When choosing the front door, each consumer is guided by three main criteria ...

|

|

The steady increase in the number of wooden buildings has become one of the most iconic phenomena ... |

You need to choose the color of a stretch ceiling at the finish stage of the design of the design of the room .... |

How to insulate the foundation with polystyrene

The layout of modern private houses and cottages provides for the presence of the foundation of the building, which requires reliable insulation. Otherwise, the heat through the foundation will go into the ground. In this article, we will talk about the methods of external thermal insulation of the foundation, popular materials that are suitable for this purpose, and how to cope with the lift of the soil and deformation of the foundation.

Content:

- The reasons for the insulation of the foundation

- Materials for the insulation of the foundation

- Foam for insulation of the foundation

- The insulation of the foundation with polystyrene foam

- Warming the foundation with polyurethane foam

- Foam against the deformation of the foundation

The reasons for the insulation of the foundation

The foundation serves as the basis of the future residential building and in general any structure. The durability and strength of the entire structure and the heat -insulating properties of the construction as a whole depend on its high -quality filling and laying. The cold foundation of the house is a cold floor that is especially unpleasant in winter.

Remember that more than 20% heat loss occurs through an unsold floor, and thermal insulation material allows you to maintain thermal energy inside the underground space. Even a practical foundation made on screw stilts is recommended to protect from the harmful effects of water and freezing in the winter season.

A significant proportion of the soils of Russia is clay, which relate to the heaving species. This soil when freezing and thawing changes its own volume. When freezing, the effect of frosty heaving is observed, as a result of which the base is shifted and deformed. Heater helps not only to maintain warmth, but also to prevent a violation of the integrity of the foundation for reasons of soil starting in the winter season, or to significantly reduce the effect of soil.

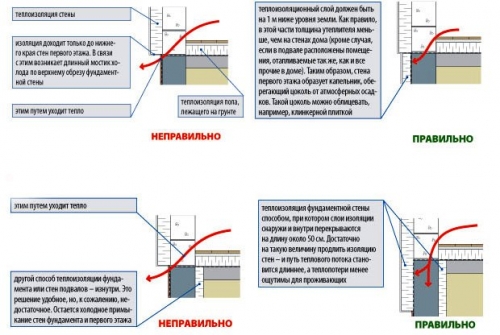

Often a layer of thermal insulation material is mounted on top of the waterproofing layer, which is laid on the foundation. The insulation at the same time serves as additional protection against mechanical damage during the process of backfill of the soil. It should be noted that the sole of the base, as a rule, is not customary to thermal insulation, because it is placed below the depth of freezing of the Earth.

Materials for the insulation of the foundation

Even in the old days, the importance of insulation of the foundation was understood, it was thermal insulated by arranging the rubble. All improvised means and various materials were used, which, at first glance, were not suitable for these purposes.

At a certain distance from the outer walls of the residential building, a fence from the boards was installed, falling asleep after that with a heat -insulating material. The best among all solutions was the option with straw, which the townsfolk covered on top to protect against water. The good gave the tenants warmth and did not disappear in the spring of the straw and fed cattle.

Sometimes they arranged a constant bunker - they fell asleep with a fence with earth, peat and expanded clay. On top it was necessary to lay the boards a little inclined, as a result, a pretty decent non-removable shop-smammake was obtained. The boards regularly served and as soon as they became unusable, the owners let them into firewood and made an abyss again.

Today there are enough different heat -insulating materials, so there is no need to use straw and peat. And the solution with the tuning works well. That's just made it already from non -wagging materials, filling with sawdust, mineral wool and polystyrene. The walls of the rubble are constructed from TsPS plates, they are not afraid of water and do not burn. If there is a lot of timber at hand, then it is perfect for this purpose.

Foam for insulation of the foundation

The building materials market today offers a choice of different insulation for the foundation: mineral wool, expanded clay, glass cotton wool. But the best solution is polystyrene. Its popularity is explained by the properties of the foam to maintain its functional indicators in any climate.

The foam is quite reliable, relatively inexpensive and easy to handle material, which consists of 98% air bubbles of the most famous natural heat insulator. This material is characterized by such technical qualities as resistance in contact with various coatings (asphalt and cement), water resistance, fire resistance and excellent thermal insulation.

The use of polystyrene under the foundation of houses that are built on loam or clay are completely unconditionally. Foam is considered an ideal material for any underground work, because it perfectly resists moisture and does not lend itself to the exposure of the destructive rays of the sun.

There are several types of foam that are suitable for insulation of the foundation structure of a residential building: pressed foam with thickness of more than 2 centimeters, an extruded polystyrene foam in size 100 by 100 by 5 centimeters, a foam of different colors, liquid polyurethane foam.

The use of each individual material is relevant in such work, but most often developers choose a foamyplex, which has a thickness of more than 20 millimeters, which positively affects the laying and decoration process. An exception for the use of polystyrene as a heater for the foundation are frequent flooding of the base of the house or its basement.

The insulation of the foundation with extruded polystyrene foam

It is advisable to insulate the foundation with plasty polystyrene foams in buildings with different functional purposes. Such a procedure has a lot of advantages: allows you to achieve an increase in the efficiency of the heating system and save energy resources.

The quality of polystyrene foam

The insulation of the foundation with polystyrene foam slabs is the most common option. This material is characterized by low thermal conductivity and high compression strength. The structure of high -quality extruded polystyrene foam is a homogeneous cloth -porous, which does not allow moisture to penetrate the material.

Water absorption per day is less than 0.2% of the volume of insulation. The small level of water absorption of this thermal insulation material provides a heater with high frost resistance. The useful service of the extruded polystyrene foam according to manufacturers has about 50 years.

Choosing the thickness of the plates

Today, polystyrene foam plates are produced with a thickness of 30 120 millimeters. To determine the required thickness of the thermal insulation layer, it is worth making some calculations taking into account such factors as the purpose of the basement, the material and the thickness of its walls, the climatic belt in which the construction occurs. In the middle lane of the country, the foundation must be insulated with polystyrene foam slabs, which have a thickness of at least 50 millimeters.

If the house has a basement where it is planned to equip a bath or wine cellar, then it is better to take plates with a thickness of 100 millimeters for insulation of the foundation. Along the angles of the base of the house, it is recommended to lay the slabs, which have a thickness of 60 100 millimeters, because it is the corners that freeze the very first.

Preparation of the foundation

When warming the foundation with polystyrene, as in other construction work, you need to perform a whole range of preparatory work. In order for the insulation of the base to be of high quality, you should remove the soil to the depth of its freezing. Clean the foundation of the remains of the soil and grind the foundation slabs with a primer primer.

If you want to save, you can independently make a primer. Melt bitumen and pour gasoline into it or diesel fuel into a proportion of 1 to 1, although diesel fuel can be added more. After drying the primer (approximately 1 hour), apply waterproofing material, since laying the waterproofing layer and the insulation of the foundation are integral work.

Waterproofing layer

As waterproofing material, you can use liquid rubber and roller bitumen materials. If you prefer liquid rubber, open the bucket, mix all the contents with a mixer and apply the spatula to the foundation.

Rolled materials are customary to be attached to the foundation by warming them with a burner. Measure the length of the roll vertically, cut and roll back into a roll. Warm up the roll from the bottom up, roll it and attach it to the foundation. This process is slightly similar to the installation of a soft roof.

Installation of polystyrene stoves

It is customary to fasten the plates on top of the waterproofing layer, fixing with bitumenlymeric mastic or polyurethane glue over the entire surface of the product or pointwise. It is important that the adhesive composition does not contain organic solvents (gasoline, acetone, toluene), because they destroy the structure of the polystyrene foam, which affects the durability of the heat insulator.

The slabs are not recommended to be fixed using mechanical fasteners, since it violates the waterproofing layer, i.e. Leaks may occur in the basement wall. Most of the extruded polystyrene stoves are equipped with the entire perimeter of the L-shaped recess, which allows the foam to the castle without the formation of cold bridges.

Cutting the place of the incorporation of neighboring polystyrene troops, it is additionally recommended to smear with mastic or adhesive composition. The question of attaching plates in two layers to achieve the desired thickness of thermal insulation material is controversial. Many experts believe that this can be done, because two layers of plates due to good adhesion of glue and mastic turn into one whole.

In this case, in order to prevent the formation in the foundation from the foam of the cold bridges, you need to lay plates with overlap of the seams of two layers. However, some experts believe that there is a certain risk of stratification of the heat-insulating pie due to vertical shift of the soil. As a result, in the gap between the upper and lower layer, water may penetrate, which causes heat loss of the house.

It is customary to lay the lower row of polystyrene foam plates with emphasis on a strict basis. The best solution is when there is a ledge in the foundation, which is made at the stage of its filling. Often, the insulation is laid on gravel-sandy backfill, where the foundation itself is installed. Remember that the insulation should be placed around the entire perimeter of the foundation.

With the backfill of the foundation, the insulation of which you have already produced, another layer of rolled roofing roofing roofing roofing roofing roofing roof should be laid between the Earth and the polystyrene. Also, from the outside, you can close the foam with a brick wall, which has a half -brick thickness, or using a profiled plastic membrane. This procedure allows you to save the foam from excessive contact with insects and water.

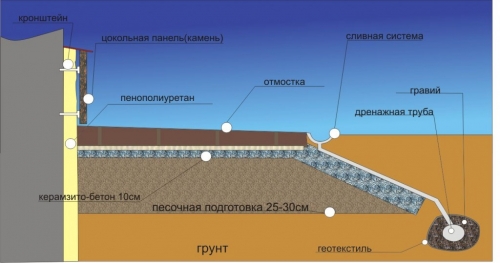

Warming the foundation with polyurethane foam

It will be possible to achieve the maximum possible thermal protection of the house only when creating a closed thermal circuit, within which polyurethane foam will close the foundation of a residential building without gaps and gaps. Polyurethane is a synthetic polymer material, which is made by the method of mixing liquid components with special equipment.

One of the main advantages of polyurethane foam is low thermal conductivity. A special technique for spraying the insulation allows you to get a continuous layer of thermal insulation, in which there are no seams, even when the foundation design has complex geometry. At the same time, the possibility of cold bridges is completely excluded.

The strength of this material is largely determined by its density. It is recommended to use polyurethane with a density of at least 60 kilograms per meter cubic to isolate the foundation. A similar density is capable of providing a strength of at least 0.25MP with 10% of the foundation deformation. The minus of the polyurethane foam is the cost of material and installation work.

The process of manufacturing the formwork of the foundation from foam and insulation occurs directly on the construction site. Apply this material to the foundation using the spraying method using the necessary equipment. The material will harden 17-20 seconds. The process of spraying polyurethane foam is much less time than the installation of plates.

It is customary to apply the material with several layers, each of which has a thickness of 15 millimeters close. At the same time, it is important to be able to correctly determine the thickness of the applied layers by eye and to predict the level of consumption of polyurethane foam. In the middle lane of the country, it is customary to apply a layer of this material for insulation of foundations, which has a thickness of 50 millimeters.

This thermal insulation material has good adhesive properties and clings to any surface perfectly. Polyuurine foam, after applying to the foundation, is waterproofed and covered with earth. In the area of \u200b\u200bthe basement, polyurethane foam can be covered with plaster. However, before applying the plaster, it is necessary to level the layers of hardened foam, cutting off the protruding places with a knife, and process the prepared surface with a primer.

Foam against the deformation of the foundation

Different types of soil have different features that make them prone to less or more to fusion. The soil, which consists of loams and clay formations, is recognized as the most healing soil. It should be noted that a similar type of soil on domestic lands is especially common and, unfortunately, is most subjected to deformation forces associated with fusion.

The mechanism of the appearance of such deformation forces is quite simple. First, the soil is moistened with water, which gradually begins to freeze when the frosty season occurs. Frozen water expands significantly in volume and thereby increases the volume of the soil itself, which begins to swell, acting with force on the foundation of the foundation.

Such a swelling at first is not too noticeable, but with the onset of spring, the soil begins to thaw. Excess moisture begins to leave the ground, which sags, which entails the subsidence of the founding of the house. This provokes the deformation of the walls of the basement and the foundation on which cracks begin to occur.

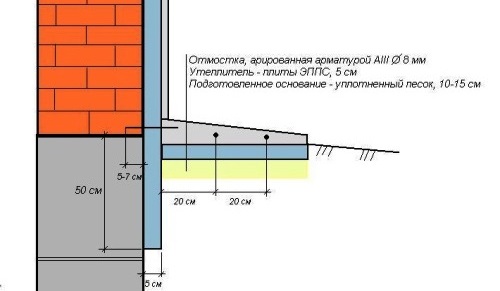

To eliminate the freezing effect, it is recommended to arrange complete thermal insulation around the perimeter of the foundation. It is customary to start work with digging perimeter excavation with a depth of 40-50 centimeters. It is necessary to fall asleep there a sandy layer, which has a thickness of 20 centimeters. Then it must be tamped with a slight bias, you should start from the foundation of the foundation.

Put the foam slabs on the sand. Since in our country soils are able to freeze by 1.5-2 meters, a similar width should be for products. The width of the insulation in the corner zones is 1.5 times larger, because the heat is lost more than on flat surfaces. Pour sand again on top of the material. The thickness of the layer this time should be 30 centimeters.

After the foundation has been insulated with polystyrene, it is worth equipping a special drainage system for the use of excess fluid from the insulation. True, this is only necessary when the foundation is placed in the area of \u200b\u200bwater -saturated soil.

Put the pipes of this system slightly lower than the floor in the building is located. The base for pipes is a layer of gravel, which is laid at a slight angle. Gravel material is also covered with a pipe on top of the pipe. If excess moisture is seeped through gravel, then it will subsequently enter the drainage system, and then go to the well pile or sewage.

Thus, the insulation of the foundation with foam can solve several problems at once. Foam prevents the ground first of all. As a result, the heating soil loses the pushing strength, and the foundation remains intact, while the basement retains heat.

Until the first winter, I thought that

Before the first winter, I thought that the insulation of the foundation was a useless waste of money. Very mistaken. Still, I had to order and insulate mineral wool through the traimer.