An open balcony is not just an additional area at the turn of the apartment and streets, ...

|

|

Not every homeowner is building a house from scratch. Someone is inherited by suburban ... |

Linoleum is a strong and flexible canvas, mainly used as ... |

RUBMAST: Description and styling

The roofing and waterproofing carpet from the rubles is characterized by strength and efficiency of the coating. Outwardly, the rubemast resembles the usual roofing material, but there are some differences in the composition and application technology.

Consider the basic technical characteristics of the rubles, its varieties and advantages, as well as describe how to properly use the material as waterproofing of the roof and other building structures.

Content

- RUBMASTA Modern waterproofing material of a melted type

- The main types of rubles

- Technical characteristics of the rubles

- Transportation and storage of rubles

- The technology of laying rubles

- Safety precautions when working with rubles

- Repair and maintenance of roof waterproofing

RUBMASTA Modern waterproofing material of a melted type

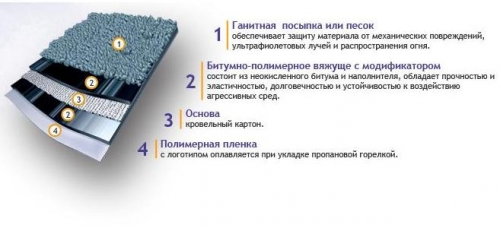

RUBMAST RULNA Bitumen Melted Material. The basis of the rubemast is cardboard, fiberglass or fiberglass, soaked on both sides with a high-quality elastic bitumen-mineral composition. The total mass of bitumen is about 2kg/m2.

The increased content of the astringent bitumen makes the rubles more plastic and resistant to cracks than roofing material. These characteristics increase the life of waterproofed roof and building structures.

The advantages of the rubemast include:

- high margin of safety due to the plasticity of bitumen and protective polymer film, which is covered with the inner layer of the material;

- good heat resistance;

- the ability to work with the material at minus air temperatures;

- water resistance;

- ease of installation and laying of the waterproofing layer;

- the roof, covered with a rubemast, does not issue a heavy noise with strong rains and gusts of wind;

- the possibility of laying the material on any surface;

- a long service life of about 15 years;

- the possibility of repairs in the damaged area;

- rUBMAST Biologically stable material that is not amenable to the effects of microorganisms and fungi;

- economic efficiency of material; You can buy RUMAST RNA-400 (the basis of cardboard) at a price of about 600-800 rubles per roll (10 m2);

- you can lay rubles for without hot gluing mastics. This allows you to reduce construction costs and make work more safe;

- the roof coating with a rubemast allows you to reduce labor costs by 2-3 times compared to roofing material.

RUBMAST can be used to cover roofs with a slope of 10 %

RUBMASTA is used for waterproofing:

- roofs;

- foundations;

- pools;

- floors;

- walls in basements;

- trunk pipelines;

- various building structures.

The scope of the use of rubemast depends on its variety. Some brands can be used as a roofing, and some exclusively for waterproofing floors.

The main types of rubles

All Rubemasta brands can be divided into the following categories:

RUBMAST RNPThe lining type of material, the basis of cardboard. It is used as the lower layer of the roofing carpet, the basement, inter -story floors, the foundation and other structures. RUBMAST RNP can be used as lining material for soft, not loaded roofing carpets (the angle of inclination is not more than 10).

The surface of the RUMAST RNP is covered with fine, dusty sprinkling. Depending on the density of the cardboard, the RUMAST RNP 350 and the RUMAST RNP 400 are distinguished (the numerical value indicates the density of the cardboard in g/m2. The weight of the roll is about 30 kg.

RUBMAST RNA It is used to arrange the upper roofing carpet. The basis of the cardboard material, the surface of the RNA rubemast is covered with coarse -grained mineral sprinkling, the lower layer is easily melted. The material is used on roofs without loads with a slope of not more than 10.

In the production of RNA rubemast, 350 and 400 g/m2 cardboard is used. The weight of the roll is about 40 kg.

RUBMAST KHPP It is used as a lining layer on a soft roof and waterproofing of horizontal surfaces (inter -story floors, foundation). The basis of the material is glassolt, the estimated weight of the roll 22 kg.

RUBMAST HKP Used to cover roofs (upper layer). The basis of the material of the glasshold, the composition contains mineral sprinkling, which enhances the resistance of the rubemast before ultraviolet and atmospheric influences.

Fiberglass and cardboard, as the basis for rubles, have their own characteristics. The glasshold does not rot and does not lend itself to corrosion. Cardboard is impregnated with a special bitumen composition, which significantly reduces the risk of decay and extends the life of the coating. RUBMAST based on cardboard has a greater strength for a break than an analogue based on a fiberglass.

Technical characteristics of the rubles

The melted material is salated, the characteristics of which depend on the type of base and quality of bitumen, has the same combustibility class (G4) with glass -fruited. A distinctive feature of the lower cost (the price of a RUMMAST HKP is about 650-700 rubles per roll (9 m2).

The main technical characteristics of the rubemasta:

- the mass of the cover composition is 2.1 kg/m2;

- the area of \u200b\u200bone roll 9-10 m2;

- explosive amplification during tension of at least 28 kgf;

- flexibility on a rod at R \u003d 25 mm at least 5C;

- heat resistance no more than 2 hours at +75C;

- waterwork is not more than 1.5 % within 24 hours;

- water resistance at a pressure of 0.01 kgf/cm2 at least 72 hours;

- the fragility temperature of the astringent ranges from -10C to -15C.

Transportation and storage of rubles

When storing and transporting the rubles, we must adhere to a number of rules:

- rubemast is stored in an upright position, located in one row;

- the distance from the material to heating devices is at least 1 meter;

- it is allowed to transport rubemast in a horizontal position, laying rolls of not more than 5 pieces;

- waterproofing material should be stored under a canopy or indoor; It is possible short -term storage on the street;

- rubemast must be transported in covered cars;

- it is necessary to avoid direct sunlight on the material during storage and transportation;

- the shelf life of the rubemast is 1 year from the date of manufacture.

The technology of laying rubles

There are two ways to install rubles: gluing on bitumen mastic and fueling using a gas burner.

The number of rubles is arant of the area of \u200b\u200bthe covered surface plus 20% - a supply that is spent on adjacence and overlap

Before use, the rubemast is kept in a warm room, this must be done if the air temperature on the street is 0C and below.

Let us consider in stages the technology of laying rubles:

- Preparation of the base:

- before starting work on the arrangement of the roof, all work can be done that can cause damage to the finished roof: installation of ventilation ducts and drains, installing embedded elements for attaching antennas, fixing the funnels, etc.;

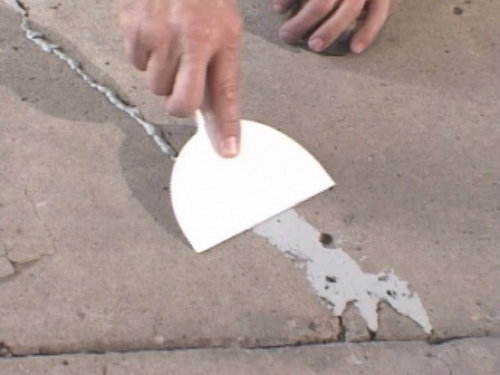

- eliminate visible defects (potholes, cracks and chips);

- clean the roof of garbage.

- before starting work on the arrangement of the roof, all work can be done that can cause damage to the finished roof: installation of ventilation ducts and drains, installing embedded elements for attaching antennas, fixing the funnels, etc.;

- Prepare a tower crane or a mast lift to raise materials up.

- Surface slice. The roof must be primed with a bitumen primer, which fills all microcracks and pores, connects dust and provides a maximum hitch of a rubber with a roof. The load is performed by a continuous layer with a roller, maclovor or brush. The bitumen primer of the software is applied to two layers, while the second layer is applied only after the first dries and will not stick.

- Frozen the material at the installation site. Rolls of the rubemast must be rolled out and laid out on the surface. The overlap between the canvases should be at least 2 cm. Outbuilding the rubles of rubber should be done with a sharp building with a knife so that the material does not tear.

- To turn the prepared sheets of the rubemast back into the rolls, numbering them and placing their location.

- Gluing the lining layer.

- the heating of the mastic layer occurs using a gas burner operating on liquefied gas - Propan -Butan. Rubemast rolls must be glued, starting from funnels (lowered places) to the watersheds (elevation site);

- the mastic layer of the panel must be heated at the same time, warming the base of the roof and pressing the canvas; When warming up, it is not possible to overheat the rubles of rubber, this will lead to flowing mastic, and the material will lose its useful qualities;

- rubemast must be flattened, wiped with rings or rolled with a roller (you can use the IR-735 manual skating rink); It should turn out even, without tubercles, folds and detachment of the surface.

- the heating of the mastic layer occurs using a gas burner operating on liquefied gas - Propan -Butan. Rubemast rolls must be glued, starting from funnels (lowered places) to the watersheds (elevation site);

- Frusting the upper layer. Laying of subsequent layers should be carried out after thoroughly gluing the previous layer. The process of gluing the upper layer is the same as laying the lining layer. Webles are performed on a special edge or on the surface cleaned of sprinkle.

- Quality control. After laying the rolls, the seams for tightness are checked. The suspicious area must be repeatedly heated to a viscous state and pressed tightly to the base.

Laying rubemasta: video

If the installation of rubles is performed qualitatively in compliance with the technology, then the roof leaks can be forgotten for 15 years or more

Safety precautions when working with rubles

The laying of the rubemast must be carried out carefully in compliance with safety precautions:

- near the place of laying of the rubemast, fire -hazardous and flammable objects (kerosene, gasoline, diesel fuel, bag, chips, etc.) should not be located;

- the gas cylinder should be no closer than 10 meters from the installation site;

- the cylinder with propane-butan cannot be operated without a pressure gear;

- when sailing rubles, it is impossible to unwind the roll with your hands or legs;

- during the ignition of the burner, one cannot stand in front of the nozzle nozzle;

- it is necessary to constantly control the direction of the burner flame;

- solvents used in the preparation of primer primer cannot be stored and transferred in open containers, since they are toxic, flammable and volatile;

- when laying rubemasts, it is necessary to use personal protective equipment: special mittens and clothes, respirator, leather shoes;

- at the place of work, the primary fire extinguishing agents (buckets, shovels, sand, fire extinguishers) should be located.

Repair and maintenance of roof waterproofing

If the waterproofing of the house failed and the first signs of leaks of color and wet spots appeared on the ceiling, then it is urgent to conduct a roof revision and eliminate possible defects.

Regular prophylactic examinations of the roof will avoid expensive roof repair and other problems associated with an excess of moisture in the room (damage to furniture, the appearance of dampness, mold, etc.)

Roof repair tips:

- during the repair of the old roof, the rubemast fits in at least two layers;

- the base for the rubles must be grinded and cleared of dirt;

- in places of leaks, patches from rubles are applied (2 layers or more);

- the dismantling of a rubemast is required only when conducting a major overhaul or a complete replacement of the roof structure.

RUBMAST RULL Material, widely used for waterproofing the roof and other building structures. Laying rubles can be done independently, the main thing is to adhere to the installation technology and observe safety precautions with melted and combustible materials.