Quite interesting, reliable and high -quality polish kitchen tiles ...

|

|

Camping floors are thin layered plates consisting of a pressed cork ... |

The architecture of modern buildings involves a wide variety of aesthetic ... |

How to make building forests with your own hands.

In the middle of the 20th century, shaky construction forests were used in construction, and workers were afraid, and often refused to work at high altitudes, since no construction of a multi-storey building was complete without accidents, often with fatal outcome. To date, the work of the builder-lifting has become safer and largely due to the modern types of construction forests, which, from the point of view of constructiveness, are a frame system that is made of standard metal and wooden elements.

In order to use forests for their own purposes, it is not necessary to acquire them into property. It is possible to contact specialized organizations in their region, which rent construction forests. They will provide you with collapsed forests, as they can be used reusable.

Table of contents

- What are construction forests

- Varieties of building forests

- Building forests made of wood

- Metal construction forests

- Frame (flag) construction forests

- Shtyrevy construction forests

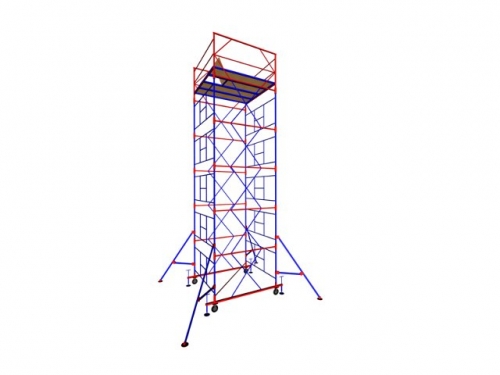

- Tower-tour

- Clinical construction forests

- Clamp construction forests

What are construction forests

Construction forests are auxiliary structures that are temporary, and which are built to perform construction and installation work. Construction forests are necessary for the placement of workers, builders, as well as building materials at a construction site. They are used both outside and inside the object under construction. Building forests are similar to a web, which envelops a new building or a building on which restoration work is underway. Thanks to modern construction forests, workers and builders work in safer conditions, with a minimum risk to health and life.

Varieties of building forests

Depending on what structural elements of building forests are made of, they are wooden and metal, and based on the method of attaching functional elements among themselves, construction forests are:

Clinical construction forests, in which components are connected by means of wedge fixing. Construction forests of this type are quite reliable and can withstand heavy loads, but at the same time, they can be disassembled very quickly. Clinical type forests are recommended for such construction work, during which it is planned to use heavy nodes and materials.

Drama building forests, here the main component element is a hard executed frame. Such forests are designed to perform plastering or painting construction work. In the frame construction forests, the frame is associated with horizontal racks and diagonal bonds using nodal compounds. Making forests of this type will cost you quite cheap.

Shtyrevy construction forests. In these forests, the connecting unit is a pin. They can be mounted very quickly or dismantled, so they are very popular among builders.

The clamp construction forests, on the contrary, are designed to perform work at facilities with a very complex configuration. Construction forests of this method of fastening are professional equipment, for the manufacture of which all significant parameters: the size and height of the working area and the distance between the tiers, as well as the step of the racks, must be selected in accordance with the individual characteristics of this object.

Is it possible to make construction forests yourself? To do this, let's take a closer look at the methods of installing each of the types of construction forests.

Building forests made of wood

Wood, wood, as you know, is one of the oldest building materials, and it is quite possible to build construction forests from it. However, they are more suitable for finishing work, not higher than a three -story private house.

Springs from drarevezin, are made of a wipes of a 50-and-a-sized board with a size of 1.50x5 cm, segments of a thinner board (for example, 2.5x10 cm), and boards of the desired length for horizontal flooring. For supports, you will need two long boards, like a beam, all the components of the scaffold can be attached to them. From scraps of a 50 centimeter board, you need to put on triangular supports for this design, then sheathe them with a thinner board.

What sizes should there be triangular supports? They must provide enough space for the builder standing on them and exclude the possibility of separation from the wall/support. Therefore, the length of the scaffold should be from 40 to 50 cm, so that the feet in no case sag outside the scope. Putings will be attached to supports, be sure, at an acute angle. The upper part (under the name is fallen) must be cut at such an angle so that it can be inserted inside the triangular support. But the lower part should be pointed for durable fixing in the ground.

Когда леса-подмости будут выведены до необходимого уровня, с помощью гвоздей или саморезов, нужно будет прикрепить вертикальную сторону треугольных опор к стене, при этом (если использовать гвозди), не вбивая их по самую шляпку, поскольку после окончания монтажных работ их придется вынимать и dismantle the forests. When assigning a staircase, we raise one after another, install, and then nail the appropriate floorboards to the supports, in which case the nails need to be driven to the stop, your safety may depend on this.

Before starting construction and finishing work, you need to make sure that the stability of construction forests. They can be erected in a height not exceeding seven meters, if you build a design above the specified distance, then you can forget about your safety. Construction forests of this design can be built from bamboo. This is how it is customary to do in the countries of Asia, because there this plant is more common than wood. At the same time, the strength of bamboo products is an order of magnitude higher than wood products.

Metal construction forests

In modern construction, especially multi -storey buildings, construction forests made of steel and aluminum pipes are used. They are manufactured by an industrial way. The frame construction forests include towers, flag and pin forests, and the modular, wedge, modular systemic and clamp forests include modular.

Before starting the installation of construction forests from metal, you need to prepare the site on which forests will be built, it should be well compacted for a greater stability of the structure. It is also necessary to organize rainwater removal, otherwise the water can wash the supporting racks, and the design may collapse or overturn.

Frame (flag) construction forests

Drama (flag) forests have a standard load of 200 kg/m2.

Their design consists of steel frames, racks for (horizontal and vertical) mounts, side frames and the so -called shoes for support on the ground.

As mentioned above, this type of forest is quite popular among builders due to the low price and ease of installation. Such forests are designed for buildings with straight facades, where masonry and finishing work are performed. The maximum assembly height of such forests is 50m.

Before starting the installation of frame building forests, you should properly consider the plan for their construction and the scheme of the arrangement of tiers with stairs, find out the views and the required number of structural elements of building forests.

The assembly of frame forests is as follows:

On the prepared site, segments 3 m long are measured and the support boards are laid out, and steel shoes are installed on top of them. They establish frames that form the first tier of forests. They are connected by braces and screeds, then the second tier is installed. Rigels are exhibited for laying the flooring. From the first to the last tier, the diagonal screeds must be installed in a checkerboard pattern. And stairwells need to be placed at an angle so that the workers can rise on vertical stairs built into the frames themselves, and along inclined stairs, which is much more convenient.

Shtyrevy construction forests

Shtyrevy construction forests have a standard load of 200 kg/m2.

Their installation is also quite simple, like in frame construction forests. In them, horizontal elements are attached to the introduction of pins into hollow tubes. Each level is collected in stages. Flates, here are installed diagonally, which is given greater stiffness.

The maximum height of the pin forests can be 40 meters. They are also used in the production of masonry work, and for decoration.

Tower-tour

The tower-tour has a standard load of 200 kg/m2.

In these designs are intended for periodic repair work of various complexity. The tower is assembled from ready-made frames that are equipped with a staircase. Their base is on wheels. The tower has two, three horizontal sites. The upper has a folding hatch for lifting and descent. The height of the towers is from 4 to 21 meters, which depends on the number of tiers. Each tier has a height of about 2 meters. They can be attributed to mobile construction forests. Thanks to the wheels, they can be moved to another place without disassembly, provided that the surface of the movement should be even.

Clinical construction forests

Clinical construction forests have a standard load of 200-300 kg/m2.

These more complex devices. The component elements of these forests can be fixed with steel wedges that are driven with a hammer. These are quite reliable forests compared to frame and pin. The maximum height of building wedge forests is about 40 m.

Clamp construction forests

Clamp building forests, perhaps, are one of the first types of construction forests. All their structural elements are connected using rotary and deaf clamps. However, they are quite complicated in the assembly.

Based on the above, it becomes clear that the only type of construction forests that can be prepared with your own hands are wooden construction forests. Despite what construction forests you choose, do not forget to take care of your safety, the facade grid will be in handy. Made of high -strength polyethylene, it will not only make construction forests safely, but also ennoble their appearance.

Vadim Burova

I got the right one

Got the necessary information!

Fast!