To protect your house from the penetration of groundwater, damp, capillary water, ...

|

|

One of the most difficult stages of repair is rightfully considered to be filled with screed. Really... |

If you purchased a suburban site and decided to independently engage in construction ... |

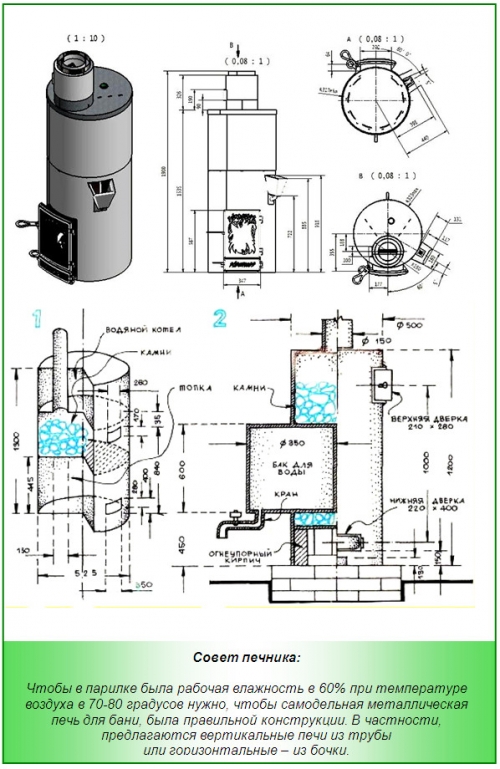

Metal bath stove: drawings, installation instructions

The modern revival of interest in the bathhouse is connected with the stunning discovery of doctors, claiming that the secret of Russian, and at the same time, the Finnish bath is revealed. The consequence of this popularization of the steam room was the furnace for a bath made. This is due to the fact that the modern market is still not able to fully satisfy the consumer demand for bath stoves, as well as with an unreasonably high price for these units. In addition, the Finnish and Russian baths are a place not only for washing, but also for the complex recreational hygienic procedures that completely restore the energy potential of the soul and body. The conditions created in serial production do not allow us to provide for a combination of specific local factors, and therefore, professional connoisseurs of baths often prefer to construct a bath unit on their own, and not to purchase factory, made by faceless standards.

Content

- Bath stove of metal: topics of the topic

- Modern metal stoves: design features

- Varieties of bath furnaces made of metal

- Metal bath stoves: advantages and disadvantages

- Form of the bath furnace: what to look for?

- Making a metal furnace for a bath: search for possible options

- Making a metal furnace with your own hands: step -by -step instructions

- Installation of a bath furnace: what to look for?

Bath stove of metal: topics of the topic

Since time immemorial, metal stoves have been famous competitors to traditional brick units, which is relevant not only for private houses, but also for baths. This is due to their undeniable advantages, such as quick heating and relative ease of installation, which is especially true for those who plan to make them on their own. Along with high thermal conductivity and excellent aesthetic characteristics, with irrational use of a metal stove or non -compliance with all the nuances in its own manufacture, we must not forget about the risk of fire. In this regard, it is important to follow all the nuances and make a bath stove in accordance with the instructions proposed by our specialists. You can find it by reading a real article.

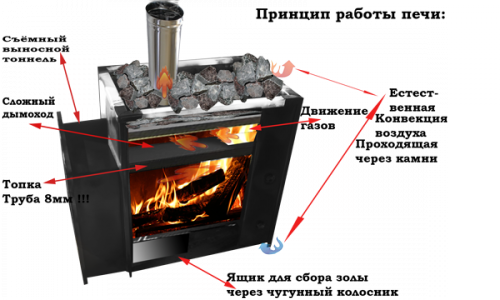

Modern metal stoves: design features

The simplest model of a home -made metal furnace is the so -called bourgeois, consisting of a box equipped with a door and a pipe. Their disadvantage is that, despite a relatively small thermal return, their need for fuel is extremely high. In this regard, they have long been considered an irrelevant relic of the past.

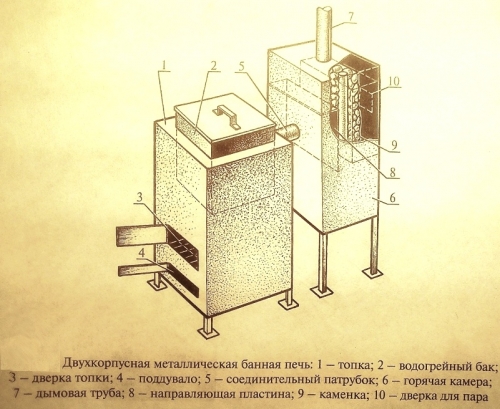

As for modern metal furnaces, they belong to a higher safety class. Their manufacture is carried out from leaf iron, the thickness of which does not exceed 4-5 mm. In addition, they are equipped with a specialized heat chamber designed for stone backfill. Often the possibilities of their design allow you to equip an additional water tank, the volume of which reaches 70 liters. To ensure uniform heating of air in the furnace, as well as to reduce its fire hazard, the metal furnace is laid out with refractory bricks.

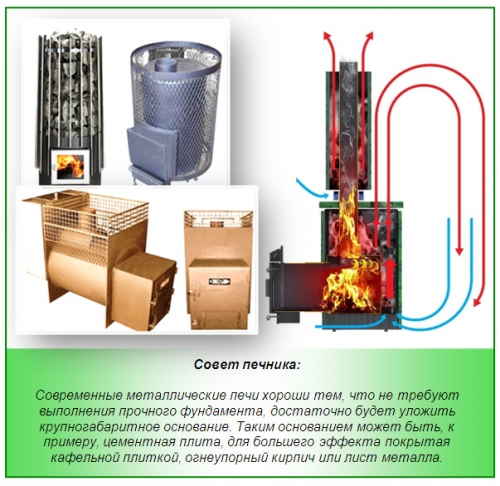

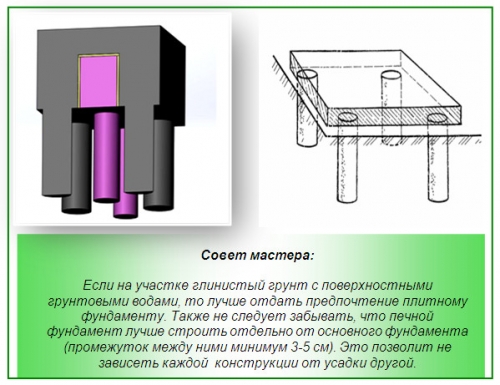

Important! By giving preference to modern metal stoves, you will save yourself from the construction of the foundation of high strength. In this case, there will be enough implementation of a large -sized base, in the role of which a cement slab can act, to increase effective with tiles, a sheet of metal or refractory bricks.

Photo of bath furnaces made of metal

Varieties of bath furnaces made of metal

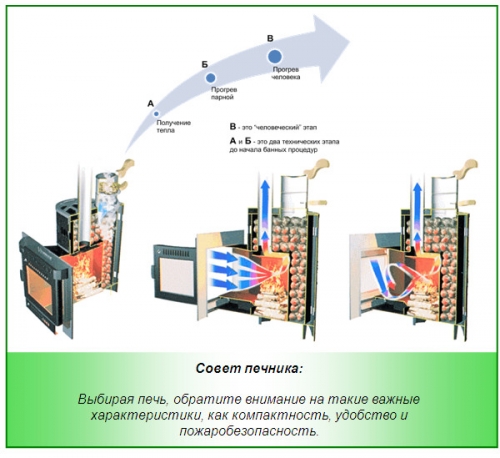

Design features: 3 types of bath furnaces

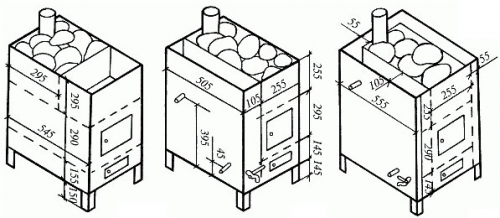

If you study numerous drawings of bath furnaces made of metal, we can conclude that from a constructive point of view, several varieties of bath furnaces are distinguished:

- Bath stoves with a closed design, due to the compactness of which they prefer to install in small baths of the family type. To increase heat capacity, this design on the outside and inside is built up with red refractory brick. Brick fixation is carried out using metallic bonds. In the middle part of the furnace, a grate for stones is installed;

- Bath stoves with an open design are characterized by the presence of a smaller tank, while their heifer is open. In this regard, having installed an open -type stove in the steam room, you will provide a faster warming up of the room. To increase the heat capacity of such a furnace, stones are covered with a galvanized lid;

- Combined bath stoves, in the design of which are distinguished by a fuel, equipped with two valves, a grille and a blunt, two pipe (with a diameter of 10 and 14 cm), in which four holes for the pipe and a roundabout are distinguished. The manufacture of such furnaces is carried out from sheets of steel with a thickness of 3-5 mm;

Type of fuel: 3 types of bath furnaces

In accordance with the type of fuel used, several types of bath furnaces are also distinguished:

- Wood stoves The earliest variety of bath metal furnaces with appropriate characteristics. They require a large amount of fuel and, at the same time, need constant and careful care. However, there are connoisseurs of such furnaces that prefer to wait slowly while they heat up, but then fully enjoy the fragrant warmth of real fire;

- Electric stoves Another variety of bath furnaces made. They consist of a metal case equipped with a heating heater and heat -insulating elements;

- Gas metal stoves for a bathhouse The most reliable and modern furnace units. They are iron structures equipped with a thermostat designed to regulate power. You can also not worry about the safety of the structure, since it implies the presence of a safety device that instantly triggers in the event of a gas damp.

Metal bath stoves: advantages and disadvantages

Since there are two main varieties of furnaces for the bath: brick and metal, we will consider the main characteristics of the latter and their advantages over stationary bricks. Firstly, as already noted, unlike stationary brick furnaces, metal units are more mobile and compact options, and therefore, they are ideal for installation in small rooms. As for the manufacture of homemade furnaces, it is not necessary to carry out their installation at the installation site, you can produce it in any place convenient for you and subsequently move to the installation site. There are two main types of structures of metal furnaces:

Hot -type furnaceAn option that is ideal for installation in episodic baths, for example, in the country. Despite the fact that it warms up quickly, it is not recommended to be used in permanent baths, since, using such a furnace, it is very easy to overheat the room, due to the inability to control its temperature;

Cold -type furnace ideally suitable for installation in heated rooms. They, like the previous version, are quickly warmed up, but the possibility of overheating is excluded, since it is equipped with a temperature control system. It is almost impossible to burn about such a stove, since the temperature of its walls rarely exceeds 50 degrees.

Advantages of bath furnaces made

Summing up, we note the following advantages:

- Small size and mobility of the structure determines the irreplaceability of such a furnace in small baths;

- Do not need a preliminary installation of a massive foundation, it is enough to equip a lightweight version of the foundation, which greatly facilitates the installation of a bath furnace;

- Features of the principle of work. Unlike brick units, metal stoves are constantly burning, in connection with which it is impossible to go to the bathhouse, having previously not protered the furnace;

- Low price. Unlike brick, the metal stove is easy to manufacture and does not require additional costs. The search for schemes of bath furnaces made of metal is also not difficult. A huge number of drawings can be found on the Internet and specialized magazines.

Disadvantages of bath furnaces made

- Quick cooling due to the inability to accumulate heat. In this regard, it is necessary to constantly maintain fuel combustion in such furnaces;

- Inability to heat large rooms;

- In order to prevent the development of a thermal blow in the process of staying in the room, it is necessary to install double walls while maintaining an air gap between them;

- Due to the fact that the fire safety of a metal furnace is much lower than that for a brick furnace, it is necessary to provide enhanced protection of the internal casing of the furnace.

Form of the bath furnace: what to look for?

Despite the fact that at first glance it seems that the shape of the furnace is an insignificant parameter, the performance of the unit and the convenience of its operation depends on it. The most common are cylindrical stoves, horizontal and curly structures, but rectangular units are most convenient in operation.

This is due to the presence of corner zones in them, which are almost never red -hot. In this regard, it is common that such a frame retains the shape of a furnace. In addition, the shape of the furnace determines the rationalism and uniformity of heating the furnace, since the maximum heating of one element helps to reduce the heating of the wall located next to the combustion zone, which contributes to the uniformity of heating the room and the balance of heat flows. In addition, the mechanical stability of the structure depends on proper warming up. It is not difficult to trace, for example, round and cylindrical stoves are less resistant to heating, and therefore, their walls are more dense, reinforced. The high stability of the rectangular furnace is due to the presence of cold corners. However, over time, the loss of form cannot avoid this proven fact.

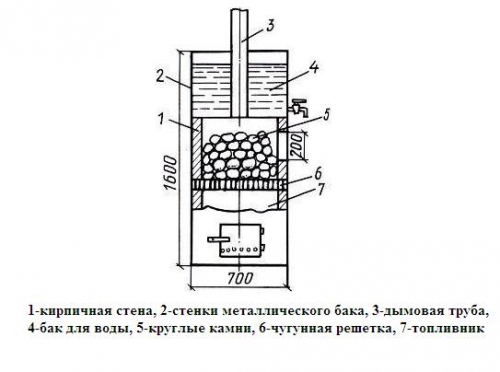

Making a metal furnace for a bath: search for possible options

For many years of using metal furnaces for the bath, many options for their own manufacture have been proposed. One of the simplest options is the manufacture of a metal stove-stove from an iron barrel, during which the lid and bottom of the barrel with the formation of the cylinder are removed. Half of the resulting cylinder is filled with bricks placed on the rib on which the grate is subsequently installed. The resulting free space is filled with stones into two -thirds, after which the chimney is installed and the improvised stove is covered with a lid. However, despite the simplicity of manufacturing, this option is considered one of the most inconvenient in operation.

If your bathhouse is characterized by a fairly small area, you can make a compact stove-stove of sheet steel, the inner surface of which is laid out with brick. The sizes of the bath furnace made of metal are quite modest and correspond to the heated area. It is enough to put the walls of the firebox in half the brick, and the chimney of a quarter. This furnace is not only easy to manufacture, but also extremely convenient in operation, since it does not require a large amount of fuel and warms up for a relatively short period of time.

There is another option for making a stove-stove for which brick is not required. This method is also easy to execute and not very costly from a financial point of view. As for the appearance, it is quite aesthetic. This design will easily cope with the heating dressing room, washing and the steam room itself.

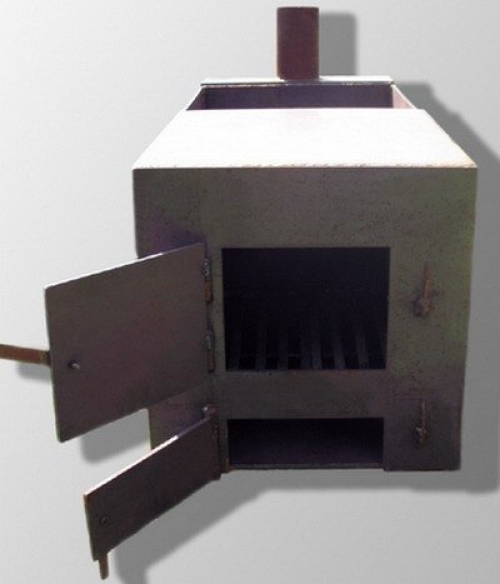

Making a metal furnace with your own hands: step -by -step instructions

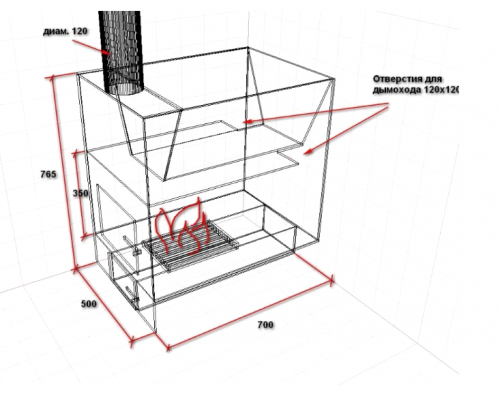

Necessary materials and tools

- Sheet steel with a thickness of 8 mm;

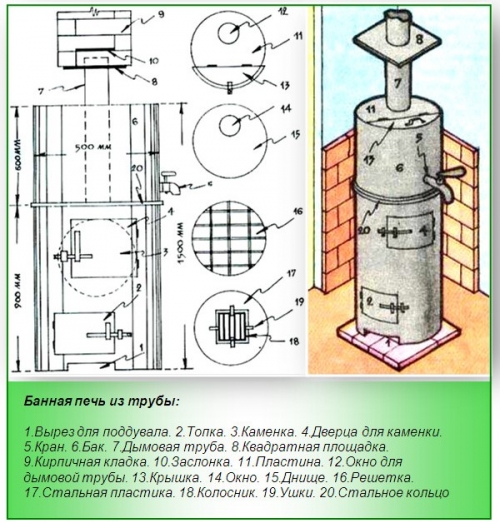

- A metal pipe, the wall thickness of which reaches 10 mm, and the diameter is 500-600 mm;

- Bar, the thickness of which is 10 mm;

- Grate;

- Claxolds and doors for the furnace, stoves and blew. In the case of independent manufacturing of the doors, you will only need the Skokolds;

- Water tap;

- About 2 meters of the pipe, 90 cm of which will be needed for the furnace, 60 for the tank, and the remaining 50 cm for the manufacture of secondary parts;

- The tools will require a grinder and a welding machine.

Stove -making management manual

At this stage, you will need a large segment of the pipe.

Important! The manufactured design involves the presence of a closed heater, and if you need to splash water into it, you need to open the door.

First of all, the pipe is cut in the pipe, the dimensions of which are 50 and 200 mm. On the inside of the pipe above the hole, fasteners for the grates are welded for this, you need a metal plate equipped with eyelets. The grate can be purchased in any construction or specialized store.

Next, proceed to the manufacture of the furnace. For it, it is necessary to make a hole in size 250 by 200 mm. The fastenings necessary for installing the stoves are welded on top, the diameter of which should be at least one centimeter. They can also be replaced with grates designed for round furnaces, which can be purchased there.

On the opposite side of the heater, a hole is made in which water is poured. Next, the stove is filled with stone, for example, talcochlorite, diabase. The use of mica -containing stones, flint and granite is excluded.

In the cover intended for the unit, a hole for the chimney is made, after which the pipe itself is installed. Despite the fact that the installation of a bathhouse can be considered almost completed, experts advise additionally installed a water tank.

To do this, the remaining, previously not demanded piece of the pipe is welded to the heater, in the lower part of which a water crane is welded. During the operation of the furnace, smoke, passing through the pipe, will gradually heat it, but its boiling will not occur. In conclusion, it is necessary to make a lid designed for a heating tank. In accordance with the diameter of the pipe used, prepare the lid and cut it in half. In the first half, it is necessary to cut the hole under the chimney, after which it is welded to the tank. The second half during the installation process must be equipped with hinges and a handle, so that the free part of the lid will remain removable.

Installation of a bath furnace: what to look for?

- It is necessary to take care of the installation of a bath furnace at the stage of building a bathhouse and on the site of the future stove, lay a fine -loaded foundation. Subsequently, a double row of bricks is laid on it and the stove is installed. To increase the fire safety of a home -made oven, it is necessary to clearly observe the rules for their installation. They are as follows:

- The smallest distance from the wall to the furnace should be at least one meter. In addition, experts recommend taking advantage of additional protection and install a foil, equipped with a layer of insulation on a nearby wall, which to prevent overheating of the tree and its subsequent fire in a timely manner;

- You can not neglect the insulation of the chimney. To do this, it is recommended to make it from a sandwich pipe, between the outer and internal casing of which is the heat-insulating layer;

- If the design of your furnace involves the removal of combustion products on a pipe made of metal, a ceiling and a ceiling node will be equipped at the junction of the ceiling and pipes.

Upon completion of the installation, the furnace can be lined with brick, which will not only add aesthetics to the appearance of the stove, but will also prevent the occurrence of burns. In addition, in this case, a closer arrangement of the furnace to the wall is allowed.

We hope that we were able to convince you that the manufacture of a metal furnace for the bath is not such a difficult event, and, using this management, you can avoid difficulty in the process of its manufacture. We do not deny that this design is not the only way to manufacture a bath furnace, but it is the easiest to install and convenient in operation.

I thought to do it for a long time

I thought to make a stove for a long time or still overpay a little and buy ready. In my opinion, the overpayment of a couple of thousand is not worth these sets. I took from Leyka.com.ua a Novoslav oven and satisfied!

There is no example of a calculation, what

There is no example of the calculation of what size should be the firebox and a stove for a certain bath

One droop in the article. Where

One droop in the article. Where are the specific sizes of all volumetric details of the furnace. How much volume is needed for the smokers, what should be the diameter of the chimney in the ratio with the volume of the furnace, at what distance from the floor should be succumbing, etc.