When building your own home, the future owner is two main tasks ...

|

|

One of the most popular floor coverings laminate. It is used in residential and ... |

Each developer is faced with the question of the exterior decoration of the building. The cladding at the same time ... |

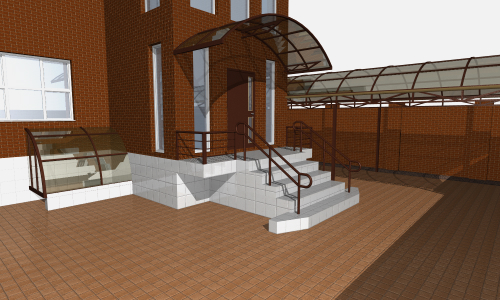

DIY polycarbonate porch

The appearance of the courtyard and the private house tells a lot about its owners. The reflection of your personality is the porch of the dwelling, which sets the tone for the entire extension. Therefore, the question of how to make a porch to the house is always relevant for our readers. To give the porch, a kind of airiness and transparency can be created from polycarbonate, which is attached to the aluminum frame with steel corners. You can do the installation of the porch of the house from polycarbonate yourself.

Content:

- Porch project

- The construction of the foundation

- Construction of the site

- Concreting steps

- Cellular polycarbonate for porch

- Profile mount

- Polycarbonate fastening

- Roof installation

Porch project

The porch serves as an integral part of each cottage or country house, its so -called face. This design consists of a foundation, a staircase of at least 2 steps, walls and roofs. It is not at all difficult to create a porch on their own, you can use almost any building material.

The style of the porch, as a rule, depends on the general style solution of the construction. The porch should not look like a separate structure, which serves exclusively to protect the entrance to the house, but should also emphasize the taste of the owners of the home.

Before starting the construction of the porch from polycarbonate, it is recommended to draw up its project, taking into account all the necessary sizes and preferences. When developing the drawing, it should be remembered that it is the porch that takes on heavy loads, because it is not built on such a massive foundation as the house itself, but those materials that are designed to make such a structure cannot be called durable.

To begin with, determine the size of an important part of such an extension - the site responsible for the convenient entrance to the residential building. It should have enough space for the movement of 2 people, the front door should not complicate the process of passing into the house. There are no specific restrictions on the size of the porch, it all depends solely on the preferences of the owner himself.

The construction of the foundation

Before the construction of the porch, you need to prepare the site for him. If the old porch was installed at this place, requiring urgent reconstruction, it should be disassembled to the base. The beginning of the construction of the porch, like any other buildings, begins with the construction of the foundation.

It is not necessarily the foundation for the porch should be similar, as in the residential building itself, but with this its design should withstand all the required load, which depends on the weight of the material and people who will move along the venue of the porch from polycarbonate. Dry the pit for the foundation, about 1.2 meters deep, which depends on the depth of the ground water and the type of soil.

In the dug pit, make a sand pillow 20 centimeters high, then you need to build the formwork and you can fill in concrete. Instead of an expensive whole foundation, you organize 4 supporting parts that will cope with the tasks no worse than the foundation. At the site of installation of the support frame, you can dig deepen and install a natural stone in them, which will perform the function of the foundation structure.

The lower parts of the support frame should be impregnated with special antiseptics, which allow the lumber to resist moisture well. The use of bitumen for such purposes is not desirable, because a tree covered with bitumen solution cannot breathe, and this provokes baking and rotting of wood in a fairly short period of operation. Pay special attention to the empty space located under the porch site.

Construction of the site

The next stage in the construction of the porch is the construction of the site. Choose a durable and reliable material for her. During the construction of the site, remember that its level should not reach five centimeters to the threshold of the house. This is necessary so that rainwater does not fall into a residential building. For the construction of the site, wood is considered the most common material. To build this design, look at the photo of the porch of the house made of polycarbonate and prepare a wooden beam of different cross -sections and a trimming board.

The most economical and reliable construction option is the use of a trimmed board with a thickness of 5 centimeters. For the manufacture of the supporting part of the porch, in order to save money, you can take not only a wooden beam, but two boards with a thickness of at least 5 centimeters, sewn with each other. The supports should rest against the foundation structure. But the porch site itself, which is held on the supports, should also be additionally fixed on the wall of a residential building.

Concreting steps

Quite often, the internal space of the porch is used to maintain different household items. For this reason, all sides of the site must be sewn up with a trimmed look. Do not leave the unclosed parts of this space. However, if your plans do not sew the bottom of the site, then with the help of a wiped board you need to tie the supporting parts to give the design of additional stiffness.

After the manufacture of the porch site, you can proceed to the creation and installation of a staircase, which is solid, or consisting of individual elements, which are fastened to each other with special mounts and materials. When working related to the manufacture of a staircase, pay special attention to such an element of the structure of the stairs as a bowstring.

This element of the stairs is needed so that the possibilities of fixing the steps of the stairs appear. In the landing structure, as a rule, it is customary to use 3 bowstring - one in the center and two on the sides of the steps. All three a bowstring should be absolutely identical, which allows the steps to have an even horizontal level.

For the manufacture of three identical parts of the staircase, a special template should be made of simple cardboard. First, calculate all the required dimensions, then transfer them to the cardboard and cut out unnecessary areas. Using such a template, make three identical bowstones, on them you will subsequently install all the necessary steps.

Before concreting steps, the formwork must be mounted. The formwork for each stage is customary to create separately. After solidifying the concrete solution at the first stage of the porch, it is necessary to fill the sand of its cavity and crushed stone. After manufacturing the first stage, raise the formwork above and pour the other steps according to this principle. Strengthen the corners of the steps with a metal corner, which should be drowned a little in a concrete solution when it dries.

To give the steps of originality they can be decorated with a floor tile designed directly for external work. In no case, the surface of the tile should remain slippery, because it will not be safe to move along it. The most suitable option for this is porcelain stoneware.

Cellular polycarbonate for porch

In order for the porch to perform its main functions correctly, one site is not enough. The porch should be equipped with walls and a canopy above the porch made of polycarbonate. Cellular polycarbonate is a unique modern material from the category of synthetic polymers. It is made in the form of hollow panels of various thicknesses and structures, interconnected by the so -called stiffeners, which are longitudinal jumpers.

Polycarbonate in its properties is not inferior to glass. It is more firmly 200 times and more easily 16 times than whole glass, but it has a similar thickness. The transparency of the polycarbonate canvas is 87%. It withstands a variety of atmospheric phenomena, is considered suitable for use in the interval of operating temperatures.

Polycarbonate is difficult to flammable, in addition, the flame fades quickly enough if it is flared up. The cost of polycarbonate in comparison with other plastics below. It was such unique properties and affordable cost that this material has made extremely popular. Even beginner builders can cope with polycarbonate, because special tools do not need this.

Profile mount

For the manufacture of a metal profile, a standard tool must have a standard tool at hand: a grinder, a drill, a welding machine, a screwdriver. Depending on personal needs, buy a metal profile: rectangular or square. Take a metal profile with a margin to have enough for work.

For fasteners of polycarbonate sheets, take self -tapping screws and thermos, so that the water does not appear at the mounting site. Materials such as a tape for a polycarbonate canvas and a profile for the end to protect the inner cavity of the sheet from dust and insects are also needed.

The walls of the porch do not need massiveness, because the roof of the porch is made of light polycarbonate. The main parts of the metal frame should be attached to the wall of a residential building. The bottom of the frame is customary to be fixed on the site of the porch of the house, and the top must be temporarily fixed with screeds, which will be dismantled later, because they will become a visor over the porch made of polycarbonate in their place.

To achieve the greatest strength of the frame, it is recommended to place its elements at a distance from each other no more than half a meter. Fix horizontal elements between the vertical racks of the metal frame, between them the distance should be half a meter.

Polycarbonate fastening

Remember that polycarbonate is customary to be attached correctly vertically in relation to jumpers. Stiffer ribs in polycarbonate should be located in length. Installation must be carried out in such a way that the collected condensate can freely exit along the internal channels. Having the material is vertically, jumpers in polycarbonate should be placed vertically to the ground. With arched structure, lay in the arc.

Be sure to take into account bends, because this requires an additional amount of material. If there is not enough sheet length, you can lay two sheets. Remember that polycarbonate expands when heated. Consider a similar heat effect during installation. Make holes on the floor of the diameter more than the screw.

Do not allow overheating from the rays of the sun, for this it is recommended to paint the supporting structures in white. Polycarbonate panels do not fasten excessively hard and do not squeeze the screws. Avoid contact of polycarbonate sheets and metal, using gaskets when fastening, which have a thickness of 4 millimeters close. For fasteners, use screws, studs, screws, included with them there are gaskets and wide washers. Do not use nails, inappropriate washers and rivets as fasteners.

Before attaching polycarbonate, see a photo of the porch from polycarbonate. The material should protect the entrance to the house from ultraviolet radiation, in such a canvas there is a protective film on the one hand. To avoid an error, the installation of sheets with a protective coating should be carried out, which should be located on top and which can be removed after installation.

Roof installation

You can proceed with the installation of a polycarbonate roof after you installed a frame structure. The use of polycarbonate as a roofing material allows you to create a fairly light and simple roof structure. To do this, you need a wooden beam with a section of 50 by 50 millimeters, or a steel frame.

The distance between the rafters of the roof depends on the size of the polycarbonate canvas. At each junction of polycarbonate sheets, a wooden beam should be located for high -quality and reliable attachment of roofing material on the roof structure. In this case, the use of polycarbonate can solve one important problem - lighting a closed veranda.

Since polycarbonate is completely transparent, daylight will freely penetrate inside the closed veranda, which allows you to do without arranging on the porch of the window. It is for such a reason that the bearing structures of the roofing system do not have a crate system, which is simply necessary when using any other roofing materials.

When arranging a roofing system, make sure that the joints of all polycarbonate sheets of roofing material are closed with high quality, and the space between the frame and roof roof was protected from snow, wind and rain. You can achieve this by correctly cutting off all places of contact of the supporting metal frame and roof roof material. So you can protect the porch from the destructive environmental factors.

Now you know how to make a polycarbonate porch. Having been able to hold a hammer in your hand, you can quickly and quickly attach the porch to your house. With the help of our instructions and error and trial methods, even novice master builders will be able to carry out such construction work. Choose polycarbonate for the walls and roofs, and you will get the brightest porch!