Recently, apartment thefts have become more frequent, and in many cases, attackers ...

|

|

Quite often, after gluing wallpaper on the surface, bubbles become visible. This ... |

The coloring of the ceiling plinth is by no means the final chord in the repair, like ... |

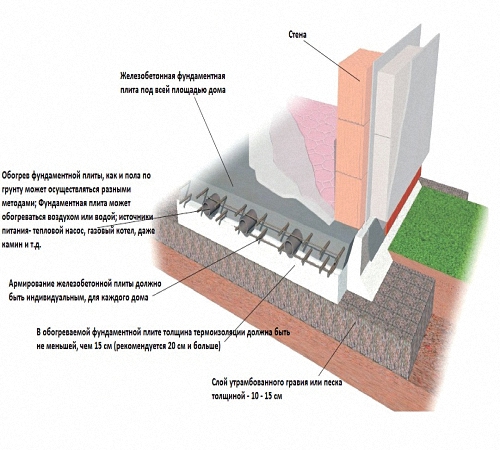

We make a slab foundation with our own hands. Recommendations for pouring and reinforcing a monolithic slab

Nowadays, when the field of building materials is rapidly developing, there are many types of foundation that differ in characteristics, species and purpose. But recently, a slab foundation has become more and more among professional developers. This type is especially convenient for owners of land with land in poor condition. And also, this option is considered one of the available ones. A person can even pour the foundation plate independently in repair matters, without applying great efforts.

Table of contents:

- Areas suitable for the use of a slab foundation

- Slab foundation advantages and disadvantages

- Calculation of materials

- Types of a slab base

- Preparation of materials and tools

- The construction of a slab foundation

- How to knead concrete for the foundation?

- Insulation

- Recommendations

Areas suitable for the use of a slab foundation

The most important feature of the slab foundation is a fine -bearing base, which is made of concrete pillow. This property allows you to fulfill its purpose even on mobile soils. Any other type of foundation is covered with cracks when the soil moves, therefore, in such areas it is necessary to use exclusively slab.

This base is perfect in the construction of houses where rigid substances are used. It prevents the structure of the structure.

Buildings that have low, in comparison with the ground, floors, must be built using exclusively a slab foundation. When using it, there is no need to build a basement and grillage.

Slab foundation advantages and disadvantages

Before proceeding with the choice of a particular product, it is necessary to weigh all its pros and cons. Let's start with the positive qualities of the slab foundation:

- He is reliable and durable. And it’s hard to argue with this. Interrogate specialists who are versed in building materials, and all as one will say that the tile is the most reliable type of foundation.

- It has a large area of \u200b\u200bthe land support, and if it is correctly laid, then the soil will not adversely affect the foundation in the cold season.

- The slab foundation is universal. The fact is that the technical characteristics that he possesses allow it to be laid on almost any ground. Therefore, most often they use this species in areas where no other foundation has been coped with the task.

- The ability to set the foundation above the depth of freezing of the Earth. This plus became possible thanks to a massive sand-gravel pillow, which prevents the effect of soil in the cold winter.

- A high level of stiffness, which does not allow the house to sag, and if this happens, then the room will not cause significant damage.

- Lack of need for the installation of a draft floor.

- The ease of device technology, which allows you to perform work on your own and save on the services of the master.

- Suitable for any type of low -rise building. The only thing that needs to be taken into account the thickness of the slab (the easier the room the thinner the plate).

- It can withstand soil movement. It is possible to build a house on floating lands, since the tile foundation will not burst and burst, but simply begin to move with them. This is the property to keep the building intact.

It should be borne in mind that all previously listed advantages will be valid, only if the installation rules are strictly observed. If in the process of laying there are violations of the technology, then the pluses can turn into minuses.

Like any foundation, some negative qualities are also present:

- One of the most basic disadvantages that customers note is the price. The high cost is justified by a large amount of concrete, reinforcement, sand, as well as crushed stone, unlike analogues. But on the other hand, the money spent quickly pays off. The tile foundation will not need frequent repairs, in expensive prevention, in addition, it will function as floors of the first floor, which will also reduce costs.

- It is not recommended to lay a tile foundation under the house, which is located on a site with a large slope. In this case, the output will be the leveling of the ground level, or the installation of the basement, but it is quite expensive.

- There are difficulties in installing the basement. In the case of building the basement, you will have to fill a monolith plate under it, which will cause significant losses to the owner.

- The occurrence of difficulties in installing the foundation on winter days. To pour concrete in the minus temperature, you will need to spend it on its heating and maintaining the heat around it.

- Difficulties in communicating wiring. It is necessary to think through the location of the water supply, electricity, etc. Before the start of the concrete is filled because it will be impossible to do after doing it.

As you can see, the slab foundation has a large number of advantages, and the disadvantages can be circumvented, however, it will cost additional costs.

Calculation of materials

Before starting work, it is necessary to calculate the slab foundation: the size of the formwork, the number and diameter of the reinforcement, the volume of concrete. All these values \u200b\u200bcan be found using a special calculator. To do this, you need to introduce a brand of concrete, width and length of the plate (in meters) and its height (in cm). Further, the program itself will calculate the number of materials necessary for arranging the foundation.

Types of a slab base

Also, before the start of work, it is worth determining the type of tile base. There are several options. The main of them:

- ordinary concrete pillow;

- the tape-pile.

This type is used during the construction of buildings with a basement. The fossa is dug up, put a concrete pillow on which, in the future, the base is installed. The entire load falls on the strip foundation.

- the base with stiffener ribs;

It is the best option among all, because it has high strength. It requires more materials and efforts to build it, so its technical characteristics exceed other types of foundations.

Preparation of materials and tools

Preparatory work also includes the assembly of a set of materials:

- concrete;

- steel rods;

- gravel;

- sand;

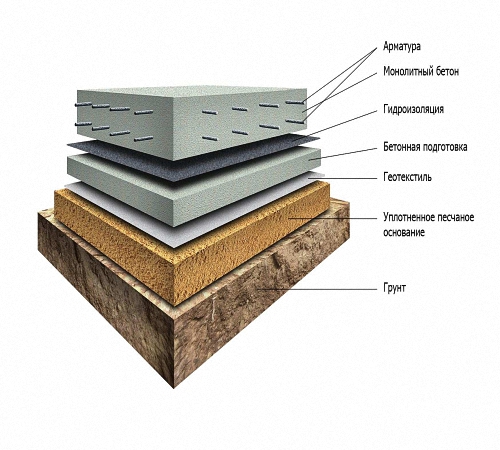

- material for waterproofing (geotextiles are most often used).

Some instruments for the slab foundation will be required:

- saw;

- a hammer;

- scrap;

- shovels;

- transportation car;

- welding device;

- bulgarian;

- roulette.

The construction of a slab foundation

The instructions for the construction of the slab foundation include several stages:

1. First of all, we conduct a geological study of the Earth, determine places with strong height changes.

2. We mark the future base.

3. Remove the soil layer and align the area where the construction will be held.

The choice of the depth of the pit depends on the type of structure (finely boiled or glued). If we consider the fine-loaded foundation, it will be enough to remove 50-70 cm of the Earth. The dimensions of the pit are selected taking into account that they should be 1-2 meters larger than the length/width of the foundation. After digging, be sure to compact the soil.

4. We design and install the formwork (wooden strong boards are suitable for its construction).

5. We pull out several trenches in the pit and put waterproofing in them.

6. We lay pipe from plastic on top of the waterproofing.

7. Pour the bottom with a mixture of sand and gravel, evenly distribute it and compact it.

8. We collect a double reinforcing cage and bind it using a special wire.

For reinforcement, exclusively rods with ribs are suitable. They will provide high -quality adhesion of the frame and concrete mix, as well as prevent stretching of the foundation plate. Using smooth rods in the work, the base will crack at the first soil subsidence. The reinforcement is laid in steps less than 30 cm. If you increase the distance, then the strength of the base will decrease significantly.

9. Put the plastic pipes in the places where there will be various communications.

Before installing them, it is necessary to fill with sand and carefully compact the backfill. Pipe are necessarily put before the start of the fill, since it is forbidden to make holes in concrete.

10. Pour a monolithic plate with a concrete solution.

Pour the slab foundation is carried out immediately. A concrete solution must be kneaded once and a large amount, so that there is enough for the entire fill. This work is quite laborious, so ideally it is worth the four. We lay concrete with uniform, horizontal layers. It is necessary to pour in such a way that the stove does not have deviations from the horizon. To prevent such slopes, in the lower part we create stiffener ribs. These are concrete strips made in the form of trapezoids. The last layer should be poured very quickly. Use a mixer or concrete pump for this.

11. Carefully smooth and level the surface.

12. Cover the resulting foundation with the film and leave it by a couple of weeks. Do not forget to moisturize the structure during the first five days.

How to knead concrete for the foundation?

To reduce the cost of work, you can knead concrete at the site of the foundation building with your efforts. But in this case, a special concrete mixer will be required. She mixes all the components perfectly, without forming lumps. This unit operates at a capacity of 250 and above Tue. At a time, you can get from 50 to 250 liters of solution. But the quantity strongly affects the time of work. If you take a small apparatus for example, then to create 1 cubic cubic cube it will take about 5 hours.

An important point is the location of the concrete mixer, it should be near the base. This will reduce the number of power you have applied.

Of course, there is an option to independently knead concrete for a slab foundation using a shovel, but this will greatly affect the quality of the future foundation.

Insulation

Of course, the best option would be to warm the foundation, to achieve a warm temperature in the room all year round. To do this, use various heaters. The most popular among them is polystyrene. Only 10 cm of layer will be enough.

There are also different types of insulation. We recommend using subservient. The insulation material is located directly under the stove.

Recommendations

Use the tips below to facilitate your work:

1. To create a high -quality base, you need to use only strong reinforcement and concrete kneading.

2. The use of a shallow base will reduce the costs of building materials by approximately 35-45% of the cost of the underground room.

3. It is very important to consider the thickness of the slab. For example, having chosen the thickness of the base of 20 cm, you will need in some places where there is too much load, to reinforce. At 25 cm, it becomes possible to knit a frame from the reinforcement uniform, without resorting to additional amplifiers. A 30 centimeter thickness will contribute to an increase in the strength and durability of the foundation, but at the same time will make you really spend money on concrete.

4. During the manufacture of a pillow of sand and gravel, the material must be laid in layers. One layer should not exceed 12 cm. After each masonry, thoroughly compact. If your pillow will consist exclusively of sand, be sure to moisturize the layers.

5. Before the start of laying the insulation material, the pillow must be covered with a dense plastic film to prevent water leakage from a solution of concrete. It is advisable to glue or solder polyethylene at the joints, or lay the sheets overlapping.

After reading this article, everyone will be able to make sure that the construction of a slab foundation is quite a simple process and is possible when creating with their own hands. The main thing is to comply with all the rules of filling and the technology of construction. If this is completed, then your foundation will last correctly, for many years.

Also, we suggest watching phased instructions on how to properly build a slab foundation of the video is located after the article.