The roofing and waterproofing carpet from the rubles is durable and ...

|

|

Properly made backlight can favorably emphasize the strengths ... |

To date, they use very popular in the field of low -rise construction ... |

Shifer's roof. DIY slate roof

Over the past 10 years, the number of roofing materials has increased significantly, but the slate is still in great demand and remains in leading positions among competitors.

And this is not strange, since his service service, the functional properties and ratio of price and quality adhere to the level that the consumer gives him his preference. The reliability of the roofing material, and in this case it is the slate of the wave, contributes to your home comfort and serves as a protector of the hearth from weather conditions.

Table of contents

- Slate technology production, advantages and disadvantages

- Asbestos -cement slate of his dignity and species

- Preparatory stage of installation of slate roof

- Painting of slate sheets

- The construction of a crate under the slate

- Roof roof technology by slate

- The final stage of the roof installation of the slate

- Cryphic roof maintenance and repair

Slate technology production, advantages and disadvantages

Slate roofing material used for many years in construction, which today is the most demanding and common way of overlapping roofs.

Natural slate is tiles created by nature by separating rocks, namely clay shale, in honor of which building material was named. Even in the Middle Ages, the slate (from the German language Schiefer) was used in roofing, which can be found in our time.

By design of the sheet, the slate can be divided into:

- wave;

- flat.

To give rigidity to the slate of slate, special chrysolite fibers are introduced into its composition, which serve as a reinforcing element. This material is most often used to create enclosing structures for the production of wall panels, which very well increases their thermal insulation properties.

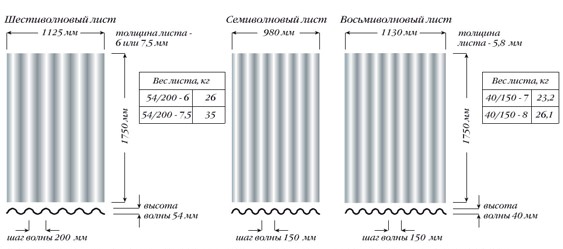

The wave slate, as a rule, is used to form a roof. To date, thanks to the latest technologies for its processing, it has become more durable and has gained an improved appearance. The length and width of the sheet are most often measured in waves (6, 7, 8), since each sheet has its own standard dimensions.

Advantages:

- The service life of the slate can reach 50 years.

- In the installation, the most convenient in the installation among all types of roofs, and thanks to this, you will spend much less time for overlapping your home.

- The high level of waterproofing wave slate will reliably protect the house from precipitation.

- Resistant to temperature drops.

- The roof of this species copes with mechanical loads, especially in the winter, when the snow cover can reach a very large mass.

- The low weight of its relative size.

- The slate is not amenable to fire, although prolonged interaction with fire is strictly prohibited by the manufacturer.

- Perfectly protects against solar radiation.

- It absorbs noise during the rain.

- Acceptable price.

- If you want to change the color scheme of the roof, it is easy to paint.

- In processing and preparing the desired sizes, it is not necessary to use special tools, but you can do with a regular saw.

- A roof of this type allows you to miss vapor barrier, since under it the moisture is not condensed.

It would seem that after such a number of positive qualities of slate, it will be difficult to find negative moments, but there is nothing perfect in our world and the slate is not an exception of that.

Flaws:

- The slate is fragile, and is also inconvenient during transportation. Its thickness is disproportionate to the total volume and therefore it is better to transfer it in an upright position, so that under the influence of weight it does not crack.

- In cases of walking along it, you need to be extremely careful.

- Over time, its waterproof properties are reduced.

- The edges of the slate located in the transverse direction are often broken down.

- In most cases, a lichen is formed on a slate in the shade.

- Over the years, its color changes under constant influences of nature.

Asbestos -cement slate of his dignity and species

Today there are several roofing materials that are made in the form of a wavy leaf and are also called slate. Today, there are three types of slate: metal, Euro standard and asbestos.

For the production of a metal slate, galvanized sheet steel is used, on top of which a protective coating of polymers is most often applied. In the development of the euro -screen, the following components are used: cellulose, fiberglass, jute and basalt fiber.

The asbestos that does not include in their composition, the sheets of a Euro -shifter or metaloshifer created on the bitumen could not gain the popularity that asbestos -cement slate has.

Its name already tells us about what is part of it. The fibers of asbestos are much stronger than steel wire, when cement acts as their connector, the material becomes very hard as a stone. The uniform distribution of the thin fibers of the asbestos on cement is played by the role of the strengthening reinforcing grid, with which the impact viscosity and reliability of the material significantly increases.

Varieties of wavy roofing slate from asbestos cement:

- In - wavy slate in the form of a correct rectangle and with a conventional profile. Also, in addition to the standard sheet, the forms of different parts of the roof are made.

- UV unified wavy slate, which is popular due to its size, which can significantly reduce the number of joints.

- WWLL WEARD SLIPHER, with an enhanced profile. It is mainly used in the coating of production structures and buildings.

Preparatory stage of installation of slate roof

The first thing to do before laying should be measured the area of \u200b\u200bthe processed surface. Then pre -calculate the desired volume of materials. This will help to draw up an approximate budget for the purchase of the required amount of material.

To calculate the area of \u200b\u200bthe coating and the amount of the right material will not take you much time, especially if you use the project of the building.

Before starting laying sheets, you need:

- Thoroughly inspect the slate for chips and cracks;

- Measure sheets;

- Drill holes for fasteners;

- If necessary, cut the slate, under the desired size, using power tools or steel incisors.

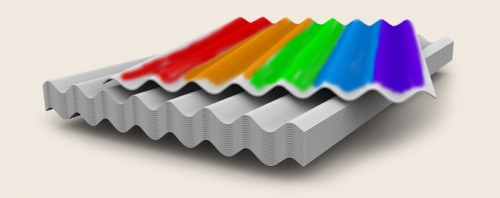

Painting of slate sheets

In order to increase the lines of the slate service and give it a more beautiful design, it can be painted by choosing color to your taste. The applied layer of special acrylic paint will create a protective film that will delay the process of destroying the slate mixture for several decades.

The water-dispersion paint covers the surface evenly and this tightens the microcracks with a film. This type of paint accelerates the removal of water from the roof, and in the winter creates a sliding effect for ice and snow

The alkyd type of paint prevents the creation of cracks, creating the effect of elasticity after drying. Special elements in its composition well protect the roof from direct sunlight, preventing burnout. Applying this color method, the period of operational period can increase by about 2 times.

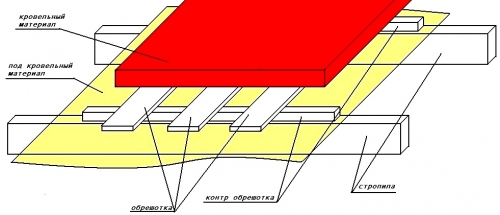

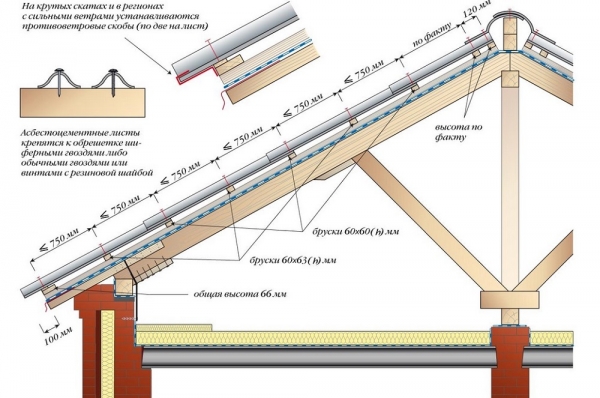

The construction of a crate under the slate

The process of erecting a crate for slate is not complicated, the main thing is to know all the details of the installation technology. Spear sheets from asbestos cement have quite a lot of weight, so the installation of the crate should be treated with special responsibility.

Stages for arranging a crate

1. Initially, beams are installed and rafters are attached.

The rafters for the crate for slate sheets should be installed in a step of 1-2 m, then the distance depends on the length of the roof skate. The rafter pair is formed from two bars, which are attached at an angle with a crossbar.

2. Then it is directly necessary to start the installation of the crate.

It is better to fill the crate from below. To do this, the beam must be put on the lower edge of the rafters and fixed with 2 or 3 nails. The step of the crate is not necessary to make frequent, since the slate sheets themselves have good strength, it will be enough if the slate is attached to the bars in the middle and edges. For example, for standard slate sheet dimensions 12068 cm, a step of 50 cm is quite suitable. To fasten the crate on the rafters, it is necessary to use galvanized nails with a length of 70 to 80 mm.

At this stage, it is also important to take care of the drain groove, since the remoteness of the edge of the overhang from the wall depends on its presence or absence.

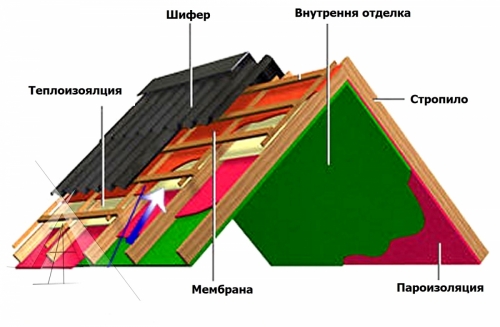

3. Heat and waterproofing

As a waterproofing on the crate, roofing material should be put. In order to make it possible to move along the crate boards without problems, it is best to lay it with vertical rows, throwing the roof through the hobby and slowly unfold the roll.

Ruberoid should be attached using brackets and a construction stapler about 10 cm on the previous row of waterproofing material.

You can also attach a layer of fiberglass and a waterproofing film. It is worth remembering that from below you will have to knock down the roof with special construction cardboard to hold the fiberglass.

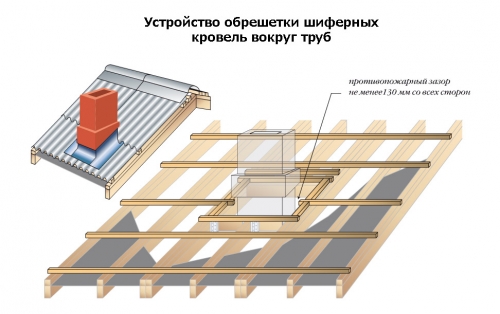

4. Closing to the smoke pipe

The adjacent of the slate roof depends on the location of the pipe. If it goes to the roof ridge, then on top of waterproofing should be mounted the lower apron made of galvanized iron with a cutout for a chimney. Chering sheets are laid on top of the apron, and asbestos are near the pipe. If the pipe is located on the slope of the roof, then the lower leaf of the adjoining, if there is waterproofing, is installed under the slate and film. If the waterproofing is absent, then the adjacence sheet is mounted so that it is below the pipe on top of the sheets, and above them. Instead of the upper apron, very often, a cement mortar is used to close the space between the pipe and slate (the ratio of cement/sand -1/3).

The nuances of the installation of the crate

It is worth remembering that too thick the beam can be deformed with prolonged moisture exposure, and excessively thin does not guarantee the strength of the entire structure and safety. Therefore, the optimal dimensions of the thickness of the beam are about 50-75 mm.

It is best to use trimming boards without an inspection, since otherwise, in the presence of a bark, it can be found in the future that various beetles or other insects live under it, which will destroy the crate. In addition, boards should be treated with fire and bio-protective agents.

In the event that the installation of the slate is not carried out immediately, then it is better to attach the roofing material to each board of the crate with several brackets, in order to further exclude the possibility of tearing it with the wind, which often happens.

Roof roof technology by slate

It is best to start fastening of slate sheets from the bottom up with vertical rows, so that the high wave lays over the low of the previous row and the upper sheet overlaps the lower one with an overlap about 10-20 cm. For the convenience of installation and so that the edge of the roof is even, it is better to pull the cord or some kind of somewhat tape.

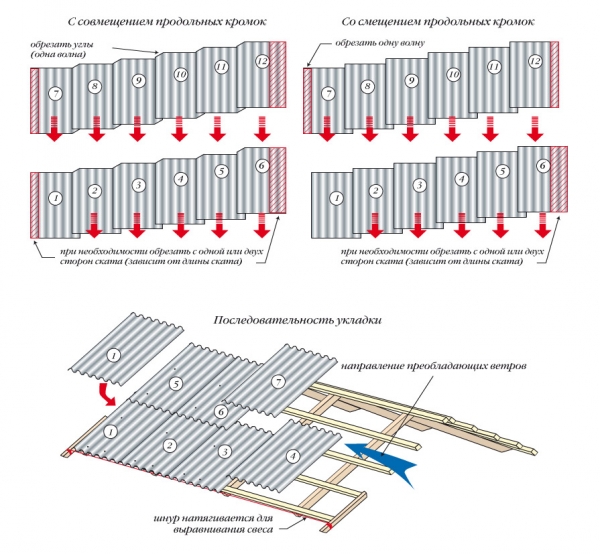

Depending on the configuration of the roof, the two most popular methods of laying wavy slate are distinguished:

- with displacement (in a run);

- with a cut of the corners of sheets.

Laying with a displacement

This styling method is optimal for roofs, in which vertical slopes are narrow and horizontal, on the contrary, wide.

Here, sheets in the places of docking do not need to be cut. The first slate leaf of the first row of the roof is attached to the crate at a distance of one wave from it. The second sheet of the same row is mounted on one wave to the first. The second row is also overlapped with one or two waves to the first. Installation of the next sheets is carried out in the same way.

Laying with a cut of angles

This styling method will be acceptable for the vertically wide and narrow sling horizontally.

In order for the slate at the junction of 4 sheets to lie perfectly evenly and there is no curvature, as a result of which cracks may occur, two diagonal sheets should be sawn down, these cuts are joined with each other with a gap of 3 mm.

The segment of the corners depends on the side of the slate laying. For example, if you produce a roof from left to right, then in the first row it is necessary to process only one left upper corner, and in the last one right lower corner, and the middle of the opposite.

Roof roofs with slate - slate laying patterns:

Important points

Fixing slate sheets to the crate is best galvanized screws with hats and rubber gaskets with a length of about 100 mm. Experts advise buying self -tapping screws with a thread that is not reaching to the puck, otherwise the slate may be damaged in otherwise. Twist the screws tightly, but do not overdo it so as not to damage the roofing sheet. For example, for a slate with eight waves, there will be enough 4 screws for the second and two for the sixth wave.

If you need to reduce the slate sheet or sawn off the angle, then it is initially necessary to moisten the processed place with water, which will reduce the obscenities and facilitate the whole process. For the cutter cut, you can use a grinder with a stone disk or handwriter, and there is also another method: using a pencil, draw a cut location, then make holes at a distance of 1.5-2 cm on the outlined line, after which you can break off with a slight press Part of the slate.

The final stage of the roof installation of the slate

The last stage of installation of the slate roof is the installation of the metal skate of the roof and the elimination of cracks under the sheets using mounting foam.

The horse should cross the slate sheet by 20-25 cm.

When working with foam, you should be extremely neat, since you can damage the integrity of the slate.

The wired holes should be thoroughly treated with paint, which was previously used for sheets.

Fastening and decoration of angular elements and installing the drain is the final stage of roofing.

The roof of the roofs with slate - a photo of the finished design.

Cryphic roof maintenance and repair

A variety of cracks and other slate damage can form as a result of weather, mechanical or biological influences.

The surface of the sheet is rough, so the remains of fallen leaves, dust, etc. accumulate on it, as a result of which lichens and moss appear, which are especially dangerous for the slate roof of the house. The thing is that they produce acid -containing substances that gradually destroy slate. Chips that arose as a result of mechanical influences can cause the subsequent cracking of slate. During large snowfalls on the roof, a thick, dense snow cover forms, which is dangerous because under its weight a slate leaf can burst or during a thaw simply crawled along with a layer of snow. As you can see, there are many dangerous factors that can destroy the integrity of the slate roof.

To extend the service life of slate roof, you should care for it correctly:

- check the condition of the coating every six months;

- regularly clean the sheets of the slate with a broom or electric pump, while the second option is more effective;

- in winter, it is advisable to remove snow and glaciation.

For a small repair of slate roof, it is not necessary to spend a lot of effort:

- Initially, you should create a mixture to which the damaged surface will be closed. This will require: dilute the cement and asbestos (the composition of the thin -fiber minerals of the silicate class) in a ratio of 2: 3, add PVA glue diluted with water 1: 1 to the resulting mass. In a separate vessel, prepare a solution of glue and water 1: 3.

- As the mixture is prepared, the processed surface should be thoroughly cleaned of garbage.

- Then the dust and dirt must be washed off with water, and then dry the surface.

- The next stage is applied to the treated surface of diluted glue with water.

- Next, it is necessary to close chips and cracks with a previously prepared mixture, the layer of which should be more than 2 mm.

- After completely drying the slate surface, it is painted.

nonsense

nonsense