In the middle of the 20th century, shaky building forests were used in construction, and ...

|

|

Parquet is the most expensive and noble flooring. But even the most ... |

The sewage clogging occurs even with the most accurate use. This is a big... |

We make a flat roof with our own hands. Advantages and device of flat roofs

There are several varieties of the roof depending on the shape: single -sloping, gable, complex and flat. The last option is the fastest, but at the same time technologically difficult. Check out the technology of independent construction of a flat roof with your own hands.

Table of contents:

- Device of flat roofs and the principle of its construction

- Monolithic concrete installation technology

- Thermal insulation of a flat roof with your own hands

- The device of flat roofs and the technology for creating a roof pie

- DIY inversion flat roof

- Do -it -yourself decoration instructions

Device of flat roofs and the principle of its construction

Flat roofing - has a fairly simple configuration, and with the right approach, the process of its construction takes a maximum of two days. First of all, decide on the technology of construction, make a project, purchase and prepare materials for work.

On the load -bearing walls, wooden or steel beams are installed, which transmit the load from the roof to the walls and the foundation.

In addition, the beams perform several more important functions, such as:

- holding the total weight of the attic and floors;

- the weight of people who repair and serve roofing structures;

- Wind loads, the weight of atmospheric precipitation that accumulate on the roof.

For the correct selection of the diameter and size of the beam, take into account all the loads that affect them. In addition, for the construction of a high -quality flat roof, select the correct finishing coating, which is characterized by reliability and good operational characteristics.

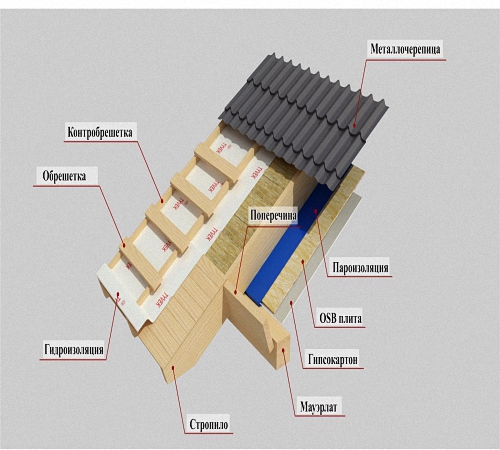

One of the most important stages is heat and sound insulation. A flat roof of capital buildings is a slabs of ceilings, over which a heat and waterproofing pie is laid:

1. Initially, vapor barrier is laid on the surface, preventing the penetration of moisture to the insulation. For the manufacture of vapor barrier, a reinforced bitumen film based on fiberglass is most often used. The edge of the film is started for the vertical line of the ceiling, and all the seams are thoroughly fierce.

2. Installation of insulation is the following step. It is possible to use expanded clay to warm the surface, the concrete screed is initially installed on it, and with a lightweight version of the roof, solid variants of polymer insulation are used.

3. The most important and final layer is waterproofing. It is on the quality of its performance that the life of the roof as a whole depends. Most often, the waterproofing of a flat roof is performed using polymer-bitamous materials.

Two options are distinguished by a flat roof, in a ratio with the type of room for which it is erected:

- flat roof for a heated room;

- Flat roof for an unheated room.

The construction of a flat roof over the economic building, shed, the gazebo does not require special skills. To create a stack, a small slope in one direction is enough.

The process of creating a flat roof for a heated room is divided into stages:

1. A plank floor is installed on the stacked beams, which is covered with roofing material or only with a large overlap on top.

2. A heater is laid on the roofing material, which is based on expanded clay or slag, filling up the insulation, adhere to a certain slope, in the ratio with a dump from the roof of melt or rainwater.

3. A screed on the basis of a cement mortar is installed on the insulation, at least two centimeters thick. After its setting, the material is processed using a primer -based primer. A roll carpet is additionally glued to the screed.

It is recommended to create a flat roof with a minimum span, thus, difficulties in its hydro- and thermal insulation are reduced. Roofs, the width of which exceeds 600 cm, is recommended only with specialists. Incorrect calculation of the loads on the beams, leads to terrible consequences: the incorrect distribution of the load and a decrease in the operation of roofing materials.

Monolithic concrete installation technology

As bearing a design for concrete flat roof, two -tower -type steel beams are. If the span of the roof does not exceed 500 cm, then beams 15 cm thick are used to arrange the roof.

For the manufacture of monolithic ceilings, we recommend using the factory concrete of brand 250. If you can’t purchase concrete, use a concrete mixer for its manufacture. To make a concrete solution, prepare the ingredients in the form:

- crushed stone, with a fraction of 1-2 cm;

- Cement brand 400.

The ingredients are connected in the amount of eight buckets of crushed stone and three buckets of cement, four buckets of sand and two buckets of water.

This is followed by the process of installing boards on the lower shelves of the beams, roofing material and a reinforcing mesh are mounted on the boards, with a minimum cell of 10 mm. To connect the nets of the grid, use a knitting wire or a welding machine. The gap between the net and the roofing material is about 4-5 cm, for this, crushed stone is laid under the net. The thickness of the concrete layer in this case is at least fifteen centimeters.

At the same time, the stripes are laid evenly, it is not allowed to leave the unfinished strip until the next day. This negatively affects the quality of the roofing. The best option is to fill the roof for one day. After pouring, the surface is rammed with a vibrator by concrete or a manual tool. Sealing concrete, make sure not to deform the grid.

Next, a plastic film is installed on the roof, preventing excessively rapid evaporation of moisture and cracking the upper layer. After the roof dries completely, with the help of insulation, a slope is built for water drainage.

Thermal insulation of a flat roof with your own hands

A flat roof differs from standard single -shock and gable species, the need for both internal and external insulation. First, the roof insulation is performed outside, and if necessary, inside.

Previously, hard insulating plates were used to warm roofs, but due to large weight, they are currently not used. The replacement of this insulation was thermal insulation materials based on basalt and mineral wool. The thermal conductivity of this material is much higher, and the weight does not weight the structure.

In addition, the insulation perfectly opposes mechanical damage and is characterized by high fire safety. The internal insulation of a flat roof is performed using refractory structures, 2-3 cm thick. Wooden strips are used to install plates on the ceiling, on which the plates are fixed with special glue or mastic. Keep in mind that before insulation of the ceiling, all lighting devices on the ceiling are dismantled.

In addition, materials in the form are used as a heater for a flat roof:

- mineral basalt wool - does not need an additional protective screed;

- extruded polystyrene foam - a great option for a roof in constant operation does not burn, differs in good soundproofing characteristics;

- polyurethane foam - does not form butt joints, does not burn and is used as an insulation of a soft roof;

- Ecowan - contains cellulose in the composition, has an additional anti -riveting coating, therefore it has a high level of safety;

- Foam concrete - is distinguished by a monolithic structure and a long service life, it is similar in structure to foam, ideal for insulation of a flat roof without creating significant loads on the foundation.

The device of flat roofs and the technology for creating a roof pie

In order to get the perfect roofing with good sound and waterproofing characteristics, it is necessary to first create a drawing of a roofing pie, which consists of:

- the bearing base - concrete or steel beams;

- vapor barrier layer;

- thermal insulation layer;

- waterproofing.

The option of changing the sequence of layers and the addition of additional materials is possible, it depends on the individual characteristics of the roof and the building itself. Additionally, after the insulation, the textile layer is laid, then covered with gravel and performed the finish. Such a roof is called inversion and is extremely rare, due to large weight. It is suitable for buildings with high fire safety requirements.

The device of a flat roof involves compliance with all the loads that occur during operation. In the ratio with this indicator, the thickness of each layer in the roof pie is calculated.

Several types of flat roofs are distinguished in relation to structural characteristics:

- unscarried roof;

- insulated roof that has open and closed systems 4

- monolithic roofs;

- Inverted roofs.

In the ratio with the operational load, flat roofs can be:

- operated;

- not operated.

Depending on the drain:

- flat roof with internal drain;

- Flat roof with an external drain.

DIY inversion flat roof

Inversion flat roofs are characterized by good operational characteristics and high fire safety. The installation technology of this version of the roof is as follows:

- laying waterproofing;

- installation of thermal insulation material;

- geotextile component;

- drainage system;

- Protective bulk coating.

Among the advantages of a flat roof of this type, we note:

- the complexity of the destruction of waterproofing;

- lack of condensate on the insulation, since it is located on top of the roofing cake;

- The ease of repair and replacement of thermal insulation material.

Excessive moisture, which is formed in the thermal insulation layer, is the reason for the deterioration of the protective characteristics of the roof as a whole. Soon it is covered with cracks and bubbles, especially in the summer of the year, when the insulation emits moisture. The complete lack of ventilation leads to exfoliation of the roof from the base.

In this case, we recommend that you equip the breathing roof. For the manufacture of the roof, roller materials are used, with excellent tightness and long service life. The heat -insulating material is installed between the bitumen mastic, and roof aerators are used for additional ventilation. Among the advantages of this coating, we note:

- lack of need for the dismantling of flooring, additional strengthening of water protection;

- laying the second layer with a slope leads to an improvement in moisture carrier;

- The possibility of using this method both with the initial installation of the roof and during the repair.

Do -it -yourself decoration instructions

Materials for decoration of flat roofs must meet certain requirements, such as:

- high strength level;

- a light weight;

- thermal insulation and soundproofing characteristics;

- resistance before ultraviolet radiation;

- duration of operation;

- Simplicity of installation and care.

Quite often, roofing roofing roofing roofing with peramin is often laid on a flat roof, however, these materials are not distinguished by a durable service life, they poorly tolerate frost and are destroyed under the influence of temperature fluctuations. Every 8-10 years of operation, the roof is re-covered with roofing material.

New rolled-bitumen coatings gradually displace a roofing material with peramin. This is due to their advantages:

- excellent performance;

- ease of installation;

- complete waterproofing of the roof;

- resistance to chemicals, temperature changes;

- Duration of use.

There are several varieties of bitumen materials for a flat roof:

1. Fiberglass, fiberglass - is characterized by high strength, resistance before mechanical damage and absolute moisture resistance.

2. Bitumen materials on a polyester or polypropylene basis. They are used as the lower layer of protective coatings, have high density, good waterproofing indicators and are used on reinforced concrete floors.

Polymer membrane materials are based on reinforced plastic grid, rubber and polymer resins. The cost of such materials is much higher than bitumen, however, compared to the latter, they have certain advantages:

- Light weight, so they do not load the foundation and base of the building;

- elasticity and tendency to stretch;

- the duration of operation, which exceeds 50 years;

- do not need to use open fire for installation compared to bitumen materials;

- To connect the joints, hot air is used.

Materials based on mastic are an ideal option for a flat roof. Rolled materials, although they have certain advantages, all of them create seams that, with increased load, pass moisture. Seamless roofing with mastic does not create butt joints and is characterized by perfect smoothness. Such a roof is called a bulk. This roof is easily applied, forming a whole canvas, there is enough brush or brush to level the material. Previously, the roof is treated with soil or primer.

DIY Flat roof video: