One of the most difficult works when repairing housing, according to both masters and ...

|

|

Often, the owners of the residential building only after the end of its construction want to ... |

The layout of modern private houses and cottages provides for the presence of the foundation ... |

What to choose: metal tile or corrugated board

Spring the time when active construction and repair work begins, especially in the country and cottage sector. Any construction requires preliminary preparation and accurate calculations. Now is the time when it is necessary to assess the upcoming work, calculate the time and the required materials. This advice is especially relevant in relation to the arrangement of the roof, since, as you know, the foundation is the key to the strength and durability of the structure, and the roof is the key to comfort and heat inside the house. In the article, consider what to choose: metal tile or corrugated board.

Content:

The range of roofing materials is unusually wide, however, in order to figure out which material is suitable for a specific task, it is not at all necessary to be a professional in construction.

All roofs are divided into:

- soft;

- solid.

If we are talking about the construction of a private house, then for a typical pitched roof, solid material will be preferable. One of the most popular in this section has recently become metal tile and corrugated board. Consider each of them in more detail.

Metal tile

In the 1960s, a new type of metal roof was developed in Finland, which immediately became widespread in Europe due to its excellent operational qualities and ease of installation.

In Russia, a metal tile appeared in 1990, since then its sales have only been growing. And according to statistics, at the moment, about 70% of our compatriots choose it as a roofing material for their home.

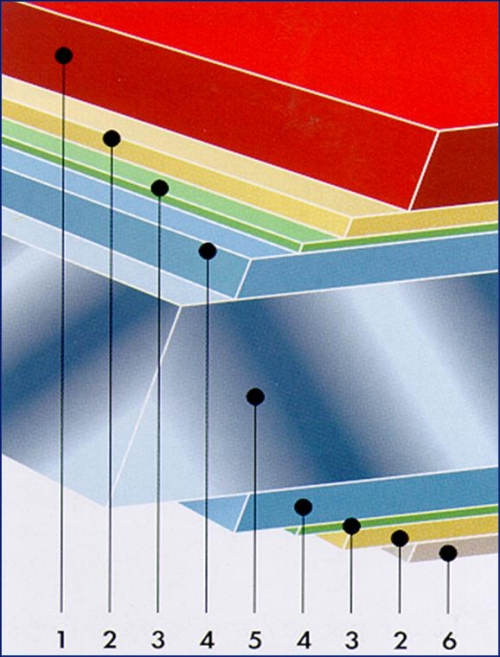

The structure of the metal tile

The metal tile is a strong sheet of steel, which is galvanized and covered on both sides by several layers of polymer coating. The material receives its shape, resembling natural tiles after transverse stamping.

The structure of metal tiles:

- polymer coating

- lench layer

- additional anti -corrosion coating

- alumocycnic or zinc coating

- steel sheet

- layer of varnish

- At the base of the sheet of the metal tile lies a steel sheet with a thickness of 0.4 0.6 mm. It is subjected to zinclovania (zinc or alumocycycm), as well as passivation, which not only effectively protects against corrosion, but also prolongs the life of the metal.

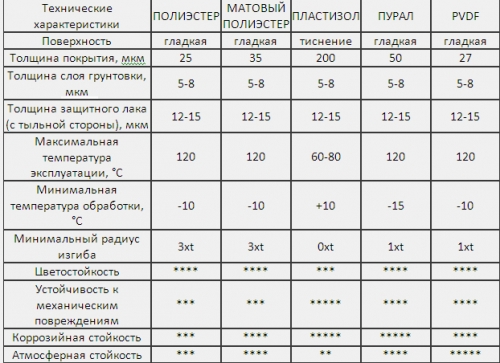

- Then the sheet is primed and covered with a layer of polymer material. It can be purple, plastic insol, polyester or matte polyester. Any of these materials of them provides protection against ultraviolet radiation, corrosion, chemical and mechanical influences, the difference in their use only in small details. For example:

- the plastisol is not recommended to be used in the southern regions, since it has low resistance to UV radiation. As a result, the material quickly loses its color, but at the same time it has very good indicators in terms of other indicators;

- polyester, including matte, has less resistance to mechanical damage. When working with it, maximum caution is required;

- pural is a modern polymer, which has excellent chemical, mechanical and UV resistance, but it is not enough to plastic deformation. Therefore, when working with him, especially if necessary, bends, you need to be very careful;

- PVDF consists of polyvinylFtoride and acrylic, most often found in the color of metallic. It has increased resistance to external aggressive environments, mechanical influences and ultraviolet light.

In the table, the characteristics of the coatings are presented in a more visual form, so that it is easier to compare them.

Advantages and disadvantages

The main advantage of the roof of metal tiles is certainly its beauty. Manufacturers offer a wide selection of materials of various shapes and colors. From an aesthetic point of view, this material wins with corrugated board, a roof made of metal tiles looks very representative.

Also, the advantages include:

- simple installation of metal tiles;

- the presence of all the necessary components for installation in the delivery set;

- the ability to accurately choose the size of the coating by size of the roof, as well as take into account all the necessary technological openings and choose additional elements for them.

- suitable for use on any roofs, including with complex geometry;

- the material has a high degree of fire safety of NG (does not burn);

- wide color palette.

Flaws:

- light weight (including due to styling technology: overlaps, additional elements). The material gives a significant load on the rafters, on the design of the roof as a whole, on the walls and, accordingly, on the foundation. Therefore, making a decision on the choice of material should be made in advance, at the design stage, so that all loads are calculated correctly;

- the possibility of corrosion. Despite the high -tech processing, the material is still based on the metal, any inaccuracy of installation or negligence of transportation can lead to damage to the surface and, accordingly, to the appearance of rust in the future.

- when installing the roof, it is also necessary to analyze the external environmental factors in advance:

- the presence of factories with the release of aggressive chemicals;

- wind roses in a given area;

- even the presence of a large number of birds in the region plays an important role in choosing a type of roof. So, for example, the metal of even the most modern processing is unstable to bird droppings;

- the price of metal tiles (since the comparison is made with the corrugated board, the price here is in shortcomings).

Tip: metal tile is quite complicated in terms of styling technology material. It makes sense to entrust this process to professionals. In terms of the purchase, it is also worth paying attention to official dealers, give preference to those companies that do not only sell it, but as a free bonus make a full roof project, calculate the loads and the necessary amount of material and additional elements. In this case, unpleasant surprises will not arise at the time of construction.

Myths about metal tiles

Several popular misconceptions relative to the roof of metal tiles.

- The metal tile is very noisy with rain and wind. Yes, you need to understand that the roof of metal has significantly higher sound conductivity than, for example, a soft roof. However, if we talk about the living roof, then, firstly, the correct quality installation provides the minimum possible noise level. And secondly, the roofing cake, which includes a layer of soundproofing, will significantly reduce the noise.

- The metal tile attracts lightning, for it, lightning protection is necessary. Lightning protection is installed on any type of roof, whether it is a metal roof or from ondulin. In addition, metal sheets are covered with a layer of polymers, which are insulating material and do not have guaranteed contact with each other.

- Snow descends from metal tiles. If the roof is pitched, then it will go from any type of type. To ensure safety for any roof, snow retainers are installed.

- Polymer coating gets off like a film. If the metal tile was purchased from an official dealer, produced by a well-known brand, then, firstly, it will be given a guarantee of at least 10 years (although it serves many times longer), and secondly, the coating in itself is not in itself damaged. Only if it is artisanal production or fake.

- Thus, we can conclude that if you do not chase pennies, but make a good project, calculate all materials and buy high -quality metal tiles, then the roof will delight for many years.

Metal tile photo

Corrugated board

This is a universal building material used not only for the construction of the roof, but also for fences and walls.

Tip: In order not to be mistaken when choosing, you need to check the marking. Roofing corrugated board is indicated by the letters K or PC.

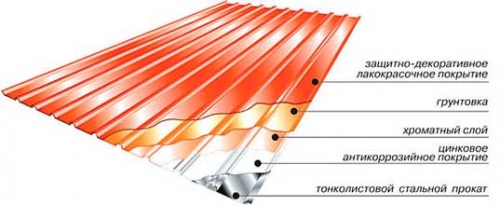

The structure of the corrugated board

A modern profiled sheet consists of several layers that provide it with excellent operational characteristics, including protection against aggressive external factors and corrosion.

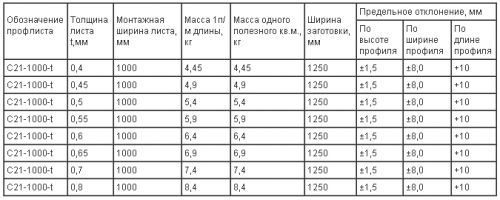

Manufacturers offer an unusually wide selection of material with various corrugation heights (8 45 mm) and sheet width (1000 1200 mm).

Tip: the larger the area of \u200b\u200bthe roof and less than the slope, the higher the corrugation should have a profiled sheet, optimally from 30 mm.

The corrugated board is very popular, which is not surprising, because people always strive for the ideal ratio of price/quality that this building material is perfectly responsible for:

- its service life is about 30-40 years;

- in addition, it allows you to work with it independently, without attracting construction specialists;

- and if you choose a sheet according to the size of the roof slope, then the installation will be elementary simply fix it on the rafters.

Advantages and disadvantages

The main advantages of corrugated board are:

- relatively low price of corrugated board;

- light weight. This factor not only facilitates the transportation of the material and work with it, but also does not have a strong influence on the overlap of the house and the foundation, and therefore reduces the whole project of the house;

- it has a high fire safety class NG (does not burn);

- high strength of corrugated board. If a sheet is used for installation with a thickness of more than 0.7 mm, then you can move around it (with a single reservation only in soft shoes);

- wide selection of sizes;

- thanks to great demand, it will not be difficult to buy corrugated board the desired color in any construction market.

The most important drawback of corrosion is the possibility of corrosion:

- when laying the material, small scratches may appear. Rusty foci also appear at the place of fastening of the sheets to the rafters. Therefore, after the completion of installation work, the entire surface of the roof is checked and tinted in those places where scratches or other surface damage appeared.

Useful tips

- Before buying corrugated board, it is necessary to make accurate roof measurements. It is best to choose sheets of corrugated board so that its width is equal to the length of the roof slope, this will greatly simplify the installation and give an additional guarantee of waterproofing. In addition, you do not have to cut the material.

- By the way of cutting a profiled sheet, it can only be performed by a saber's saw or passive scissors. A popular Bulgarian forms many sparks that, falling on corrugated board, destroy the upper paintwork, which further leads to corrosion. Self-cutting the risk of rust in the places of cut, so it is so important to correctly calculate and choose the material, since at the manufacturer all the edges are processed and painted.

- When fixing corrugated board, you should not use nails. This increases the risk of corrosion, and there is also a risk of separation of the material at the place of attachment in strong winds. In addition, nails do not provide hermetic fit to the rafters, and therefore there is no waterproofing. As a fastener, it is better to use screws that are screwed with a screwdriver or drill at the lowest speed. 2-3 months after laying the roof, the screws in the places of fastening can get out, they must be pulled out.

Corporal photo

Conclusion

Metal tape and corrugated board are very similar in their characteristics materials. The decision to use one of them is made after solving the following issues:

- Will roofing work independently?

- Is an aesthetic moment important?

- Is there a need for savings?

Based on the answers received, you can clearly understand whether to choose corrugated board for the roof or metal tile.

Building store and

The store of construction and finishing materials http: // Remertvest.rf/ offers building materials wholesale and retail. Our store has a wide range of products at minimal prices, because We work directly with factories and manufacturers. We cooperate with Russian and European firms of finishing materials and have a well -established sales network, so we are always in stock building materials in bulk, and the supply of construction projects in Moscow passes as quickly as possible