Often cottage villages and horticultural massifs do not have a centralized ...

|

|

The operation of the asbestos-cement slate reaches 50 years. However, with proper ... |

Many designs, styles and directions in the interior dictate their rules. Moderate ... |

Pill laying. Paul from the cork

Camping floors are thin layered plates, consisting of pressed cork and cork veneer. In general, a cork is a special oak breed. This material has become popular thanks to the beautiful appearance and simplicity in operation. He also proven himself in children's rooms, like soft and warm flooring. The article will talk about the floors from the cork.

Content:

- The advantages of the floor from the cork

- Disadvantages of the cork floor

- Types of flooring from cork

- Production floor production technology

- Cork

- The main manufacturers of cork floors

- The peculiarity of the tree from which the cork floors make is that it has the properties of the regeneration (update) of the cortex, and its life expectancy varies within 200-250 years, however, the bark begins to get from it upon reaching the age of 25 and the bark and Do this every 7-10 years.

- Before getting into production workshops, the material is withstanded for a long time in the open air, about six months. But this is a necessary procedure, since during this time traffic jam significantly increases its characteristics. The natural cork is rather elastic and elastic, and even if it is loaded and deformed, then after weakening the pressure again returns the former form.

Floors from traffic jams photo

- That is why this material is ideal for flooring. Of course, in addition to excellent restoration ability, the cork coating also has a lot of other advantages.

The advantages of the floor from the cork

- The main positive quality of traffic jams is attributed high environmental characteristicsand, after all, this is a type of natural coating with unique properties, among which the relief of physical tension, as well as contributing to the creation of a favorable microclimate in living space.

- Noise insulation and sound absorptionWhen walking on such a floor, the sound of steps is completely absorbed. Even if there is no furniture in the room, but only the bare walls and cork coating on the floor, then the appearance of an echo is excluded in this version. But it is worth noting that if rather noisy companies live in the neighborhood, then the coating will not save from loud sounds.

- Thermal insulation Such a floor even in the most severe frosts seems slightly warm to the touch, at the same time in the summer, during periods of severe heat, it does not heat up, that is, the optimal temperature regime is supported by this material all year round.

- Does not absorb odors A undoubted plus, since many natural materials are very unstable to this problem, the coating from the cork does not have such shortcomings and any unpleasant odor present in the room is quite easily eliminated.

- Does not accumulate static electricity This is also important for flooring, because the main problem of many materials is that they very much attract dust, the floor from the cork is devoid of such quality, since it simply does not attract small organic and inorganic particles to itself. Of course, if there is a lot of dust, then in any case it will be deposited on the flooring, but it is much easier to remove it from a traffic jam than from other materials.

- Stress resistance You can not be afraid to put heavy objects on the material, due to the high strength, the coating does not suffer from such an effect, the dents, although they remain from the long location of the object in one place, but after the thing is cleaned, soon the cork product returns an even look again.

- Aesthetic and presentable view Here, perhaps, you should not even paint all the beauty and splendor of a similar coating, and given the fact that modern technologies allow you to apply various textured images that imitate many popular and luxurious materials, the choice of consumers will definitely be over the cork floor. In addition, the panels can be laid in various combinations and receive quite attractive mosaics.

- Long operational period Natural traffic jam is able to serve without changing its characteristics, for more than 100 years, of course, the material that is used for sexes can boast of a little shorter, but still, in general, this is more than 10 years, the main thing is to monitor the upper layer and on time of it update.

- Bactericidal (antiseptic) Properties many bacteria simply do not experience contact with this material, also does not cause allergic reactions, does not rot and is not subject to mold lesions.

- Positively affects natural air circulation in room.

- Light and elastic In structure, material.

- A high fire safety indicator Thanks to the special structure of the product, such a floor does not support combustion and does not secrete harmful substances when heated.

- Low water absorption Which also relates to the positive properties of the coating, that is, even the fluid spilled on the floor will not damage the product from the cork. This indicator is in the range of 1-2 %. This is an additional plus for those homeowners where such incidents with neighbors often happen as gusts of pipes or just trite - forgot to close the water. Even if the cork is nourished by moisture, then soon (after drying) it will completely restore its original appearance. But this indicator is manifested in the best way only in cases where the floor is mounted hermetically, that is, all joints and castle joints will not be exposed to moisture.

- Excellent depreciation This property is extremely useful when walking, as it significantly reduces the load on the feet and spine.

- Universal product You can mount the coating in any room in the house, as well as in public places. The traffic jam is not terrible and it is allowed to walk even in heels. That is, the material is suitable for use in the corridor or in the kitchen.

- Independent installation is available And the possibility of replacing damaged tiles can also be attributed to one of the advantages, since in cases of damage during operation only a small area is possible to replace it and continue to use other products.

Disadvantages of the cork floor

The existing shortcomings are unable to block all the above advantage, but they should be mentioned.

- So, the most important minus of such a coating is his high price. On average, for 1 m2, manufacturers ask for from 1-1.5 thousand rubles, which is far from a resident of our country. But given all the advantages of the material, such an acquisition will last a rather long time without changing its excellent qualities, so this is a very profitable investment. The price of the coating will depend on the thickness of the product (on the thickness of the layer of natural cork) and a specific type of coating. The manufacturer in this case does not have a meaning, since all known brands produce approximately the same product quality, which differ only in texture and coloring.

- Another coverage problem is that in some models it is completely traces of heavy objects do not disappear interior. But it should be said that this most often happens in cases where a cork coating layer is not thick enough.

- Abrasion of the upper layer During operation, you can also avoid if the material is provided proper care, in addition, this is characteristic only of those materials that do not have an additional protective coating.

- It is not advisable to mount a warm floor technology With the top layer from the cork, this is due to the fact that heat simply does not pass through this coating, but will remain inside.

- Required special care It is recommended to cover a varnished cork once a year with a new layer of varnish, and the vinyl plug requires processing with special mastic.

In general, these are all possible disadvantages available in the flooring of the cork, but it is worth saying that in different types of products the listed properties can appear differently. Therefore, before finally making your choice, you need to familiarize yourself with a type of cork coating for the floor.

Types of flooring from cork

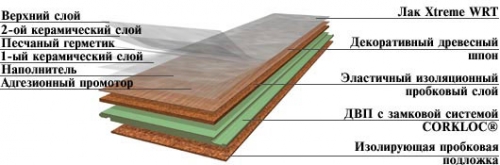

The plug plug is a material consisting of several layers. Depending on what technology the floor is mounted, the product may differ in composition. As a rule, the lower layer is an agglomerate, and the upper layer is veneer.

Products are of three main types:

- cork parquet or laminate Castle traffic jam on the floor is laid by the method of floating floor, the main advantage in the ease of installation and dismantling, most often glued on the MDF plate and has the size of the panels of 90x18.5 cm, is easily mounted by means of a locking connection, but unstable to moisture, since the MDF can start exfoliate;

- cork plates (or adhesive plug) An important feature is that such material requires a sticker on the base. It is produced by square tiles with dimensions of 30x30 cm, 45x45 cm, as well as in the form of rectangles 45x15 cm, 60x30 cm and 60x90 cm, it is such a floor that is most resistant to moisture and it is allowed to mount in bathrooms, in the kitchen and corridor, especially if it has an upper protective layer;

- roller plug for the floor It has low resistance to mechanical damage, used as a substrate for the laminate.

Production floor production technology

- In the floor covering, there is a layer of cork crumbs is a material obtained by grinding the bark and drying it in special installations, and then mixed with adhesive and compressed. Such a product is made in the form of a canvas with a cellular structure, which, with further use, is cut into plates of the required size.

- A decorative veneer from the cork is glued to the resulting plates. Further, the product is polished and covered with polyurethane varnish. This technology is characteristic of single -layer adhesive plates. Many modern manufacturers also offer a three-layer product, where an agglomered substrate is the lower layer, and a MDF plate is laid in the middle (in which a lock system is usually arranged).

- Another characteristic feature for the flooring from the cork is that the upper lacquer layer is quite durable due to the special application technique. First, the surface treated with varnish is subject to drying under the influence of UV rays. Then, the second varnish layer is applied, which is extracted under pressure. As a result of such processing, the coating becomes durable and is not inferior in its wear -resistant characteristics of natural parquet.

Modern manufacturers offer several varieties of floor traffic jams:

- whole veneer products are the most expensive view, but at the same time the highest quality, it may differ in the color of the products, has impressive dimensions of the layer up to 6 m2;

- the products from the veneer with the agglomerate for production use small crumbs and selected particles of cork material, belongs to the middle price category;

- the agglomerate product is made of the smallest particles and pressed into a single whole, the cheapest type of coating.

Outwardly, it is very difficult to distinguish one product from another, it cannot be said that the operational characteristics have a large difference, the main minus of cheaper products is that a large number of additional substances (plasticizers) are present, which means that environmental properties are significantly reduced.

Laying traffic jams on the floor

The floor from the cork can be mounted in several ways, what specific to choose depends on the main type of material used. Thus, the floating floor is considered the main technologies (that is, the connection of only tiles, without fastening to the base) and adhesive (fixing using the adhesive composition on the base).

It is recommended to install the floor only in warm periods of the year. This is necessary so that the difference in the temperature of the warehouse and indoor does not have large indicators (no more than 7 degrees). High humidity in the room is not allowed, a value of 65%is considered limit.

The main set of tools

- kiyanka or rubber hammer (useful to a greater extent for a floating floor, but adhesive tiles can be tapped);

- small -toothed saw (optimally use disc saws or electrolobsics, since from almost all manual saws the cork begins to crumble), you can replace with a regular construction knife, but it is possible to cut only single -layer coatings;

- for the floor mounted according to adhesive technology, you need a roller for rolling for cork it is desirable to use a heavier tool than, for example, for wallpaper, it is best if the roller is made of metal;

- a spatula for applying adhesive composition, large width and with a small comb (necessary for applying glue to the base) and a roller, also for applying glue, but already on cork tiles themselves;

- building level, corner ruler, roulette and a recitting cord;

- selected wedges, this element is recommended to be made from traffic jams, since any other materials can split and cut through the cork coating;

- set of components skirting boards, thresholds, glue.

- Before you glue the cork on the floor, you should definitely take care of how to wash glue protruding on tiles, specialists use a substance such as solvent for these purposes. It is not recommended to maintain the tile abundantly with this tool, since the appearance may suffer from this.

That is, as you can understand from a set of tools, the main part of them is required for the installation of the glue floor, laying laminate plates or coating, floating floor, less demanding on the set of tools.

Preparation of the base for cork floor

- The cork floor does not differ from many other types of coatings, it also requires even, smooth and dry foundations. But it must be taken into account that the concrete surface is not smooth enough and during operation it is possible to rub the cork, even if it is firmly glued to concrete.

- In addition, sand and cement screeds and concrete bases should be very carefully dried before proceeding to the next stage of alignment, since the coating from the cork is porous and will absorb all moisture into itself eventually.

- In order to check the moisture level of the base, it is necessary to cover a small area with a plastic film (from 3 m2) for a day. After time, the presence of condensate is checked, and if it is not, then you can safely proceed to the next stage. If the drops of water appear, then before processing the surface, dry it for 3-7 days and again check for evaporation.

- It is recommended to close all the cracks and cracks, especially in the area of \u200b\u200bskirting boards and heating systems. Since moisture can occur from the lower rooms. It is advisable to use waterproofing and vapor -permeable materials that create a protective barrier, which is very relevant in cases when basements are located below.

- It is best to use self -leveling screeds (for example, Vetonite Vetonite 3000), moisture -resistant plywood or gypsum fiber sheets. Such bases are ideal for the flooring of traffic jams. It should also be noted that the changes in height should not be more than 2 mm for every 2 m. All joints in the room are treated with silicone sealant. This is especially true for rooms such as a kitchen, a bathroom, a balcony and a corridor. Excess composition must be removed and carefully aligned by the resulting seams.

- The last thing to do is to primed the surface. This is especially important when installing adhesive cork plates, since primitive compounds increase the adhesive indicators of the base.

Technology for laying traffic jams

- The tile should not be unpacked immediately after it is delivered from the store or from the warehouse. It is optimal to withstand it in conditions of installation at least 3 days. In this case, it is necessary to observe the temperature and humidity level. So, the floor should have a temperature of at least +18 degrees, and air humidity should not be higher than 65%.

- The laying of adhesive plugs does not start from the corner, since in this case it is impossible to perform visually attractive installation. Experts advise starting installation in the center of the premises. For clearer positioning, the applied marking is used, which is quite easy to make with a reciting cord.

- Decol Vern (based on polychloroprene) or Wakol D 3540 (on a latects-acrylic dispersion basis) is used as adhesive composition. Such compounds are used for application and on the base and on plates. The glue on the floor is applied with a gear spatula, and for a cork it is best to use a roller.

- The adhesive composition is maintained for at least 10 minutes, each manufacturer indicates a specific time, and only after its expiration does the installation of cork tiles begin to the floor surface. There are also special adhesive compounds, which allow you to clearly withstand the required time before the start of gluing, as they initially have white color, and when the necessary time acquire a transparent look.

- The tiles are thoroughly pressed to the base and to each other, ironed with a heavy roller or tapped with a rubber clay and left for about a day. Also, each manufacturer exactly indicates what time it is necessary for the adhesive composition for complete drying.

- After that, the surface is necessarily cleaned of small particles of dust and debris. You can do this with a vacuum cleaner. When the floor is cleaned, they begin to apply varnish. This product should be designed specifically for cork coatings, most often it is polyurethane two -component compositions on water -based. Parquet varnish will not be appropriate here, since it is not able to provide the necessary strength and at the same time elasticity.

- The hardener is added to the main container with varnish, and the mixture is mixed for 1-2 minutes. After that, you can start a little pour the composition on the surface and level it with a roller. It is best to process with varnish in a few layers (at least 3), only then it is possible to preserve the cork coating in perfect condition for a long time. It is allowed to apply both with grinding of the surface, and without such a procedure. The varnishes themselves can be matte or glossy. The final drying occurs after 4-5 hours, but for greater strength, it is best to leave the surface for a day.

- You can only load the adhesive floor only after 5-7 days. Therefore, until this time has expired, it is better to abandon intensive movement on the coating, as well as the arrangement of interior items.

Laying adhesive plug video

Laying a castle cork

- It is the floating technology that is most often used in residential premises, since the tile in this case is softer. The most important condition is to check the evenness of each tile, otherwise gaps may occur, then this will lead to the formation of creaks and backlash when moving along the floor.

- They also pay attention to the back of the tiles. It should be smooth and evenly colored. If this is not the case, then most likely, it was added to the mass of the cork material of the sawdust, and this reduces the characteristics of the product.

- The cork floors with a castle connection is usually mounted in the direction of the fall of light from the window, then the joints will be the least noticeable. The preparatory stage practically does not differ from the preparation of the base for adhesive tiles, that is, the surface should also be clean, even and dry.

- Concrete and cement screeds are covered with moisture -resistant films (with an overlap on each other at least 20 cm). A substrate is laid on top of the film, with an indent from the walls by 1.5 cm. The material for the substrate can be made of thin plug rolls.

- Tiles begin to be laid along the wall so that the groove is facing the room. Do not place cork tiles directly to the wall, optimally leave a gap of about 5 mm. It is recommended to mount the ONE not one row, but two at once. If necessary, cutting the planks, this procedure is performed from the crest, since by cutting the groove, you can damage the product.

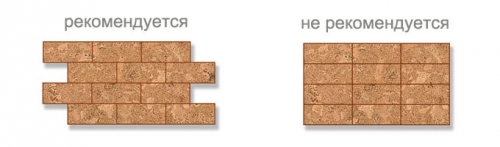

- It is necessary to monitor the shift of the seams, it should be about half the tiles. In principle, the styling technology is not much different from the installation of the laminate, the comb at an angle is inserted into the groove and the lock is snapped. To press the products to each other as tightly as possible, a rubber hammer is used, which are slightly tapped on special wedges.

- After the installation of the entire floor surface is completed, the excess film is cut along the wall, and the joint is closed with a skirting board, which, as it were, slightly hangs over the floor. In this state, the baseboard is held for about a week to let the tiles take the desired shape. The significant advantage of such a sex is that after installation on it, you can immediately move around, as well as arrange furniture.

Cork

- If the floor is covered with a varnish layer, then approximately every 2-3 years remove the coating and apply a new varnish. Experts recommend doing this a little more often, but everything is individual and depends on the operating conditions. In some cases, it is possible to replace the lacquer layer no earlier than after 5-7 years, so you should carefully monitor the floor and at the first signs of wear of the upper coating, replace it yourself or with the help of masters. Vinyl coating requires processing with special mastic, such a procedure is done every 2 years.

- Regular care for the cork floor is that the coating is subjected to weekly wet cleaning. To do this, use a well -squeezed rag or special napkins with a mild exposure detergent applied. It is forbidden to use abrasive compositions or brushes, since the cork is afraid of scratches. It is not advisable to put latex or rubber rugs on top of the product, since during operation they will leave a trace that cannot be removed.

In order not to suffer with the choice of detergents, it is better to purchase special solutions for cork care. Such funds are gently caring for the surface, and also give shine. Otherwise, the care of the cork is quite familiar, it can be vacuumed daily or wipe the coating with clean warm water quite persistent.

The main manufacturers of cork floors

The main manufacturers of cork coating are concentrated in Europe. These include such brands as:

- Egger - Germany;

- Wicanders - Portugal;

- Corkart - Portugal;

- Corkstyle - Switzerland.

Also now, the cork coating of the Russian manufacturer Polympex under the Maestro brand is quite popular. True, goods are made in Portuguese factories.