The foundation for the veranda is no less important design than under the house itself. A wish...

|

|

Over the past 10 years, the number of roofing materials has increased significantly, however ... |

After the construction of a reliable roof, you need to make sure that it copes with ... |

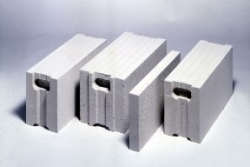

Aerated concrete. Features of the material, characteristics and application

This unique material is widely used in housing construction. It is suitable for the construction of all types of walls, including bearing. Excellent soundproofing properties, fire safety, frost resistance and light weight allow it to be used in the construction of industrial bases, livestock farms, and residential buildings. Aerated concrete blocks are not susceptible to decay in comparison with wood. Masonry is carried out much faster than from bricks, while the price of aerated concrete is significantly lower. In the article, we consider the main characteristics of aerated concrete and the stages of construction from it.

Content:

- Malician production technology

- Properties of aerated concrete blocks

- The sizes of gas concrete blocks

- Tool for processing aerated concrete blocks

- Quality criteria for material

- Building a house from aerated concrete

Malician production technology

The cellular structure is almost 85% of the volume of the entire block, so this material is very lightweight. All components (quartz sand, cement, lime) are closed with ordinary water and stirred in a special mixer for 5 minutes. Hydrogen formed by the reaction between aluminum paste (powder) and lime forms pores. Bubbles in size from 0.6 to 3 mm are evenly dispersed throughout the material.

In metal containers or forms, the main chemical reactions occur. The mixture is subjected to vibration that contributes to the grasp. After hardening, all irregularities from the surface are removed by a steel string. The layer is divided into blocks, and then they are sent to an autoclave installation. The final calibration of finished blocks is carried out by a milling machine.

Before buying aerated concrete, you need to ask with the use of what processing it was produced.

- Autoclant processing. This stage significantly improves the technical characteristics of aerated concrete. Here, for 12 hours with high pressure, a ferry is carried out, the temperature of which is almost 200C. Such a heating process makes the texture more homogeneous, thereby improving the strength properties (at least 28 kgf/m). Its specific thermal conductivity is 0.09-0.18 W (m ∙ K), which allows you to build walls in one row (400 cm) in almost any climatic conditions, but excluding the northern regions.

- Non -circular technologyit consists in the natural hardening of the mixture. In this case, it can be done with your own hands, since special equipment is not required here. The strength of blocks in this production does not exceed 12 kgf/m.

Properties of aerated concrete blocks

- Ease.The D500 block in size 30x25x60 cm weighs about 30 kg, 22 bricks are required to lay the same volume, the weight of which is twice as much as 80 kg.

- Thermal conductivity. The cellular structure creates a thermal insulation effect. Also, this material is able to maintain heat, and in the summer season a pleasant coolness. It should be noted here that the thermal conductivity of the block with a thickness of 375 mm is equivalent to masonry made of brick more than half a meter.

- Fire safety. The raw materials used in production are of mineral origin, in its properties not fuel. Therefore, blocks are able to withstand the effect of open flame for 3 hours.

- Frost resistance.Subject to technology at all stages of construction, this material is able to withstand more than 25 freezing/thawing cycles.

- Strength.A high compression strength is achieved by passing through an autoclave installation. For example, the strength of the D500 block is 28-40 kgf/cm. Such parameters allow you to use it when erecting the supporting walls of the structure up to 5 floors.

- Economy.Thanks to large dimensions and lightweight, construction stages are carried out faster than from other materials. Such installation work can be performed even by one person. These characteristics reduce transportation costs and expenses for the installation of the foundation.

- Easy to process.You can give it any form using manual means, for example, a hacksaw or saw. The block is easily cut, drilled. Conduct a stroke, score a nail or make a working hole under the outlet is not difficult. This property of the material will make it possible to realize interesting and original projects from aerated concrete of any complexity.

- Environmental friendliness. New technologies make it possible to produce this material from raw materials that do not secrete toxic substances. In environmental purity, it is inferior only to wood, but at the same time not subject to combustion, decay, and insects.

The sizes of gas concrete blocks

Aerated concrete blocks are blocked and wall. The first includes blocks with a thickness of 75 to 200 mm, and the second from 250 mm or more. Participation is intended for interior walls, internal non -explorer structures. And a wall aerated concrete is used to erect the supporting walls of the building or other structure.

- Blocks with a thickness of 75 mm are mainly used as insulation of supporting black walls, for example, from brick.

- With dimensions of 20 and 25 mm are used to build walls of outbuildings or household buildings that do not require special energy -saving properties (garages, sheds).

- Blocks are suitable for laying the bearing walls, the thickness of which is from 375 mm and higher. In this case, for insulation of construction in certain climatic regions, it will only be enough to perform plastering work on the external walls.

It is also important to know:

- Aerated concrete blocks are produced with a density of 350, 400, 450, 500, 600, 700, marked by the letter D.

- The length can be 600 and 625 mm.

- Width 75, 100, 150, 200, 250, 300, 350, 375, 400, 500 mm.

- Height 200, 250 mm.

- Compression density from 1.0 to 7.5 MPa.

- Frost resistance is in the range from 15 to 50.

- The shrinkage when drying does not exceed 0.5 mm/m, this parameter corresponds to all sizes of the blocks.

Tool for processing aerated concrete blocks

This porous material has a low density, so it is easy to process. And thanks to the correct geometric form, laying blocks is carried out without any difficulty. Without making a lot of effort, aerated concrete allows you to carry out a strip under communication and embody the most complex architectural designs.

Blocks can be given any slope, bevel. For the construction of small households, outbuildings, a regular hacksaw with a metal blade or a hand saw is used. Such a tool is ideal for small volumes, where it is only necessary to correct blocks for window and doorways, corner places.

You can improve the quality of work using additional devices:

- metal corner;

- ruler and pencil;

- rubanok for skirting surfaces of the walls.

Tip: Chain saws are not suitable for thin and accurate work, because the cut is wide and not very neat, respectively, the edges begin to crumble.

- Also for work is used and electric saber saw. The cuts are thinner and more accurately compared to the chain analogue. It is adjusted to the blocks of blocks in size, grooves, grooves, strobes for laying communications. It can be used as a hand saw directly on the spot.

- Band-saw It is used in large construction. The distinctive properties of this tool is a high performance and even sections.

- Incisors A hand tool that is perfectly performed by strokes of grooves for the laid electrical networks, pipes and other communications.

Quality criteria for material

This material has established itself in the field of construction. Its rectangular shape and ease of processing contributes to quick work on construction. The size of the block corresponds to 4 standard bricks. When laying it, no special skills are required, if there is experience in laying bricks, then there will be no problems with aerated concrete.

The main criteria, their pros and cons:

- Saving after construction.Plus - this parameter is approximately 0.2-0.5% and it is almost invisible, for example, the shrinkage of a wooden house is almost 15%. There are no minuses.

- Aesthetics. Plus - thanks to even walls, the finish is made easily and quickly. Minus - you can’t do without these work, since the gas concrete blocks in the masonry look very ugly.

- Environmental friendliness.Plus - it consists of sand, Portland cement, ash and a small share of aluminum. Minus - in many European countries it is forbidden to build residential buildings from aerated concrete due to aluminum powder.

- Fire safety.Plus - there are no combustible materials in the composition, therefore, aerated concrete is characterized by increased resistance even to an open flame. There are no minuses.

- Life time.Plus - a strong structure is not subject to decay and mold. The block is able to withstand a large number of freezing/thawing cycles. Minus - under the influence of constant adverse conditions, for example, moisture and damp, loses its strength characteristics and begins to crumble.

- Masonry blocks.Plus - the geometrically correct shape and size of the block allows masonry very quickly. It is easily processed by a regular saw, giving any configuration. There are no minuses.

- Thermal insulation.Plus - masonry in two rows will provide average indications of thermal insulation. Minus - the maximum coefficient of this parameter is 0.12 W/m, so the structure needs additional insulation.

- Economy.Plus - a low price for blocks, makes it possible to consider aerated concrete very affordable material for construction. Minus - the costs of a more durable foundation, final surface finish, wall insulation eat saved finances.

Building a house from aerated concrete

Calculation of the material

Any construction work begins with the calculation of the material. The sale of aerated concrete blocks is carried out in cubic meters, so the calculations are carried out as follows.

For example, it is planned to build a house with dimensions: 16x12 m and 3 m high. First, the area of \u200b\u200ball walls is calculated:

- (16+16+12+12) ˣ3 \u003d 168 m or

- 16ˣ2ˣ3+12ˣ2ˣ3 \u003d 168 m.

Further, the result is multiplied by the thickness of the block 0.3:

- 168ˣ0.3 \u003d 50.4 m - this number of blocks is necessary for the construction of walls. Interior partitions are calculated in the same way.

Foundation

More reliable grounds for aerated concrete are considered:

- strip monolithic foundation;

- unsuccessful foundation from a monolithic slab;

- column foundation.

The choice is carried out depending on the parameters of the soil and on the project of the house itself. But in any case, waterproofing is necessary and if a basement or basement is planned, then the wall insulation must also be provided.

The base of the building under construction is recommended to be made of brick, the cubature of which is calculated in the same method as for blocks.

Glue for aerated concrete

- The minimum deviations of the size of the blocks (1 mm) allow you to masonry with a special adhesive solution. The glue is applied with a thickness of not more than 3 mm, so the heat loss is minimal. After all, heat loss occurs not only through the surface of the material, but also through the pantry.

- The thin layer of glue increases the thermal resistance of the structure by 20-25%, compared with the sand-cement mortar. In addition, despite the high cost, thin -haired masonry significantly reduces the consumption of this material. The use of adhesive solution will provide cleanliness in the working area, giving an aesthetic appearance of the house being built, the building.

- The powder mixture consists of quartz sand, Portland cement, mineral and polymer additives. It is only necessary to shut with clean water (about 30) and mix the adhesive solution is ready for use. The ratio of fluid and powder is indicated on the packaging with glue. Remember, an increase in water reduces the strength characteristics of the solution.

- Before use, the glue is thoroughly mixed. To apply it, a gear spatula is used. Correction of the position of the block can be made within 10-15 minutes. In a shut -up form, the solution is recommended for several hours.

The technology of laying aerated concrete blocks

The work will require: a toothed spatula, a shirt, a hand saw, glue, level, a brush and the blocks themselves.

- A glue solution is applied to the block and flatly laid out on the prepared surface. If necessary, the block is aligned with a shirt, small particles and other contaminants are removed with a brush. Excess solutions are neatly removed, but do not grind into the seams.

- Be sure to check each block for vertical and horizontal level. Remember, it is impossible to disassemble the masonry for adjustment, it can only be broken or broken. It is very important to lay out the first row evenly, it is advisable to use a sand-cement mortar for these purposes, thereby compensating for all irregularities.

- The work begins from the corner, for the accuracy of the masonry, a stretched thread is used, intermediate and corner blocks act as beacons. During the construction process, the dressing of the seams should be observed. The displacement of a row should be at least 8 cm in relation to the previous one. The required size of the block is given using a conventional hacksaw.

- At night and in rainy weather, the horizontal surface of the masonry is covered with a film. Such manipulations should be carried out until the roof is mounted. If the construction is winter, then the whole structure is isolated.

How to lining a house from aerated concrete

Facing work will give an aesthetic look to the facade and protect the walls. They are not performed immediately after the construction is completed by the house, you need to give time for shrinkage. It should also be remembered that the external finish is carried out only upon completion of internal work. Plassing or filling of the floors saturate the blocks with moisture, so it needs to be allowed to go out.

- Put and paint.These manipulations are started only after the masonry dries. Reinforcement with a net will significantly increase the life of the facing layer. The plaster is applied with a thin layer and then is covered with facade paint using the tint of the desired shade.

- Brick brick.A more respectable view will find a built building if you linen it with brick. Such work can be carried out both in parallel to construction, and after its completion. It is important to adhere to the following rules here:

- the maximum height of the wall of piece material should not exceed 15 m;

- this masonry must be based on the foundation or on the foundation beam;

- it is necessary to equip a ventilation gap so that the condensate does not accumulate in the interlayer space.

- Ventilated facade. This method of facing will provide good ventilation, protect the walls from precipitation, and give solidity to the structure. Fasteners are selected depending on the density of the blocks. During installation, it is recommended to take into account some features:

- the distance between the wall and the installed facade increases with the height of the house. When installing panels on high -rise buildings, such a gap can be 20 cm;

- ventilation holes are combined with basements and cornices, while the lower ones are better to combine with ventilation and moisture removal systems. The total area of \u200b\u200bthe holes should correspond to the calculation of 75 cm per 20 m of the wall;

- as thermal insulation, it is recommended to use hard materials, the density of which should be from 90 kg/m and higher. They should be equipped with windproof and vapor -permeable coatings.

But with regard to the color, texture and style of siding, the choice is simply huge and limited only to the fantasy of the owner of the structure: all kinds of colors, imitation of wood, metal, stone.

Internal work

Special requirements for the decoration of the interior are not presented. Only for heated rooms with high humidity such as: bathroom, steam room, sauna, bath need high -quality moisture insulation.

- Plassing of aerated concrete blocks does not differ from ordinary work. The surface is aligned, cleaned, primed and then plaster is applied. You can perform staining with water-dispersion paint with the addition of the tint of the required shade. Such walls are advised to glue with paper wallpaper, they increase the resistance of air permeability.

- The finish is also performed with drywall sheets, which can be mounted both on the prepared frame and glue directly to the walls, thanks to the flat surface of the blocks.

- If ceramic tiles are selected as facing material, remember that it will significantly reduce the vapor permeability of the wall. This finish option is optimal when the outer surface of the wall is plastered. It should be noted that the simultaneous decoration of the internal and external surfaces of the walls with vapor -permeable materials is prohibited.

In order for a country house under construction, the cottage turns out to be strong, warm, reliable and durable, it is necessary to observe the technology of construction at all stages of work. Otherwise, there is a chance that all finances and efforts will be in vain. Do not neglect the advice of experienced foremen, but better contact specialists who will carry out the necessary calculations and create a project that meets all construction standards.

For me with the same material

For me, two things were important with the material of the material - the price \\ quality and speed of construction. That is why, in the end, I stopped precisely on gas blocks and did not lose your mind. And if you want to save a little, I advise you to buy all the building material in the winter. I did so, purchased in winter right at the Kottage factory and left it right on their warehouse for free keeping. https://cottage-samara.ru