How differently people relate to their dwellings! For some, the house is a fortress for ...

|

|

After the decision has been made on the choice of finishing materials for painting, it remains ... |

External slopes are an important detail of the window structure. They are mounted not only ... |

Parquet board substrate: features of choice and styling

The parquet board can be laid on a concrete screed, wooden floor or plywood base. Regardless of the type of black coating, most masters say that waterproofing and substrate are mandatory conditions of competent installation. Why is it so important to make a layer a place with a base and directly coating? The article will talk about which substrate for the parquet board is better.

Content:

- Which gives the use of a substrate for a parquet board

- Tuplex substrate

- Parkolag

- Foamed

- Foil

- Cork -board

- General principles for choosing a substrate for a parquet board

- A little more about the parameters

- How to lay a substrate under the parquet board and installation of the floor

Which gives the use of a substrate for a parquet board

You should start with the fact that any material laid under the parquet board has a couple of important missions: extend the life of the flooring and make its use as comfortable as possible. But these goals are achieved at the expense of the following substrate qualities:

- Correction of small surface flaws. Many can doubt the need for this quality, because before laying the board the surface of the floor in one way or another is aligned. This is true, but even a very experienced builder is difficult to achieve perfect evenness, for example, a cement screed. So saving on the substrate for the sake of this point is certainly not worth it.

- Additional thermal insulation. In addition to the fact that the warmth of the base under our feet is a very frequent criterion according to which comfort and comfort in the house are evaluated, the substrate normalizes the microclimate between the base and the final finishing material.

- Noise insulation. In addition to the low thermal conductivity of the substrate, the noise of the owners of the apartment extinguishes and work in the opposite direction. That is, they do not miss the noise from the neighbors from below. Convenience for the inhabitants of two apartments is provided with one material. And in addition to steps, the substrate will extinguish vibrations and the sounds of the work of household appliances.

- Waterproofing. Its necessity has already been mentioned above. In order for the parquet board to serve for a long time and does not deform, its protection against moisture is needed regardless of what microclimate has developed in the house or apartment. The substrates in one way or another serve as a barrier to the barrier between water and the parquet board.

All of the listed signs are more or less inherent in the substrates that will be considered below. In addition to such characteristics, the consumer is important to have such qualities as:

- the durability of the material;

- its environmental friendliness and security;

- strength (so that the weight of furniture and a large accumulation of the people do not affect the substrate);

- and, of course, the price.

The choice of materials is large, and their properties are different for them. It makes sense to compare the pros and cons of each to find the ideal.

Tuplex substrate

It is an excellent model of material in which the developers tried to cover the entire range of tasks solved by the substrate.

- It consists of three layers. The first vapor permeable. Thanks to him, moisture and condensate will not accumulate and harm the parquet board. They will linger in the second layer of foamed polystyrene and will be removed from it through the open edges. This feature will require the acquisition of skirting boards with a special ventilated structure: they not only tightly press the package board to the floor, but also do not delay moisture displayed by the substrate.

- Since the polystyrene foam is a good insulation, the blunting is recommended for use in country houses, private buildings and cottages. If the floors do not differ in the apartment in the apartment, then the use of such a substrate can improve the situation.

- Sound insulation in such a material is also at a high level. TUPLEX Polymer Environmental Product. Its density allows not only to align the base well, but also to distribute the load qualitatively. A parquet board with such a substrate is under reliable protection.

- The price of this substrate for the parquet board is 90-120 rubles/m2.

Parkolag

- One of the components of this substrate for the parquet board bitumen mastic. Cork granules are evenly distributed along a layer of bitumen. They provide reliability of strength and sufficient ventilation.

- Such a substrate was an ideal material, if it were not for a significant minus: the proximity to heating systems or high temperature in the room serve as a kind of catalyst for a reaction, in which bitumen mastic begins to secrete harmful formaldehyde. So extremely high indicators for heat and sound insulation, good protection against moisture fades compared to possible health damage.

- European quality standards do not recommend the use of such material.

Foamed

- Those who are looking for the most affordable option should opt for such a material as foamed. You can buy such a substrate for a parquet board for 20 rubles/m2.

- Properly selected in thickness, it will cope with the main tasks of the material laid under the parquet board. She can (albeit less than the copies described above) serve as noise and vapor barrier, provide a layer for additional insulation of floors in the room. All this becomes possible thanks to the porous structure, which, unfortunately, lacks strength and durability.

- The period of professional suitability at the substrate from the foamed sawn is limited to the family for ten years. At the same time, none of the sellers honestly admit how long the roll lay in the warehouse. The material will not just sit down, as some buyers believe (this would be the smallest of evils).

- The substrate will break up to the state of the powder, which in no way extends the service life of the parquet board. Another significant minus is exceptional combustibility of the material. Such a lining will quickly light up, while it will highlight extremely poisonous pairs.

- Poster reviews are used by the Penopremium Floores parquet and laminate market.

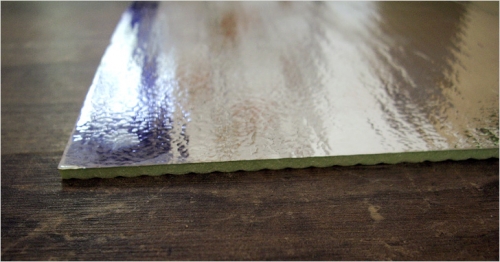

Foil

- This material is a kind of modification of the above substrate of foamed propylene. It is on it that an additional layer of foil is applied as the basis. This is done in order to improve thermal insulation and water protection indicators. With the absorption of noise, such a material will also cope well.

- His service life still remains small, therefore, it is more expedient to use it as a substrate for inexpensive and not too durable flooring, for example, under the laminate. For an expensive and high -quality parquet board, it is preferable to choose another option.

Cork -board

- A substrate for a plug parking board is the best option for a children's room. Thermal insulation and absorption of noise are absolutely necessary qualities in this room. This is a durable, durable and elastic material.

- Its environmental friendliness guarantees that no harmful evaporation and formaldehydes during its operation will harm human health.

- The thickness of the cork substrate for the parquet board is from 1.5 to 8 sometimes 10 mm. In the case of laying a parquet board, do not chase large indicators. The best option would be to purchase a cork substrate with a thickness of 2 mm. Material with smaller dimensions will not withstand the load and begin to crumble, and a denser option will undermine the castle type of connection of the parquet board from the inside. Neither one nor the other service life will increase, but rather only harm it.

- Of the significant drawbacks, in addition to the cost, there is only one constructive minus: the cork substrate is very afraid of moisture. If the lining gets wet, it will lose all its abilities and require a complete replacement. Laying a cork substrate is recommended only in rooms with a small humidity, while arranging the most reliable layer of waterproofing. If it is not possible to find a substrate on sale, which is already with such protection, then it will not be difficult to cope with the task with your own hands.

- But as a reward, the consumer receives excellent material: not pressing over time, perfectly eliminating irregularities and minor defects on the floor, environmentally friendly, not amenable to decay processes.

General principles for choosing a substrate for a parquet board

Before laying the substrate, it is necessary to consider the parameters that will be decisive in the choice of material:

- the conditions in the room where the parquet board will be mounted. Evaluate possible loads on the floor in the room, humidity and temperature;

- environmental Safety. The bedroom and the nursery demand that the substrate meets all safety standards;

- the quality characteristics of the substrate are no less important. The absence of a waterproofing layer can be compensated by its independent implementation, but it is unlikely that anyone wants to change the floors after 5 7 years;

- the ratio of the quality of the flooring and lining for it. If an inexpensive laminated parquet board was purchased, designed to replace after 7-10 years of operation, then there is no need to spend money on an expensive substrate. A completely non -budget dumb or cork material will not justify the funds spent on them. This is the case when foamed propylene (independently or with a foil layer) will be the best solution;

- it is advisable to choose a high -quality soundproof substrate for parquet. The best indicators of cork materials.

Additional vapor barrier: when can it be required? For those cases when laying plywood or any other obviously dry base is performed on sheets, reinsurance in the form of an additional vapor barrier layer is not required. This is especially important if a dumb or parkolate is purchased as a substrate. It is better not to take risks with a cork lining, and lay a layer of polyethylene for protection. And the cement screed will require the flooring of the vapor barrier layer in any case, regardless of the materials.

A little more about the parameters

- The question of the necessary thickness of the substrate excites many customers. Still, the assertion strengthened in the mind, which means better, pushes many to the acquisition of thicker material.

- It is worth starting to begin with the fact that according to construction standards there is a clear definition of an even base. It is considered such when the height drops on a pair of square meters do not exceed 3 mm values.

- The thickness of the substrate equal to two millimeters is sufficient to smooth out such nuances. The cork and foamed propylen are distinguished by their elasticity. If you put them with a too thick layer, then this will only increase the changes in height. As a result, with a large load, the parquet board will be deformed in the joints.

- The lock mechanism is quite dense, but such hard effects will first cause a creak, and then the coating elements will begin to break out.

How to lay a substrate under the parquet board and installation of the floor

- Both a multilayer parquet board, and a coating option made of an array, require laying according to the same technology.

- The base should be even, durable, not to have cracks and obvious changes in height. The permissible deviations have already been mentioned above.

- It is recommended to keep the purchased parquet board in the room at normal room temperature for a couple of days.

- When working on installation, it is important that the thermometer does not fall below + 18 C, and the humidity does not exceed 65% (with a minimum acceptable value of 35%).

- Before laying the substrate, an additional waterproofing layer is laid on the even surface, if it is dictated by the conditions of the room. On top of it, the substrate material is spread. Since this is in most cases rolled material, the canvases must be rolled out along the entire length of the room, and together they should be fastened with adhesive tape. The mats of polypropylene are laid close to each other, with a displacement of the next row (in the manner of brickwork). Between themselves, they are also glued with tape.

- On the other side of the parquet board, which will fit the wall, the spike is cut. The gap between the wall and the first row should be 10-15 mm. To make it uniform, use pegs of the same width or cutting of the board.

- The panels in the front row are connected with the help of a lock and gently tightly bent to each other using a kiyanka (or a regular hammer, but then the blows are carried out through a wooden block to damage it and the lamellas themselves).

- Parquet is laid. This improves its strength characteristics and helps him better distribute the load between the lamellas. Therefore, the second row begins with a short element. It is about a third shorter than the first board in the initial row. First, all the lamellas of the second row are joined between the length. And then they click with the first at a slight angle. The work is carried out in stages, you need to start from the edge, and gradually put into the connection of subsequent lamellas. Each connected board is tapped.

- To tightly knock out the last lamella in the row, a clamp is used.

- The third strip of panels begin with a board two -thirds smaller than the original. The operation on the connection is similar to the above actions.

- The fourth row will duplicate the initial (along the length of the first board). And according to this algorithm, the entire coating is laid.

- The hardest thing will have to fit the lamellas to the door frame or where you need to get around the heating riser. In the boards you will have to mark and carefully cut it according to the pipe configuration.

- After the installation work is completed, spacer wedges along the walls are removed and skirting boards are mounted.

Now, when the need to acquire such a material as the substrate is not in question, it remains only to purchase an acceptable option, to properly put a parquet board and enjoy a warm and durable floor in your apartment or house.