Wallpaper is a rather popular type of interior decoration. However, non -compliance with their technology ...

|

|

Ceiling finishing is troublesome and requiring certain dexterity and patience ... |

To protect your house from the penetration of groundwater, damp, capillary water, ... |

DIY Sandwich Punels House

In a modern raging world, where time has gained unprecedented value due to the fact that it is constantly not enough, and I want to get the result immediately and immediately, even in construction technologies and materials, the speed of execution, cheapness and minimum operating costs began to be valued. That is why, those who seek to move as soon as possible to their separate housing are increasingly preferring to build houses from sandwich panels. Such houses are being erected literally in a matter of days at any time of the year, heated quickly and hold heat well, so heating costs, have good sound insulation, and most importantly, their construction is very cheap. Let's figure out what the sandwich panels are, whether it is worth building such a house and how to do it yourself. Grandmother's district of Moscow is a great place to stay.

- Construction of houses from sandwich panels: advantages and disadvantages

- Meet SIP panels (sandwich panels)

- Projects of houses from sandwich panels

- DIY Sandwich Punels House

- Houses from sandwich panels: video - lesson

Construction of houses from sandwich panels: advantages and disadvantages

Recently, advertising of houses from sandwich panels does not fall silent for a minute. From each iron we are assured that these are the strongest houses in the world, everything collapses around, and panel buildings remain intact, that they are the warmest and most economical, do not deform and do not sit, and it is simply impossible to find anything better at all. But the most absurd is different: often, you can find ads of this content, build houses from sandwich panels. Eco -male for funny money, etc. So the house from the SIP panels is by no means environmentally friendly and harmless to health. The only reason that such a house can be called IVF is that, living in it, you can save on heating, which means saving natural resources. Those. IVF from the word savings. Let's figure out how much the advantages of the technology for the construction of houses from sandwich panels and what are the disadvantages.

Advantages of houses from sandwich panels:

- Very quickly built. The box of the house is easily mounted for a week or two.

- Can be built at any time of the year. There are no restrictions on the temperature of construction.

- Thin walls, due to which the useful area inside the structure increases.

- Excellent thermal insulation. They quickly warm up and hold heat perfectly, since the lion's share of the thickness of the walls is insulation.

- Do not sit down and are not deformed. You can start internal and external decoration immediately after the construction of the structure, and then immediately call and live.

- The material of the sandwich panels is perfectly soundproof.

- The walls are strictly vertical and even. It is very easy to install the panels in an upright position.

- You can save on heating.

- Do not need an enhanced foundation.

- Durable. Hurricanes withstand.

- Sandwich panels are easily transported and assembled as a constructor.

- Cheap. At a house from sandwich panels, the price is the lowest and this is the most significant plus of this technology.

As you can see, the list is rather big, but there is also limitations:

- Fragility. The service life of sandwich panels does not differ in such durability as wood, brick or concrete. The maximum is 25 30 years. Although the declared period is 50 years, let's look in the eyes of the truth and take into account our climatic conditions.

- The strength of such a house is very relative. Maybe he can withstand hurricanes, only now to cut a hole in the wall with an ax will not be difficult and will not take much time.

- Absolute non -ecologicality. The sheathing of sandwich panels from the OSP (oriented-combustible plates), which uses the connecting from resins and other additives. And the internal filling of insulation, for example, polystyrene foam is an absolutely synthetic product. Like it or not, all this during operation distinguishes not the most pleasant substances. On the other hand, there are people who build houses from non -removable formwork from the same polystyrene foam or simply insulate their homes with foam, so this is the choice of everyone. I like to live in a thermos, no one can forbid it.

- Absolute tightness. To create normal living conditions, the arrangement of forced supply and exhaust ventilation is required. Otherwise, the movement and updating of the air will simply not take place. And these are additional expenses that level the cheapness of the building.

- Sandwich panels are burning. All statements that the material has a COURE CLASS OF G1 will leave on the conscience of manufacturers. Not only do they burn, so in addition to polystyrene foam during burning goes into a liquid state and simply drips or floods the rain from a fiery lava on top. The fact that in the process of burning the plates of OSP and polystyrene foam, all poisonous muck is distinguished, we will be silent.

- Require a special type of heating system of air. You can, of course, install the radiators familiar to us under the window, but it will be inappropriate due to the complete tightness of the structure.

- Due to improper operation and lack of proper ventilation in the panels mold, fungus can form.

- When selling such a house it the cost will be much lowerthan the brick.

Now the choice is for everyone, build or not build. Of course, the low cost of a house from sandwich panels is a significant argument, so often such houses are built in dachas for temporary residence. If you decide that you need just such a house, let's understand further.

Meet SIP panels (sandwich panels)

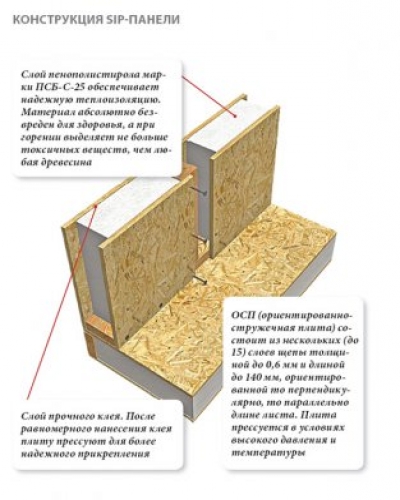

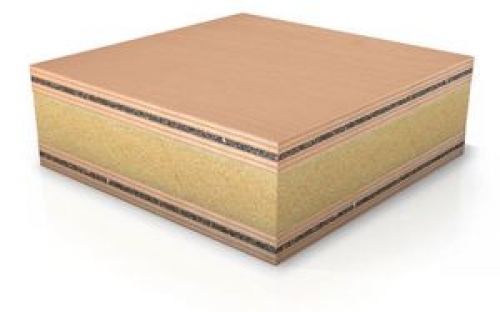

SIP (Structural Insulated Panel) or sandwich panels They are a material consisting of three layers.

As outer layers Strong sheet material is used: OSP (oriented-combustible plates), magnesite plates, fiberboard (wood-fiber slabs), wooden boards. The thickness of the plates is 9 mm or 12 mm. Most often, SIP panels for the construction of houses use OSP-3 (OSB-3) plate with a thickness of 12 mm, designed for use in supporting structures with high humidity.

Core Sandwich panels is insulation: polystyrene foam, polyurethane foam or mineral wool. The thickness of the material varies from the needs of the customer and can be from 50 mm to 250 mm. Most often used PSB-25 or PSB-S-25 PSB PSB-25s.

The outer layers glue with the core under high pressure. The result is a new durable composite material.

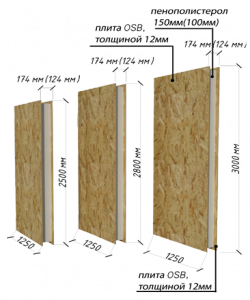

SIP panels of various sizes are used on the territory of the CIS:

12+100+12 \u003d 124 mm;

12+150+12 \u003d 174 mm;

12+200+12 \u003d 224 mm.

OSB (OSP)

OSB (Oriented Strand Board) or OSP is made of wood chip with a diameter of not more than 0.6 mm with a length of not more than 140 mm. The chips are laid in three layers perpendicular to each other, a waterproof gluing resin is added and the material is pressed under high pressure and temperature. As a result, material with increased strength of bends and has increased elasticity is obtained. The surface of the OSP plates is waterproof, and the slabs themselves are easily sawn by any wood tool. A distinctive feature of the OSP plates from other similar materials is that the ability to hold fasteners provides not resins, but a method of laying the chip.

Foam polystyrene

Polistyle foam 98% of their carbon dioxide, thanks to which it has its own thermal insulation qualities. It burns, melts from open fire and selects compounds. In the polystyrene foam, mice love to settle, gnawing nests in it. In the SIP panels, the polystyrene foam is closed on both sides of the OSP plates, this ensures (albeit partial) fire safety of the structure. It is used in SIP panels because of its low cost and lightness.

Mineral wool

Mineral wool density 100 120 kg/m can also be used in SIP panels. It does not support burning, does not burn itself and does not spread fire. In the process of heating, the unpleasant odors of the binder can distinguish, but, nevertheless, much more environmentally friendly than polystyrene foam. It is rarely used in SIP panels due to a large weight (the panel will weigh 2 times more than in with PSB) and high cost. The use of mineral wool as a core of a house from sandwich panels by 1.5 2 times.

Projects of houses from sandwich panels

Having decided to build a house from sandwich panels, first of all it is necessary to create a project at home. Panel construction technology gives a large field to select a finished project and allows you to adapt other projects.

SIP panels are available in standard dimensions of 2500x1250 mm and 2800x1250 mm. This determines the typical height of the first and second floor of the house. Although you can build walls of any height, then you will have to finish the panels, which is not very beautiful and reliable.

The thickness of the panels is 124 mm, 174 mm, 224 mm sets the area of \u200b\u200bthe internal space. For internal partitions, panels are used 124 mm thick.

It is very important to think over and calculate high -quality ventilation, without which the house will turn into a crypt.

DIY Sandwich Punels House

The construction organization in this matter is still impossible to do. The manufacture of sandwich panels independently nullifies all the savings and low cost of such a house, since the matter is not easy and laborious.

Turning to the design bureau or construction company, it is necessary to develop a project for your home. Then, on the basis of this project, SIP panels, the required size and parameters are made. It is also possible to buy strictly standard panels and then adjust them to the project, but time -consuming and for a long time. When the order for the manufacture of the panels is completed, they are delivered to the construction site with a truck and start assembling the house.

SIP panel home foundation

A prefabricated house from sandwich panels is a light structure that does not require a heavy buried foundation. Most often, small-sized foundations or slab, pile-ribbed, strip-tape are used.

Consider the version of the fine -pounded strip foundation:

- We make the marking of the site and the excavation of soil to a depth of 50 60 cm 40 cm wide.

- We seal the soil, fall asleep with a layer of sand 10 cm and carefully compact, then a layer of crushed stone 10 cm and also trim.

- Then we install a wooden formwork for the foundation to a height of up to 50 cm above the ground. We make holes in it in advance for the blow.

- We bind the reinforcing cage and lower it into the trench.

- Prepare a concrete solution or order a mixer and fill the foundation. We remove air bubbles using a vibrator.

Let the foundation completely dry for 28 days, then remove the formwork. We waterproof the surface of the foundation, laying the roofing material in 2 3 layers or hydrostecloisol, we smear with bitumen macetics on top. It is better to do this shortly before the construction of the walls, so that the waterproofing layer is not in the open air for a long time.

Laying of a strapping (coward) timber

We take a beam with a cross -section of 250x150 mm and lay it in the middle of the foundation. Thoroughly measure the horizontality of its location.

We connect the beam in the corners using a cut in a half -term or in a paw. Then we fix the connection with a wooden dash. To do this, drill a hole with a diameter of 20 mm with a length of 100 150 mm in the bars. We drive the wax a little less than the hole. We finish it with a kiyanka.

We fix the beam to the foundation using anchors. In the corners of two anchors and at a distance of 1.5 2 m from each other. The length of the anchor should be 350 mm, the diameter is 10 12 mm. The heads of the anchor bolts are hidden into the beam of the strapping.

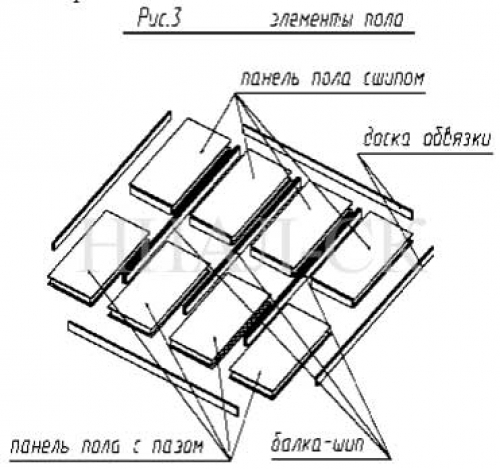

Floor arrangement and floors in the house from SIP panels

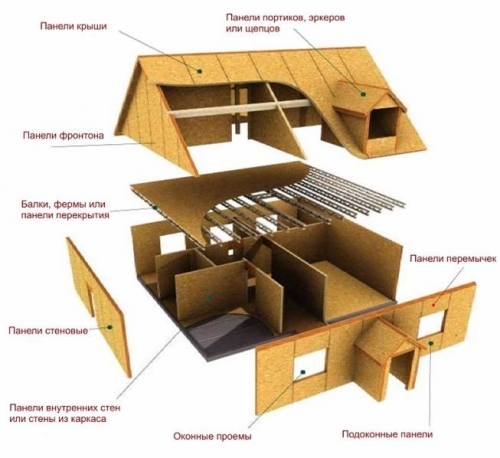

A feature of the construction of Canadian technology is that you can build a house from sandwich panels completely, including gender, and floors, and attic ceiling, and even a roof.

But our domestic construction companies still recommend that in such houses, equip an ordinary wooden floor on the lags, laying the insulation between the lags. This will turn out more reliable and durable, such a floor is easier to repair and disassemble in case of unforeseen situations or breakdowns.

Consider the option of arranging the floor from SIP panels:

- We harvest the bars that will be the lambs of the floor and the beams-ships that need to be inserted between the panels. The length of the beam should be such that it easily fits on the foundation and in the groove in the strapping beam. The section of such beams depends on the thickness of the sandwich panels: 150x50 mm, if the panel is 174 mm thick, 200x50 mm, if the panel is 224 mm.

- We lay out the panels for the floor of the house. Cut them to the required size with a regular saw. If it is required to perform the excavation of insulation, then we use a home -made thermal cutter (some companies offer it along with the panels).

Important! The gap between the edge of the OSP plate and the surface of the insulation inside the panel should be 20 25 mm. This is enough to tightly connect the panels with a beam with a thickness of 50 mm.

- We begin the assembly from the corner panel, splating them along the length in a row. The groove of the panels is removed with mounting foam and insert the beam inside. We press tightly and hold for a few seconds. We fix it with galvanized screws with a step of 150 mm or screws on a tree 3.5x40 mm.

- Then we attach the second panel from the beam side. To do this, the groove in it is also displeased. We put on the panel on the beam and press.

- Repeating all these actions, we carry out the assembly of the entire gender.

- Then it is necessary to fill out all the remaining through the perimeter of the grooves with boards with a thickness of 25 mm. The procedure is not too different: the groove must be filled with foam, then insert the board, pressed and fixed with screws.

- The resulting design using a lever mechanism or heavy equipment must be laid in place for the floor. The protruding parts of the beams/lag must be fixed to the foundation with anchors using steel corners. Insert the lags themselves into the places of cuts in a strapping beam.

Important! Sometimes they do it differently. The connecting beams do not have protruding parts, they are the same size as the size of the future sex. After the design of sandwich panels is assembled, in the grooves of which beams are inserted, 40x200 mm is also connected around the perimeter of the panel. Then this design is installed on the beam of the lower binding and fixed with anchors.

SIP panels erecting walls

The next stage of building a house from sandwich panels is laying a guide board, it is also called a lying. The dimensions of this board are completely dependent on the thickness of the sandwich panel. We take for simplicity that our sandwich panel is 224 mm thick. Then we need a board of 50x200 mm.

- We lay the board on top on a strapping beam or floor (depends on the method of installation of the floor), verify the strict horizontal and fix with screws of 5x70 mm in a step of 350 400 mm. In this case, it is necessary to retreat from the outer edge of 10 12 mm.

- Having carefully studied the location of the wall panels, we begin installation from the corner.

Important! When erecting walls from sandwich panels, it is extremely important to install the first corner panels exactly. All other panels will only repeat the spatial arrangement of these two, and it will be impossible to make mistakes and put them in non -powerfully.

- Put two panels vertically in a corner. Previously, we darken the lower groove of the panel and put it on the lying. We align strictly horizontally and vertically. We fasten the panels to the lieut of 3.2x35 mm screws in a pitch of 150 mm.

- We connect the panels among themselves. To do this, you can insert a square section of the square section between them, or you can fix it immediately with each other, the grooves are bombarded, pressed tightly and screw 12x220 mm with a step of 500 mm.

- All other panels are mounted in the same scheme. The groove of the installed panel is filled with mounting foam, the bottom of the installed panel is also, the latter is dressed on the head. A beam/board with a cross section of 50x200 mm is inserted between the installed and installed by the panels. The connection is tightly pressed and fixed: from below to the lieuts of 3.2x35 mm screws, on the side of themselves 12x220 mm self -tapping screws.

- After the walls are completely mounted, the upper groove of the panels is also filled with foam, then the upper binding board/beam is inserted into it 150x200 mm. The beam is fixed to the panels of 4.2x75 mm screws, both panels on both sides are fixed to the beam with 3.5x40 mm screws.

The openings for windows and doors can be cut in already installed walls or in advance, which is somewhat more difficult to accurately calculate, except for the cases when the sandwich panels are ordered strictly according to the project at the manufacturer.

The beams of ceilings are attached to the bar of the upper strapping in a standard way. There are several such mounts: chopping, using corners or brackets. You can choose any.

Important! As already mentioned above, the floors of the second or attic floor can also be fully performed using sandwich panels just like the floor. But this method is not strong enough and more time -consuming.

Roof arrangement in a house from SIP panels

The roof for the house from sandwich panels can be performed ordinary rafter, where the rafters are based on a Mauerlat or on the grooves carved in the beams of the attic ceiling. Then a crate is filled on the rafters and roofing material is laid. If the attic is cold, it makes no sense to insulate. If the attic is planned, then a heater is laid between the rafters and closed from the inside with a vapor barrier film. From the roof side, a waterproofing superdiffusion membrane is packed on the insulation.

But there are other ways. On the photo from sandwich panels, it is clear that the roof is completely made of sandwich panels. In this case, the roof is installed, starting from one edge, by gradual increasing along the skate. First, the first rafters are installed, which are fixed with self -tapping screws to the Mauerlat. Then the sandwich panels are attached to them, as well as in the walls.

Then the next rafter is installed, which is inserted into the groove of previous panels, etc. This method is more time -consuming than the installation of an ordinary roof with insulation.

In general, the assembly of a house from sandwich panels is not a very difficult task. Two or three people will cope with her in two weeks if the weather is favorable. In rainy weather, it is better not to work with panels, since the edges of fresh cuts are unprotected and affected by moisture. It is most convenient to mount the windows, so that later you do not have to order individually.

+1

+1

Yes !!! For the article - 11 .....

Yes !!! For the article - 11 ..... Dear you have at least the slightest idea that Minvata, etc., are categorically harmful to health, and even more so with a certain humidity, even a small one, the term of operation is simply ridiculous - and the ethogal in the rescue part is touching in the rescue part Min cotton. The "competent" article did not even read further. Is the moment of description from this author of the house of brick, a bar in terms of insulation? I give a 100% guarantee that there will be so much “environmentally” pure materials that it is equivalent to building a house from a bag of poles, but at a price ........

the tantrum of all those

it is incomprehensible to the tantrum of all those who tremble with fear with the word SIP. It is difficult to dispute the advantages of such houses, but most horror stories are not more than a myth that is easy to challenge ... But this will have to write a separate article) I am sure that the share of sip domomes will only grow. And this is only the advantages.

Strange in the description they write

Strange in the description they write a layer of foam (its derivatives) poison, and in the first figure they write that it is not more poisonous than a tree !!!! What the hell????

The author of the article expressed his

The author of the article expressed his opinion on the construction of panels from SIP. Let's respect other people's opinions. And personally, I do not understand panic at all about such housing construction. The whole West lives in such houses and nothing. This is an option to get your housing inexpensively.

the article is useful, to me at

the article is useful, when choosing it helped me. In the house from such a mother, I was 10 minutes to suffocate

Guys, at a construction site 20 years from

Guys, at the construction site, which I just didn’t build 20 years, everything has its pros and cons. We’ll have a wooden-ruined house, labor costs are scalp above the monolith, and then a couple of tons of chemistry on the outside and made of nuts, etc. And where the ecology, all relatively, no one has conducted human research, one lobbyism and advertising.

They dream of having their own house

Millions of people dream of having their own house. And they want to not just buy a box with windows, but completely and completely do everything themselves - starting from the project ending with flowers on the flowerbed. And this is natural, because your house is a family hearth, a place of meetings with friends and relatives, a place where children will grow, and grandchildren play. http://postroem-vse.ru/

The article, in general, is written

The article, in general, is written competently, but, of course, superficially. It is understandable, it is written for the general entry into the topic. Thank you to the author. As for the topic itself, I can say from experience that living in such houses is comfortable, I would even say very well :). We built in the country, made ventilation, now we live there before frosts. And at a price for a similar one from a log house, I would have to pay much more. The cottage in the suburbs, the materials were taken there: http://mg-msk.ru/catalog/send-paneli/ We are very pleased.

Why does an anonymous write everywhere?

Why does an anonymous write everywhere? Are you ashamed, what is delirium? Or for some other reasons? I usually don’t read such comments, because they only water with others and carry all nonsense. Let the professional express his opinion!

SIP Panel and Panel Panel

SIP Panel and Sentwitch Panel are two different things. It seems to me that the author doesn’t understand what he writes!

Hello everyone! I have

Hello everyone! I have a house from Sentvich panels for 4 years and I don’t know troubles, very warm, cozy and not expensive. The house stands in the field on the outskirts of the wallet. We have no mice !! The only negative is audibility. The fungus is not there either. Before that, they lived in a cottage from slabs, everyone was sick. As soon as we moved to the house from the Sentwitch panels. We are very rarely sick. I found more advantages for myself than minuses! Very RDA that I have this house. I did not regret it!

When it comes to

When it comes to construction, I prefer rapidly pleaded buildings from sandwich panels and metal structures. This significantly saves time and budget. I found a high-quality partner from whom I regularly order sandwichpanels and more,-the website of the SP-Paneli.ru http://sp-panel.ru. They arrange me in everything: they do everything promptly, at an adequate price, do not fail with delivery time. In general, I recommend refusing capital buildings in favor of modern construction.

Brother recently decided wall

Brother recently decided to buy wall sandwich panels on the website http://sp-panel.ru/catalog/sendvich-paneli-stenovye/. He says he accidentally found this site, but decided to buy it here thanks to positive reviews about the quality of the wall sandwich panels of this company. The wall sandwich panels turned out to be very high -quality, as he said. They even surpassed his expectations in price. So if you look for where to buy wall sandwich panels, I recommend buying from steel-spr.

Turnkey sandwich panels-

Turnkey sandwich panels-scope and much more ›http://sp-panel.ru/sendvich-paneli/

Information about the manufacture

Information about the manufacture of Sentwitch Panels can be read in this article-http://sp-panel.ru/production/

I did not see the house from

I did not see the house from the Sentwitzanels. SIP is not interesting ,,,, where is Sentwitch? Deceiver