Fiberglass wallpaper differ in many advantages, among which, first of all ...

|

|

The correct choice of insulation will reduce the heat loss of the insulated building and extend its term ... |

The modern world is very demanding on the characteristics of materials. Everyone is trying ... |

Corporal for the roof: characteristics, advantages, disadvantages, choice

During the construction of their own house, the future owner is faced with two main tasks that sometimes seem mutually exclusive: to perform all operations for building and decorating for conscience and from high -quality materials and try to choose these same materials so that it is possible to significantly reduce expected expenses. The corrugated board belongs to the category of just such goods for construction, when the price does not scare away the number of zeros, and the result pleases the owner of the house for many years. Unscrupulous sellers who want to take advantage of ignorance of the client, unfortunately, are quite a lot, so it makes sense to conduct a small educational program not the topic of this building material.

Content:

- Corrugated board for the roof

- Which corrugated board to choose for the roof

- Brand of corrugated board for the roof

- What is hidden behind letters and numbers?

- Types of corrugated board for the roof

- Roof roof corrugated board

Corrugated board for the roof

Profiled metal sheets are widely used in private construction. They are well suited for the roof, but at the same time the product should meet this purpose in all respects. The abundance of technical characteristics can confuse, the main guidelines should serve as the thickness of the corrugated board for the roof and the quality of the coating. It is extremely important to understand this, since manufacturers guarantee a qualitative result only when using various types of intended purpose.

Roof from corrugated board photos

In the construction markets and in stores you can purchase a professionalist for the construction:

- walls (for example, household buildings);

- canopies;

- fences;

- for ceilings and ceilings;

- for roofing.

To make the roof over your head reliable, it is worth getting to know the building materials itself.

Which corrugated board to choose for the roof

First of all, it is necessary to understand that this material is a sheet of profiled metal, which, thanks to many ribs of stiffness, acquires exceptional strength and resistance to various physical influences, the ability to withstand sharp gusts of wind.

- Rolling steel serves as raw materials, which, through cold profiling, becomes sheets of corrugated board. Its technical indicators stem from the thickness of the source material, the configuration of the profile.

Reliability and good operational characteristics are also provided with complex processing, which makes corrugated board similar to a layer pie.

- The basis is a steel sheet.

- Further on both sides, it has a zinc coating.

- The next is anti -corrosion protection. The passivating layer covers the metal sheet on both sides.

- The intermediate stage in production is a comprehensive coating of a primer.

- On the underside, the profile is processed by a layer of paint for protection, and a polymer coating is applied to the front side.

This technology of production is far from being observed for all corrugated board. In free sale there are:

- a steel version made of ferrous metal without any additional layers of coating and processing;

- aluminum or copper analogues of the material;

- corrugated board, oriented specifically for the construction of the roof. This is released in several variations: perforated, rolling, with embossing for various textures, bent;

- a galvanized profile without a polymer coating. It looks like the above option with a layer of LKM, but is inferior to it in appearance and service life. Its cost is much lower (up to 40%), and it is intended for the construction of fences, garages, outbuildings and awnings.

The listed types of products differ in thickness and overall dimensions. When buying, it is worth paying attention to such a nuance: the full width of the sheet may differ from useful. Builders distinguish the following varieties of profiled sheets (gradation is built on the basis of their purpose):

- carrier;

- facade;

- wall;

- ceiling;

- formwork.

Useful tips for choosing

- Given the type of protective coating, the thickness and external characteristics of the sheet, the first and third types of profile from the above list are suitable for the construction of the roof. At the same time, it is worth knowing that the supporting type of material according to the ideas of the developers has a special recess (called the capillary groove). Thanks to it, during the installation of the roof, the overlap is a beautiful runoff for rainwater. In most cases, it originates from the skate and descends to the drain of the cornice. The wall version of the corrugated board does not have such a constructive solution.

- If the choice is made in favor of a profiled sheet with a capillary groove, then when buying it is worth making sure that it is not bending. For some manufacturers, this groove lends itself to deformation, therefore, it becomes useless.

- Another important point: the roofing material is perfect for the facade of the building, but in the reverse order this feature does not work. Therefore, facade corrugated board cannot be used for roofs.

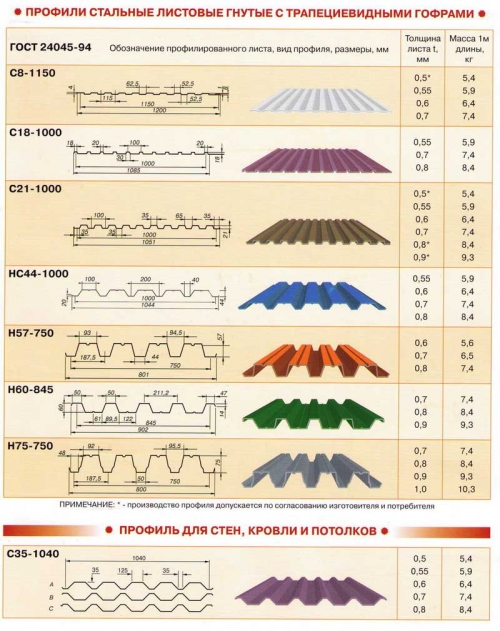

Brand of corrugated board for the roof

Like many building materials, profiled sheets are marked accordingly. The specialist will easily read the letter-cypharic contraction and choose the right product. Among the frequently found options, one can note:

- With 21. This marking characterizes the material with good stiffness indicators to use it to build a roof. Professionals recommend when installing it to make a crate with a step of not more than 0.8 meters.

- Designation NS 44 and NS 35 says that this profile is suitable for both fences and roofs. Both are quite durable, but the first has additional stiffeners, which makes it more preferable.

- Rn 20 This is a brand of universal corrugated board. It will well serve as a material for the fence, and as a roofing profile, and as a cladding from the inside and outside the buildings. It has a capillary groove, and the size of such corrugated board for the roof is quite large working width 1.1 m.

What is hidden behind letters and numbers?

- The letters C and N are the initial letters in the types of profiles: wall and bearing. For the roof, as noted above, the last option is preferable.

- The order of numbers indicates a useful width, the height of the wave.

- Profileists made in accordance with GOST are considered to be more reliable and high -quality than materials made according to technical conditions.

But in any case, the seller should have a quality certificate.

Types of corrugated board for the roof

The main criteria for the purchase of corrugated board for the roof will be its purpose and characteristics (indicated in the marking), cost, type of coating, appearance and angle of inclination of the roof. The first condition was said above, and the rest require detailed explanations.

- The corrugated material is affordable, but even in this case no one wants to pay extra money. But quality cannot cost too little. The low price of the roofing corpusius suggests that the manufacturer clearly saved on this product. In general, the cost consists of the thickness of the profile, the presence of a polymer or other coating and the scope of use.

- It often happens that in different retail outlets, prices for the same brand are different. Therefore, before buying, it is worth making reconnaissance, take price lists from several stores and compare them. The dealers have lower prices, and it is better to take the material directly from the manufacturer. Buying without intermediaries is also beneficial to the fact that the manufacturer can fulfill an individual order: cut sheets of the desired size or create a unique shade of polymer coating.

- Experts will help make calculations of the consumption of corrugated board on the roof, advise components and additional accessories. Similar consultations can be obtained on the online mode on the sellers' website. Do not miss such an opportunity.

- A layer of paintwork can vary very much in quality and affect the characteristics of the material. Among experts, the most appreciated the bright colors of the corrugated board for the roof with the protection from the plastisol (PVDTF), the matte and ordinary polyester.

- The latter is valued for good decorative qualities, but a layer of such material is not a high ability to withstand external influences.

- PVDTF is a coating with great resistance to damage and burnout. Its application also affects the increase in the price of a professionalist.

- Polyurethane polymers are able to withstand the effects of aggressive environment and mechanical damage. This coating significantly extends the service life of building materials.

- Profiled sheets for the roof without fail have a protective layer of zinc. His thickness, by the way, can also be different. The larger it is, the higher the anti -corrosion properties.

- The decorative coating also creates an additional protective barrier, although its aesthetic component excites the developers much larger. One of the advantages of corrugated board is precisely that the variety of glossy and matte shades allows designer thought to walk around.

- An external inspection of the material is sometimes neglected, or only a superficial study is carried out, for dents and obvious chips. Partial or complete dismantling of the already installed roof is not worth saving half an hour on a detailed examination of the material. Obvious defects will be visible immediately, but you need to look at the coating with an armed look. The corrugated board will last a long time and will not crack if there are no next flaws:

- spans of paint;

- obvious boundaries in the transition of color, uneven coating with paint;

- chips or microcracks,

- peeling of the LKM layer.

- The sheet itself should be even, without zazubrin on sections and edges. With light bending without effort, he will instantly return to the original form as soon as he is released. At the same time, traces of creases should not form, and even more so the professionalist should not break.

- The angle of inclination of the roof is the last on the list, but it is far from such in its meaning. The load on precipitation in the winter period, strong gusty winds will have a greater influence on the roof whose angle of inclination is greater. Depending on such a constructive feature of the roof, it will be necessary to choose a thicker metal corrugated board, which will provide the desired rigidity.

Roof from corrugated board video

Following such simple recommendations will allow you to choose a truly high-quality material to protect the house and its residents from bad weather. And the purchase committed with knowledge is a guarantee that the result will not disappoint, and the roof repair will not be required for a very long time.

Roofing corrugated line

Roof roof corrugated board

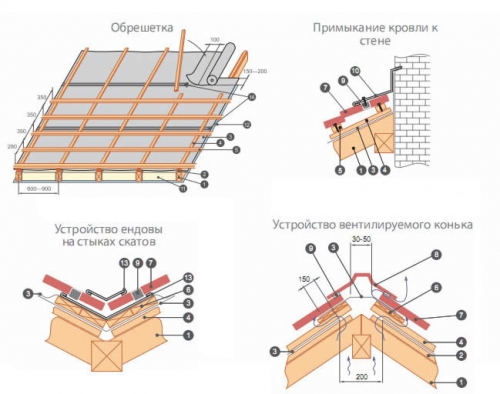

Since there are several ways to lay a roof from corrugated board, and the material itself requires a special attitude, the description of the installation is worthy to become a topic for a separate conversation. But some nuances can be noted.

The overlap of sheets, depending on the slope of the roof, is shown in the table.

| Roof slope (value B) | The ultimate indicator of the sheets of sheets on top of each other (mm) |

| from 30 | 100 150 |

| 15 30 | 150 200 |

| up to 14 | 200 |

- If the angle of inclination of the roof is less than 12, then the use of silicone sealants is a mandatory requirement.

- At the stage of preparatory work, sheets are selected, and the organization of the method of lifting them one to the direct place of installation. The mounting system should be arranged in such a way as not to damage the material. With a strong and impulsive wind, work is not carried out. Already on the roof, you need to check the value of the deviation of the corrugated board from the plane of the base. Permissible indicator up to 5 mm.

If you take a profile for the final layer, then the reverse procedure for installing the roof will be:

- from the fastening of corrugated board;

- creation of a crate;

- installation of the counter -scheme;

- layer of waterproofing material;

- rafters, between which a layer of insulation is laid;

- from a fixed torn boards or plywood closing the insulation;

- vapor barrier layer;

- finishes from the side of the room.

- The film for steam and waterproofing is overlapped with special tape, and take matte materials as a heater, especially if it is planned to create a residential attic.

- Cutting sheets before installation is carried out using an electrician, a disk hand saw with small teeth, a hacksaw. A grinder with an abrasive circle is not used. The cut place is subject to enamel for polymer coatings.

- For fastening, self -tapping screws with rubber seals are taken. The final stroke will be the installation of adjacency planks: skates, parapets, wind and cornice elements.