And you knew that the installation of a stone, slate or fence made of metal profile between ...

|

|

In the process of choosing what to build a house - a log, is quite popular ... |

The use of a warm floor system for heating the premises has already stopped ... |

How to make a gable roof

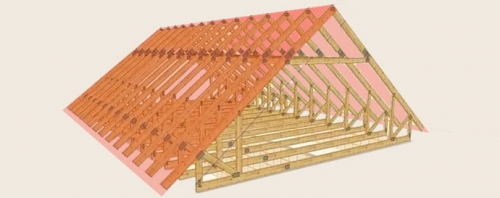

The durability of the walls of a private house and comfortable living in it directly depend on a reliable roof. Among the various types of roofs for country houses, a gable roof is most common. It owes its popularity to the simplicity of design, ease of erection and the presence of a large attic in which you can equip the attic. Performing the construction of a gable roof with your own hands, it is necessary to have an understanding of what you are doing and be able to handle the tool. Therefore, before making a gable roof, you should familiarize yourself with the device of the roof, its elements, installation features and develop its project.

The device of the gable roof

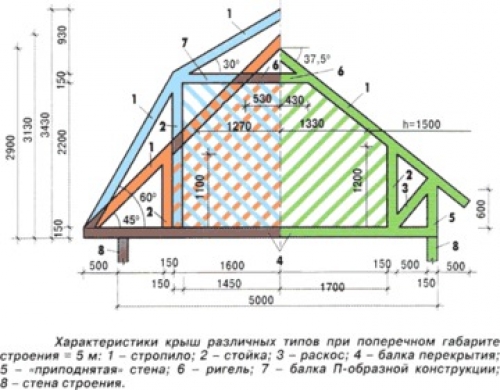

The choice and creation of the design of the gable roof begins at the stage of designing the house. But if you have to redo the roof of the already built house, then the project of the gable roof can be developed separately and then implement it. The main thing is to preserve the overall architectural style.

Before you build a gable roof, it is necessary to develop its project with drawing documentation. You can create it yourself. This will require the skills of working with the computer and knowledge of the architectural program, for example, Archicad. When performing such work for the first time, it is best to seek help and advice to a specialist. Also, all the work on the project can be delegated to relevant organizations that have been doing this for more than one year and can provide a number of gable roofs that are already ready and time -tested.

Gable roof: photo

To create a roof project yourself, it is necessary to understand the structural elements and materials for its construction, since without this knowledge you can make a serious mistake.

The design of the gable roof consists of the following main elements:

- Roof.

- Chatter and counterparty.

- Skate run.

- Rafters.

- Mauerlat.

- Racks.

- Flates and diagonal connections.

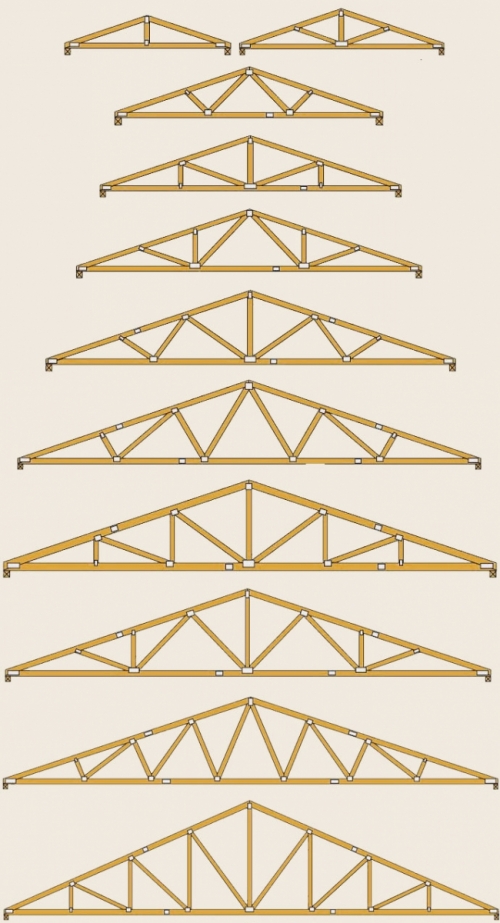

Important! Two rafter legs, interconnected and reinforced by braces, are called a farm. The photo shows several types of different farms.

All these elements are part of the rafter system, which can be of two types: hanging and layered. The first is used in the case when the rafters are based only on two external walls. The second type has three or more supports of external and internal walls. These two types can be used at the same time. For the part of the house where there are intermediate supports, they use layered rafters, and where there are no such supports, hanging.

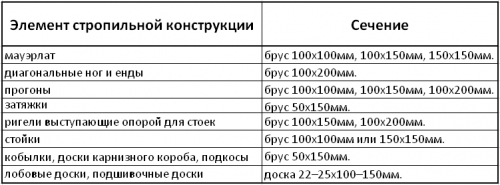

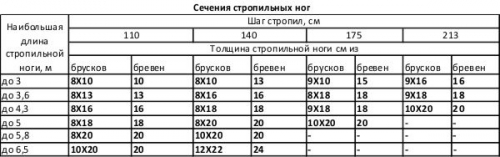

Material for rafters and crate can be metal or wood. In private construction, the tree is more preferable, and the reason for this is its low cost and availability. The table below shows all elements of the rafter structure and the recommended cross section of the wooden beam and boards.

Table No. 1

When creating a project, it is also necessary to take into account the length of the rafters and the step with which they will be installed. The thickness of the beam will depend on this. It should be noted that a wooden beam with a maximum thickness of 250 mm is presented on the market. This is quite enough for roofs with a length of rafters up to 7 m and a step of 150 cm. But quite often the stepal step is adjusted to the size of the insulation, so as not to cut the latter and get a denser fit. In such cases, a gross larger beam is required to create a reliable design. The output in this situation can be glued beam, the thickness of which reaches 300 mm, which in combination with supporting frames will make the roof as reliable as possible. The table presented below shows the relationship of the thickness of the rafters and their length.

Table No. 2

By tradition, the angle of the gable roof is chosen in the range of 11 45. But in order to get more accurate data, you need to know a number of factors on which the angle of inclination will depend. Firstly, this is the material used for the roof. Secondly, these are wind loads in the region where the house is being built. Thirdly, these are snow loads in the selected region. All these factors are interconnected. For example, if you make a large angle in the region with strong winds, you will have to strengthen the rafter structure, which will entail additional costs. In addition, the larger the angle of inclination, the greater the area of \u200b\u200bthe roof and, accordingly, requires more materials. But in the region with large precipitation, the small angle of inclination will lead to the fact that they will accumulate on the surface and thereby increase the load, which will also require increased rafter structure.

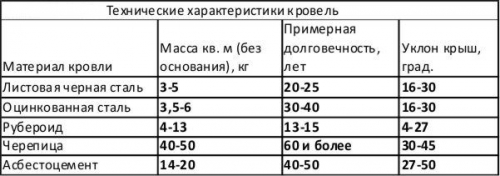

The table below shows the angles of inclination for various types of roof:

Table No. 3

When accepting the snow load, it is necessary to first determine in which area the house is located. To do this, you can use the special card below, as well as SNiP load and exposure. Then conduct a small calculation.

So that the roof does not play the role of a sail, and at the same time the precipitation rolls along it, for calculations it is necessary to use a map of wind belts and SNiP loads and exposure.

Important! When performing calculations to identify the optimal angle of inclination of the gable roof, it is necessary to remember this type of precipitation as snow, or rather, its thermal insulation characteristics. The thing is that snow is natural thermal insulation at negative temperatures, and its presence on the roof will preserve heat in the house. Therefore, do not do too much angle and rush to get rid of all precipitation from the surface of the roof.

Gable roof: video

The construction of a gable roof

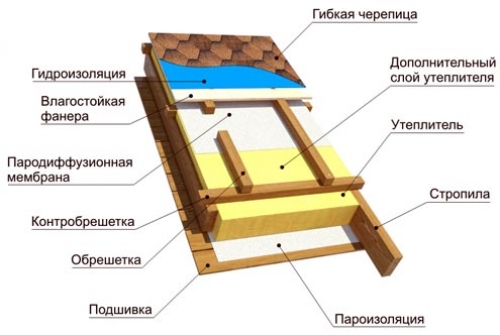

All work on the construction of a gable roof is divided into three main stages. The first is the construction of a rafter structure. The second creation of insulating layers, namely the heat, hydro- vapor barrier and, if necessary, soundproofing. The third laying of the roofing. Using a previously made drawing of a gable roof, and having purchased all the necessary materials, you can proceed to its construction.

Rift construction construction

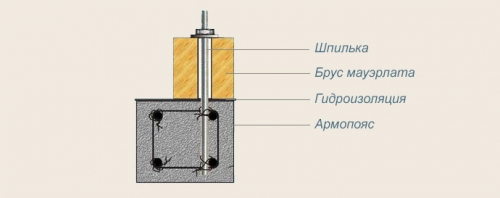

The first thing to do is to lay down and fix the Mauerlatians. To do this, along the perimeter of the walls of the building, as well as on the intermediate walls, lay a layer of waterproofing from roofing material. On top of the roofing material we lay a wooden beam designed for Mauerlat and fix it to the walls using metal studs previously equipped into the walls as shown in the figure:

A metal hairpin is a rod with thread. The length of such a hairpin is selected from the calculation that its half will be embedded in the wall, and the protruding part should be 3 4 cm above the laid Mauerlat so that you can tighten the nut.

Now proceed to install the rafters. You can do this work in two ways. The first is to collect the farm on the ground, and then raise it to the top. The second assembly of the farm directly at the place of its installation. Which of these two ways to choose is to solve directly to the masters. In any case, for the convenience of installing the rafters and the creation of the same type of farms, it is worth making a template on which the rafters will be cut and connected.

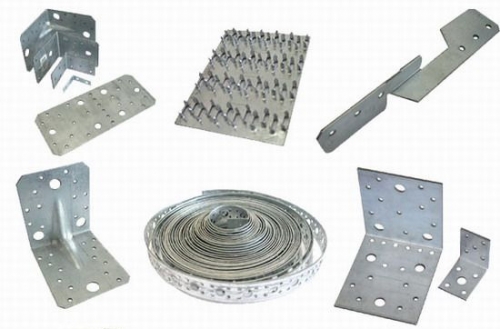

To make such a template is quite simple. To do this, we take two boards, a little larger than the rafters in length, lift upstairs and install in place like rafters. We align them vertically, make sure that the top of the skate is exhibited in accordance with the drawing and connect the boards with one nail. Now you can, lifting or lowering the ends of the boards, get the required angle of inclination and, having achieved the desired, connect the boards with a transverse bar to fix them in this position. Using this template, we adjust the rafters under it and then connect them. To combine the rafters with the Mauerlat, we make pieces in the form of a rectangular triangle in them, and for the connection we use stamped metal corners or brackets.

We mount the farms at the beginning and at the end of the building, then pull the cord between them. We make sure that the horizon level is perfectly even, in case of distortion, we slightly lower one of the farms. Under this cord we install all the other rafters with the step specified in the project. Then we mount the braces, crossbars, retaining beams and frames.

Important! To connect the structural elements and its amplification, it is best to use stamped metal nail plates, corners and brackets.

Isolation of a gable roof

After installing the rafters, you can proceed to the creation of a multi -layer insulating pie, which will protect the internal structures, maintain heat and coolness in the house. Isolation consists of several layers: waterproofing, vapor barrier and thermal insulation. In some cases, when roofing materials with a low level of noise absorption are used, noise insulation is also equipped.

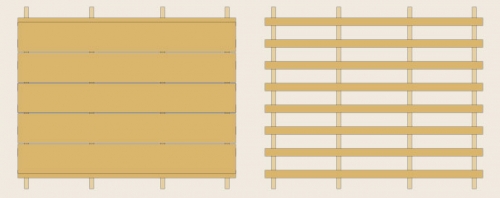

We begin to create an insulating pie from laying a waterproofing layer over the rafters. To do this, you can use various films and membranes, which will reliably protect from moisture penetration inside and at the same time pass the excess outward. We begin to lay the materials themselves from the bottom up, letting them with an overlap of 15,100 cm. As a mount, we use wooden rails with a thickness of 25 mm. These slats are a counterparty and are attached to the rafters along. It is worth noting that the counterparty allows you to equip good roof ventilation. On top of the counterparty we lay the main crate, which goes perpendicular to the rafters, and to which the roof will be attached.

Important! There are two types of crate: continuous and discharged. The first is used for soft and roll roofing materials. The second for materials such as slate, tiles, galvanized sheet.

Having finished with waterproofing and a crate, we proceed to the arrangement of thermal insulation. Various materials are used as insulation. The most popular of them is mineral wool, glass wool and foam. But today, other thermal insulation materials can be found on the market, which are more suitable for roof insulation and are not inferior in characteristics already familiar. Among such foamed glass, algae ramps, extruded polystyrene foam. When choosing a particular material for roof insulation, you should focus on its characteristics:

- Thermal conductivity should be, the lower, the better.

- Specific gravity. The smaller, the more thick the layer can be done without increasing the structure.

- Moisture resistance. The higher it is, the better.

- As well as the fire hazard and environmental friendliness of the material.

Important! Having selected mineral or glass wool as thermal insulation, you should be prepared for the fact that it absorbs moisture very well, while losing its insulating properties. Even having created excellent waterproofing, cotton wool will draw moisture from everywhere like a sponge.

The thermal insulation material itself is laid between the rafters. As noted earlier, the stepal step is selected for the size of thermal insulation. Therefore, mats or slabs simply fit into the plug between the rafters. A vapor barrier film is pulled on top of thermal insulation, which is fixed with wooden rails nailed to the rafters with a step of 50 cm.

Important! If in the future it is planned to arrange the attic, then the thermal insulation layer must be strengthened. This is done very simple. On top of the thermal insulation laid between the rafters and a layer of thermal insulation is laid on top of the rafters themselves. For these purposes, extruded polystyrene foam with the selected quarter in the end is perfect. This is necessary, since the rafters are cold bridges, in addition, if there are small cracks somewhere, the continuous layer will block them.

Laying the roof

The final stage in the construction of a gable roof with your own hands is the laying of the roof. Today in the market you can find many different roofing materials. The choice depends on the financial capabilities and wishes of the owners. Especially popular are metal tiles, bitumen tiles and slate sheets. In many ways, such popularity is due to the simplicity of styling and the reliability of these materials. Regardless of which roof was chosen, its laying occurs from the bottom up. Thus, the overlap of sheets is ensured, which makes it possible to drain water and not get inside.

The construction of a gable roof with your own hands is a very responsible business. The slightest mistake in the calculations during design and during construction will result in additional costs or a decrease in the reliability of the entire structure. If you have to perform such work for the first time, it is better to be safe and invite an experienced master who will lead the work.