The foundation is the basis of the building, on the correct manufacture of which depends ...

|

|

For millennia, such natural elements as fire, water, air and earth ... |

Particular importance has recently been attached to an increase in the functionality of buildings with ... |

Glued beam - Features of the material

When building a house, it is important to choose a material that can combine as many positive qualities as possible. One of these materials is a profiled wooden glued beam. The basis of such a bar is boards, tightly glued together. The technology for processing boards to create glued beams appeared not so long ago, so not everyone knows about the various properties of this material. The technology was developed about 30 years ago in Finland, so it is also called Finnish glued beam.

Content:

- Material for production

- Manufacturers

- Production technology

- Why glued?

- Advantages of a house made of glued beams

- Flaws

- Environmental friendliness

- Design

- Thermal insulation

- Life time

- Fire safety

- Price

Material for production

The material for the production of glued beams is the boards of coniferous breeds, most often from pine. Luggage is a little less common, since its processing is more complex, which significantly increases the price of such a beam. It is also possible to combine various wood species, for example, cedar is used as the outer layer, and pine is used for the inner layer. However, these materials have different density, which can negatively affect the design of your home.

Manufacturers

Producers of glued beams are in almost every region and neighboring abroad. The bar brought from Finland is very popular. When buying glued beams, be sure to learn about the quality of products, look at all certificates and read reviews for the manufacturer.

Production technology

The technology consists of several stages of processing, which is well affecting the quality of the final product. At the first stage, the boards are dried in special chambers, after which the content of moisture in the milkboard is only 10 %.

Then there is a check for defects and their elimination. The defect means rot and the presence of knots, the number of which can be regulated by the customer. After that, sorting the boards is done, then they are sent to glue using a special composition. The number of boards used in gluing depends on the desired width. Using the latest technologies when gluing boards, you can get a beam with a length of up to 12 meters. Also, when gluing, a powerful press is used, thanks to which the boards will be interconnected very tightly, it will be impossible to separate them.

Why glued?

Most likely, some may have doubts about the quality and reliability of glued beams. Although it is glued, but in terms of strength and reliability it is in no way inferior to a log log house and even surpasses in some parameters. The glue that is carried out is a mixture that is different from the usual types of glue. Using this composition, under the press between the boards there is a diffusion (growing one surface to another), and the adhesive itself is practically gone between the seams. As a result, the boards will be reliably connected in a single beam, the strength of which will be very high. It is most often made to order, but to save time you can purchase a ready -made glued beam.

Advantages of a house made of glued beams

There are a lot of advantages from a house erected from glued beams, but the most important thing is the preservation of the original shape, that is, the wood does not sit, does not bend and does not curl. This means that having erected a box, you will not need to wait until the house gives a shrinkage, you can immediately insert the windows and doors into the openings, make the repair, so the time of construction of the house is significantly reduced. Also, due to the low moisture content, the formation of cracks is practically excluded, unlike houses from whole logs with high humidity, after which cracks begin to appear. It is important that all the details (beams, rafters, etc.) are made with high accuracy, which makes the structure even stronger and more reliable. The strength of a wall of glued beam is also at a height and it can be compared even with a brick or concrete wall. It has such strength due to the use of modern technologies in manufacture.

Flaws

Glued beam will have a high price compared to other materials. Also, impaired technology or the use of poor glue can contribute to its stratification and loss of various properties.

Environmental friendliness

Environmental friendliness, which has begun to bother everyone recently at the house of glued beams at a height. The glue that glue the layers of the beam is used in the manufacture of, for example, a kitchen board, which means that it is completely harmless to humans. And the tree is able to regulate the level of humidity in the room, which will make it impossible to develop bacteria and fungi. The tree will also filter part of the air, which will make the house suitable for people who are allergic and increased sensitivity.

Design

As for the interior wall decoration, it can not be performed at all. The surface of the walls is smooth and even, therefore, to create a cozy and modern species, it will only be enough to treat them with varnish. There are also a huge number of different design solutions and accessories that will create a unique design of a wooden house. In addition, with the unnecessary decoration, you can save a lot of money and time.

Thermal insulation

Thermal insulation is unusually high, it surpasses not only brick or concrete, but also a log log house. This is achieved due to the lack of cracks through which heat loss occurs. Also in the role of the heat insulator are the layers of glue. The bars themselves are tightly interconnected, which avoids drafts.

Life time

Nobody knows the exact acceptable service life. But it is committed for sure that it can be compared with brick or concrete buildings. The alleged service life is several centuries, but no one else confirmed this figure or denied.

Fire safety

Glued beam has high fire resistance compared to other wooden materials. This is due to the fact that there are no cracks and gaps inside it and outside, and the board itself is designed under the press, so that the fire of such a wall will happen for a very long time, which is confirmed by experiments.

Price

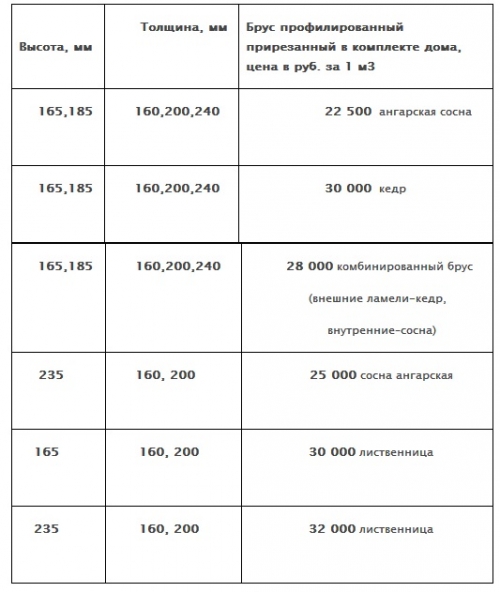

The cost of glued timber in different regions is different, so we take the average prices in the country. And to find out the exact price of this material, contact the manufacturer in your region.

Glued beam is durable,

Glued beam is a durable, environmentally friendly material that does not shrink. A huge plus of glued beam is that houses are built very quickly. Our house http://www.home-projects.ru/proekty_domov/karkasnye/yonkers-kb/ built in just a couple of months, this is much faster than erects a house from other materials.