Decorative ceiling decoration important stage of repair work and ...

|

|

The piece parquet is really durable and at the same time enough ... |

The quality and duration of the operation of any building determines primarily it ... |

Laying tiles on a wooden floor

For a long time, experts practice the use of ceramic tiles as facing material, which is due to a set of its operational characteristics, including strength, fire resistance, wear resistance and moisture resistance. Given these advantages, the floor covered with ceramic tiles can rightfully be considered one of the most practical and functional. The expansion of the possibilities and technological solutions of production has led to the fact that the boundaries of using ceramic tiles have expanded significantly, and today it is the main finishing material for the floor, not only in the kitchen and in the bathroom, but also in other rooms of the house or apartment. However, all experts, without exception, argue that the quality of the flooring is determined not only by the operational characteristics of the material, but also from the effectiveness of aligning the base surface. This is due to the fact that ceramic tiles, possessing considerable weight and high density, belongs to the category of heavy materials, and therefore, not every basic base can withstand it and one of these basics is a wooden floor. Why are wooden floor and ceramic tiles incompatible categories? Firstly, this is due to the tendency of wood to various deformations against the background of changing temperatures and humidity, which will lead to unusable to linear shifts of floor ceramics. These changes will cause cracks, chips, the reinstalling of the elements from the base and their displacement and coloring of the seams. However, these problems are easily fixed if all the secrets that the masters follow in this case. In connection with the relevance of the topic, in this article we consider the technology of laying tiles on a wooden floor, as well as the most popular nuances of its installation.

Content

- Does it make sense to lay tiles on a wooden floor?

- Difficulties arising when laying wooden tiles, and methods for their elimination

- Varieties of floor tiles and its advantages

- Laying ceramic tiles on a wooden floor

- Preparatory stage: how to prepare the base?

- How to put tiles on a wooden floor?

Does it make sense to lay tiles on a wooden floor?

The increasing availability, and, consequently, the popularity of ceramic tiles, the main trend that has formed in the construction market over the past decades. Due to the variety of assortment and collections of facing ceramics represented by the manufacturer, even the most demanding buyer will be able to choose a facing coating to his taste. But, often, the process of choosing the material is not the most problematic, and real difficulties arise at the stage of laying tiles on a wooden floor. Unlike the technology of laying porcelain tiles on a concrete base that has long been developed and does not represent difficulties, in the process of laying tiles on a wooden floor, certain difficulties arise, having sorted out which, you will understand that they are easily fixable.

But, despite this, some experts do not recommend combining wood and ceramic tiles, considering it a useless venture. Consider why.

- In most cases, they consider it simply irrational to cover the warm wooden floor with cold ceramic tiles;

- Due to the fact that floor ceramics have water -repellent characteristics, laid on a wooden floor using tile glue, it violates the breathability of wood, and therefore, it begins to rot and collapse;

- The operational period of floor ceramics significantly exceeds the life of the timber and wooden boards of the draft base, which also casts doubt on the expediency of laying ceramic tiles on a wooden floor;

- Ceramic tiles, characterized by high strength and weak abrasion, is subject to tangible fluctuations under the influence of linear expansion of neighboring elements;

- The wooden floor is not characterized by static, which is a prerequisite for laying floor ceramic tiles.

Often, many believe that the aesthetic characteristics of wood are lower than those for ceramic tiles, but experienced specialists do not consider this too convincing argument, justifying this by the fact that in most cases ceramic tiles are used not in order to decorate the room, but due to sanitary-hygienic reasons . Despite the fact that the effectiveness of the use of ceramic tiles as a material that protects the wooden coating from moisture remains in question, at the moment it remains the main reason for the flooring of ceramic tiles in combined bathrooms, showers and wooden baths in one word in rooms in need of frequent wet cleaning . However, before starting styling, it is necessary to decide on the method of its installation, as well as choose the most rational technology.

Important! Experts recommend refusing to lay floor tiles in a new wooden house or in any structure with new wooden ceilings for at least 2-3 years, during which intensive shrinkage will be completed.

Difficulties arising when laying wooden tiles, and methods for their elimination

- The first and, perhaps, the most important difficulty is associated with a more difficult installation and laying of floor ceramics and is due to the fact that due to the wooden base it is much more difficult to achieve the required rigidity. To correct this situation, a large amount of concrete will be required, which is associated with increased costs;

- However, pouring a concrete foundation is not a solution to all problems. Even having implemented it, you will not be able to achieve a completely monolithic structure of the base, which is a prerequisite for the effective operation of floor ceramics. Otherwise, the concrete screed will soon begin to crack and quickly destroy, which, accordingly, leads to the cracking of the flooring;

- There are also difficulties in preparing the floor itself: if during walking it creaks and bends, tiles cannot be laid on it and before installing the flooring must be disassembled, and then remove the stalling and rotten boards and cover the floor with corrosion equipment. In conclusion, it is necessary to thoroughly align the plane of the base and only then proceed to laying the tiles.

From all of the above, we can conclude that wood is an unreliable material prone to deformations from both the lack and from excess moisture. The floor mounted just a few years ago already has the initial signs of deformation, which may not always be noticeable, but they always affect the monolist of the ceiling, and therefore, some tiles disappear, and some completely crack. To prevent this, it is necessary to create a special layer between the tree and the tile, leveting all possible fluctuations in the floor. In this case, its solid side should be facing the tile, and elastic to a wooden basis. In addition, it is necessary to remember the need for ventilation, which will prevent rot and subsequent destruction of wood.

Varieties of floor tiles and its advantages

The modern construction market tirelessly affects buyers with a wide range of floor tiles, which can be classified in accordance with different signs.

The first sign, according to which you can distinguish several varieties of tiles, shape. The form distinguishes:

- Square;

- Rectangular;

- Hexagonal;

- As well as tiles with uneven (wavy) edges.

In accordance with the material used for the manufacture of tiles, they distinguish:

- Granite tilesmade from natural rock, which is characterized by strength and resistance to mechanical influences. There are two types of tile granite coating:

- polished coating characterized by a smooth, mirror surface;

- a heat -processed coating, a distinctive feature of which is a natural appearance and a pronounced structure.

- Ceramic tilesconvenient to care and resistant to aggressive effects of chemicals. In most cases, it attracts the attention of buyers with a wide range and a variety of colors and drawings. The versatility of ceramic tiles is another distinguishing material: it is suitable for decoration of both the bathroom and the kitchen and the hallway. One of the varieties of ceramic tiles is a tile coating that has gained more and more popularity recently;

- Porcelain tiles, unlike ceramic, made in one stage and representing a monolithic coating. The operational characteristics of the material are such that it can successfully imitate stone, marble, wood and even skin. Due to its high thermal conductivity, porcelain tiles retains heat for a long time, and therefore, it can be used as a floor covering in the case of installation of a warm floor;

- Cork tileAn ideal solution for apartments and private houses of developers suffering from allergies. It has the ability not to attract dust and not covered with mold, and is also characterized by increased resistance to moisture, and therefore, even during prolonged operation in the bathroom, the cork floors will not begin to rot. However, due to the low resistance of cork tiles to the sun and mechanical influences, it is recommended to use it to arrange the flooring in the bathroom and toilet, where the effect of these factors is minimized.

Unlike a wooden coating, ceramic tiles are characterized by a number of advantages, due to the presence of which it can be used as a floor covering in the kitchen, in the bathroom and hallway. Consider what the advantages of ceramic tiles are:

- Lack of tendency to fire;

- Non -toxicity and environmental safety of the material;

- Resistance to aggressive chemicals;

- Resistance to high mechanical influences;

- Does not conduct electric current;

- For a long time retains its initial performance in conditions of high humidity, constant exposure to sunlight, low or high temperatures;

- Unponduved in leaving another advantage of ceramic tiles.

Laying ceramic tiles on a wooden floor

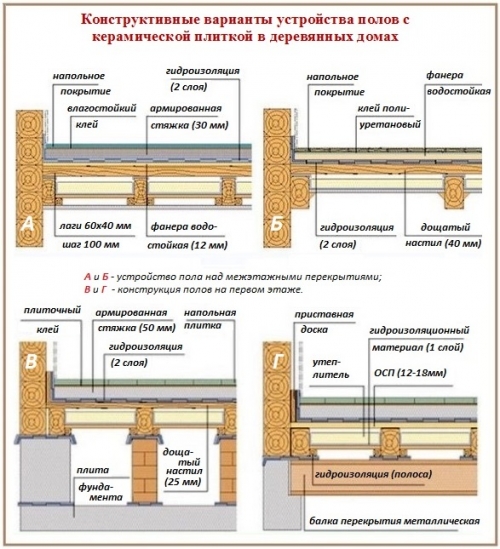

In the classic version, experts compare a wooden floor with a multi -layer sandwich, fully or partially made of lumber. There are many options for manufacturing a wooden floor, listing and detailed consideration of which is not the topic of this article. In this regard, we will consider the basic constructive variations that masters have to face in the process of laying ceramic tiles on a wooden floor:

- The lags that remained after the dismantling of the fruits and the resulting substrate;

- Wooden flooring, for the construction of which a moisture -resistant plywood or sheets of chipboard were used, with lags under it;

- And finally, a moderately worn wooden structure, which is a full -fledged plank floor.

This information is provided in this article due to the fact that the amount and volume of repair operations is determined not by the technology of flooring, but by the initial state of the base. This is due to the fact that the fastening of the ceramic elements of the flooring is always performed according to one, clearly established algorithm, and all the differences in the process of repair work are determined by the initial state of the base and the volume of the necessary preparatory measures, the ultimate goal of which is to create a perfectly even, durable, and most importantly static foundation suitable for laying floor ceramics.

Preparatory stage: how to prepare the base?

First of all, the master involved in laying tiles on a wooden floor is faced with the task, which consists in preparing the base that compensates for all the consequences of the natural movement of wood, which in any case occurs during operation.

Important!If the multi -layer pie of the wooden floor is mounted correctly, it performs the following functions:

- Preservation of the monolithic of the flooring;

- Minimization of static load on wooden structural elements;

- Providing effective wood ventilation.

Important! As a draft base for laying floor ceramic tiles on a wooden floor in the kitchen and other rooms with high humidity, it is recommended to abandon the use of plywood and GVL in favor of boardwalks, from the surface of which are removed old varnish and paint and covered with an antiseptic. DSP, plywood and GVL with water -repellent properties are recommended only in dry rooms.

Revision of a wooden foundation

Initially, the term wooden floor means not only boarding floorboards that can be seen from the outside. It is a multilayer design, which consists of powerful beams laid under it, and a substrate located under the boards. In this regard, before starting laying tiles on a wooden floor, it is necessary to carry out a thorough audit and inspection of all wooden elements of the floor.

Due to the fact that the decoration of the new wooden floor is recommended exclusively using a dodgy board, this follows that the audit will undoubtedly imply a complete analysis of the floor. The absence of creaks is not a reason to refuse this event, since the floor was already in operation and underwent certain functional changes.

Important!If the laying of the lag was carried out with a step of 50 cm, the floor must be completely shifted, since it will not be able to withstand the weight of the screed and ceramic finish.

If you have no complaints about the existing design, its audit must be done in the following order:

- First remove the existing flooring;

- Then the lags and beams are checked, the spoiled and beginners are replaced by the elements;

- Using the level, the horizontal floor is checked and, if necessary, it is aligned;

Important! If the lift of the lag in the usual way (by clogging the wedge or laying out of lumber waste) is difficult, the board is sewn on top, and, focusing on level indicators, excess is tightened.

- Further, all the constituent elements of the wooden structure are processed with antiseptic impregnation or mastic, choosing the technical specifications of which implies the maximum frequency of the update;

- After the antiseptic impregnation has dried up, the space between the lags is filled with fine -fractional expanded clay, which is covered in such a way that at least 5 cm for ventilation remains between the surface of the heat insulator and the upper line of the lag;

- Then the floorboards are prepared for reverse styling, since plywood or GVL cannot cope with the specified task in conditions of high humidity. However, to arrange a small kitchen, bathroom or hallway, these materials may well be used.

Important! If you want to cover the floor under the laying of ceramic tiles with black use boards, you need to remove varnish or paint from them. The easiest way to do this is using a sharp scrap or sandpaper, however, the modern market offers to do this in other ways, acquiring a special chemical washing or a hair dryer, softening a protective and decorative coating.

- The boards that have become draft are laid back, I leave a gap of at least 3-5 mm between them to ensure the likely expansion of the draft floor. For fastening the boards, galvanized screws are used, which are screwed one at a time, and two in extreme lags;

- If defects are detected from previous mounts or small defects, they must be masked with putty;

- The black floor is aligned with a grinding machine or it is closed if it does not need to be aligned;

- A technological gap of 1 cm is left along the perimeter of the floor, which is filled with silicone mounting foam or glued with a polymer membrane tape. For this, a strip of a membrane, the width of which is 30 mm, is bent in half and one part is attached to the lower edge of the wall, and the other to the floor;

- The gaps between the boards are also filled with mounting foam or glued with a polymer membrane;

- To form a monolithic insulating layer, the black floor is treated with heated olifa or latex impregnation;

Important! If for waterproofing you preferred the Olifa or impregnation, without waiting for their final drying, cover the prepared surface with a painting mesh, which will contribute to the creation of a continuous layer of waterproofing that prevents the effects of moisture and compensating for the natural movement of wood.

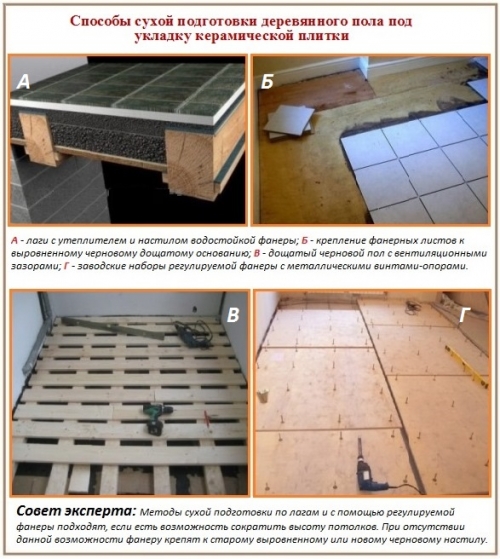

Installation of a lightweight screed

- The further stage of preparing the base necessary in order to effectively lay the tiles on the wooden floor, involves the device of a solid, rigid base for laying floor ceramics. It implies a standard screed that is facilitated by the fact that excess mechanical effect can harm wood.

- The arrangement of a lightweight screed for laying tiles on a wooden floor in a bathroom, kitchen and other rooms can be carried out in three ways:

- Pouring a traditional concrete screed with a thickness of not more than 3 cm. For this, the black base is laid and waterproofing is arranged, on top of which a metal mesh is covered and fastened with self -tapping screws, after which a cement or polymer screed is poured;

- Instead of traditional compositions, you can use glue -based glue or two -component polyurethane glue, after polymerization creating an elastic layer that prevents the cracking of tiles as a result of wood deformations;

Important! A liquid glass -based solution can be prepared independently. For this, two parts of washed and sifted sand, one part of the water and two parts of liquid glass are mixed.

- In dry rooms, experts recommend that operational dry alignment using moisture -resistant drywall or TSP plates, which are laid in a run at an angle of 30 degrees with respect to black boards. The seams are additionally sealed with specialized compounds designed to work with GCL.

How to put tiles on a wooden floor?

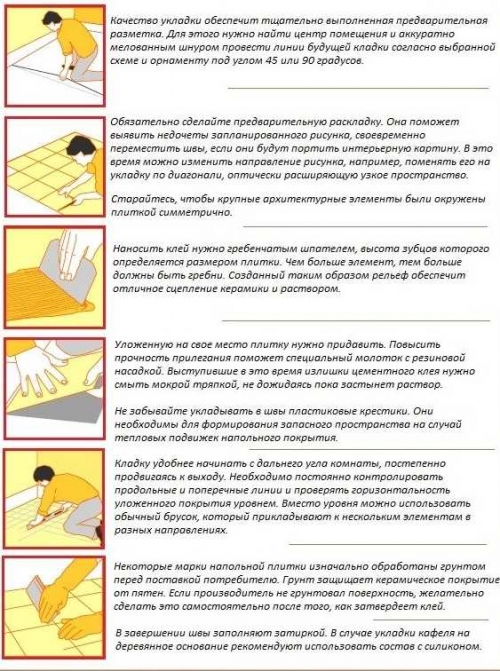

Before the final laying, preliminary fitting is carried out. Cutting parts cannot be avoided, but it is better to lay the chopped parts on the periphery or in shaded areas, and therefore, the preliminary layout begins with the central part. Immediately determine how many tiles are subject to cutting and cut them in advance using a grinder. Further actions for laying tiles are no different from the standard laying of the tile to any other surface and are as follows:

Find the center of the premises by crossing the diagonals. The room is divided into four even segments, drawing them using a coated masking skin.

In accordance with the instructions presented on the package, glue is prepared. It is not recommended to prepare the adhesive composition in an amount exceeding the amount of glue required for the decoration of 1 sq. meters of the floor;

Important!It is recommended to abandon the use of mastic in favor of cement glue. The traditional grout is recommended to be replaced with a silicone composition of a suitable color.

- Using a spatula-glue, the solution is applied to the floor surface, while the size of the spatula teeth depends on the size of the tile. For tiles with large dimensions, the size of the teeth of the comb should be 0.8 mm;

- Tiles are laid on the treated surface, inserting plastic crosses into the butt seams;

- At the same time, the longitudinal and transverse sections are constantly monitored, as well as horizontal using the construction level;

Important! Alignment of the masonry can be carried out until the glue composition is completely hardened. To adjust the longitudinal and transverse directions, just shift the tile. If the tile is sunk, it must be separated, add the solution and lay it back.

- The remaining glue from the surface of the tiles is removed with a soft damp rag, without waiting for the solution to dry. Upon completion of laying, the seams are moistened and wiped.

If in the process of laying the tiles you took into account all our recommendations and have not forgotten about all the features of wood, floor ceramics will serve you before the construction of a new structure, retaining your initial operational characteristics.

Tiles on wooden floor video