The arrangement of water supply and sewage systems on the site is one of the most ...

|

|

Granite a symbol of hardness and unshakability. Natural stone unites in ... |

The security and inaccessibility of any home depends on many factors, and the presence ... |

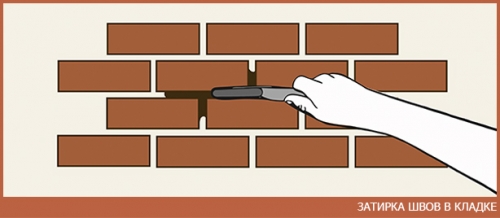

Brick masonry seams

If you purchased a suburban site and decided to independently engage in the construction of a brick house, experts do not recommend forgetting about a number of nuances associated with brickwork technology. One of these nuances is to expand the masonry of brick masonry. Its importance is due to the fact that, regardless of the final purpose of the building, before the start of operation, its brick walls should be subjected to qualitative aesthetic design. And one of the external decorations is to expand the seams of brickwork. However, experts argue that the seams in brickwork can be done not only at the time of the construction of the wall, but also on the old masonry of the building, which has already been in operation for many years. Naturally, the technology of extension in both cases will vary. As the seams of brick masonry are expanded, as well as what are the differences in the technology of the seams of the seams of the newly erected wall and the wall of the building that was in operation to these and other questions you will receive an answer in this article. But, before moving on to the consideration of the technology of seaming, we suggest you familiarize yourself with some theoretical aspects of brickwork.

Content

- A little theory: layout systems of masonry seams

- Brick masonry seams: relevance of the issue

- Types of seaming: the main characteristics

- What is the purpose of the seams?

- Features of the use of brick masonry seams

- Switching technology: step -by -step guide

- And finally

A little theory: layout systems of masonry seams

As you know, the main requirement for a brick wall is stability, which allows the dressing of brick masonry seams. It is performed in such a way that each overlying brick rests with two or three underlying bricks and at the same time overlap the seams between the lower bricks. It was this way of laying bricks that was called a dressing. It contributes not only to an increase in the stability of the wall, but also to the uniform distribution of loads on the brick wall in the case of uneven precipitation and temperature deformations. In construction practice, the following types of dressing were most used:

- Chain single -row dressing;

- Three -row dressing;

- A multi -row dressing.

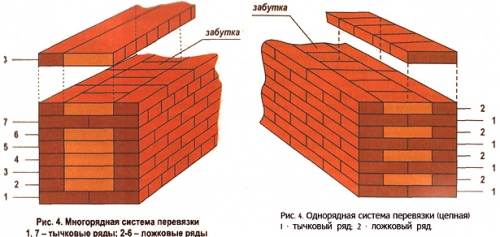

Each of them is characterized by reliability, as it firmly combines bricks into a single system. However, it makes sense to consider each separately. Experienced masters know that the rows of brickwork, depending on the location of the bricks are divided into spoon and pumpkin.

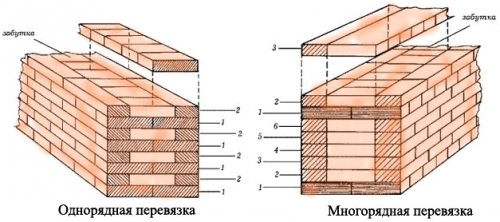

Technology one -row dressing Brick masonry involves the alternation of spoon and tech rows, and is most often used most often when the walls are not provided with facing bricks.

Three -row dressing, which is a popular variety of a multi -row system, involves the dressing of every three spoon rows with poke rows. In most cases, a three -row system is used in cases where pieces and columns are laid out.

A multi -row dressingit involves laying out spoon rows, which every 5-6 rows are tied with pupping rows. As for the number of spoon rows, it depends on the thickness of the brick. If it is 65 mm, it is necessary to lay out 6 spoon rows, and if it is 88 mm, the technology of a multi -row dressing involves laying out 5 spoon rows.

Brick masonry seams: relevance of the issue

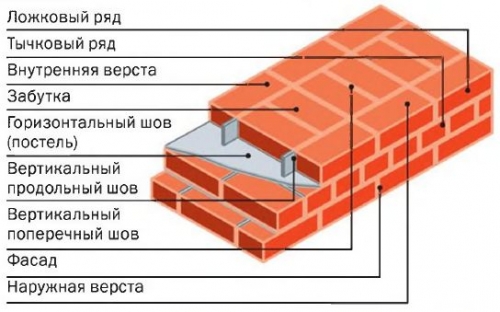

Traditional brick masonry involves the presence of vertical and horizontal brick masonry sutures. The technology of brickwork involves filling them with a solution intended for binding bricks into a single whole. After the brick ligation of the excess of the solution, which protruded outside the seams, is removed. Having carried out this, they are embroidered with brick masonry seams, which is the process of grouting seams in order to increase their tightness. Thanks to this procedure, the wall becomes not only attractive, but also resistant to external adverse factors. In this regard, we come to the conclusion that the embroidery of brick masonry seams significantly extends the operational juices of the building.

Types of seaming: the main characteristics

Before you familiarize yourself with the algorithm and technology of putting brick masonry seams, first of all, it is necessary to familiarize yourself with the possible options for setting up brick masonry joints, which are most often used in construction practice.

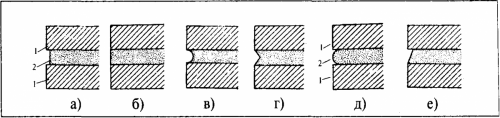

Rectangular cutting Or, the so -called extension, the flush is one of the simplest and, accordingly, popular methods of stitching seams. Technologically, this method involves cutting from the wall of an excess solution using a cell, and then the seams between the bricks are treated with a brush with a hard pile. After such processing, the seams are clearly distinguished;

Rectangular buried Used as a decorative decoration of brickwork. Despite the fact that this method is more time -consuming, its use is inappropriate for the processing of brick masonry, which is exposed to atmospheric precipitation. The technology for performing this method of expanding implies primarily the removal from all seams of the solution to a depth of 5-6 mm, their subsequent compaction and smoothing a new solution using rounded nagel;

Bent extension A popular way of grouting seams, involving the use of a special tool for stitching seams with the same name embroidery. First of all, this method involves cutting an excess solution with subsequent processing of their semicircular decay throughout the entire length of the seam;

Smarted update A method whose use is relevant in conditions with a harsh climate. Before its implementation, the irlo is thoroughly sharpened, after which, by directing it at an acute angle, the solution is cut off. The optimal level of the deepening of the tool is 3-4 mm;

Important! In the process of stitting, it is important to observe the sequence of their processing: first, vertical seams are processed and only then horizontal.

At the same time, according to experts, the thickness of the seams of brickwork is not given a decisive value, and it varies within 10-12 mm. This rule is due to the Rules of SNiP, according to which the size of the brickwork sutures is variable and for a horizontal suture ranges from 10-15 mm, while for vertical these numbers are varied within 8-15 mm. In addition, situations often arise when builders prefer thin seams, the thickness of which reaches 3-4 mm. This is due to the desire to save cement mortar.

Important! The thickness of the brick masonry sutures is very variable and can undergo a change depending on the climatic conditions in which the building is located, the desire to save materials, as well as responsibility and pedantry with which the master approaches the performance of the work.

What is the purpose of the seams?

Due to the fact that many structures are dispensed with seams and are operated for a long time, we consider it necessary to consider the main functional purpose of the seams of brickwork. So, what is it?

As noted earlier, it significantly increases the aesthetic characteristics of the building. Using this method of decorating the structure, you can effectively disguise the difference in shades, if the solution is kneaded gradually, within a few days;

The use of grout for brick seams allows you to prevent the destruction of the cement base, which allows not only to extend the operational period of the building, but also to postpone the overhaul for a long time. This is achieved by reducing moisture that falls on the seams, since it is it that destroys the brickwork, and, as you know, the price of restoration of the brick wall that has undergone destruction due to crack formation and wall collapses leaves little pleasant impressions;

Having put the seams of brickwork in accordance with all the rules, you can significantly increase the thermal insulation characteristics of the building and maintain heat in the room in the cold season;

Features of the use of brick masonry seams

- Masters should know that the seams are relevant not only for houses erected from construction bricks, but also for those that were built of double silicate brick M150.

Important! The main rule that must be observed when declaring the sutures of the wall subject to decoration should not be previously plastered, since the seams of brick masonry are a kind of analogue of the finishing material, the application of which is carried out only on a separate part of the surface.

- The use of stitches for finishing street walls is most common;

- Internal work is also often not without its use, which is permissible in cases where the finished surface needs to give it a certain color;

- Walls erected from natural stone can also be finished using brick masonry seams;

- The laying of masonry can be carried out at any stage of construction, whether it is the direct construction of walls or the decoration of the building after it will be for a certain time to be operated and will shrink. However, in the case of the first option, the removal of an excess solution occurs more painlessly, since being fresh, it does not have time to dry, reaching the stage of the seams. In the case of the seams of the old house, this happens much more complicated, since the solution becomes significantly stronger;

- In addition, if you decide to start declaring the seams on the old building, in the process of removing the old solution it is necessary to perform a more thorough deepening of up to 10-15 mm;

- We must not forget that to increase the strength of the structure at the construction stage, the dressing of brick masonry seams is used, which implies laying out the overlying series of bricks not parallel to the underlying, but with some displacement;

- In the process of embroidery, it is important to use only sharpened tools, for example, it can be a chisel designed to remove a hardened solution. Only if the tool is sharply sharpened, you can efficiently remove the hardened solution, otherwise there is a risk of slipping of the tool and damage to the building material.

Switching technology: step -by -step guide

Since you carefully familiarized yourself with the theoretical aspects of the seams of brick masonry, it is time to study the algorithm for its implementation, consisting of several stages.

Stage No. 1: preparation of brickwork

Like any construction event, the seams of brick masonry begins with the preparatory work. What are their essence? Consider further.

Obsis of contamination, including dust are removed from the surface of the walls undergoing processing. After that, using a brush with a hard pile, cement seams must be cleaned of the coarse contaminants. It is also possible to use the device, which is based on the use of high pressure. It is thanks to him that you get the opportunity to remove even the smallest particles that are not noticeable to the eye;

Having finished cleaning the surface, prepare a roller and a bucket of water, and then moisten the seams with which you plan to carry out work in the near future.

Important! Masters advise not to put the seams of brickwork in the hot season, since in this case the solution dries extremely quickly, which contributes to the violation of the entire extension technology. It is also recommended to stop the work in the event of the rain that has begun, since the solution can absorb excess moisture, which also contradicts the technology of seams.

Stage No. 2: Preparation of the solution

The solution for the stitches in masonry is implemented by construction stores in the form of a dry mixture, the components of which are strictly indicated on the packaging, or in the form of a finished solution. If you purchase a dry mixture, it must be diluted with water, the amount of which is indicated on the package with the mixture. Regardless of whether you purchase a dry mix or solution, you must follow the instructions indicated on the packaging, and also clearly observe all these proportions. In addition, it is necessary to strictly take into account temporary restrictions during which the solution must be fully used.

To mix the solution, it is better to give preference to an automated method and use a specialized drill equipped with a mixer nozzle, since mixing a solution manually is much more laborious and more expensive in time.

Important! Experts do not recommend knew the solution for applying to all walls at once. In their opinion, it is better to prepare it in small portions and use mainly an electric concrete mixer for this. If you apply a too liquid or already slightly dried solution to the temperature seam in brickwork, this is fraught with impaired integrity due to the first sharp temperature difference.

Stage No. 3: Returning of brick masonry seams

Initially, remove a small amount of old solution (10-15 mm will be sufficient). If in some places there is a destruction of brickwork at a deeper level, apply a knowingly larger amount of freshly prepared mixture.

Then again take the brush with a hard pile and carefully remove traces of the solution from the wall. In hard -to -reach places, the solution is removed using special devices or a chisel that we wrote about above.

In the upper part of the wall, it is necessary to prepare the stage for stitching the joints. Despite the fact that the most effective way, as before, is the installation of forests, you can use the stepladder.

By fully preparing the surface, you can proceed to applying the solution.

Important!In the process of applying the solution, remember that the key to a high -quality final result is the uniformity of the applied mixture and the complete absence of comco -shaped masses.

The technique of applying the solution during decomposing the seams of brickwork involves its application with some excess, which is immediately removed using the cell.

Next, take a narrow embroidery, and carry out intensive impression of the solution into vertically oriented seams. At the same time, it is important to press and not to smoot it out, since only the use of this technique allows you to get rid of the excess of air, which, if the work technique is not observed, can remain between the old and new layer of cement mixture.

Next, horizontal seams are processed using a long embroidery, which is operated so that the solution is evenly distributed throughout the seam.

Further, the desired shape is given to the new solution, which can be carried out using improvised means, for example, a plastic tube or rubber hose, using which you can make a concentrated seam. To get a beveled seam, experts recommend using a wooden bar, before work with which it is necessary to clearly determine its size. And the use of a sharpened wooden peg will easily turn a rectangular seam into a buried.

Important! If in the process of embroidery the seams it overtakes you, temporarily stop working and isolate the processed surface using ordinary plastic film.

As can be seen from the above instructions, the process of seaming the seams is not particularly difficult and can be carried out even by a newcomer in the construction business. Of course, being a beginner in this industry, most likely you will spend more time than an experienced master, but a significant plus is that you can save by refusing the services of workers.

Important! When erecting brick buildings with your own hands, remember the existence of deformation seams in the masonry, which, which, you can protect your construction from possible seismic fluctuations in the area, uneven shrinkage of the structure or sharp temperature changes.

And finally

We understand that most of our readers are not a professional in the construction industry, so we tried to clarify the entire process of decomposing brick masonry sutures as much more detailly. You can only get acquainted with the proposed materials and follow our tips. To facilitate the process of understanding the entire technology, below will be offered a video in which the process of making brick masonry seams is once again considered in detail.