The piece parquet is really durable and at the same time enough ...

|

|

Many designs, styles and directions in the interior dictate their rules. Moderate ... |

A wooden house is undeniably durable and reliable, but it also has ... |

DIY roofs. Features of the installation of a melted roof

Almost the only roofing material that can be covered with a flat roof is a swimming roof. It is a roll material from polymer bitumen components based on a canvas. The roof of the roof is excellent waterproofing material that is used to cover residential facilities, industrial buildings, warehouses, hangars, shopping centers. Like any roofing material, the melted roll roof has its own characteristics that affect the technology of styling and operation. Installation of the swimming roof must be carried out in compliance with all instructions and recommendations, the strength of the coating depends on this, its moisture resistance and durability. In addition to a flat roof, the melted materials can be used on roofs with a small slope. The type and structure of the necessary material depends on the angle of inclination of the slope. In this article we will talk about the types of modern melted materials, the features of their marking and choice, as well as the intricacies of the installation of the material from beginning to end.

- Paled materials for the roof

- Installation of a melted roof with your own hands

- Features of the installation of the melted roof on the pitched roofs

Paled materials for the roof

More recently, a bituminous mastic of hot application and roofing material was used to water roofs. To melt the briquettes of mastic on the roof, there was a boiler, under which the fire was constantly burning to maintain the temperature. The roofing material laid on mastic does not last long, only 10 years, after which the roof had to be completely blocked. The cardboard base of the roofing ground, saturated with bitumen during the laying, was gaining water over time and rotted on hot days and cracked and destroyed in the cold. Ruberoid is very cheap material and is still used in some types of work, but they are already trying not to cover the roofs. Instead of roofing material, the market offered modern materials.

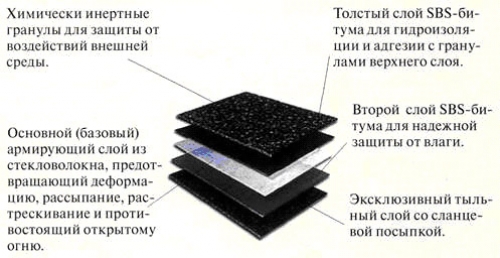

A more complex structure, a strong base, increased plasticity, frost resistance and inappropriateness of decay make modern fused roofing materials durable (up to 30 years) and universal. Also, the melted roll roof has a different no less important advantage on the back of the canvas already there is a layer of mastic, which is necessary for gluing roll material to the base.

The materials of the swimming roof are not the same, they differ in the main, polymer binding, type and fraction of sprinkling. All this affects the place and conditions of their use. To know which material in what conditions is used, let's deal with the characteristics of each of them.

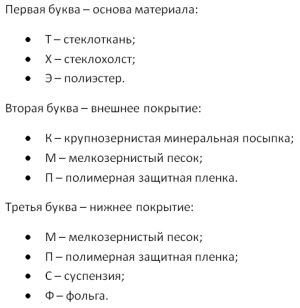

When choosing a material for a melted roof, pay attention to the marking, the characteristics are hidden in it:

Type of the basics of melted materials

The basis in modern melted materials is not subject to decay, mold formation, which distinguishes it from cardboard. But at the same time, each material has different strength indicators, which affects the price of the material and the region where it can be used.

Glasshold (X) the least strong base material. The quality of the roll material is completely dependent on the impregnation with bitumen substance. The glass chloride is low -elastic, so it is necessary to handle the rolls very carefully and neatly during transportation. If the material is deformed, then it is likely that in the process of laying it cracks. Submarine -based materials are not recommended to be used to cover residential buildings, as they are short -lived.

Fiberglass (T) is stronger than the fiberglass and is intertwined glassy.

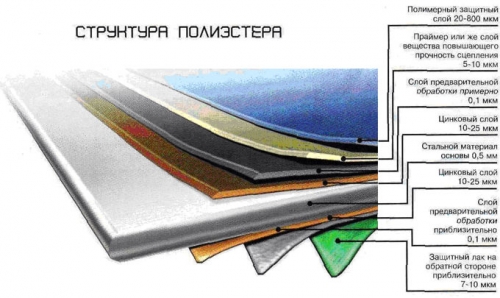

Polyester(E) The most durable, reliable and expensive material for the base. Polymer fibers are located in a chaotic manner, and this provides high strength of the material, increases wear resistance, so the melted materials based on polyester withstand large mechanical loads.

Type of binder

No less important is the type of binder, which is impregnated with the material of the swimming roof. It is a bitumen mixture.

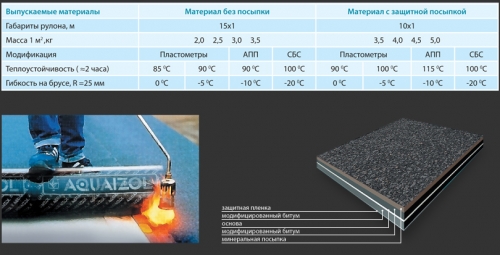

Oxidized bitumen It costs the cheaper, but does not have the best performance characteristics. The materials of the melted roof, which are impregnated with oxidized bitumen, can be used to arrange the lower layer of the roof. If you use it as the upper layer, then the material must be protected from ultraviolet rays with various sprinkles. The material with oxidized bitumen can be used to arrange roofs in regions where there are no temperature changes.

Polymerized bitumen The negative temperatures are withstanding from -15 C to -25 C. The exact range depends on the polymer used. Isacttic polypropylene (IPP) and attic polypropylene (APP) increases the density of the material and tensile strength indicators, the melting temperature also increases. Most often, the appendation of the APP is used, as it is cheaper, and in terms of qualities it is inferior very little. Materials with the addition of APP are called plastic or artificial plastics.

Styrobutadianstyrol(SBS) so improves the quality of the material of the swimming roof that it is recommended to be used in regions with a harsh climate, as well as to cover roofs with a complex relief. Materials saturated with stylbutadianstyrolets gently repeat the surface relief and adjust better. These materials are used in roofing more and more often and received a simpler name of rubberobitums or artificial rubber.

Sprinkling for protective coating of melted materials

To enhance the upper layer of roofing material, special sprinkles are used. They allow you to withstand mechanical damage, precipitation, the scorching sun and withstand the influence of ultraviolet rays.

Sprinking varies not only by the type of material, but also in size:

- Polvoid sprinkling. Protects the canvas from sticking in the roll. Materials with the lower and upper dusty sprinkles are used in the lower layer of the roof pie;

- Fine -grained sprinkle;

- Medium -ry sprinkling;

- Coarse -grained sprinkling;

- Scaly sprinkling.

Mineral sprinkles are sometimes replaced by a foil layer or polymer film.

When choosing a material for a melted roof, it is necessary to take into account the following nuances:

- The angle of the slope of the roof and the complexity of its relief;

- Temperature in summer and winter time;

- The amount of precipitation per year;

- Deformation loads of the building (shrinkage, etc.);

- Roof operation.

The dimensions of roller materials for the melted roof can be different: length 7 20 m, width 400 1050 mm. The material must be laid in several layers, from two to five.

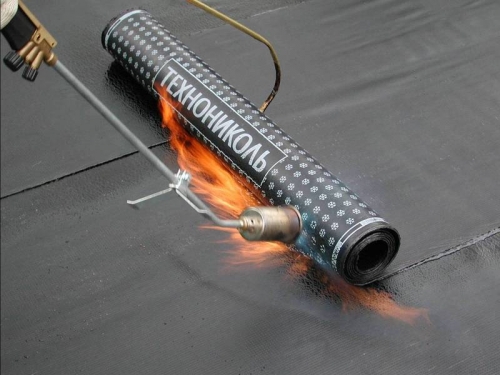

Installation of a melted roof with your own hands

For independent installation of the swimming roof, three people will need at least: one warms up the lower layer of bitumen on rolled material with a gas burner, the second rolls a roll, and the third lends and rolls the material with a roller. The fourth man will not hurt to bring new rolls if the roof area is large. The burner used should work on propane-butan, which you can stock up in cylinders. It is extremely important to observe the technology, otherwise the roof will not last long and the money on the material will be spent in vain.

Installation technology for a melted roof

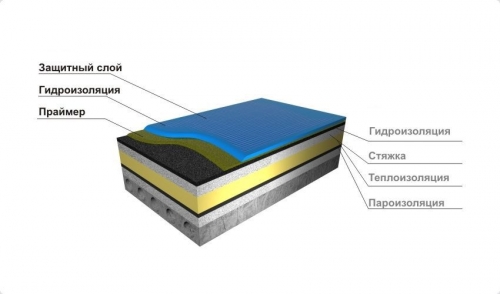

Consider the option of laying a roof on the roof of a residential panel house:

- The base of the floor slab.

- Vapor barrier film.

- Thermal insulation of stone cotton wool in the slab positions of high density, extruded polystyrene foam.

- Cement-sand screed with a layer of 2 cm to 10 cm.

- Coating with a primer or bitumen mastic.

- Laying the material of the swimming roof in 2 3 layers or more, if necessary.

Do not neglect any point. The device of the melted roof involves the use of all elements of the roof pie. For example, the lack of vapor barrier will lead to the wet of thermal insulation material from warm vapors coming from the living room. This will lead to the loss of the material of its thermal insulation properties. But pay attention to this only mineral wool, extruded polystyrene foam is not afraid of moisture. It is also impossible to lay roll material directly on thermal insulation, as this significantly reduces its strength characteristics.

Preparation of the base

If the base is reinforced concrete slabs, then before the start of laying the swimming roof, it is necessary to remove all the garbage from the roof and get rid of large irregularities, potholes, and height changes. All cracks and other defects should be sealed using a repair solution. Further work can be started only after the repair composition is completely dried.

Laying vapor barrier

Film vapor barrier is necessarily laid with an overlap of 10 15 cm. The joints are glued with construction tape. In those places where vapor barrier material adjoins the vertical elements of the roof, it must be brought to vertical elements to such a height that it is above the future layer of thermal insulation material.

Laying thermal insulation

As a thermal insulation material for a flat roof, you can use mineral wool in plate positions and extruded polystyrene foam. Each of these materials has its own advantages and disadvantages. For example, mineral wool does not burn and does not support combustion, but is able to absorb moisture and lose its properties. And extruded polystyrene foam is not afraid of moisture, but it melts under the influence of fire and can completely destroy with a fire. Therefore, choose the material that you like best.

To warm the roof qualitatively, thermal insulation material must be laid in two layersso that the seams between the plates in different layers do not match. So you can completely avoid cold bridges. Extruded polystyrene foam plates are sometimes attached to the base using special dowels, but they can also be glued. Mineral wool slabs can be laid without special fastening, but glued together with hot bitumen.

After laying the heat -insulating material, it is necessary to fill the leveling screed With a layer of 2 to 10 15 cm. Temperature-shrinking seams with a width of 5 mm are necessarily performed in the screed. The whole screed should be different from the heat -mustard seams per squarels with a side of 6 m.

In places of adjacency to vertical elements, sides of 10 cm high must be made. They can be made of concrete solution, filling the angle between the vertical element and the horizontal surface. The angle of the side should be 45 degrees.

Important! After 4 6 hours after pouring the screed, its surface must be covered with a primer. You can cook it from bitumen, for this it is bred with kerosene in half. You can also smear with bitumen irregularities and cracks.

To install the roof, the prices depend on whether it is necessary to perform the screed or not. For example, the device of a soft roof with the arrangement of a reinforced screed costs 15 20 cu. for m2.

Before starting the laying of the material, it must be checked by the moisture content of the surface, it must be dry. The screed and primer should dry completely. You should also install the necessary water intake funnels for the drain.

Installation of the swimming roof instructions for laying the material

Now you can start laying the swimming roof. The first layer can be made of material with an impregnation of oxidized bitumen. To ensure greater tightness of the coating and waterproofing of the base, thermal seams must be covered with waterproofing material 15 cm wide. If you want to order work in a construction organization, you know that the price will depend on the installation of the roofing roof on the number of layers of roller material. Laying material in one layer will cost 6 9 cu for m2.

For those who decided to carry out installation on their own, we provide step -by -step instructions on how to lay a swimming roof:

- The laying of the melted roof from the lowest point begins.

- First, the roll is unwound, the integrity of the material is checked. Then it is necessary to fix one edge of the canvas. To do this, the material moves to the very edge of the site where it will be attached, then the edge is heated by a gas burner and the material is crushed to the base.

- Now the canvas must again be rolled into the roll to the place that is already glued to the base.

- To fix the canvas to the base, it is necessary to heat the lower layer with a gas burner. To do this, the flame of the burner is located so that it warms up the surface of the roof and the lower layer of the material. As a result, a roller of molten bitumen should form in front of the roll of material. As the roll rolls, it serves to adapt the material of the canvas with the base.

- If the work is carried out efficiently, then rollers of bitumen 2 cm wide should act along the edges of the canvas. While one person evenly warms up the canvas, the second should carefully unfold it with a special hook. Walking on the newly laid -saved roof is undesirable on sprinkling traces of shoes. The third person should roll the canvas with a rink, leaving it and finally removing the air bubbles.

- Immediately after gluing one tape/roll, it is necessary to check the quality of gluing seams. To do this, you can walk along the canvas and if somewhere the edge has come off, put it with a spatula and glue it again, warming up with a gas burner.

- The movement of the rink should be directed from the axis/middle of the roll to the edges, at some angle. The edges of the roll are rolled with particular thoroughness.

- The next canvas is glued with an overlap. The lateral longitudinal overlap should be 8 cm, and the end 15 cm.

- The joints of the paintings must be performed in such a way as to eliminate moisture under them. Those. In places where there is even the slightest slope, the overlap should be in the direction that provides the flow of water from the surface, and not getting inside.

- The laying of the rolled swimmer roof on the vertical elements of the parapet is carried out in this way: first, a piece of the canvas is cut off, then its edge is nailed to the upper part of the parapet with nails or screws, then the canvas is glued by heating the bitumen with a gas burner.

- To lay the material in the internal and external angles formed by vertical elements, it is necessary to cut off two pieces of material and glue them with a large overlap at the site of the corner.

- After laying the first layer in the places of receiving funnels, it is necessary to lay the roll material so that a square of 70x70 cm is formed around.

- All subsequent layers are laid in the same direction as the first, cross -laying is prohibited. Rolls must be fastened so that the joints do not match.

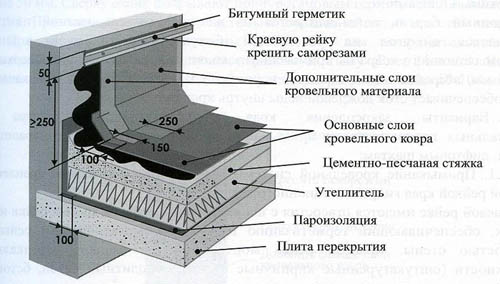

The most difficult in laying the swimming roof is to ensure the adjustment of the material to vertical elements. Consider this in more detail.

Features of the adjustment of the material of the material to vertical elements

Bypassing the vertical elements of a flat roof with a melted material is called an increase. It is necessarily performed in two layers:

- A piece of the canvas of such a width is cut off that it goes to a vertical element of 25 cm and is located horizontally at least 40 cm wide.

- The upper edge of the canvas is attached at a height of 25 cm with nails or self -tapping screws.

- Then the lower layer of the canvas is heated and glued.

- The next layer should go to a vertical element by 35 cm. A piece of the canvas of the corresponding size is cut off.

- Its upper edge is folded into a steering wheel 5 cm wide. The edge is attached immediately above the edge of the already fixed first layer and fixed with a special mounting rail.

- Then glue the rest of the canvas to the base, both vertical and horizontal.

Installation of a roof cost: in one layer 6 9 cu For M2, for two layers 8 16 cu for m2. Repair of a soft roof is not too different in cost from laying new material, so you should not save.

Features of the installation of the melted roof on the pitched roofs

Sometimes laying soft swimming roof is practiced on a pitched roof with a slope of up to 50. The technology of laying material on the pitched roof is somewhat different from laying on a flat roof.

First of all, the swimming roof is laid only on a continuous crate from OSP plates (OSB) or moisture -resistant plywood. The insulation is laid in the gap between the rafters from the inside of the room of the attic or attic, so it does not contact the roofing material. A vapor barrier film is also spread there.

The surface of the OSP plates must be covered with a primer made of bitumen mixed with diesel fuel or gasoline, kerosene. Then the roll material is rolled down and glued, warming up the lower layer. Laying begins from top to bottom, since the length of one roll is enough to cover the entire roof slope. The material is spilled with a manual tool resembling a mop or roller. It is necessary to remove all the air bubbles from under the material.

The melted material is laid with an overlap of 10 15 cm in several layers. Please note that when laying on the pitched roof, layers of the material can be located crosswise.

Installation of gutted blood with your own hands is quite a feasible task. It is worth noting that in particularly complex places, the roof can be waterproof by pouring hot bitumen. This will ensure greater tightness than laying the cut segments of the material even in three layers. Also, instead of rolled materials, you can use modern material with liquid rubber, which is sprayed to the surface of both a horizontal base and vertical elements. Rubber coating makes the whole base hermetic, without a single seam. For spraying liquid rubber, special equipment is used, so if you want to use this option, you will have to order a service in a construction organization.