumper and facial masonry, it is necessary to put the insulation layer. As a heater, you can use mineral wool, which is also suitable for wall insulation. In any case, the thickness of the insulation should be about 100 millimeters. Insulated should be put in the formwork and pour concrete.

If you use mineral wool, the future window will rest against its surface. At the same time, filling out the joint with installation foam will not give a complete guarantee of the stability of the frame. Therefore, the slopes of the window opening must be laid with filling brick so that the window rests on it and after that it is firmly fixed with mounting foam.

It is worth noting that when using the sloping masonry on the slopes, the slopes will have to be insulated again. If you do not want to create unnecessary troubles and do not want to apply a repeated layer, you can use a slightly different way of insulation of the jumper. It is also reliable and even simpler. To do this, you can use extruded polystyrene foam instead of mineral wool.

This insulation is known for a more durable surface. The thickness of its sheets should be about 30 millimeters. When installing the window, the gap between the frame and the insulation material should be filled with foam, which will rest against the hard plane of the insulation and reliably fix the window in the opening. In this case, you may not use an additional layer of insulation.

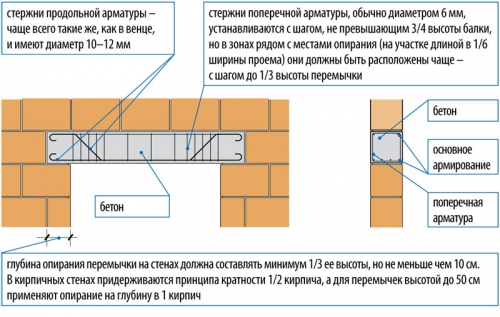

Reinforcing reinforced concrete jumper

The diameter of the reinforcement will depend on the type of product, a slab or a bar reinforced concrete jumper. For our case, you can use ordinary reinforcement, which perceives small loads and is unnecessary. This type can be used due to the use of a reinforced belt and a light roof structure.

For our jumper, you can use the fittings of two threads. Its diameter should be 6-8 millimeters. The prepared reinforcement should be laid along the jumper. The rods of the reinforcement must be stuck with knitting wire. To connect the reinforcement, it is not required to use welding. In the end, you will get a grid that looks like a ladder in appearance.

The procedure for strengthening the formwork

When you install the horizontal shield of formwork, you should use supports. Many builders neglect this rule and do not take into account the rather large weight of concrete, which is approximately 2.5 tons per meter cubic. When the solution is poured into the shape, it can bend the shield or shift it, which will affect the shape of the future jumper, which will no longer be remade.

Therefore, it is better to take care of a reliable form and its stable design in advance. When you fix the support, it is necessary to place it in the center of the opening, closer to the window. In this case, the internal edge will be fixed to the vertical shield, so it will not be able to sag.

Fill the form with concrete

For filling, you can use concrete with a mark of 200. To cook it, you will need cement, crushed stone and sand in proportions of 1: 2: 5. It is recommended to pre -rinse crushed stone and clean it from dried dirt, and sift the sand well. For the preparation of concrete, it is very important to use fresh cement, then the concrete will turn out to be more durable.

First, the mixture must be mixed in a dry state, then add water. It is worth noting that the quality of the resulting concrete depends on the quality of mixing. You can mix the composition manually with a regular stick or use a concrete mixer. When you fill in the solution, the reinforcement should be slightly lifted above the horizontal shield.

This is done so that in the future she completely drowned in concrete and does not peek out. Therefore, put brick fragments (20 millimeters with thickness) under the reinforcing mesh and begin to fill the concrete solution. When the concrete is completely frozen, you can start installing the wall above the form.

If you can choose, it is advisable to make a quarter in the window. This approach is beautiful and practical. This will protect your room from drafts, cold air and hide the cracks with installation foam. The dimensions of the quarter should be 5 centimeters on top of the windows and on the sides. From below - at the site of installation of the windowsill, the size should be 2 centimeters.

Standards for installing jumpers

To strengthen the openings in the external supporting walls, it is necessary to use only fortified jumpers from concrete of the most severe brands. They should be hardened by reinforcement from stressed metal. Each type of jumper, whether it is reinforced or slab reinforced concrete jumper, and the size of the size are designed for certain loads that the element should withstand. It is very important to strictly observe the permissible depth of the support of the jumper.

The size of the wall must necessarily correspond to the width of the window or doorway. For example, for an opening, the width of which begins from 1,500 millimeters, the support depth should be about 125 millimeters. If the width is up to 1800 millimeters, the norm of depth should be about 200 millimeters. If the width is from 1800 millimeters, the norm of depth should be at least 250 millimeters.

Very often the reason for the instability of the reinforced concrete jumper is the choice of the wrong type or violation of the rules of installation. If the defect was not found during the construction process and after its completion the facing masonry began to shift or cracks appeared on the walls, it means that marriage was made during the construction. A jumper made of concrete for a carrier wall could not withstand the load.

Destruction could also occur due to the severity of the jumper of external facing masonry. In the latter case, you can correct the defect. To do this, disassemble the concrete masonry and make another jumper. But the first case is already impossible to fix. The building must be rebuilt, since it is unsafe for living.

Tips for the manufacture of a jumper

When creating reinforced concrete jumpers, you need to strictly follow the technology that we described above. But, in addition, it is necessary to pay attention to some subtleties and nuances of this work process:

- Be sure to adhere to the sizes of reinforced concrete jumpers. The height of the jumper made of concrete should be no more than 1/20 of the length of the opening, and the width is recommended to be made along the width of the wall so that the excess ledges are absent.

- With self -manufacture, the diameter of the reinforcing mesh should be 14 millimeters. Then the reinforced concrete belt will be quite durable.

- The lower part of the formwork and the spacer is recommended to be removed after 25 days so that the concrete can get stronger completely.

- It is advisable to use only purchased jumpers or make them using formwork. This approach is more professional and reliable.

- It is better to fill the jumper when its upper part will stand in one level with the top of the last brick, gas block, etc. This method will allow you to continue masonry without differences.

- When you fill the solution into the formwork, compact it well to avoid the appearance of voids.

- If you cannot decide on the type of jumper for your construction, it is better to consult with a professional.

- Rumors should be selected according to the type of severity that they can perceive. You can fill them already in the opening. This approach will save your finances and time.

- In the manufacture of reinforced concrete jumpers for windows, it is advisable to make windows with a quarter.

- For openings of windows and doors, it is recommended to choose ordinary non -consuming jumpers. To do this, prepare reinforced belts and structural elements of small weight in advance.

As you can see, it is not at all difficult to make reinforced concrete jumpers on your own. In addition, you can choose one of two production options described above. The main thing is to calculate in advance the amount of the necessary materials and prepare them. With careful observance of technologies and construction standards, you will get a strong, reliable and durable jumper. We wish you to make a high -quality jumper of reinforced concrete, which will delight you for a long time!

installation foam is not

installation foam is not a load -bearing and installation material. The window block should be attached to the supporting structures with fixing elements, and not foam !!!

where are the formulas and examples of calculation

where are the formulas and examples of calculating the load -bearing load of the jumper?

You are probably mistaken in the first

You were probably mistaken in the first paragraph of the Soviets. Having written that the height of the jumper is not more than 1/20 from its long. Maybe no less? This is a serious moment.

Really 1/20?

Really 1/20?