Almost the only roofing material that can be covered with a flat roof ...

|

|

Vetonit (Vetonit) is a trademark that produces powder building ... |

Previously, tiles made solutions for ceramic tiles on their own ... |

How to make a roof heating with your own hands

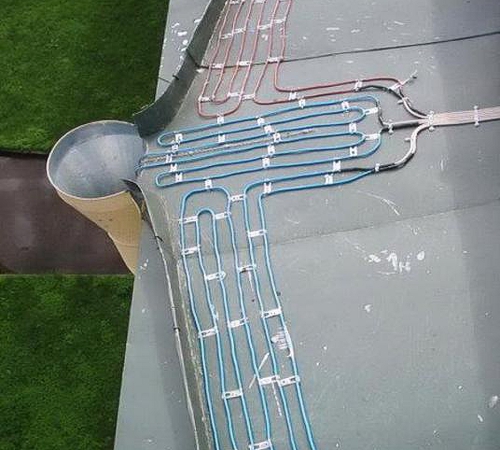

During the colds on the roofs and water drain systems, ice forms, which is dangerous not only for the roof, but also for people, since the ice breaking off from the roof carries a serious threat. To prevent the formation of ice, is equipped with a roof heating system. Its installation is similar to a warm floor system - a heating wire is installed over the entire area of \u200b\u200bthe roof. This process contains many nuances that you need to know.

Table of contents:

- Reasons for the formation of ice on the roof

- Roof heating system overview

- Roof heating, installation, general review of work

- Phased instructions for the installation of roof heating

Reasons for the formation of ice on the roof

1. One of the reasons for the formation of ice. The low quality of thermal insulation of the roof. Under it there are heated rooms that heat the surface and lead to ice crust and icicles. Snow begins to melt from heat loss even at low temperatures, melt water moves along the roof area, and the water freezes again on the planes with a lower temperature. In this situation, it is necessary to eliminate the root cause of warming the roof, if you install thermal insulation correctly, then it will work efficiently and economically.

2. Another reason for the formation of ice seasonal and daily temperature fluctuations. Even if the entire structure of the roof is set correctly, temperature fluctuations in the daytime and at night lead to the formation of ice. This scheme is similar to the above, with the difference that the role of temperatures in different parts of the roof plays the role here, but the temperature difference throughout its area at night and day. In the afternoon, the rays of the sun fall on the house, which heat it and make the snow masses melt, and at night, when the temperature drops, they freeze again and the crust forms. In such a situation, cable heating of the roof will help.

Roof heating system overview

The principle of operation of the heating system is based on the heat transfer from the mounted electric cable. The system is mounted on the roof, in gutters, drain pipes, in all places of accumulation of ice and snow masses. Heating provides a stable surface of the roof surface, so that the snow melts evenly, goes into the wasteland, without forming ice and icicles.

1. The functional purpose of the heating system:

- warns the growths of icicles;

- helps to remove melt water from the surface of the roof;

- warns the blockage of water drain systems, and, consequently, their deformation;

- reduces the mechanical load on the roof;

- completely eliminates the need to remove the stitch and ice from the roof manually;

- extends the life of roofing coatings;

- It does not require a person’s participation in the management of the system, automates the heating of the roof.

2. The components of the elements and circuit heating circuit:

- electric heating wire;

- parts for fasteners;

- Managing shield:

- in -end three -phase

- cHETHETRECHICE CONTARACTRACTRICA;

- intercourse for zaphorn disconnect;

- automates for each phase, single -pole;

- lampa signal;

- automatic device for the trim of the TCPI, which controls the thermosate.

- Details of the distribution:

- a drinking force wire;

- the wire is signal, which is located in the solers of the Termostat and the control of the block;

- montacious

- continuous and cloth couplings for non -governing prospects.

3. How the roof heating system works:

- The heating part is an electric wire that heats the roof and water flow. The wire passes from the front part of the yends, gutters, water plots, livestocks, trays, drain pipes. It is selected in such a way as to meet all fire safety rules, with high strength against mechanical loads and resistance to temperature changes, humidity and direct sunlight. The cable heating system of the roof does not require dismantling for the summer period, it is suitable for all types of roofs;

- The distribution and information part consists of power wires, installation elements and distributing boxes. This part of the system plays a distribution role, it transfers electric power to the heating element and ensures the passage of signals from the sensors of control of the roof heating to the control cabinet and vice versa;

- The control unit is thermal controllers, air heaters, control shield, starting parts and protection, adjustment devices. The control system is selected based on the power of heating elements. If the system is equipped with self -regulating wires, then they are functioning without a control system, the power is regulated based on the precipitation and ambient temperature. But for the correct and effective operation of the system, it is necessary to install temperature controllers.

Roof heating, installation, general review of work

- It is necessary to make sure that all heating sections correspond to the area of \u200b\u200bthe roof heating areas, pieces of the desired size are cut out of them, the couplings are mounted, laid out and fastened;

- Using the strips of the mounting tape, the electric cabbet is fixed in the gutters across the gutter. To achieve maximum strength and durability of the structure, it is necessary to select a thick mounting tape. The step of installing a tape for a resistive wire is 0.25 m, for a self -regulating wire 0.5 m. During fastening the tape on the gutter with rivets, a sealant is used as an additional fastener;

- On the inside of the drain, the wires are attached with a manting lent or the terminal tube. If the height of the drain pipes exceeds 6 m, then the wires are additionally mounted on a metal cable with a shell of insulation, which reduces the load -bearing load;

- In the rejoice of the pipes and the ration, the heating wire is mounted with zaspetka and lecta;

- To KROSTEN, electric wires mount the lecta and Germany;

- Fixed to the MOTASS, proding, determine the indicator of the insulation of the bending parts;

- Install sensors of thermostat, signal and power wires;

- carry out installation of the control cabinet;

- measure the spraying, manage the wires of power and signal;

- monitor the device of protective termination of work;

- Thermostat is adjusted;

- Conduct activities for start -up and commissioning.

Phased instructions for the installation of roof heating

1. Creating a project of a roof heating system:

- The zones that require heating are determined;

- a cable for heating the roof and control elements is selected;

- The place for the installation of the compound elements is determined;

- the number of electric wires and the method of installation are planned;

- The power of the system, phases, protective machines is calculated;

- The method of installation of power wires is determined;

- Automatic equipment of the control shield is selected.

2. Determination of zones for the installation of the system:

- the heating zones are the zones of the mass collection of snow and ice masses on the roof, they are formed due to weather conditions, material and roof design. The best scheme for heating the yends, roofing overhead and drain at the same time. It is mistaken to believe that the price will decrease by heating of the roof if the wires are laid only on the surface of the roof, since such a system is not enough for high -quality functioning. In gutters and drainage pipes, ice congestion often form, which do not allow to pass through the water.

- the total length of the electric wire is equal to the area of \u200b\u200ball parts of the roof, which are selected for the installation of heating elements. In structures with slopes located at an angle, where there is a danger of snow mating, it is necessary to install a system of delayed snow masses. Heating wires are installed in a zigzag between the edge and the snow stopper system. Heating the flat roof of the installation of such a system does not provide and is limited to the installation of heating wires on drainage gutters and pipes.

3. The choice of wires:

- Resistive auspically product from memes and isolation, has a stable indicator of resistance, heating and power. Another advantage of such a wire is low. The principle of its operation is that the vein from the metal is heated under the influence of internal resistance. Most often, such wires are used to heat large areas of the roof and waste structures. The best option is the laying of a zonal resistive electric wire with a nichrome heating thread. These wires have a power that does not depend on the length, that is, the material is cut into areas of any size;

- The self -regulating wire is considered more technological, consists of aMatric, insulation, braids and the shell of the outer. Its design includes a matrix that changes resistance and heating level based on an external temperature. If the air temperature rises, then the number of conductive tracks in the matrix decreases, which reduces the power of the self -regulating wire;

- Mixed type of wire is the best option in quality and price. Most often, the wires are not expensive, resistant type for heating the roof, self -regulating cable is mounted on water drain systems.

4. The components of the control system:

- a thermoregulator with a heating system with a necessary temperature range, most often the run is -8 - +3S;

- The weather station controls the temperature, the presence of precipitation on the roof and the process of their melting. It contains in its design a temperature sensor and a humidity sensor, there are models that have a rain and melting sensor in tandem.

5. Installation of the cable and connecting boxes:

- Connecting boxes are mounted in such a way that free space and access for technical work are left. Most often, boxes are mounted on a roof, not far from the heating sections, installation on parapets, attic, fences, and visors are also allowed;

- To carry out the correct procedure for the installation of heating, it is necessary to start it by calculating the length of the wire and determining the installation site. The length of the yendov, composite parts of the system is measured, the assassin of water drain systems is calculated. In the calculations, the ratio for every 100-150 mm of the rail is required a power of 30-60 watts per meter, a power of 200 watts per m2 is selected for 150 mm thickness;

- The wires are mounted in gutters of water flow and areas around them. Their length is calculated, based on the drawings, the length of the water flow of water is taken into account and about 10% of the reserve is left. The number of threads of the wires is located in the width of the width of the railway, the udal mockery is 400 W/m. The wires are mounted with zaklepka and lent;

- Also, wires are laid on cornices, water flow funnels and pipes. Self -regulating wires are used for waste systems, if the rezistial wire is mounted, then the surgery is installed with threads to exclude contact. The distance between each separator is 25-30 cm, the number of threads is selected based on the diameter of the pipes of water drain, their material and climate;

- The wires are laid on drainage trays, water collections, lends and joints of individual parts of the roof. The number of mounted threads of the wire ranges from 2 to 4, the wire in the valleys is fixed from below and from above with a cable and ribbon;

- The power is calculated according to regulatory indicators, which are 18-22 watts per meter for resistive wires, 15-30 watts per linear meter for self-regulating wires. If the water drain system is made of polymer, then the cable power is taken no higher than 17 W per linear meter, in this case, when using the system, the drain will not deteriorate;

- The supply wire is traps based on the requirements of the PUE, which depend on the conditions of the motorcycle;

- To protect against an electric shock, a defense unit of RCDs I UT \u003d 30 mA is installed;

- For the equipment of the roof heating system, the heatoscope is insulated without holes, for this, an aluminum tape is used, which is attached along the entire length and tightly pressed to the roof;

- If the roof is not equipped with a water flow system, then the dripping line is mounted on the design with a small slope, with a large slope the dripping loop.