With the help of redevelopment of the room, it is possible to solve many problems associated with ...

|

|

Laying tiles in the bathroom or in the kitchen an integral stage of major repairs, with ... |

Food cooked in the fresh air is unusually tasty and useful. Any owner ... |

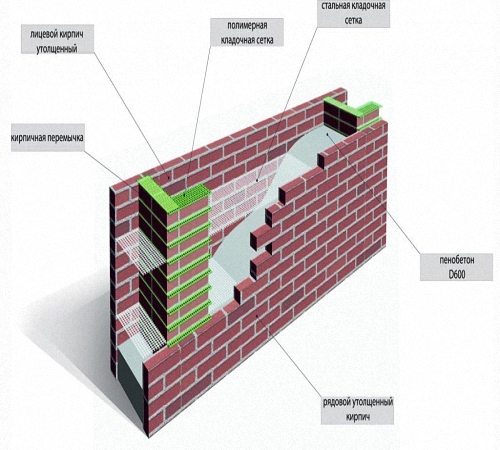

Foam concrete and aerated concrete: comparison characteristic. Differences between foam concrete and aerated concrete

Before building a home, you need to ask yourself the question of what material the house will be built of. Many factors are taken into account: climatic conditions, material capabilities, the purpose of the construction. The strength and comfort of the structure depend on the material. It must be borne in mind that the walls of the house be fireproof, environmentally friendly, protect from noise. Very often the question is what to purchase: foam concrete or aerated concrete. It would seem that there is no particular difference, but let's consider carefully if this is so. Maybe some of these materials is more priority and why.

Table of contents:

- Advantages of aerated concrete

- The advantages of foam concrete

- The composition of the foam concrete

- The composition of aerated concrete

- The difference between foam concrete and aerated concrete

- Disadvantages of foam concrete

- Disadvantages of aerated concrete

- Comparison of foam concrete and aerated concrete

Advantages of aerated concrete

When choosing between aerated concrete, foam concrete, brick or wood, it is necessary to take into account the advantages of each of the materials. Speaking about aerated concrete, it is worth noting that for the construction of a house from this product it is not necessary to have construction skills. Buildings from aerated concrete are easy to build, finish, repair and redevelopment. Because of this, aerated concrete is widely used in modern construction. Aerated concrete of lime, sand and cement is made. This is an artificially created building material, with a porous structure, more than eighty percent filled with air and gas. Thanks to these features, aerated concrete has low thermal conductivity, low weight, ease of use and processing.

Among the main advantages of aerated concrete, the following can be distinguished:

- low cost of aerated concrete is considered one of the most inexpensive materials for the construction of houses;

- excellent thermal insulation abilities, the material perfectly retains heat, which makes it possible to reduce heating costs in winter, and not feel high temperatures in the summer;

- ease of use with aerated concrete is easy to work, even a beginner will be able to make a masonry of aerated concrete, it is quite large, light, which makes it possible to transport, lay, cut and polish the surface;

- vapor permeability of the structure of the blocks provides the revolution of the steam out of the room;

- the use of aerated concrete allows you to build a building into one layer without additional insulation;

- it dries very quickly, it is not recommended to cover with plaster, which will block air access;

- safe for health, non -toxic due to the fact that manufacturing is based on only natural materials;

- helps to build a solid quality house.

Aerated concrete allows you to build:

- partitions;

- external walls;

- internal supporting walls;

- walls for reinforcement.

The main characteristics of aerated concrete:

- high thermal conductivity;

- density;

- strength depending on the density;

- refractory;

- vapor permeability;

- soundproofing;

- big sizes.

Houses made of aerated concrete are durable, do not expose rodent attacks, have high thermal insulation.

The advantages of foam concrete

Foam concrete material that serves for the manufacture of houses. The basic requirements for modern products for building houses are:

- low cost of material;

- long service life;

- high level of thermal insulation.

Foam concrete is ideal for these requirements. The material is relatively inexpensive, the service life of the blocks is more than eighty years, the material is able to withstand even the most severe winters, while it is able to retain heat.

Foam concrete belongs to a group of cellular concrete with high thermal insulation. The block is made by mixing cement mortar, sand, water and aluminum powder. It is the powder that reacts with other components and gives the composition a foamed look. In the middle of the material is a large amount of air, which gives such high thermal insulation abilities to blocks.

Speaking about the advantages of foam concrete, it is worth noting the following advantages of raw materials:

- the ability to pass air, which allows maintaining the level of humidity in the room;

- material of a relatively small weight, which reduces the load on the foundation;

- due to the large size of the block, the construction of the home is carried out in a shorter time;

- when erecting walls, you can use a solution of a solution-blanket, which will cost cheaper;

- it is much easier to apply finishing material to the walls of foam concrete than on the surface of other materials;

- foam block environmentally friendly material, completely safe for the health of living family members;

- it has a refractory ability, when a fire occurs, it does not ignite.

As can be seen from the described advantages of the product, foam concrete is ideal for housing construction and is a competitor to other materials for construction.

The composition of the foam concrete

Foam concrete can be purchased at a construction store or made independently. For this, it is necessary to study the composition of the product. As already mentioned, at the end of the work, it turns out a block, in its composition and appearance resembling a sponge for washing dishes. The number of air compartments depends on the density of the material and varies depending on this. The composition of the foam concrete is regulated by the document, it is it that regulates the quantitative and qualitative filling of the block. The requirements for the material are the following:

- the use of a cement of a special brand, which contains no impurities;

- the use of water of a certain amount and quality;

- sand of the right quality, the content of the quartz part of which should not exceed seventy percent;

- the number of foamers according to the recipe for the manufacture of the product.

Featers may have two options:

- natural;

- synthetic.

Using a natural product allows you to get high -quality blocks and environmentally friendly. The artificial foaming makes it possible to reduce the cost of the material. Sometimes additional components are used, such as ash, fiber -fiber.

There are also ordinary standard foam blocks and reinforced. The latter are necessary with high loads on the walls.

The composition of aerated concrete

Aerated concrete artificial material intended for the construction of dwellings. External and internal walls can be made from it. Due to its porous structure, the material does not have a large load on the foundation. High thermal insulation abilities make this material widely in demand.

The type of classification of aerated concrete depends on its purpose, shape, manufacturing technology and composition:

- the method of processing the material can be autoclave and non -circular;

- by their purpose, the block can be material for thermal insulation, for design, and mixed structurally insulating;

- by the shape of the block are y-shaped straight and grooves.

For the manufacture of blocks, you must use:

- sand;

- cement;

- water;

- gypsum, aluminum;

- water.

As an additional component, it can be a slag or ash. Depending on additional impurities, blocks are divided into such types:

- cement;

- slag;

- lime;

- ash;

- mixed.

Aerated concrete porous and sponge material. For the preparation of an autoclave block, it is specially processed in autoclaves for hardening. Those blocks that were frozen in natural conditions are called non -cereal. Unlike autoclave blocks, these are subject to mechanical influence to a greater extent, therefore it is rational to use non -autoclastic blocks at low loads.

The difference between foam concrete and aerated concrete

At first glance, it may seem that there is no difference between foam concrete and aerated concrete. On the one hand, both the first and second material are a product called cellular concrete. Thanks to the cells and the air contained there, the material becomes more valuable from the physical and technical side. Each of these types of concrete is made by autoclave, artificial, or non -circular, natural, methods. Autoclane requires the use of special equipment for the hardening of raw materials, and non -circulative reaches condition in natural conditions. Between foam concrete and aerated concrete there is a big difference manifested in the following features:

- composition of products;

- characteristics;

- operational abilities.

Disadvantages of foam concrete

Even having so many useful properties, foam concrete has its own disadvantages, which many do not know about. If you decide to build a house from foam concrete, study the strengths and weaknesses of the material. Knowledge of the disadvantages and shortcomings will help to eliminate them in time and navigate that after the construction of the finished project there are no unpleasant and unexpected consequences.

Among the disadvantages of the material, one can highlight the following:

- the composition of the foam concrete is the aluminum powder, which reacts with other components, and although manufacturers argue that this composition is completely safe, it is better to carry out careful work on surface decoration, although this will increase the cost of construction, but will be able to protect those living in the home;

- products for connecting blocks so that blocks are well interconnected and do not destroy the seams, it is recommended to use not a cement mortar, but a special adhesive base, the use of glue helps to enhance the thermal insulation properties of the construction;

- the cost of materials for gluing blocks of glue is much higher than the cost of a cement mortar, this significantly increases construction costs, but also, on the other hand, makes the laying of blocks as high quality as possible;

- the composition of the block since the composition of the blocks includes lime, gradually over time it causes oxidation processes in reinforcing joints of the house, over the years the wall strength is disturbed to avoid this, it is recommended to cover the reinforcement with an anti -corrosion coating, which also significantly affects the cost of construction.

Disadvantages of aerated concrete

Aerated concrete, which has firmly entered the construction industry, is often used to build private dwellings. The construction of the house does not require special knowledge or special equipment. The structure of the blocks allows you to produce various manipulations with them. The material is fireproof and breathing.

But even with such a large number of positive properties of the material, aerated concrete has many disadvantages that should be taken into account when building a house:

- Increased moisture permeability and water absorption is due to the structure of the blocks, the porous inner surface absorbs water and accumulates it, if it does not bother about this at the construction stage, then the gradual accumulation of a large amount of moisture worsen the quality of the material and its properties.

- Insufficient thermal insulation, such a feature of the material appears after the blocks accumulate moisture, but if sufficient waterproofing was carried out, the voids are filled with air and this provides high waterproofing. They also carried the material not on a special glue, but on a cement mortar, its thermal insulation properties will be reduced.

- High gas permeability allows the walls to breathe, but this happens only in the warm season, at negative temperatures and strong winds, the thermal protection of aerated concrete is reduced.

- The insufficient strength of the blocks due to the insufficient strength of the material must be used by a special reinforcing layer, a supporting pillow. This reduces thermal protection, and special additional funds make construction more expensive.

- Low cold resistance moisture, which falls into the pore of the material, leads to a decrease in cold -resistant qualities, this can be prevented with a qualitatively performed waterproofing.

- The appearance of cracks in the blocks is not elastic enough, they are prone to faults, poorly tolerates the shrinkage of the foundation, and can break as a result, in a few years cracks appear. This does not cause the destruction of the house, but leads to a decrease in qualities.

- Poor quality plaster plaster, laid on blocks, is destroyed over time.

The disadvantages of aerated concrete can be smoothed out with proper use and enjoy a cozy and high -quality room. You can find a large number of offers and explanations on how to eliminate the likely problems with products in the future.

Comparison of foam concrete and aerated concrete

There is a difference between foam concrete and aerated concrete, not only in production technology, but also in the technical characteristics of materials. Consider these differences:

- Blocks differ in composition: for the manufacture of aerated concrete, lime, sand, cement and water are used, cement, sand and foaming agent are needed for foam concrete.

- Materials differ in the cost of foam blocks cheaper, do not require special glue to connect surfaces, like gas blocks.

- The quality of the appearance of materials in various aerated concrete blocks is better observed by the proportion than in foam blocks. As a result, laying is facilitated, there is no need to align the rows with the help of a solution.

- Materials differ in strength, aerated concrete several times stronger.

- Due to the fact that the structure of the pores in foam concrete has a closed shape, the surface made of foam concrete breathes worse. On the other hand, it holds heat better.

- Foam concrete is more resistant to water and protect it with waterproofing is much easier than aerated concrete.

It is not easy to make a choice in favor of any one material. Both concrete options have a slight weight and do not overload the foundation. They have excellent heat and sound insulation compared to other building materials. The large surface of the blocks allows you to build housing in a short time. The materials do not burn, are not damaged by rodents, do not rot.

To answer the question that of them is better not easy, and in some cases it is preferable to use foam blocks in other gas blocks in some cases. The climatic zone, weather conditions and many other objective factors should be taken into account.

If you still have questions about how to build a house from aerated concrete or from such a material, watch the video, there you will find answers to all the questions that arise and you can decide which material is better to use in specifically to your case.

absolutely illiterate article

absolutely illiterate article. All confused. what foam and what gas. Better to read other articles

all messed up

all messed up