Car owners pay special attention to their maintenance, because not always ...

|

|

Modern and unique in design aluminum glass doors ... |

The quality and duration of the operation of any building determines primarily it ... |

Cracks in logs. Causes and methods of prevention

The steady increase in the number of wooden buildings has become one of the most significant phenomena of the new millennium. The desire to take a break from the exhausting consequences of urbanization and recharge with the positive energy of nature becomes the reason for the instinctive understanding that this can only be done in your own cozy corner, located outside the bustle of the bustle and built, certainly from wood. However, the developers are waiting for problems here. Due to the fact that most of them are the victims of urbanization, engaged in the arrangement of wood houses, the owners strive to transfer the generally accepted analogies of urban construction to wooden buildings that do not allow the appearance on log walls absolutely no flaws. Misleading with such stereotypes, developers who discovered at least the slightest cracks in logs fall into a panic, the result of which there are many expensive and, sometimes, useless events.

Content

- The reasons for the formation of cracks in the wires

- Preventive measures that prevent the formation of cracks in logs

- Semetization of cracks in logs: which materials to choose?

- Cracking in logs of acrylic putty

- Elimination of cracks in logs using acrylic sealant

- Arbogips: preparation and methodology of sealing cracks in logs

- Konophazing moss cracks in logs: main advantages

The reasons for the formation of cracks in logs

Having discovered cracks in the logs of the log house, many owners first think about why they appear. The reasons for this process lie in many factors affecting the tree during its operation. However, the main one is in different amounts of moisture found in the inner and outer layers of the material. According to experts in the field of wood, drying, the surface layers of the tree strive to reduce their size under the influence of academics, while the humidity preserved in the inner layers of wood prevents the vasushka of the inner layers. As a result of this, there is a discrepancy between compressive and stretching forces, the activation of which occurs in the inner layers. If the strength of external influences is much higher than the strength characteristics of the wood, a crack occurs.

In addition, the intensity of cracking depends on the time of the year when the harvesting of wood was carried out. If the harvesting of the material was carried out in the warm season, when the intensity of sap flow is the highest, in this case the risk of cracking increases significantly, since the tree will be characterized by increased humidity.

Thus, the conclusion suggests itself that in the process of natural drying of wood, cracking in an inevitable process, which is not possible to exclude it completely. The only thing that can be undertaken in this situation is to minimize the size and number of newly formed cracks. How to achieve this? Read further.

Preventive measures that prevent the formation of cracks in logs

Natural drying

The most effective way to prevent cracks in the gallendled log is a long -term drying of wood in natural conditions, which is necessary to carry out before the start of its use. The effectiveness of this event is determined by the uniformity of drying the inner and outer layers of natural material, which can be achieved only in natural conditions. Thus, cracks can be prevented by balance of the speed of drying the external and inner layers of wood, which will ensure a uniform transition of the inner layers to the outer ones. A similar balance is achieved only due to natural drying in a shady, cool place, the duration of which is at least two years.

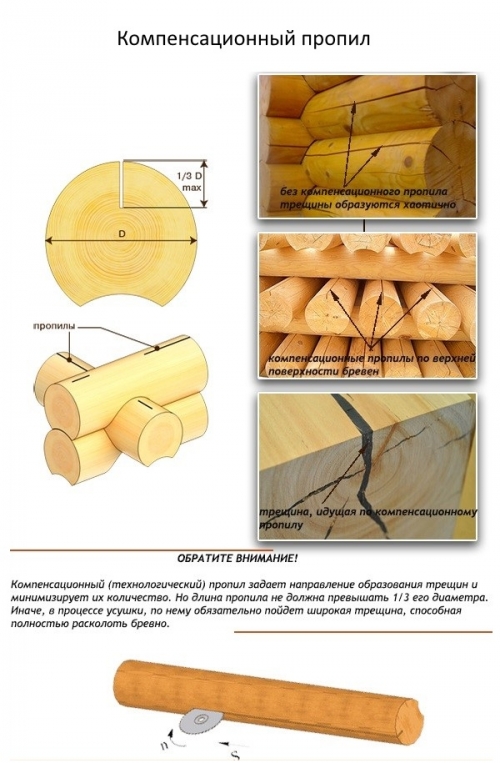

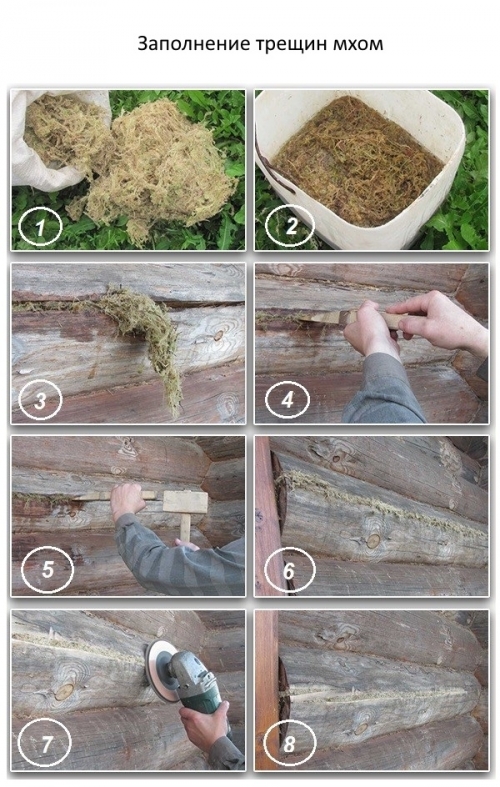

Compensation cut

There is another event with proven effectiveness, which has found their application among developers who seek to prevent the process of cracking. The essence of compensation cut is to reduce tension in wood fibers. Compensive or unloading cut on the upper surface of the log or along its axis. The outload can be carried out both along the entire axial surface, and bringing only to the ends of the log.

To prevent moisture from getting into a cut, it is blocked by a overlying log. In the process of natural drying, the cut will gradually expand, which will subsequently lead to a reduction in the number of cracks and a decrease in the depth and width of the existing ones. It is important to remember that the depth of the so-called technological cut should not exceed 1/3 of its diameter, and the thickness of 7-10 mm, which otherwise can lead to the formation of a crack, which contributes to the split of the log. Perform technological cut using a chainsaw or a galinder machine.

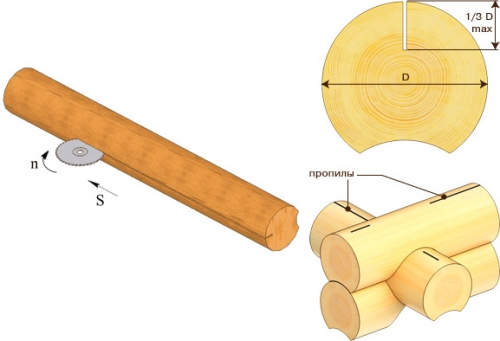

Measures implying the sealing of the ends of the logs

Considering the fact that the ends of the logs are primarily subjected to drying, which contributes to an earlier and, importantly, intensive formation of cracks, a number of measures that prevent this process were developed. The essence of the measures is to block the ends of the logs with the help of sealants, which will prevent the premature output of moisture and drying out of wood. If only lime was used in time immemine for sealing the ends, today the construction market offers a wide selection of wax solutions, oil varnishes and varieties of olifa, which will cope with this task much more efficiently.

But what to do in the event that preventive measures have been conducted late and the crack has already formed? How to make cracks in a log and prevent them from the spread of rotting rotting? There are many ways and materials for sealing cracks in logs of the log house.

Semetization of cracks in logs: which materials to choose?

The construction market offers the following materials for sealing cracks in the log:

- Acrylic putty;

- Acrylic sealant;

- One -component polyurethane sealant;

- Arbogips.

Cracking in logs of acrylic putty

Acrylic putty is suitable for sealing cracks in a log characterized by small sizes and depth. If these indicators exceed 3-4 mm, after the acrylic putty harden, you find that it began to crack. The construction market offers developers to purchase ready -made puttys, which are plastic compositions, which are obviously painted in the color of one or another wood rock. The putty, made in accordance with innovative technologies, is much more frost -resistant and waterproof, dry and differ faster and differ in durability.

Elimination of cracks in logs using acrylic sealant

The owners of wooden buildings faced with the question: how to close cracks in the log?, Should know that this event is possible with the help of a modern acrylic sealant material for cracks intended for intervention of intervention sutures between the timber and logs, as well as bought and small cracks in the walls of log houses and baths.

However, there is an opinion that it is not recommended to fill a crack by acrylic sealant to a depth of more than 5 mm, as this significantly reduces the quality of sealing.

In the event that the crack depth exceeds 5 mm, the cracks are laid in the depth of the crack from polyethylene, on which the sealant is subsequently applied. A positive result of such an event is due to a low clutch of polyethylene and acrylic sealant, which allows you to create a fastening tape characterized by high elasticity.

Arbogips: preparation and methodology of sealing cracks in logs

Another material for sealing cracks is Arbogips, which is a mixture of a water solution of gypsum and filler, in the role of which are most often sawdust, straw cutter or crushed bark.

- The preparation of arbogypsum is not difficult and involves the addition of sawdust to dry gypsum, based on a ratio of 3: 1 with the subsequent addition of water. In this case, the ratio of water and gypsum is 1: 2. If it is necessary to obtain a more plastic composition, a few drops of shampoo are added to the original mixture.

- The resulting arbogips is invested in the existing cracks with a spatula and left until completely dry. A similar sealing method is very effective, since the Arbogips is characterized by a high degree of adhesion to the tree, which at times increases the operational period of the material.

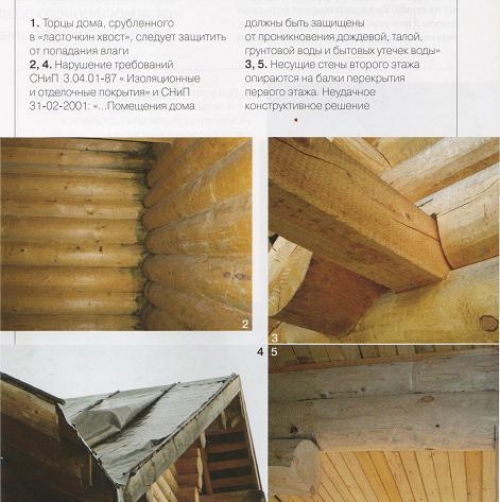

Konophazing moss cracks in logs: main advantages

In the village huts, one of the common ways to close up deep cracks, known since our grandfathers, is to close them up. This method is not only functional, since it allows you to eliminate the bridges of the cold, but aesthetically significant, since it does not spoil the appearance of a log structure.

Before hemp, dry moss is immersed in a container with water for half an hour, after which the water is drained and the moss is squeezed. Moisturized moss is rolled into rollers and with the help of a shoulder blade fill in cracks. To achieve maximum compaction of the moss, they tap along the shoulder blade until the layer of moss begins to spring. After drying, which lasts on average 2-3 days, an increase in moss in volume occurs, which contributes to reliable clogging of all the cracks.