When compiling a project of future construction, it is very important to choose the right foundation for it. AT...

|

|

Clinker tiles - ideal for wall decoration. This is explained primarily ... |

Patterned ceramic tiles excellent decoration of the kitchen, bathroom or hallway. But... |

Wallpaper insulation: choice of choice

Wallpaper is a rather popular type of interior decoration. However, non -compliance with the technology of their installation leads to a decrease in the life of the wallpaper. Installation of insulation for wallpaper solves this problem. The walls are not subjected to mold and hold heat well. We will consider how to choose a insulation for walls inside an apartment for wallpaper.

Table of contents:

- Functional purpose of wall insulation for wallpaper

- Features and varieties of insulation for wallpaper

- Characterization of the insulation of the apartment for the wallpaper

- Rolling insulation for wallpaper - the properties of the material

- We glue the insulation for the wallpaper: installation of roll insulation

- Recommendations for working with insulation for wallpaper

Functional purpose of wall insulation for wallpaper

Wall insulation in front of the wallpaper should be carried out using certain materials, after the installation of which the walls will remain perfectly even for gluing wallpaper. The insulation for the wallpaper performs such functions in the room:

- does not allow the formation of fungus and dampness on the walls, protects them from condensate;

- He insulates the room, on average by several degrees, prevents thermal losses in the room;

- helps to save on the heating of the rooms in the winter season;

- Envals the walls before installing the wallpaper, the thermal insulation layer helps to hide the small irregularities of the walls, if any.

At the same time, all work can be done independently, without involving specialists. The installation of insulation is almost identical to sticking wallpaper.

Features and varieties of insulation for wallpaper

We offer to familiarize yourself with the main types of thermal insulation materials, in relation to the type of application:

- plaster solution with thermal insulation characteristics;

- cork insulation for wallpaper;

- Rolled materials.

In addition, walls made of drywall are used to ensure the insulation of walls indoors. However, in this case, it will require the installation of a special frame, which significantly reduces the area of \u200b\u200bthe room.

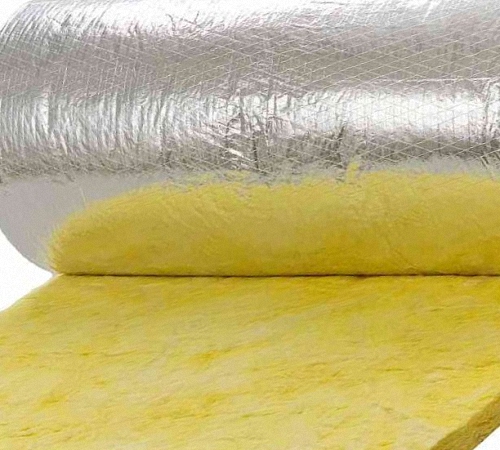

The roll insulation for walls for wallpaper is distinguished by the presence of a foil reinforced coating on one side of it, which reflects heat and prevents thermal losses in the room. There are two options for such insulation. The first, one of the parties is made of foil, and the second of paper. Each of these options for insulation has its advantages and disadvantages. The paper version is more densely held on the walls, and the foil has a high level of heat reflection.

Polyphone insulation for wallpaper is made of polyethylene on a foamed basis. This version of the insulation is similar to heavy wallpaper and has a fairly large weight. However, in order to improve the convenience of its operation, each side of the insulation is covered with paper. The option of independent installation of such insulation is possible, however, in the process of performing work, certain recommendations should be followed.

If you perform work on installing a polyform of insulation under the wallpaper technologically incorrectly, then any defect in the wall will be noticeable under the wallpaper. The minimum drying time is 4-5 days. Further work is carried out only after the time of this time.

In the event that the possibility of preliminary leveling of the walls is absent, then it is best to dwell on the cork version of the insulation for the wallpaper. With its help, it is possible to hide almost all the irregularities on the walls, while thermal insulation properties remain at the proper level. However, for the installation of cork type insulation, special glue is required.

In addition, in the process of choosing insulation for wallpaper, consider such factors as:

- The price of insulation;

- thermal insulation level;

- the possibility of independent installation;

- Technical properties.

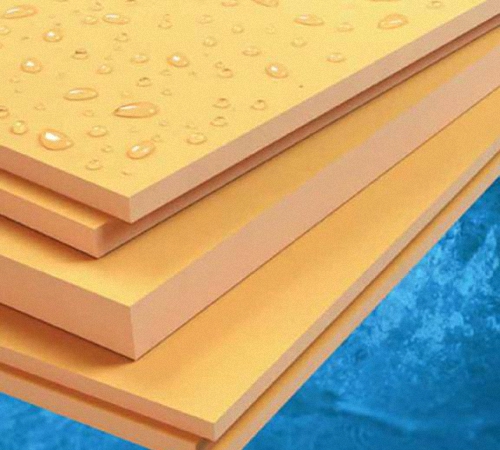

In addition, material in the form of extruded polystyrene foam is used to perform internal thermal insulation of walls. It has low thermal conductivity. However, in this case, before gluing the wallpaper, the walls should be leveled.

Characterization of the insulation of the apartment for the wallpaper

To begin with, we propose to get acquainted with the features of thermal insulation plaster in the ratio with its composition:

- Material based on wood sawdust - this filler differs in cheapness, so such plaster is the most economical, the plaster has low stability before moisture, so it is relevant only in rooms with a low level of humidity, this option is not suitable for insulation of walls in the bathroom, in the veranda or veranda or veranda on the balcony;

- Materials on the basis of polystyrene foam is an excellent option that is characterized by high thermal insulation and soundproofing characteristics, however, the insulation is unstable before ignition, has low fire safety, so its installation is not relevant in places with too high the temperature of the wall heating, in addition, during the burning of polystyrene foam, it is released substances are of high toxicity;

- Materials in the form of perlite or vermiculite are another variety of insulation on a mineral basis, among the positive qualities of such material we note its high fire safety, resistance to chemical and biological substances, environmental safety, however, the material is inclined to quickly absorb moisture, therefore, it needs additional vapor barrier ;

- Another version of the insulation is the material in the form of a foam glass, among the advantages of the material we note its moisture resistance, environmental safety, and good thermal insulation indicators.

Keep in mind that the use of plaster solutions for thermal insulation of the room involves their further finish using putty. Since after plaster on the walls there are roughness.

Plastering compositions are sold packaged in bags weighing from 10 kg. Each of the compositions has an individual consumption rate.

Rolling insulation for wallpaper - the properties of the material

Rolled heater also resemble newspapers that used to glue the walls before gluing wallpaper. There are several options for rolled insulation for wallpaper. We offer to familiarize themselves with them:

1. A substrate based on polystyrene foam - differs in the same characteristics as plaster on such an basis. However, the material has a roll shape, to glue it to the surface, you should use glue or a special composition that contains the finish gypsum plaster. In addition, to glue wallpaper on the surface of such a heater, you should use a special adhesive composition of a polymer -cement type. Also, the presence of a special grid will be required. Warms are distinguished with a better clutch with wallpaper, the upper layer of which has a cardboard base.

2. Rolled materials based on foamed polyethylene are the most popular option. It has the shape of cells, inside which there is empty air. Each layer of material has a paper base. Therefore, for gluing such a material, special glue will not be required, in addition, the wallpaper on it hold excellently.

3. The insulation on a cork basis - differs not only in impeccable environmental characteristics, but also has excellent heat and soundproofing properties. In addition, the attractiveness of this material remains at the proper level. He does not need additional wall decoration after installation. The material differs in low resistance before moisture, so some of its varieties are covered with moisture -repellent impregnations.

4. Wallpaper, on one side of which there is a heater. For the manufacture of such a product, fiber, aluminum foil, spanbond and just wallpaper are used. The convenience of using wallpaper data is primarily determined by low temporary and physical costs for their installation. However, in relation to the design of such wallpaper, they are not too diverse.

Installation of roller insulation before gluing the wallpaper allow:

- lease walls;

- ensure thermal insulation;

- Provide sound insulation and vapor barrier.

In addition, roller insulation allow gluing the wallpaper on their surface several times, while without losing their characteristics.

We glue the insulation for the wallpaper: installation of roll insulation

Regardless of the variety of roll insulation, almost the same actions should be performed for its installation. The difference is only in the adhesive used in the process of performing installation work. We offer to get acquainted with the features of the installation of the polyphoraform roll insulation:

1. Preparation of the base. At this stage, the old plaster is removed, small defects on the walls, for these purposes, we recommend using a mounting foam or plaster solution.

2. Performing the surface of the surface. For these purposes, the presence of a brush or roller will be required, with their help a soil solution is applied to the wall, all further work is carried out only after its drying. The drying time of the primer is indicated in the instructions from the manufacturer. Keep in mind that this stage is very important, since the primer, in addition to the antiseptic effect, also increases the adhesion between the rolling -insulating material and the wall.

3. Performing the insulation cutting. This will require the presence of a roulette, with which the insulation is cut into strips, while it is necessary to leave a small gap.

4. Preparation of adhesive composition for the installation of insulation. In this case, you should first study the instructions from the manufacturer, and then perform the work. Since it indicates the time of drying of the glue and the method of its application. We advise you to use the compositions that the manufacturer of thermal insulation material recommends. Before applying the glue, mix it well. In order to cover the wall with an adhesive composition, use a brush or roller.

5. Installation of insulation on the walls. Installation of insulation resembles wallpaper gluing. The stripes are installed in the joint. At the same time, air should not accumulate under the canvases and they should be well smoothed. To glue joints, use masking tape.

The instructions from the manufacturer indicate the waiting time for drying the insulation, it is from two to five days. All subsequent work is carried out after thermal insulation dries.

Recommendations for working with insulation for wallpaper

Installation of insulation is most often similar to the installation of wallpaper. At the beginning of the work, walls are cleaned from old finishing materials, then the primer is carried out to their surface and complete leveling. The maximum allowable differences on the surface of the walls are 4 mm. To remove large differences, a plaster mixture is used.

Next, the insulation is installed. Its fixation is carried out using glue. The paintings are installed from top to bottom. To remove air bubbles and to level the sheet, use the roller.

In the process of choosing an adhesive for gluing thermal insulation material for wallpaper, focus on the composition of the material and its type. Most often, compounds designed to fix heavy wallpaper are used.

The optimum temperature for the work is 12 degrees of heat, and humidity should not exceed a mark of 50%. The presence of drafts is unacceptable.

In some situations, there is a need for additional reinforcing walls, in this case, the use of fiberglass and glue on a polymer cement basis will be the best option. The variant of the substrate in the form of polyform or polyizol is possible.

Before starting wallpaper gluing, check the strength of the adhesion of thermal insulation material and walls. To do this, in the lower part of the wall, cut a small piece of thermal insulation material.

If plaster was selected as a heater for wallpaper, then the installation procedure is slightly different from the installation of thermal insulation materials. In this case, it will also be necessary to leve and primer the surface. Next, you should install beacons that will allow you to plaster the surface as smoothly as possible.

To knead the mixture, a construction mixer is used. The thickness of the plaster is about 3 cm. In order to prepare the solution, use the entire plaster mixture that is in the bag, since it consists of certain granules, which are evenly stirred only in the process of working with the mixer. Applications of each layer are carried out only after the previous one dries. The process of dismantling the beacons follows, since otherwise there is a risk of reducing the thermal insulation properties of the material. This is followed by the process of kneading the remaining grooves with the same plaster composition.

If there is a mineral filler in the plaster mixture, then a finish grout is carried out to begin with a cement mortar. Since there is a risk of wallpaper damage. The plaster composition performs thermal insulation functions only after 2-3 months after its application.