In order to ensure ventilation in the bathroom, the threshold is built. Threshold in the bathroom or in ...

|

|

The external decoration of a wooden house requires special attention, since it is from the quality of it ... |

Despite the rapid development of the construction sphere and the emergence of the latest methods ... |

Caramoblock. Features of the material, characteristics and application

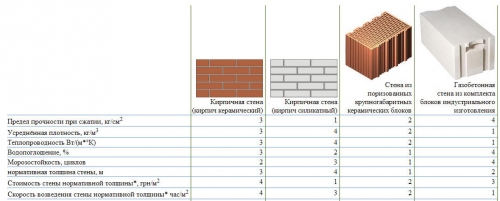

For millennia, such natural elements as fire, water, air and earth have been used by man to create building materials with unsurpassed quality characteristics. And today, bricks and ceramic blocks have excellent operational properties. From the point of view of ecology and financial investments, these materials are still relevant. In the article, we consider the features of such building material as ceramic blocks.

Content:

- Advantages of construction from porcelain blocks

- Porcelain blocks of characteristics

- Production of ceramic blocks

- Masonry of packets. Tips

- What can not be done when laying porcelain blocks

Advantages of construction from porcelain blocks

The ceramoblock is young, which appeared a little more than thirty years ago, has already managed to win the love and trust of many specialists in the field of construction due to its excellent operational qualities, as well as simplicity and most importantly the speed of masonry.

- This material is characterized by high thermal insulation properties and environmental friendliness, in addition, it has all the advantages of ceramic brick, which has been used by people in construction for millennia, since analogues of the same quality and reliability have not yet been invented.

- A brick has always been a choice of No. 1 for those who want to build a house for themselves and their family, which will serve more than one generation for a long time. A true family hearth, offering, reliability, protection, calm and comfort. The structure and its composition do not require special means of care or special maintenance, only minor cosmetic procedures. All these advantages of bricks are also preserved in a house with masonry from porcelain blocks.

- The production process involves strict quality control at all stages. Therefore, each block meets all norms and standards. This means that the material will last for many years.

- During the construction using ceramic blocks, you can be sure that in the future, with the introduction of more stringent energy -efficient requirements for building materials, the building will fully satisfy them without requiring additional investments.

- Where we are talking about comfortable living conditions, natural building materials have no equal. The porous structure of the porcelain block allows maintaining the optimal humidity in the room, providing the necessary balance between the level of humidity from the outside and inside, creating natural vapor barrier. Ceramic blocks can not only quickly absorb excessive moisture indoors, but also quickly take it away, which will allow the surface of the walls to remain dry at any time of the year.

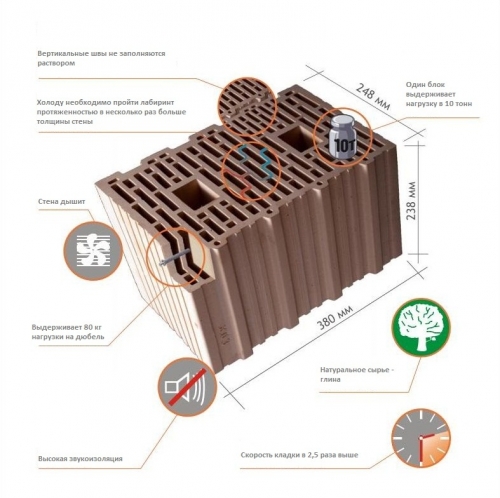

- A special shape of the blocks, the presence of holes and the porous structure allows you to achieve very high values \u200b\u200bfor the thermal insulation qualities of the material. One of the infrequently mentioned, but significant conditions for thermal comfort in the room are the temperature of the surface of the brick facing the house. If it is much lower than room, then a feeling of cold and discomfort is created. However, the heat -insulating properties of porcelain blocks allow you to avoid such an effect, and the temperature of their surface reaches a comfortable room mark.

- Warm surfaces of the porcelain unit, its ability to remove moisture, the complete absence of harmful impurities in the composition allows you to talk with confidence about the creation of a healthy climate in the room.

Porcelain blocks of characteristics

Thermal insulation properties

- The secret of unique thermal insulation qualities of porcelain blocks is the air filling its numerous pores and holes.

- In the manufacture of blocks, small wood sawdust is added to the clay, then the blocks are burned in the furnace at a temperature of about 1000C. Sawdles at this temperature burn out without a trace, leaving only tiny micropores filled with air, which provide thermal insulation. The porosity of the material and the carefully designed pattern of holes reduce the flow of heat and thereby reduce heat loss through the outer walls.

- The paparam block not only absorbs the natural thermal energy of the sun, but also retains the heat of the house emanating from the batteries. The release of absorbed heat does not occur immediately, but after some time. A similar effect is called a phase shift. It allows you to save electricity, since temperature fluctuations are aligned by absorption and release of heat.

- Thus, in the house of ceramic blocks is comfortable and warm in winter, and fresh and cool in the summer. Due to its low relative humidity and rapid drying, the structures from ceramic blocks provide optimal thermal insulation.

Fire safety

- The blocks passed through the fire during production, and they have already developed immunity to fire.

- In the event of a fire, ceramic blocks do not burn and do not produce any harmful fumes. For example, with a wall thickness of 8 cm and above, ceramic blocks receive NG status, which means non -combustible.

- In European countries, a slightly different gradation system regarding the resistance of fire, there this factor is called F90, which means that the material is able to resist the open fire for 90 minutes, that is, the victims have a whole hour and a half in order to get out of a dangerous place .

Noise insulation

- Life in a big city imposes such requirements for building materials as ensuring silence and peace from the outside world or neighbors.

- Premises made of ceramic blocks demonstrate an excellent level of sound insulation.

- For special needs, there are also specially designed soundproofing blocks.

Constructive strength

- Porcelain blocks show good results in such an indicator as compression strength. Depending on the needs, there are several types of blocks. However, they all have excellent stability of the form.

- It is worth noting that some manufacturers developed ceramic blocks that could withstand the earthquake. Thus, even in seismically active regions, it is safe to use porcelain blocks during construction, as they showed reliability ten times the indicator of ordinary bricks. They not only have extremely high mechanical strength, but also demonstrate a high level of adhesion to the solution, which ensures the reliability of the entire building as a whole.

Saving

- No matter how surprising it may sound, the cost of materials used for walls does not significantly affect the final budget of all construction. However, these materials themselves significantly affect comfort in the future room. From the advantages of using ceramic blocks from the point of view of finance, it is important to note:

- reducing the timing of the construction of the walls. The size of the porcelain blocks compared to the brick is larger, respectively, the masonry period is less. Sometimes construction time is reduced by two to three times. At the same time, they are proportional to the size of the brick, so any project of a brick house can be easily changed to ceramic block;

- lower consumption of the material, including the solution;

- reduction of energy costs during operation.

Keramoblock Sizes

- The price of porcelain blocks depends not only on the manufacturer, but also on their size. The most popular blocks with the designation are 14.3NF, 10.7NF, 4.5NF. The number before the abbreviation indicates how many times the paparam block is larger than the standard brick in size (25x12x6.5 cm).

Production of ceramic blocks

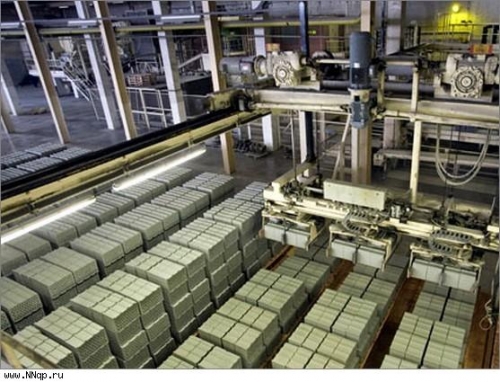

Most of the porcelain blocks that can be bought in Russia today is imported from European countries. And this means not only the excellent quality of the material, but also the observance of all technical standards in the manufacture, as well as the care of the environment.

- Clay mining.First of all, the quality of raw materials is evaluated, this work is performed by experimental geologists. After clay is mined and laid out in layers in warehouses. In this form, it lies for about a year, such a field allows you to achieve the correct consistency of the material.

- Clay processing.At the second stage, clay is delivered to the factory from the warehouse and placed in a distribution machine. Water, sand, wood sawdust are added to it and mixed in a homogeneous mass in a mixer. Then this mass enters the grinding machine, where the machine separates equal small granules. After that, they are sent on the conveyor to the extrusion press.

- Formation.At this stage, the clay mass turns into a block with the help of a press, which under pressure pushes it through a special matrix. The resulting blanks are cut into separate bricks. From one matrix (depending on the machine) you can make up to 10 million blocks. The resulting porcelain blocks are laid on pallets and sent to the dryer.

- Drying.The drying process lasts up to 36 hours for thin blocks and up to 45 hours for thicker ones. The moisture content is reduced from 26% to 2%. Further, the blocks are prepared for the next stage of the firing, they are laid on refractory pallets and sent to the furnace.

- Burning.In the furnace they are from 6 to 36 hours. For heating, as a rule, natural gas or coal is used. The temperature in the furnace is at least 900 C. It is at this stage that the clay mass receives constructive strength, as well as its main feature of the porosity of the material.

- Grinding.More expensive types of bricks, such as those used for facing, are subjected to grinding.

- Package.After the porcelain blocks are removed from the furnace wagons and polished them and prepare them and prepare for shipment.

Masonry of packets. Tips

The basic requirements for laying naps are:

- safety;

- load bearing capacity;

- long service life and maintenance of size;

- fire safety;

- thermal insulation;

- vapor barrier;

- noise insulation.

To ensure all these requirements, it is necessary that all masonry elements participate in this process, that is, not only ceramic blocks, but also plaster and solution.

- The thickness of the solution is about 10-12 mm, usually this is enough to align a small difference in the height of the blocks. If it is larger or less, or generally uneven, then the strength of the masonry may be insufficient. In addition, different seam thickness can cause unwanted tension in certain areas of masonry. The solution is applied with an even layer, so that the block is the entire surface on it.

- For masonry of porcelain blocks, ordinary cement is mainly used, however, unlike blocks (which are often called thermal blocks for their unique heat -insulating properties), the cement mortar has much worst thermal conductivity, its use significantly reduces the thermal insulation properties of the future building. In vertical seams, this disadvantage can be simply eliminated by using blocks with grooves that lay in the groove-gluing system with each other. In horizontal seams, in order to avoid this undesirable effect, manufacturers recommend using a light heat -insulating pantry.

- The ligation of masonry from porcelain blocks is one of the most important static indicators. To ensure the safety of the building, the constructed design, whether it is a wall or pole, should behave as a single element. The dressing is calculated quite easily: the vertical seam between the two neighboring blocks in two rows should be shifted by 0.4xh, where H- the height of the porcelain unit.

- Before laying the first row of blocks, it is necessary to make sure that the foundation of the building is perfectly even, if there is a slope, it is aligned with a solution. Then, after the solution dries, a waterproofing layer is laid. To check the evenness of the masonry, it is necessary to use a straight rail, a plumb line and level.

- The masonry begins with corner blocks. Outside, they are connected by a cord along which the entire row will be laid. Blocks are laid only in a fresh solution close to each other (dressing in a groove and a comb provides proper styling). The rows are aligned with a level and a rubber hammer.

- If there are stupid or sharp corners according to the project in the house, then their dressing is carried out after the cuts of the blocks. You can saw them on desktop circular saws or using manual chain electric saws.

What can not be done when laying porcelain blocks

- Porcelain blocks do not fit the long side along the walls, this is a violation of the technology laid down by the manufacturer.

- They cannot be laid together with other masonry materials.

- It is important to monitor the uniform thickness of the seam between the rows.

- You can not carry out the laying of blocks without dressing.