Thinking about the construction of their own home, developers are increasingly giving ...

|

|

For a long time, experts have been practicing the use of ceramic tiles as ... |

Thermal insulation of any building, whether it is a garage, an apartment or a country house, requires ... |

Vinyl floor: photos, types and characteristics

Of great importance in the interior of the premises of any purpose is the floor design. It should carry not only a decorative component, but also meet the operational characteristics. Vinyl modules do not take the last place among finishing materials for the floor.

Content:

- Review of the advantages and disadvantages of vinyl floors

- The structure of vinyl tiles for the floor

- Types of vinyl floors

- Preparation of the base for quartz vinyl coating for the floor

- Laying quartz of vinyl tiles for the floor

- Buy vinyl floors

Today, PVC products are offered on the market, which have become popular due to the convenience of installation and unique physical and technical properties. Polivinyl chloride floors are distinguished by a rich color spectrum and durability. They tactilely and visually imitate parquet, ceramic tiles, leather or granite coating.

Review of the advantages and disadvantages of vinyl floors

The flooring is used for laying in residential premises, offices and offices of organizations or enterprises.

Vinyl floor photo

This material makes its positive qualities widely in demand, among which it can be noted:

- high wear resistance. PVC floors will last at least 12 years, world -famous manufacturers give a guarantee to cover 25, or even 35 years;

- water resistance. Such a coating is recommended for installation in a spa, bathroom, bathroom or in the kitchen;

- soundproofing. Thanks to a special substrate, the module perfectly absorbs the noise up to 20 dB, which is comparable to muffled colloquial speech;

- high plasticitywhich greatly simplifies the laying process. In addition, this property gives the material to stress stress;

- anti -slip surface. It is simply impossible to perform pirouettes on such modules;

- lightness of styling. Polyvinyl chloride products are presented in 3 variations: on an adhesive basis, with planting on a solution and a castle connection;

- price. The cost of material per square meter. m taking into account additional materials below the price of cork or parquet floors.

It is worth noting that the listed positive qualities are characteristic of vinyl floors from proven manufacturers. Especially if quartz was added during the manufacture.

Vinyl, like any material, has a number of disadvantages:

- unpleasant odor, characteristic of new material. The cause is chemicals used in production;

- the need to carefully prepare the surface for styling. Here, even the smallest, it would seem, insignificant unevenness, in a rather short time will lead the vinyl floors to deformation;

- high susceptibility to rubber. Therefore, it is worth preventing the effect on the PVC heels with rubber nibes, carpet coatings on a rubberized base and wheels of heavy furniture;

- if the coating is of low quality, then under the influence of ultraviolet rays, it will quickly acquire yellow spots-radiation.

Before purchasing, it is recommended to check the vinyl coating for the availability of appropriate certificates and quality guarantees.

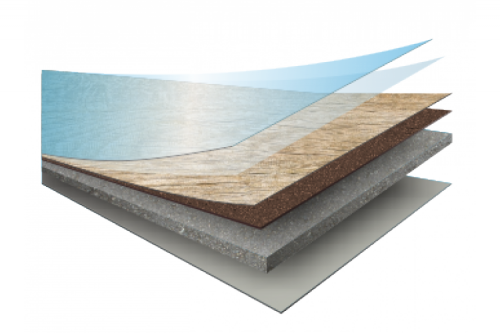

The structure of vinyl tiles for the floor

Thanks to the multilayer structure, such modules combine the elasticity of linoleum, the strength of the stone, the stability of ceramics and the simplicity of laying the laminate.

- The lower layer is made of polyvinyl chloride, which gives strength to the module and provides adhesion with the floor surface.

- On top of PVC under high temperatures, fiberglass is applied, acting as a reinforcing frame.

- Next is the main laying of polyvinyl chloride with the addition of quartz and sand.

- The next layer is a decorative film repeating the texture of marble, natural wood, natural stone and other materials.

- The surface from solar activity and abrasion protects a polyurethane coating with a embossed, anti -slip layer.

Types of vinyl floors

Polyvinyl chloride products are presented in the form:

- rolled material, the width of which is 2 m;

- tiles with sizes of 300x600 mm with a lock connection or a self -adhesive base;

- laminate, where modules can be 100x920 mm or 180x920 mm.

For rooms with high cross -country class 43 vinyl products are purchased. The upper polyurethane layer of such a coating has a thickness of 0.5 mm. For home use, 33 or 34 of the strength class is enough, here the thickness of the protective film is 0.2 and 0.3 mm, respectively.

- Vinyl floors with a lock Equipped with a spike-paz system, which allows you to mount panels with high speed. However, such a coating requires a perfectly flat basic surface.

- Self -adhesive tiles They have a layer of glue on the back surface, temporarily protected by a special film. Such products are securely fixed to any surface with a non -butter base.

- Adhesive floor material It is laid using a special solution. Glue should be purchased, recommended by the PVC coating factory. Only in this case we can talk about reliable installation to the basic floor.

Preparation of the base for quartz vinyl coating for the floor

- Before laying, purchased coating, it is necessary to give acclimatization at room temperature for 2-3 days, spreading it in a horizontal position.

- Installation is carried out at 18-24 degrees, especially if it is a tile for which glue is required.

- The surface for laying should be clean and even without cracks, potholes and other defects, and the moisture content of concrete floors does not exceed more than 5%.

- The basic floors are cleaned of fat spots, dirt and building debris. Immediately before laying polyvinyl chloride products, the surface is exhausted and treated with a primer.

- The modules are mounted close to each other. The temperature gap between the wall and tiles can not be left.

- When installing glue products, a roller is used, with which air bubbles are removed. The speaker is removed with a clean rag moistened with ethyl alcohol.

- To give the tile the required shape or fit to the required sizes first marking is applied to the material. Then, by means of a sharp knife, the line is cut into half the width of the product, after which it is bent and cut completely.

- The modules with a castle connection are additionally fixed by glue, nails or screws. Also, glue is not used to clutch tiles with foamed substrates and insulation materials.

- The warm floor system is disconnected at least a day before the installation of the vinyl coating. The distance from the heating elements to the tiles should be at least 1.5 cm.

- To avoid too obvious repetition of the pattern and color distinction near the located PVC elements, it is recommended to mix tiles, that is, take them alternately from different packages.

- The floor made of polyvinyl chloride is ready for operation immediately after installation. However, the arrangement of furniture is carried out after a couple of days, and wet cleaning of adhesive modules is carried out no earlier than 5 days later.

Laying quartz of vinyl tiles for the floor

Training

- Like any work, the installation of PVC modules requires the preparation of the draft surface. It should be even and durable. To save adhesive solution, it is recommended to close all the depressions and cracks with putty, cement mortar or by means of cycles. The choice of the method depends on the material from which the base is made.

- The presence of exfoliating areas is not allowed on the base floors. As a stable base, old parquet, floor tiles can serve as a stable base. To ensure a rigid base for wooden floors, sheets of drywall, plywood, fiberboard or chipboard can be performed.

Fitting

- Experts recommend first laying out the modules on dry, to determine the most acceptable option for laying (without displacement, in the form of brickwork, in the diagonal direction).

- The breakdown of the room is carried out by means of a laser and a painting cord. For this, the middle of the length of the room, which are connected by the line, is calculated. A perpendicular line is drawn through the center. Thus, receiving four equal quadrangles.

- If built -in furniture or heavy equipment is installed near the wall, then during installation, you should take into account this moment and move the axis of styling to the priority.

Laying

- Installation begins with the center of the room, where the two sides of the product should definitely coincide with the corresponding sides of the axial marking. Tiles are gradually increased from the middle of the room to the walls, according to the selected scheme. Elements are laid without gaps, forming a whole coating.

- In vertical surfaces and other protruding elements, the vinyl is cut into the corresponding forms. It is recommended to prepare a template that is adjusted with high accuracy.

- Self -adhesive products are mounted quite simply, for this a protective film is removed from the back. By light pressing, the module is fixed in the right area. Each element is additionally smoothed with a roller that removes the remaining air.

- Tiles resembling laminate in shape are mounted with a visible corner located opposite the doorway. The rules for laying vinyl planks with a castle connection are the same as that of the floor covering made of wood -fiber material. Here the spike and groove is carried out to a characteristic click.

- If laying is carried out on a concrete base, then first the surface is covered with waterproofing material.

- The modules for which adhesive composition are also necessary are also mounted without much difficulty. Much attention is paid to the glue itself, namely the time of its polymerization.

- Before the work, an instruction to knead the adhesive mixture on an acrylic basis is studied. The consumption of glue, as a rule, does not exceed 0.5 kg per 1 square meter. To use too much in reserve is not advisable. Firstly, this is an unjustified glue consumption, secondly, all excesses will show up the hillocks on the surface of the tile, but thirdly excess will still have to be removed.

- The composition is applied to the site designed for tiles with a gear spatula. You should not cover with adhesive solution a large area at once, otherwise it will grasp, and it will not be possible to glue the product. You can adjust the position of the tile for 15-20 minutes.

- The glued vinyl is walked in a roller in all directions, the excess glue at the joints is removed with a dry clean cloth. For a frozen composition, a rag moistened in ethyl alcohol is used.

- Relik is re-rolling after 30-40 minutes. Along the way, an examination of each element is carried out for peeling parts, special attention should be paid to the angles of PVC tiles.

Vinyl floor video

Buy vinyl floors

Modern floor material has many positive operational characteristics. This is an ideal coating for people who value practicality. Using vinyl modules, you can create a strong and functional coating without a significant investment of funds and time costs. But its quality and cost vary depending on the manufacturer.

- Vinyl floors tarkett The most popular in Russia. They produce a special collection of Art Vinyl, which transfers the pattern and texture of natural wood with absolute accuracy. But the price of this vinyl floor is equal to the price of a grade 33 laminate and is 550-750 rubles/m2.

- Vinyl floor Allure (USA) was the very first floor of this category. The manufacturer claims that in terms of strength it is not inferior to porcelain tiles. He surpasses Tarkett's products with his characteristics, but the price per square meter is already 2000-2500 rubles/m2.

Thanks to the wide color scheme, polyvinyl chloride tiles fit perfectly into the interior decorated in any style.