Among the latest developments of universal decorative coatings for decoration ...

|

|

To date, there are a large number of finishing materials for the ceiling ... |

How great it is to lie down on the warm sand of the beach or walk barefoot on the heated sun ... |

PVC roof membrane - choice, installation

Thanks to the rapid development of the construction market and the introduction of innovative technologies in the production of building materials, a membrane roof, while at the end of the last century for a wide consumer unknown innovation, has currently conquered the championship from the usual materials for the roof and occupied a strong niche in its field. What is the reason for the popularity of the PVC roof membrane? According to experts, this is due to the features of the recipe of the membrane of the waterproofing roofing. It implies the inclusion of the latest generation and specialized additives in the material of the material, due to the unique characteristics of which the PVC roof membrane acquires the properties of plastic roofing material resistant to the destructive effect of ultraviolet radiation and low temperatures, as well as retaining its characteristics throughout the entire operational period.

Content

- PVC roof membrane: Search for new solutions for effective roof protection

- Advantages of using roofing PVC membranes

- The most popular manufacturers and price categories of PVC membranes

- A few words about the specific features of the material

- Roofing membrane device: installation technologies

PVC roof membrane: Search for new solutions for effective roof protection

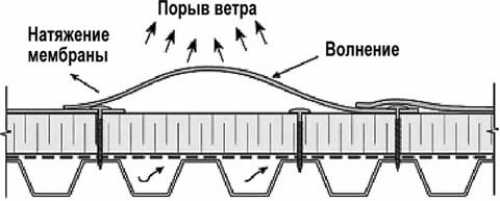

Due to the fact that the exploitation of open roofs of commercial and residential buildings is associated with the continuous influence of the destructive environmental factors, such as wind and snow loads, the destructive effect of ultraviolet radiation and frequent temperature changes, it becomes necessary to search for new ways to protect such a viasal roof .

The impact of anthropogenic factors becomes even more destructive, primarily associated with violation of the rules of installation and subsequent operation of the roof. Often the most destructive is the fall on the roof of heavy objects, cleaning snow and ice using sharp tools or moving along the roof when negative air temperatures are reached without its additional protection.

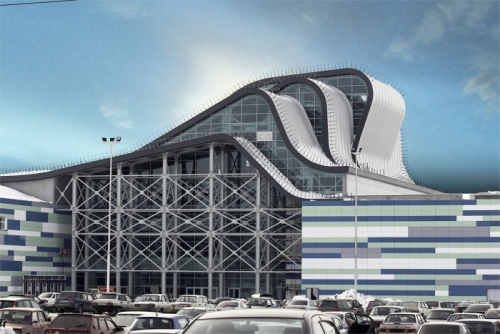

Given the specific features of the polymer membrane, the device of the roof with its use is relevant on buildings, which are characterized by a flat roof with a large area, most characteristic of shopping centers, transport and industrial enterprises, as well as other structures, to the operational characteristics of the roof of which increased requirements are imposed.

Roof membrane photo

Advantages of using roofing PVC membranes

Despite the fact that polyvinyl chloride membranes, the structure of which includes plasticized polyvinyl chloride (PVC), began to be used for waterproofing the roof in the second half of the last century, they gained wide fame over the past few years. Even taking into account this, the absolute number of roofs from PVC membranes in Europe is more than 25% and is growing steadily with each subsequent year. Having absorbed the latest innovative technologies in the field of chemistry, the roof PVC of the membrane is recognized as the most profitable roofing, which proved in practice many years of operation of operation and undeniable advantages, which are as follows: as follows:

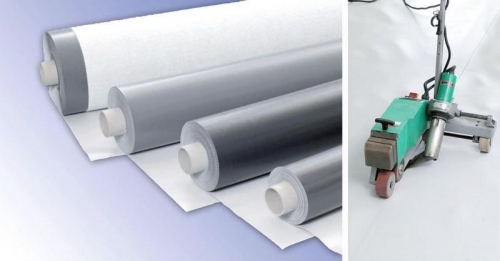

- Technology, due to the fact that the connection of the rolls is carried out using air heated to high temperatures, excluding open fire, which allows the fusion of the upper and lower layers at the molecular level. This determines the absolute water resistance of the material, as well as the reliability of welds;

- Elasticity, which ensures the stability of the roof of PVC to ruptures and mechanical damage, is achieved by entering the material of a certain share of elasto -forming substances;

- Chemical stability, which has become the advantage of material due to a special chemical composition. It is thanks to this quality that the PVC roof membrane is resistant not only to ultraviolet radiation, but by the aggressive effects of almost all acids, alkalis and salts;

- A high level of tightness, ensured by a special structure of polymeric materials. It is thanks to the uniformity of the polymer materials from which the PVC roof membrane is made, it is a flexible and monolithic material with absolute water resistance;

- Fire safety allows you to protect the polymer roof only if the focus of fire, which is not every material. By explaining the point, we consider it important to mention the environmental friendliness, which is due to the lack of distinguishing harmful substances during operation and even burning;

- Preservation of the initial performance in a wide range of temperature conditions;

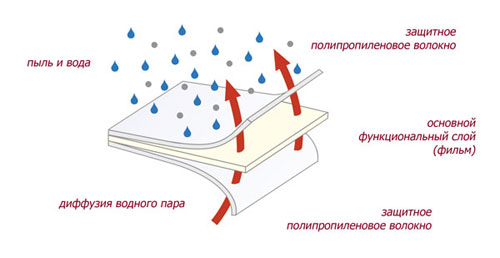

- The vapor permeability, contributing to the evaporation of condensate in the warm season, which has accumulated during the cold. The indicated advantage allows you to prevent bloating and subsequent deterioration of operational characteristics;

- The simplicity of installation measures, which can be discussed due to the lightness of the material that facilitates not only the process of its transportation, but also laying, as well as other necessary manipulations (the weight of the roof membrane, or rather one square meter of the material does not exceed 1.3 kg). In addition, the installation of a membrane polyvinyl chloride roof can be carried out regardless of the material from which the base is made, whether it is wood, concrete or profiled sheet. The only thing that needs to be done in the process of its installation to spread fiberglass or geotextile material in the case of an old bitumen base. It will act as a dividing partition and thereby increase the operational characteristics of the roof;

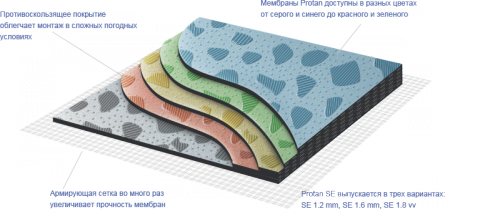

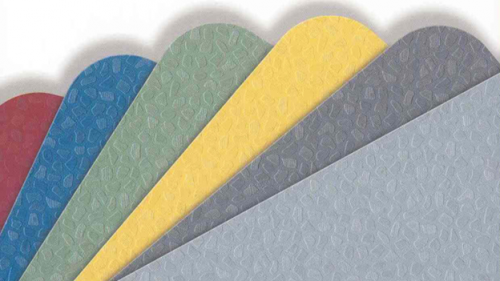

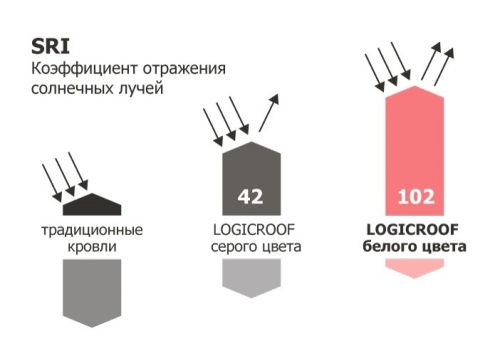

- And finally, architectural expressiveness due to the lack of color restriction of the material.

The widespread use of the roofing PVC of the membrane in the process of installation measures indicates a significant increase in the design of the design and subsequent construction of buildings and structures, as well as the transition to a new level of reliability and safety of buildings. In Russia, the transition to a new stage of construction development associated with the use of a polymer roof membrane was predetermined by its above advantages, which cannot be noticed by both beginners and professionals of their field.

The most popular manufacturers and price categories of PVC membranes

Despite the relatively recent distribution of roofing membranes in the field of domestic construction, consumers of all social categories have the opportunity to buy a roof membrane of all famous manufacturers, both domestic and foreign.

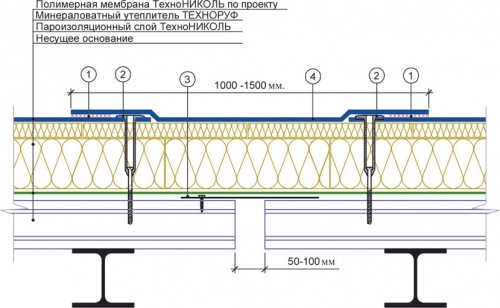

The most popular manufacturer in the domestic market is the company Technonikol, which has established itself as one of the most reliable suppliers of roofing materials. The membrane of the roofing techniconicol, produced under the brands of Logicroof and Ecoplast, is carried out taking into account modern extrusion technologies at the full cycle factory, which became the Russian pioneer in this industry. A clear adherence to specialized innovative technologies allows you to produce one of the highest quality roofing materials in this industry, which has a homogeneous structure and high operational characteristics. Technonikol Corporation produces two production lines of the Logicroof and Ecoplast membranes, the impeccable quality of which is confirmed not only by all kinds of quality certificates, but by multiple reviews of customers who have received a positive Logicroof and Ecoplast to use a positive operational experience.

Since we were talking about the thickness of the roofing PVC of the membrane, a question will be natural regarding the choice of material of the most suitable thickness. As for this characteristic of the membrane, the presented rulers in the assortment offer the consumer roof membranes from 1.2 to 2.0 mm. Experts say that membranes with a thickness of more than 1.8 mm are in a group of excellent and good quality, which can not be said about membranes with a thickness of less than 1.5 mm. Thickened membranes are characterized by increased shock strength, which contributes to longer operation of the roof in conditions of frequent mechanical influences. At the same time, there is no strict dependence between the thickness of the roofing and the final cost of installation measures, which indicates that the thickness is not the main factor that determines the cost of the membrane. In this regard, the total cost of the finished roofing does not observe a significant difference between the coating made using a thickened and standard membrane.

A few words about the specific features of the material

A characteristic feature of the materials of the special class, which belongs to the roofing membrane, is a fundamentally new, previously not practiced approach to roofing. The membrane is easily welded using automatic, semi -automatic and even manual equipment, the quality of which (namely the quality of welds) is a determining factor for ensuring the most effective waterproofing characteristics of the roof. The inconsistency of these parameters can cause a violation of the integrity of the roofing canvas, and also lead to the frequent occurrence of roof leaks.

In order to get the highest quality of the weld, as an indicator that determines the quality of welded measures, first of all, it is necessary to choose the most optimal welding parameters, the main of which is the temperature indicators of the air and the speed regime of welding equipment. Despite the fact that these parameters determine the quality of welding work, they are not constant values \u200b\u200band are very variable in conditions of changing weather conditions, such as wind speed, air humidity, temperature regime and others. That is why, after a sharp change in weather conditions, before proceeding to the beginning of welded events, experts recommend that a small membrane sample trial.

Despite the fact that the device of the roofing membrane is relevant for a wide variety of roof types, including complex configuration, its use will be the most optimal for the installation of flat roofs, as well as a roof characterized by a small slope.

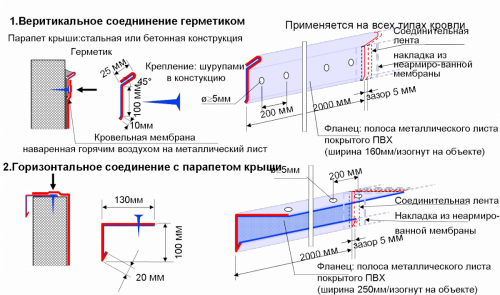

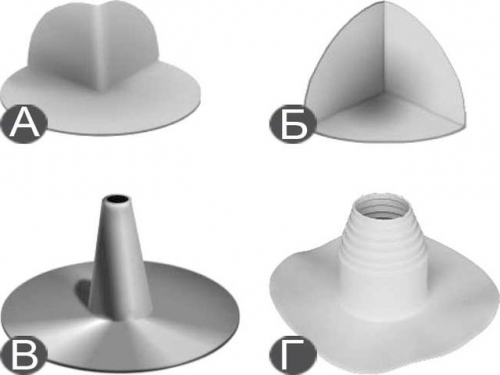

Roofing membrane device: installation technologies

One of the main goals of laying a roof membrane is the device of the waterproofing layer, which determines the absence of the need to arrange additional waterproofing. Another important advantage of using the roofing membrane is the ease of installation measures, which contributes to the frequent installation of a roof membrane with your own hands, which can be carried out without additional preparation of the base.

Moreover, there is no need to remove the previous waterproofing layer. The only necessary event preceding installation measures is drying.

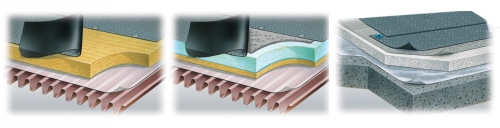

For the convenience of understanding the essence of installation measures, experts offer all existing methods for installing a roof membrane to classify into three main groups:

The ballast method

The use of this technique is especially relevant in conditions of roof installation, the slope of which does not exceed 10 degrees. In the process of the roof device, the laying of roofing material is carried out freely throughout the roof, fixing it only around the perimeter and in those places where the membrane is compared with vertically oriented surfaces of the roof, such as chimneys, ventilation structures and other vertically oriented planes of the roof. As the name can be seen, in order to hold the roofing material on the surface of the roof, it is pressed with ballast, the minimum mass of which is at least 50 kg/m2 of the roof. Most often, the role of ballast materials is performed by paving slabs, gravel, pebbles or concrete blocks.

An important parameter that must be taken into account in the process of arranging a roof by a ballast way is the bearing capacity of the roof, the overload of which is fraught with a violation of its operational characteristics.

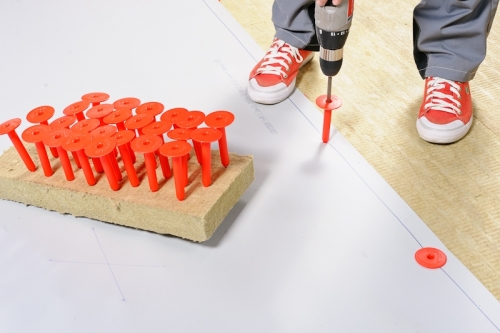

Mechanical method

It is used in cases where the slope of the roof exceeds 11 degrees. The basis for fastening membrane materials can be corrugated board, reinforced concrete, wood, and brick. The mechanical method of fastening can be implemented in the process of applying various methods.

The first involves fastening membrane materials using telescopic fasteners, which are plastic umbrellas characterized by the presence of a wide hat, as well as metal anchors. The mechanical method of fastening is practiced in those places of the roof where the laying of the roofing canvas is present. In this case, the step between the fasteners cannot exceed 20 cm.

When practicing a mechanical method of fastening, it is necessary to provide additional protection of the roof from mechanical damage, for example, laying geotextile materials under the base of the membrane.

The second type of mechanical method of attaching a polyvinyl chloride membrane involves welding using hot air, since this technique provides the highest strength characteristics of welds. Welding of the roofing membrane, namely the longitudinal edges of polyvinyl chloride canvases, is carried out using a specialized welding machine. In the process of this technique, the polymer material melts, which contributes to the formation of a monolithic coating in which there are no stress points, often caused by frequent leaks.

Adhesive method

It is also implemented in the process of using two methods:

- The adhesive method involving the use of molten bitumen materials. It is carried out using specialized materials with a bitumen-polymer base, which are equipped with an adhesive layer, on the outer side of the covered with silicone paper;

- A glue method involving the use of specialized adhesive mixtures.

The use of this methodology for the device of a membrane roof justifies itself in cases where the developer has to deal with a roof characterized by a complex configuration and non -standard geometric features. In this case, the attachment of roofing material is carried out through the use of bilateral adhesive tapes.

The gluing of the membrane is not fully carried out, but fragmented, which is advisable for the formation of conjugation in the case of a roof with a complex configuration. The disadvantage of this method is its limited use when working with PVC roofs: not all membrane materials can be fixed using this technique when arranging roof roofs with complex configuration characteristics. Despite this, this technique has its own advantages: the roof, equipped using this technique, is resistant to strong winds.

Thus, the roofing PVC of the membrane is a material characterized by the ease and lack of creating an additional load on the supporting base of the roof. Since the material has a minimum, almost zero water resistance, its use is relevant when arranging a roof, characterized by intense intentions of ice or accumulation of standing water. Increased resistance to aggressive natural influences allows the use of a roofing membrane where sudden temperature changes in a wide range are a familiar phenomenon.