I immediately want to draw your attention to the fact that installation of multi -level ...

|

|

Floors made of marble crumbs are most often found in the halls of public buildings. But in ... |

They start choosing a plinth when the flooring is ready, because these products ... |

Vetonite: Features of the material

Vetonit (Vetonit) is a trademark that produces powder building mixtures used for a wide range of finishing and construction work. Among products that are most popular, one can name the finish putty for walls and ceiling, floor aligning screeds, as well as tile glue. The mass distribution of the products received due to their excellent qualities and an affordable price. The production of dry mixtures in Russia is engaged in the company Weber-Vetonit, which is the industry unit of the Saint-Gobain International Industrial and Construction Group. The article will talk about the main features of dry mixtures of Vetonite.

Content:

- Briefly about the manufacturer

- Vetonite characteristics

- Assortment of goods and approximate packaging prices

Briefly about the manufacturer

- Saint-Goben is one of the largest corporation in the world for the production of construction products. It was founded in France in the middle of the XVII century, and today has 1.5 thousand companies in more than 60 countries around the world. The head company is located in Paris. Construction mixtures are only one of the four areas of activity in which the corporation invariably occupies a leading position.

- In 1992, Weber, specializing in building materials, joined the Saint-Goben industrial group. Weber has been led by Weber since the beginning of the 20th century, when J. Weber and Zh-b. Bruthens began to make facade plaster. Today, Saint-Gobain Weber has more than 200 branches in 42 countries, and after the acquisition of the Maxit industrial group (Maksitgroup), its factories also appeared in the Russian Federation.

- All manufactured products meet the highest European requirements, which is confirmed by international quality certificates. Vetonite is universal and highly specialized materials for decorating almost any surfaces.

Consumers who stop their choice on the vetonite are guaranteed to get an excellent result, but due to what can this be achieved?

Vetonite characteristics

Putty verton

- Speak mixtures are used to final alignment of surfaces, the quality of their application directly affects the overall impression and appearance of the finished renovated room. Vetonit putty creates a perfectly even surface, and their main purpose is to close the cracks, layers and cracks after gross main construction work.

- Like all types of putty, Vetonite mixtures are divided into three subspecies: cement, polymer and gypsum. These are mainly finished putty designed for facing the ceiling and walls. The basis for their application, there may be many materials of concrete, drywall, brick, gypsum and others, even a putty has been developed, which is applied to painted surfaces.

- The mixtures are universal and are used both indoors and outside the building. Although putty and create a perfectly smooth and smooth surface, they still do not have special decorative qualities, therefore it is allowed to apply almost any decorating materials wallpaper, embossed plasters, tiles, acrylic or water-based paints, and so on on top of the layer. The putty itself is not adhesive compositions.

The main competitive advantages

- These are environmentally friendly products that are created only from safe components for humans and nature.

- Due to excellent water resistance, the mixtures have universality and the ability to use even in rooms as pools (a waterproof mixture should be labeled on the package).

- Powdered mixtures have such a small fraction that the applied layer acquires an ideal almost mirror smoothness.

- The applied layers of putty are not afraid of adverse weather phenomena, including such as frosts, rain or hail, which means that they can reliably serve even during facade decoration for many years. In addition, products have been developed that can be applied even at a negative temperature (labeling snowflake on the package).

- The putty layer enhances the thermal insulation and noise -absorbing properties of the walls and ceiling.

- Output form.All the putty products of the company Weber are produced in paper three-layer bags, the middle layer of which is made of polyethylene (dry powder) of 5, 20 and 25 kg or in plastic containers (pasto-shaped) for 10-12 liters.

- Binding.Cement, polymer glue, limestone, gypsum can act as a binder.

- The main purpose.There are several varieties of putty, distinguished by their main purpose:

- for alignment of the plastered surface or concrete base before the subsequent finish (staining, gluing wallpaper, cladding with ceramic tiles);

- for sealing the seams formed between the sheets of drywall;

- application of a putty layer on a previously painted surface.

- The color of the finished composition.The main shades of the applied layer are white, gray or yellow, which corresponds to the color of the acquired dry mixture.

- The size of the granules.Small-fractional powder mixture, the size of which is 0.3-0.5 mm, a fraction of a pasty substance not more than 0.06 mm.

- Temperature.The surface during processing and ambient temperature should be in the range from +5 to +25 degrees (for frost -resistant species from -10 degrees).

- Vetonite products consumption.On a surface of 1 m2 when applying a layer of 1 mm, 1.2-1.4 kg of dry matter is required, consumption when filling the joints 100-200 g/m2.

- The volume of water for closing the mixture.To prepare putty, add 290-350 ml of water per 1 kg of powder substance.

- Viability.The prepared cement mixture should be used within 2 hours, after which it loses its qualities, it is not recommended to breed, if the composition includes polymeric binders, then the viability of the finished solution can be 12-24 hours, and subject to storage in a closed container and up to 2 -x days.

- The time of complete drying.The applied layer freezes for 3 hours, for complete drying, you should wait at least a day, the larger the thickness of the layer and the number of layers, the more time it takes to dry.

- The thickness of the applied layer.It is recommended to apply 1-3 mm at a time (depending on the brand of goods in one pass, a layer of up to 5 mm can be applied).

- Frost resistance. At least 75 freezing cycles / defrosting for powder products and 10 cycles for finished solutions.

- Strength coefficient. After one month, the layer is able to withstand the mechanical load up to 10 MPa.

- Adhesion coefficient.The adhesion strength with a surface is approximately 0.9-1 MPa.

- Shelf life. The goods can maintain their quality for 12-18 months, while maintaining the integrity of the factory packaging, as well as under the proper storage conditions, a dry room, where air humidity is not more than 60%.

- You can apply putty mixtures to the processed surface both manually and mechanized method using automatic installations.

- The base is properly prepared by dust and dirt, it must be durable, dry, solid and not contain substances that reduce adhesion (oil or fat spots). Windows and doors must be closed in the room in which the finish takes place to exclude the possibility of the formation of drafts.

- To prepare the solution, it should be in a large container, preferably from plastic, pour the required amount of water, the temperature of which is approximately equal to 20-25 degrees (not more than 40 OS). Then, dry powder is filled into the container (it is not recommended to change the sequence) and is thoroughly stirred using a construction mixer or a drill with a special nozzle for 5 minutes. After that, the prepared mixture is maintained for at least 10 minutes, for better dissolution of the astringent, stir again and you can proceed to use.

- When applying a few layers of putty, vertonite, it is necessary to dry each previous one. A dried surface, before the subsequent finish, it is recommended to sanded with fine sandpaper and cleaned of dust.

Vetonite plaster

Several types of dry plaster mixtures from Weber-Vetonite, which are produced both directly at factories in Russia and other countries, for example, in Finland, are delivered to the Russian construction market.

- Vetonite plasters are, as a rule, cement mixtures, as a filler in which sand and limestone can be used, and additional components, such as micro -fiber. The most popular product is weber. Vetonit TT - universal plaster for most bases.

- Decorative plaster capable of creating a unique relief is widely used. They can be applied on a surface pre-treated with any type of plaster (cement, gypsum, lime-cement), as well as gypsum-plane and gypsum-fiber bases.

The main competitive advantages

- Products can be used on most well -known materials of concrete, aerated concrete, ceramic or silicate brick, foam concrete and so on, preparing the base for the subsequent finish using tiles, glass or plastic plates, as well as for putting their putty.

- Vetonite plaster is distinguished by special frost resistance and water resistance, due to which it is allowed for facade work, as well as for plastering of bathrooms, warehouses and other rooms with high humidity or low temperature.

- Unnecessary hardening and excellent adhesion with the surface.

- Output form.The manufacturer supplies its product in paper bags, with a packing of 5, 20 and 25 kg. Decorative plasters can be produced in the form of a finished solution, in a plastic container of 15 kg.

- Binding.The binder is cement.

- The main purpose.Depending on the type of product, it can be used in the following cases:

- the creation of a decorative layer, for subsequent staining with water -dispersive colors both inside and outside of residential and public buildings;

- preliminary leveling of ceilings or walls in rooms with any humidity;

- local application when leveling surfaces for subsequent construction and repair work.

- The color of the finished layer and the mixture.The shade, the resulting layer is gray for simple plasters and light gray for products designed for subsequent staining.

- The size of the granules.The powder substance has a maximum fraction size of not more than 1 mm. Decorative plasters, depending on the texture, have from the fraction from 1.5 to 4 mm.

- Temperature.The solution can be applied at a temperature of +5 to +30 degrees, if the packaging has a marking in the form of an asterisk or there is a Winter inscription, then the plaster is used in the cold season, at a temperature of -10 degrees.

- Vetonite products consumption.For applying a layer of 1 mm to an area of \u200b\u200b1 m2, it is consumed from 1.2 kg to 2.4 kg of dry matter.

- The volume of water for closing the mixture.Water consumption per 1 kg of dry matter from 160 ml to 300 ml (the exact amount is always indicated on the packaging and it is necessary to follow the recommendations in order to obtain the finished layer as strong and high -quality as possible).

- Viability.Cement solutions very quickly lose their vitality, as a rule, it ranges from 2-3 hours.

- The time of complete drying.Each layer applied should withstand up to 2 days and only after this period of time, you can proceed to subsequent repair work. Within a week after completion of the finish, the plaster gains 50 % of the strength.

- The thickness of the applied layer.Vetonite plaster can be applied in one pass with a layer of 2 to 10 mm, maximum thickness 3 cm.

- Frost resistance. Dry powder is able to withstand 75-100 cycles of complete freezing / defrosting.

- Strength coefficient. After 28-31 days, the plaster applied can withstand the load equal to 6-8 MPa.

- Adhesion coefficient.On a concrete base, the adhesion strength will be in the range of 0.5 MPa.

- Shelf life. It is necessary to store goods in factory packaging, without damage to its integrity. In a dry room, the product can maintain their properties and qualities for 1 year.

- The surface for applying the solution must be properly prepared. To do this, it is cleaned of dust and dirt, if necessary, the base is strengthened with a reinforcing net. If there are oil or fat spots, they should be removed, as they will reduce adhesion. All those who have great bumps are embedded. Before applying the diluted mixture to the concrete base, it must be treated with a primer so that concrete does not absorb moisture from the solution.

- Knead the solution in clean water, room temperature (20-25 degrees). Be sure to observe a sequence at which dry powder is added to the liquid, and not vice versa. To improve adhesion, 10 % of the water can be replaced with a dispersion primer. Stir the solution using a construction mixer or drill, until all lumps dissolve. In the process of application, the finished mixture is stirred without additional adding water or other liquid.

- When decorating facades, it is important to protect the applied layer from rain, snow and direct sunlight for 24 hours. The resulting decorative surfaces can be painted after 72 hours, to reduce the flow rate, the embossed layer is recommended to be treated with silicone or silicate primer.

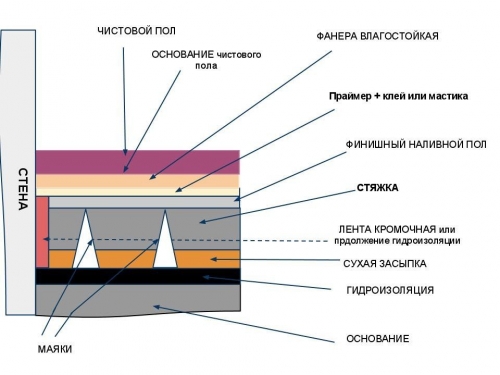

Pouring floors/floor sprayer

Burning floors are self -leveling mixtures used for floor screed. Weber. Vetonite products allows you to create a perfectly flat surface, with a layer thickness of 1 mm to 25 cm per passage. The solution can be used to arrange floors in residential and office premises, both in new buildings and in structures with a long service life.

The main competitive advantages

- The resulting surface has an almost mirror appearance and does not require additional grinding or alignment.

- It can be used as a base for any floor coverings, even under the subsequent finish with very thin materials.

- Due to the high strength of compression, the finished coating can withstand heavy loads, in addition, internal reinforcement allows the mixture even on deforming surfaces.

- The mixture has a fastest set of strength, which allows you to walk along a poured layer in an hour, and lay the flooring after 2 hours.

- It can be used even on complex bases, for example, on top of the old wooden floor, ceramic tiles and other materials, thanks to the addition of special polymer components to the composition.

- It forms a soundproof, heat -resistant and moisture -resistant layer.

- Output form.It is produced in the form of dry powder, packaged in three -layer paper bags of 5 and 25 kg, for reliable protection from environmental exposure, the middle layer of packaging is made of polyethylene.

- Binding.As a binder, special cements are used.

- The main purpose.The mixtures are intended:

- for leveling concrete and cement-sand bases;

- to create screeds for the subsequent installation of flooring;

- to create the main floor layer on balconies and terraces;

- a warm floor for the system device.

- The color of the finished composition.The shade of the mixture is determined by the presence in the composition of cement, which gives the finished layer a gray tint.

- The size of the granules.The maximum size of the powder substance is from 0.6 mm to 3 mm.

- Temperature.The solution is poured in rooms with an air temperature from +10 to +25 degrees, it is considered optimal to maintain a temperature within +15- +20 degrees.

- Vetonite products consumption.When applying a layer of 1 mm on an area of \u200b\u200b1 m2, 1.4-1.8 kg of dry matter is consumed.

- The volume of water for closing the mixture.To prepare a working solution per 1 kg of dry matter, 200-300 ml of fluid is added.

- Viability.The prepared mixture requires immediate use, since after 15 minutes it begins to harden.

- The time of complete drying. After 1 hour, it is allowed to walk along a flooded layer, after 2-3 hours you can lay the flooring.

- The thickness of the applied layer.It is allowed to make a layer, the thickness of which varies from 1 mm to 25 cm.

- Shrinkage. A month after use, a layer of layer up to 0.5 mm/m is possible.

- Strength coefficient. After 28 days, the bulk floor is able to withstand the load of up to 30 MPa.

- Adhesion coefficient.Clutch with concrete base 1 MPa.

- Shelf life. Bags with a mixture are stored in an unpucked form in a dry room for 6-12 months from the date of production.

- The mixture is used in covered rooms. When pouring the floor, it is necessary to tightly close the windows and doors and maintain a constant temperature within +10- +25 degrees for at least 7 days.

- The base under the bulk floor must be cleaned of dust, and also make sure that it is dry and durable (if it is concrete, then it should survive for at least 2-3 months). If the upper layer of the processed surface has exfoliating materials, then they should be removed. The place of possible leakage of the mixture is closed without fail.

- It is best to primer the surface with a special composition, for example, with the variber vertonite MD 16. If it is supposed to apply more than 1 layer, then each of them should be processed accordingly. Dispersions and primers prevent the formation of air bubbles and provide better adhesion to the base.

- To prepare a working solution, clean water is poured into a plastic or silicone container, and then dry components are poured out and everything is thoroughly stirred with a construction mixer.

- It is best to use the mixture immediately. It can be applied both manually and mechanically. It is optimal to fill with strips, the width of which varies within 30-50 cm. It should be started from the corner, the flooded solution is distributed by a steel spatula and rolled with a needle roller (to release the existing air).

- It is not allowed to take breaks during pouring, if too large area is processed, then it should be divided into small areas, installing the limiters.

Assortment of goods and approximate packaging prices

The industrial group Weber. Vetonite produces, in addition to plaster and spacecraft and bulk floors, many more dry building mixtures that have proven themselves in the domestic market. Such materials include adhesive compounds used for the installation of heat -insulating plates (mineral wool, polystyrene foam) and for laying porcelain tiles, tiles, stone plates, including at minus temperature. Almost any surfaces of concrete, drywall, brick, wood and so on can be used as a base. The table contains average prices for dry Vetonite mixtures.

| Type of goods | Mark / purpose | Price / packaging |

|---|---|---|

| Putty |

Finish-vr+

It is used in dry rooms for walls and ceilings, the production of Finland. |

670-680 rub. / 25 kg. |

|

LR paste

Ready putty mortar in the form of a paste. |

690-700 rub. / 12 l. | |

|

LR Fine

The super -finished mixture, which contains a polymer binder, is designed for decoration of ceilings and walls in dry rooms. |

650-670 rub. / 25 kg. | |

|

Finish-qr

For decoration of ceilings and walls in dry rooms, Finland production. |

610-620 rub. / 25 kg. | |

|

Finish vh(gray) For finishing surfaces in wet rooms, Russia's production. |

590-600 rub. / 25 kg. | |

|

Finish vh(white) For finishing surfaces in wet rooms, Finland production. |

920-940 rub. / 25 kg. | |

|

S.iloite gyproc JS

For sealing the joints formed during laying plasterboard sheets, as well as for decoration of walls and ceilings in dry rooms, Finland production. |

780-850 rub./ 20 kg. | |

|

Rend Facade (white) The putty on the basis of cement, the main purpose of the facade decoration, is also used to apply the finish leveling layer. |

540-570 rub. / 20 kg. | |

|

Rend Facade (gray) The putty on the basis of cement, the main purpose of the facade decoration, is also used to apply the finish leveling layer. |

400-450 rub. / 20 kg. | |

| Plaster |

TT

The plaster mixture on a cement basis, has increased moisture resistance and frost resistance, is used to pre -align the walls inside and outside of public and residential buildings. |

350-370 rub. / 25 kg. |

|

TTT

The plaster mixture on a cement basis, lightweight, is used for preliminary alignment of surfaces, has moisture and frost resistance. |

360-380 rub. / 20 kg. | |

|

414

The plastering mixture on a lime-cement basis, with the addition of micro-fiber, is intended for external and internal work. |

630-650 rub. / 25 kg. | |

|

stuk cEMENT (gray )

Cement -based plaster can be used as a facade mixture, the thickness of the applied layer up to 5 cm. |

390-450 rub. / 25 kg. | |

|

min 1.5 z

Decorative plaster, which creates the texture of the fur coat, the filler fraction of 1.5 mm, is allowed to be subsequent staining with water -dispersion paints. |

1600-1700 rub. / 25 kg. | |

|

min 2.0 Z

Decorative plaster, which creates the texture of the fur coat, the filler fraction of 2 mm, is allowed to be subsequent staining with water -dispersion paints. |

1600-1700 rub. / 25 kg. | |

|

min 2.0 r

Decorative plaster, creating the texture of the bark beetle, the filler fraction of 2 mm, is allowed to be subsequent staining with water -dispersion paints. |

1600-1700 rub. / 25 kg. | |

|

min 1.5winter

Textured plaster (fur coat) with a grain of 1.5 mm, can be used at a temperature of -10 degrees. |

1600-1700 rub. / 25 kg. | |

| Screeds / aligning mixtures |

3000

The self -leveling mixture for the floor, the production of Finland. |

700-725 rub. / 25 kg. |

|

4100

A fast -hardening moisture for the floor, with a layer thickness of 2 mm to 3 cm, production of Finland. |

542-620 rub. / 25 kg. | |

|

4150

Bulk floor. |

540-630 rub. / 25 kg. | |

|

4310 Renoveysh

A self -leveling mixture can be used on complex grounds. |

885-920 rub. / 25 kg. | |

|

4350

Bulk floor. |

880-920 rub. / 25 kg. | |

|

4400

A rapidly setting floor mixture used on concrete and cement-sand bases. |

990-1000 rubles. / 25 kg. | |

|

4601

Bulk floor (industrial). |

1230-1250 rub. / 25 kg. | |

|

4630

Bulk floor. |

1230-1250 rub. / 25 kg. | |

|

4650

Bulk floor. |

1350-1370 rub. / 25 kg. | |

|

4655

Bulk floor. |

1350-1370 rub. / 25 kg. | |

|

5000

A fast -hardening bulk floor, the solution is intended for manual application. |

570-580 rub. / 25 kg. | |

|

5700

The basic leveling mixture, the production of Russia. |

280-300 rub. / 25 kg. | |

|

6000

The bulk floor, applied layer from 1-25 cm, hardening time 3 hours. |

375-385 rub. / 25 kg. | |

| Adhesive mixtures |

E.asy fix

For tiles and porcelain tiles for internal and external works |

230-300 rub. / 25 kg. |

|

Granit fix

For porcelain tile and drywall. |

280-300 rub. / 25 kg. | |

|

Ultra fix

Elastic composition for external work. |

570-585 rub. / 25 kg. | |

|

Ultra fix winter

A cement mixture for tiles, drywall and blocks used in facade work in the winter. |

420-450 rub. / 25 kg. | |

|

Profi Plus

For gluing porcelain tiles. |

345-440 rub. / 25 kg. | |

|

Optima

Glue for tiles in dry and wet rooms. |

195-250 rub. / 25 kg. | |

|

mramor

White adhesive composition used for light tiles. |

990-1000 rubles. / 25 kg. | |

|

therm S.100

Universal adhesive mixture. |

440-450 rub. / 25 kg | |

|

therm S.100 winter

Composition for gluing mineral wool and polystyrene foam at low temperatures |

490-500 rub. / 25 kg. | |

|

therm EPS

Glue mixture for the installation of polystyrene foam. |

330-350 rub. / 25 kg. | |

|

Kf

Elastic adhesive composition for floor tiles. |

680-700 rub. / 25 kg. | |

|

RF

For gluing tiles and drywall sheets for complex bases. |

700-750 rub. / 25 kg. | |

|

MW

For gluing plates of mineral wool. |

450-470 rub. / 25 kg. | |

| Pantry mixtures |

Ml 5

Color mixture for laying silicate and ceramic bricks. |

15150-16000 rub. / 1 t. |

|

PSL Concrete

A fast -hardening mixture for sealing vertical seams in concrete structures. |

14000-14500 rub. / 1 t. | |

|

Jay Sl N169

It is used for sealing brick joints. |

400-420 rub. / 25 kg. | |

|

Jay Bi 600/3

A non -shaped mixture. |

1000-1100 rub. / 25 kg. | |

|

Jay Bi 1000/3

A non -shaped mixture. |

1200-1250 rub. / 25 kg. | |

|

C06

Cement mixture, production of Russia. |

220-250 rub. / 25 kg. | |

|

Block

Pantry mixture for bricks and blocks |

240-250 rub. / 25 kg. | |

|

Block Winter

The masonry mixture for blocks and bricks can be used at low temperatures. |

290-300 rub. / 25 kg. | |

| Furnace mixtures |

Ml Savi

Clay -based furnace solution. |

400-420 rub. / 25 kg. |

|

Ml Tuli

Fireproof pantry. |

1200-1300 rub. / 25 kg. | |

| Grout for seams |

Deco

Grout for seams between stone, glass and ceramic tiles, with fine -fractional grain and a wide range of shades. |

150-200 rub. / 2 kg. |

|

Prof

Grout for seams, with a quick set of strength, 8 color shades. |

350-400 rub. / 5 kg. |

In addition to dry building mixtures at Weber plants, acrylic, silicate and bitumen paints, primers and dispersions are made to prejudice the bases and subsequent application of bulk floors, putty or plaster, as well as all kinds of impregnations, antiseptics, substitutions (bituminous pastes, suspensions, improving properties screeds, mastic for isolation, and so on).

By going to the store, it is very easy to get confused among a huge selection of goods and products, but vetonite products can be found at once. These are yellow paper bags (less often white), on the left side of which there is a strip with the name of the goods - 2/3 of the black color (the name of the manufacturer is indicated), and on 1/3 of red, orange, green and other shades (the brand of the product is indicated) . By purchasing powdered building mixtures or finished veton solutions, you can always be sure that the repair made will be of high quality and durable.

can vitonitis be lining

can vitonitis be lined with the setting surfaces of the walls?