The appearance of the courtyard and the private house tells a lot about its owners. Reflection ...

|

|

When arranging a country household, a reliable fence and entry gates are very important ... |

Liquid wallpaper can be called a rather original solution for wall decoration in the apartment ... |

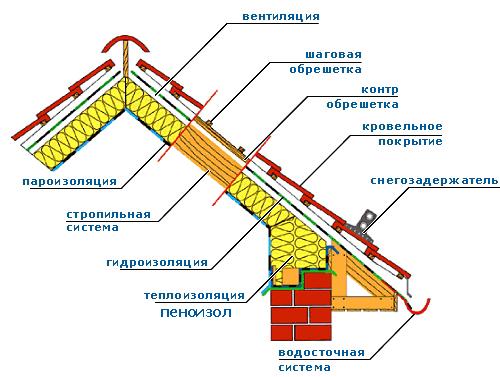

Roof heat insulation device

After the construction of a reliable roof, you need to make sure that it copes with its task to protect your home from precipitation, and think about its thermal insulation, since heat leaks in most cases occur through the roof. By the way, the process of thermal insulation of the roof in importance is in the second position after creating the tightness of the coating. With all the variety of roof structures, the process of insulation is carried out according to similar principles. And how right now you will find out!

Content:

- The essence of the roof insulation

- Roof insulation materials

- Preparation for the installation of thermal insulation

- Roofing thermal insulation options for arranging

- Laying thermal insulation material

- Internal and external insulation

- Warming and flat roof insulation

- DIY thermal insulation device with your own hands

The essence of the roof insulation

The roof is the weakest element in the design of a residential building in relation to heat loss. The orientation of thermal flows up causes much higher heat leaks compared to the walls and basement. Heat heating through an uninvited roof often reach 30% of all losses of low -rise buildings. In connection with the growing rates for heating and energy carriers, the minimization of such losses brings tangible benefits.

The lack of thermal insulation or incorrect laying of the insulation provokes the formation of condensate on the inner surface, which entails a violation of the microclimate in the house, the formation of fungus and mold. In this case, the roof will heat up with heat flows that go from the attic of the building, so in winter the snow settled on the roof quickly melts, flowing down the slope down and turning into ice and icicles, as well as deforming the roof and violating waterproofing.

One of the important factors that affect such indicators, a humid and temperature regime, the maintenance of which is provided by specific thermal insulation materials. For insulation of the roof, thermal insulation materials are used, which provide the most qualitatively to the heat in the house in accordance with the established building codes. The insulation should have low water permeability and a certain vaporimity of the ability to pass steam, giving the roof the ability to breathe.

During the construction of private houses, the design of cold attics was traditionally used, when the main insulation was carried out on the surface of the ceilings, i.e. On the floor of the attic. A similar approach was associated with a lack of thermal insulation material, which could be laid on rafter structures. The modern approach allows you to insulate the undercarbon space according to the rafter structures themselves, while creating a full -fledged attic and increasing the living space at minimal costs.

Roof insulation materials

Particular attention should be paid to the choice of insulation. For roof insulation, materials are used that differ in terms of thermal conductivity, vapor permeability, moisture leveling and mechanical characteristics, durability, resistance to fire, ease of work and cost. When buying a thermal insulation material for warming the roof, you must pay attention to the following criteria:

- Compliance of the material for building standards and standards for ecology.

- The scope of use of the material choose the material exclusively for roofing.

- The speed and ease of installation of the insulation should not require large labor costs and cause difficulties in work.

- The useful life of the selected coating.

- Water -repellent properties - insulation material should not absorb moisture, since its thermal conductivity will decrease.

- Steaming characteristics are best chosen to choose a thermo -insulating material with one side covered with foil.

It is necessary to select the insulation material so that its thickness provides the power supply of the building, according to the requirements of SNiP, therefore it should be determined based on the thermal conductivity of a certain material. If the thickness of the rafter structures is not enough to organize the appropriate insulation, then to solve this issue it is necessary to use a more effective insulation with a low level of thermal conductivity.

The main characteristic of insulation is the average density. Thermal insulation materials are divided into dense, medium, light and very light. Highly density materials will not always provide high thermal insulation, but they can withstand more significant mechanical loads and create increased loads on the supporting structures of the insulated house. The insulation density is 20 - 200 kilograms per cubic meter. Let's look at the main types of insulation:

- Fiberglass and glass wool. The material has a large level of sound absorption and light weight. The price of the heat insulation of the roof fiberglass is relatively low. However, in terms of its thermal insulation characteristics of the glass wool, other heaters are not inferior.

- Mineral and basalt cotton wool. The insulation is performed on the basis of rock fibers, it is a finished rolls or plates of various sizes. Depending on the desired result, it is customary to lay out the insulation in one or a couple of layers. The material has low hygroscopicity, provides a high level of soundproofing and does not burn. In the manufacture, mineral wool insulation passes toxicological and radiological inspection.

- Extruded polystyrene foam and polystyrene. These materials in the processing are easy, have a low weight, differ in minimal thermal conductivity, are not exposed to pernicious moisture. Such methods of thermal insulation from each other are distinguished only by thermophysical characteristics: polystyrene foam (foam) is airy -resistant, and the foam has high breathability. They are both combustible, but this problem can be easily solved with the help of a fire -retardant layer and antipyren impregnation.

- Penophol. This material is foamed polyethylene, which is covered with aluminum foil. Its main features are in low thermal conductivity and moisture absorption, as well as a small thickness, which allows you to save space.

Preparation for the installation of thermal insulation

Before engaged in the work on warming the roof, it is mandatory to correctly prepare the surface. It is necessary to start by checking the rafters for rotting, fungus, mold, moss, various parasites and damp beams. If you find the listed defects in a small amount, then it is worth cleaning the rafters with sandpaper, then treat with a special antiseptic and paint enamel, oil or bitumen paint, isolation in this way from the effects of natural environment factors. If the damage is significant, then it is better to replace the rafters.

At the second stage of preparatory work before fastening the heat -insulating material, it is necessary to check the wiring for serviceability. Repair its damaged parts, replace the worn wires, call the switches, carefully check all the connectors, joints, fasteners and joints. In case of complete unsuitability of the electrical wiring, it should be redone.

Roofing thermal insulation options for arranging

There are many methods of thermal insulation of the roof in construction practice. What way to use in each case will depend on the complexity of the design of the roof and the material used for its insulation. Let's look at them in more detail.

Laying thermal insulation material

There are several methods of laying thermal insulation material:

- Rolled method. When creating thermal insulation, it is customary to use rolls with a substrate that appears on the sides. From rolled thermal insulation materials, a foil insulation with a filler filler and a substrate is released. The high level of thermal insulation is achieved due to a small density of 15 20 kg/cubic meter. meter.

- A full way. To do this, pull a metal mesh with cells that have dimensions of 15 by 15 millimeters, and fixed with hairpins, which are located in a checkerboard pattern. Then the laying of the material is carried out.

- Folding method. Such thermal insulation of the roof is used in the presence of a difference in intervals between the beams of the rafters. The material for filling is a fibrous or granular vermiculite, foam glass or perlite sand. The heating process provokes an increase in the volume of vermiculite by about 6-8 times. Filling is an ideal way of insulation of non -standard roofs. But this method should not be used in a blown attic to avoid its weathering.

- Leaf insulation. Mineral -fiber mats, polystyrene or polyurethane plates are materials. The sheet heat insulator is attached directly to the rafters of the roof. The costs of its transportation and styling, due to low weight, are significantly lower, if compared with other methods of thermal insulation.

- A blowing way. Within the framework of this technique, a mass of fibrous polymer is used as a material, which is fed by blowing through an elastic pipeline. A similar method is not suitable for attics under the roofs of a complex shape. To carry out blowing isolation, it is customary to use material made on the basis of pure from the environmental position of pulp fibers.

- Sprayed thermal insulation. Spraying can be carried out on any surface. Apply polyurethane foam on all elements from the inside of the roof, it expands and fills in qualitatively all the cracks and cavities. There is no need for additional fastening, because there will be not a single seam. The material is considered resistant to decay and the effects of harmful microorganisms, and is characterized by a large period of operation.

Internal and external insulation

Internal insulation is the most popular option for thermal insulation, which is suitable for pitched and flat roofs. The internal insulation of the roof is carried out according to this technology: first, the internal skin of the room is laid, a steam -barrier, then a heat -insulating material, and then wind and waterproofing.

The final heat -insulating layer is the roofing material you have chosen. Remember that the insulation should have the necessary width and be adapted to certain climatic conditions. But the main thing is to ensure that the material does not weight the roof, and provide gaps that are required to remove moisture from the structure.

External insulation of the roof is carried out on the basis of flat roofs using hard plates, which, therefore, are pressed with concrete slabs or pebbles. When organizing external thermal insulation, it is very important to calculate the strength of the roof in order to protect yourself from the collapse of the roof.

Warming and flat roof insulation

The choice of the thermal insulation of the pitched roof is carried out, depending on the features of the building. If the house is in operation, and you do not provide for the dismantling of roofing material, the main or additional insulation of the roof must be carried out along the inside of the roof - directly on the rafters.

If the building is only during the construction process, and you have not yet mounted the roofing material, then it is worth warming the outside of the pitched roofing structures, and the internal crate will be the support for thermal insulation material. For roof insulation, you can choose one- or two-layer thermal insulation. But at the same time it is worth using only insulation, which has the same density.

Rall roofs on the rafters are usually insulated with heat -insulating materials that differ in low density (25-50 kilograms per meter cubic), designed exclusively on atmospheric influences and temperature. Remember that the materials should not create a large load on the design.

During the construction of a new house for thermal insulation of a flat roof, it is recommended to use a two -layer method of insulation. The lower layer is required for thermal protection, and the top is needed for distribution for the entire load structure. A single -layer method is customary exclusively when repairing and reconstructing old roofs.

For thermal insulation of flat roofs, dense heater must be used, which should withstand significant loads from snow and water, since precipitation often accumulates on such roofs. Flat roofs from corrugated board need to be insulated with mineral wool, basalt and polystyrene stoves, which have a density of about 220 kilograms per cubic meter. The roof on the reinforced concrete slab is insulated with denser materials, for example, PPH-200 plates.

DIY thermal insulation device with your own hands

Roofing thermal insulation is a multilayer system consisting of an internal vapor -permeable layer, insulation and upper membrane material, which is characterized by one -sided moisture permeability. A similar design is called a roofing cake.

Manufacturers of modern building materials offer a ready -made pie to consumers, but you can create it with your own hand at the proper level of quality. The first layer is a moisture -proof material that protects the layer of insulation from excess moisture, which comes from the room. Usually use foil, polyethylene and other materials.

The styling of the material is carried out on the inside of the supporting elements without passes in a single layer, gluing the junction of the connection with sealant and fixing the strips to the wooden structures using galvanized cloves or construction stapler. If it is impossible to lay the material with one layer, you need to create overlapes, which should be more than 100 millimeters.

The vapor barrier upper layer is necessary to ensure moisture to outward and prevent it from entering the layer of thermal insulation material. The laying of thermal insulation material is carried out directly to the vapor barrier material. In this case, it should be precisely cut in size, since its crushing is not allowed.

You can achieve the planned and calculated efficiency of thermal insulation of the soft roof only if you prevent the formation of cold bridges when laying the insulation. To do this, the roofing material must be laid without interrupting other elements of the structure. There should not be in the thermal insulation layer of planes and hollows for air passage.

Thus, to save energy resources, to recreate in the house the most comfortable microclimate is capable of only high -quality laying of thermal insulation. Therefore, it is not recommended to save on it, you need to strictly follow the technology in order to avoid such fatal errors as the use of the material of inappropriate width, the installation of insulation of small thickness. Also remember that the maximum possible effect of the procedure for warming the roof will be achieved exclusively with an integrated approach to the thermal insulation of the house.