Nowadays, when the field of building materials is rapidly developing, there is ...

|

|

In order not to waste time and effort on the restoration of an old wooden floor, on ... |

The parquet board can be laid on a concrete screed, wooden floor or plywood ... |

DIY plastic ceiling

Until recently, we could not imagine what you could do with the ceiling, except to whitewash or cover with a water -based. If I wanted something funny, glued with wallpaper. With the advent of new building materials in our life, completely new technologies for the ceiling finish began to arise. The arsenal of such design solutions also includes the installation of the ceilings of stretch, suspended, mineral, glass, mirror, stained glass, from drywall, as well as with wooden or plastic panels. We’ll talk today how to make a plastic ceiling.

Content:

- Features of plastic ceilings

- The advantages of a plastic ceiling

- Choosing plastic for installation

- Selection of materials and tools

- Preparatory work

- Installation of the box on the ceiling

- The ceiling sheathing with plastic

Features of plastic ceilings

Plastic panels for such ceilings are made of safe and harmless material polyvinyl chloride. In our country, PVC panels are used everywhere to decorate ceilings and walls, as well as for the manufacture of containers for food and food. So do not doubt the environmental friendliness of the material.

It is important to remember that plastic panels for walls and ceiling are different, and it is not recommended to buy some to replace others. The panels for the ceiling are much easier, and this is an important detail, although their mechanical strength is much lower. If you use the wall panels when installing the ceiling, there will be a large load on the frame, which is not very safe. And using plastic panels for the ceiling during wall decoration, you can eventually observe their deformation.

A plastic ceiling is a type of suspended ceilings. On the frame, which is attached with special suspensions, plastic lining is mounted. For the frame you need wooden rails (you can use a profile from metal). For the manufacture of the ceiling itself, you can use simple inexpensive materials, but it is better to spend money on better plastic. Fastening panels of plastic on the ceiling provide a skirting board for plastic ceilings and a figurative profile.

When installing ceilings from plastic, there is one nuance. The appearance of the surface depends on the selected panels. When buying glossy panels, the joints of the docking will be inconspicuous on such a ceiling, they are practically not visible. The glossy ceiling is a reflective surface, which looks quite original. If you plan to make a ceiling from matte, colored and patterned panels, then be prepared that the seams will be visible quite clearly.

The advantages of a plastic ceiling

If you, making repairs in your apartment, plan to make a ceiling from plastic, your choice is quite far, because such a ceiling has many advantages. Firstly, if you are flooded by neighbors, you will not have to redo the plastic ceiling, and if the flooding is not serious, you will not notice anything at all. And this is a big plus, because the ceiling, glued with wallpaper or whitewashed, would have to whiten or glue a second time.

At the end of the work, you will receive a perfectly even ceiling, which, if desired, can be washed with water or detergents. But even if you do not bother with the departure of a plastic ceiling, he still will not lose his beauty and originality. Even in case of temperature difference, the ceiling will retain its flat surface. The ceilings glued with wallpaper over time fade, and the plastic will retain its appearance for many years.

Using such a ceiling, you can not only hide large irregularities or pipes, but also turn them into a particle of the interior, arranging in that place beautiful modern lamps. The ceiling can be made not only smooth, but also embossed, using wide panels with contours. Another advantage of the suspended ceiling made of plastic is its price. Of course, this is not the cheapest type of ceiling, but, nevertheless, it will cost you much cheaper than, for example, a stretch ceiling. In addition, the air layer that forms between the ceiling and plastic creates good sound insulation.

Since PVC panels are surprisingly moisture resistant, they are logical to install them in the bathroom. When flooding, plastic panels are able to withstand water weight and not be afraid of the main enemy of moisture called mold. Especially if the polyvinyl chloride panels are also installed on the walls and in the kitchen. For the same reason, such a material is remarkably suitable to conduct a cladding of a home catering unit. Plastic panels in the kitchen are especially good, because such a ceiling is easily washed with conventional detergents, and, as you know, with constant operation of the gaspel, all surfaces are packed with soot.

Choosing plastic for installation

First you need to calculate how much material you need. This is quite simple if you know the area of \u200b\u200bthe ceiling. If not, then it can be measured. The premises of a complex configuration will need to be divided into pieces of rectangular areas on the ceiling, then the results should be rounded up. If the room is rectangular, everything will be easier to measure.

When buying, you just need to look at the packaging of the area of \u200b\u200bone plastic panel must be indicated there. Take into account the number in the packaging of the panels, you think how many panels are needed in order to block the entire area and add a little (given the trim and the like).

It will be determined with the type and color of plastic directly when purchasing. The design of the entire room depends on which panels you choose to install the ceiling made of plastic. White panels are the cheapest, and panels with a pattern and texture will be more expensive. All panels should be made in one color (color scheme), and the drawing, if any, should be accurate and correct. If the panel catches the eye than the rest, or vice versa is very dark, it is best to change it to the one that will fit perfectly into the overall tone of all panels.

When you buy such material as plastic, you need to be very careful and inspect each panel, because defective models are not desirable to use. When you purchased plastic, when transporting it to the house, remember that it cannot be damaged, because then during installation it will not fulfill its function and will not create perfectly even joints.

Selection of materials and tools

So, first you should get acquainted with the most common profiles for attaching plastic panels:

- The starting profile, which is most common. Such structures serve to close the ends of the panels and are attached to the ceiling around the perimeter of the entire room.

- H-profile is also called connecting. Based on the name, it is used to increase the length of the panels.

- The F-profile is designed to close the ends of the plastic panels at the outer corners when moving to another plane. That is, one wall is sheathed with PVC panels, and the one that is not around the angle.

- A plastic ceiling baseboard is in essence the same starting profile, but slightly ennobled.

- The external and internal plastic corner is used to close the end panels at the inner and external corners.

- A universal plastic corner can be glued to any corners, but it looks unpromising.

To determine the number of profiles, you need a scheme drawn in advance. Draw on paper a proportionally reduced ceiling. It should be borne in mind that the profiles should be defended from each other by 60 centimeters. Thus, it will be easier to deal with the number of bars, the footage of the baseboard and profile. It will also be necessary to buy suspensions for the frame, lamps (if necessary) and fasteners.

Profiles that are attached around the perimeter are also required. The number of screws for fastening panels and dowels that are necessary to fix the profiles is calculated taking into account the number of necessary profiles plus reserve. If desired, replace the profiles with a wooden beam and use brackets instead of screws. So you can reduce the cost of the process and simplify the assembly of plastic panels.

To calculate the amount of the required ceiling plinth, it is necessary to divide the perimeter of the ceiling by 3 (if the segment length is 3 meters). You will need: a ruler, a wallpaper knife, a roulette, a building level, a hacksaw for metal, drill, a stepladder. As well as a drill, a perforator, dowels, screws, a painting cord, suspensions and ceiling profiles. When all the tools are prepared, and the materials are purchased, you can start installing the ceiling.

Preparatory work

Basically, preparatory work when installing a ceiling made of plastic with your own hands is not needed, but if you wish, you can fumble it with sandpaper medium grain paper. Of course, if you make such a ceiling in a room with increased humidity, for example, in the bathroom, it is better to treat concrete overlap with an antifungal composition.

The first step is to determine the level of the future ceiling (how many centimeters it will be lowered down). If you still decide to mount the lamps, do not forget to leave a place for them. Basically, lamps have a depth of five to ten centimeters.

If you mount the lamps yourself, pay attention to the resistance of the purchased wire, but without certain knowledge in this matter, it is better to contact a professional. It is better to fix the wires above the plastic in advance and bring them to the switch. The wiring must be isolated and hidden behind profiles. Next, make markings on the wall around the perimeter.

Installation of the box on the ceiling

Determining the horizontal, it is important to remember that the oblique ceiling will be striking, so that everything should be measured more than once, measuring first the height of all corners and choose the lowest. Then you should retreat 5 centimeters to the floor and mark the horizontal, using the water level. In the corners and at the ledges you should leave marks, as in the photo of the ceilings made of plastic. Further, using the painting cord, beat the lines that have previously determined.

On the marked strip, which shows how lower the ceiling will be, you need to lay holes for dowels. This must be done using a drill or perforator. Through the profile, you need to make holes directly. In these holes you need to insert the dowels, and attach the ceiling profile to the wall. The usual length of such profiles is three meters, but they can be interconnected if you suddenly have a very large room, inserting one into one. At the same time, do not forget to fix the profiles with each other with bugs.

A profile should be attached to the wall along the entire perimeter of the room, and on the ceiling of the suspension, to which the ceiling profile will be attached. The suspensions should be fixed along the straight line. The necessary lines can be created using a painting cord, not forgetting about the distance (about 60 centimeters from one another).

After that, you need to pull the thread of the leska. This must be done as shown in the video about the ceilings of plastic, across the entire room, from wall to wall. Then this thread should be attached to the dowels that already hold the profile. It is important to remember that if you pull the thread of the leska incorrectly or not strong enough, sagging cannot be avoided, but it is necessary to make a perfectly flat horizontal.

At the level of the thread, the profile should be fixed. To do this, you need an assistant who will hold the profile so that he is in maximum proximity to the thread, but does not touch it. Attaching the profile to the suspensions, you need to bend them. When the frame is built, you can proceed with the ceiling with plastic. The plastic itself is recommended to be attached with clips-clips, not forgetting about the points of contact with the profile. Even the smallest seams are better to close with silicone, and remove excess material with a spatula so that the ceiling looks neat.

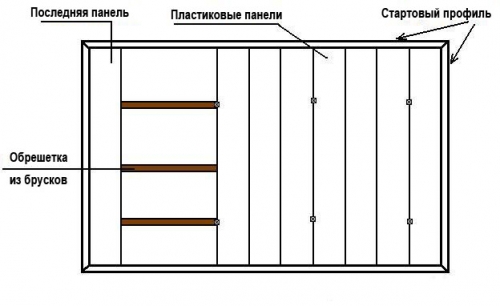

The ceiling sheathing with plastic

When you started working with plastic directly, pay attention to the room. If it is slightly skewed around the perimeter and uneven, then the first plastic strip must be cut very carefully to properly hide this drawback. It is necessary that the next stripes are attached to the profile perfectly, at a right angle.

It is important to know before making a plastic ceiling, that the installation of panels can be carried out not only across the room. You can install the panels along and diagonally, and the coloring, thus, will be easy to combine if you want to get the original ceiling with an unusual pattern as a result. If you have chosen thin plastic, then you can bend it by finishing off the corners, this will help create an unusual design. There is also a special corner plastic that hides the joints of the panels. With the help of plastic, you can also make a multi -level ceiling.

Installation of PVC panels on the ceiling starts from one wall. They need to be cut exactly along the length of the surface with a hacksaw on metal, jigsaw or grinder. Cutting the first panel, it needs to be made a little shorter than the width of the room, approximately 3-5 millimeters. Stir the edges with a skin or abrasive grid. Try not to rush the panel. And most importantly, before installing, do not forget to remove the film from them!

It is necessary to work carefully, because this material is quite fragile. It is necessary to treat plastic before lining. If you have already managed to cause damage to the purchased plastic, you can try to hide them with a silicone, preferably white. This option is not suitable if you opted for color plastic, because silicone is white and transparent.

Fix the first panel tightly with self -tapping screws on the profiles, fasten all subsequent panels to the rails of installation profiles according to the type of designer. The most difficult stage of the entire procedure is the installation of the last panel. Cut off along the length by a millimeter less than a distance from one wall to the starting profile in the opposite. Insert the panel in one side until it stops in the profiles, directly into the corner.

In this case, the second end will hang out freely, put out the panel from the first corner and insert it. Between the penultimate and the last panel you will have a small gap, but they must somehow dock. At times, this manages to do it independently, but most often it does not work out. Then you can use the masking tape. Stick a couple of strips across the last panel and pull it to the previous one.

For installation of the lamp, it should be noted on the panel location with a pencil. Then you need to cut a hole using a stationery knife. Insert the lamp into the hole and connect the wire with it. The wires need to be launched under the ceiling. If you need to install several lamps, it is recommended to connect them parallel to each other.

At the end of the installation, the room is very transformed. But it will also need to be poisoned by frieze around the perimeter. This is done in order to hide the location of the plastic. And if you take into account the moisture resistance and practicality of such a ceiling, we can say that this is a fairly profitable choice for repair in your house.

Building store and

The store of construction and finishing materials http: // Remertvest.rf/ offers building materials wholesale and retail. Our store has a wide range of products at minimal prices, because We work directly with factories and manufacturers. We cooperate with Russian and European firms of finishing materials and have a well -established sales network, so we are always in stock building materials in bulk, and the supply of construction projects in Moscow passes as quickly as possible