An additional way of increasing living space is the arrangement of the attic ...

|

|

When the balcony requires a capital repair, it is important to think over everything. This is a new glazing ... |

The process of finishing the basement of the building is a rather important process that ... |

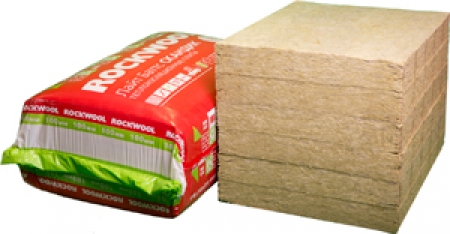

Square Light Butts: characteristics, reviews, styling

Thermal insulation of any building, whether it is a garage, an apartment or a country house, requires serious and rational calculation. It is necessary to calculate the heat loss of the building, the minimum thickness of the insulation, vapor permeability of the material, placement of the dew, take into account the requirements of SNiP.

When carrying out thermal insulation work, it must be taken into account that the insufficient thickness of the thermal insulation layer will lead to the displacement of the dew point into the wall, its freezing, which will negatively affect the explosive qualities of the structure. This will reduce the lines of the structure of the structure. An increase in the heat -insulating layer in excess of the norm will lead to unnecessary financial costs.

Content

- Rockwool leader of a stone -free thermal insulation group video, video

- Rockwall Light Battts insulation

- Installation of stone cotton wool Rockwool Light Batts Scandic

Rockwool leader of a stone -free thermal insulation group

Thermal insulation based on basalt fiber is widely used in all types of construction from private housing construction to industrial scale. The inorganic base is formed by melting rocks of the basalt group.

Thermal insulation is the main characteristic of stone cotton wool. The thermal conductivity of the material is 0.035-0.04 W/ms. In this case, the density of the material is up to 50 kg/m3. Using thermal insulation, heating costs can be reduced more than half.

In addition to thermal insulation properties, the insulation has excellent sound insulation. The structure of the material has an open porosity, which helps to wore sound waves up to 60DB, inhibits any noise sources.

Vapor permeability. Throughout the day, a person produces up to 5 liters of water vapor. Therefore, through the windows, doors and walls, moisture is constantly transferred. Steam stoves are well passed by steam (the vapor permeability module of Light Batts is at least 0.3 mg/m*h*PA). At the same time, moisture is not delayed in the insulation, thus the high vapor permeability of stone wool allows you to easily and reliably remove excess moisture from the premises and enclosing structures. High vapor permeability allows you to create a favorable internal climate in the room and avoid moisture -inflammation in the structure. Thermal insulation slabs are hydrophobicated, which provides water -repellent properties of the insulation.

Fire resistance is one of the most important properties of building material. The basalt fibers withstand the melting temperature of about 1000C. The insulation prevents the spread of fire in the event of a structure of the structure. Basalt -based insulation is also used to arrange smoke removal systems.

The thermal insulation service lines for more than 50 years, while it does not lose its physical properties, providing reliable heat and sound insulation.

The material is produced by a roll shape or in the form of plates. Thickness from 25mm to 150mm.

Rockwall Light Battts insulation

Rockwool Light Battt plates Light self -supporting insulation. Available only in the form of plates. In winter, he warms up, and in the summer it retains a comfortable microclimate, which helps to save not only heating, but also on air conditioning. The heater slabs should not be subjected to load. The fibers in the insulation are hydrophobicized, which prevents water absorption and in accordance with BS 2972-75 it is 1-1.5%. Even the direct ingestion of water on the insulation will not have a negative effect on its insulating abilities.

Mineral wool plates are used for heat-insulation, attic, inter-story floors, light walls of frame houses, walls for siding, partitions, balconies, baths and saunas. The thermal conductivity of the material is 0.036-0.041 W/ms, depending on the ambient temperature, which fully corresponds to GOST 7076-87 materials and construction products. The insulation owns a normal sound absorption coefficient at the level of the requirements of GOST 16297-80 Soundproof and sound-absorbing materials, belongs to a group of non-combustible materials.

The company improves the quality of its products every year. In March 2009, Rockwall presented a new Flexi technology. It provides for a springy pushing long edge, which simplifies the installation of insulation plates and does not require pruning of plates in narrowed places and in the size of the guides. Having installed insulation in the guide plate, it will straighten and completely fill the space between the guides. The spring side of the plate is marked with red stripes, which contributes to a simple identification of the installation direction. The width of the spring part of the edge is 50 mm.

Light Batts Scandik

In 2012, Rockwool launched a new line of products of the vehicle of Light Batts Scandic. Scandic technology allows, due to the compression of insulation by 60%, reduce the volume of packaging. After opening the packaging, the slabs acquire the original shape without loss of the quality of the insulation. Light Batts Scandic is produced by packs of two sizes: standard 800x600mm, convenient for transportation even in a passenger car

and XL size 1200x600mm.

It is good to use for insulation of large areas, the installation rate increases. Also, a QR code is placed on the packaging of the insulation, by counting which you can download the instructions for the installation of insulation.

Installation of stone cotton wool Rockwool Light Batts Scandic

Installation of insulation plates must be carried out by observing safety regulations. When working with the insulation, you will need a small arsenal of tools and protective ammunition.

Remedies

Stone wool slabs consist of the smallest hairs of basalt fiber, which, falling on the skin and in the mucous membranes of a person, cause burning and itching. Also, a phenol -formaldehyde resin is used as an astringent material, pairs which negatively affect the organs of the respiratory system and the human body as a whole. When installing stone wool, the use of personal protective equipment is mandatory. When working, you will need:

- rubber gloves;

- respirator;

- protective glasses;

- overalls or clothes with long sleeves;

- hEAD BEAUTION (hat, helmet).

When laying wool slabs, avoid drafts that will move dust from cotton wool. After installation, close the insulation with vapor barrier, plywood stove, plasterboard sheet or HLK. This minimizes the entry of dust from cotton wool into a dwelling.

It is forbidden to keep food and water for drinking on the site of work. Do not allow contact with insulation of children and pets. At the end of the installation, it is necessary to clean the remnants of the insulation. Workwear and shoes must be changed to clean.

Tool

For the installation of thermal insulation in the already prepared frame you will need:

- construction stapler;

- construction knife;

- a hammer;

- metallized adhesive tape;

- roulette or construction line.

Installation rules

When warming the attic from the outside, it is necessary to pre-lay the moisture-windproof membrane. It protects the insulation from the condensate of the metal roof. At the same time, it is vapor permeable, which allows the roof design to breathe. The film is attached to the rafters using a construction stapler. On top of the membrane, the rails of the counterparts are nailed to install the ventilation gap. With the length of the roof slope up to 6m, the ventsor should be at least 50 mm. With the larger length of the roof slope or a complex roof design, the size of the ventilationzor must be increased.

The orientation of the insulation plates will depend on the steps of the rafters. On the axes of the rafters are installed with a step of 600, 800 and 1000mm. Leaving this, you need to select the method of installing insulation. It should be remembered that in the light between the rafters the distance will be smaller by the thickness of the rafters, in most cases it is 50 mm. Since the boots of Light Batts Scandik have a springing side, they are easily inserted between the rafters with a step of 600mm, for the rafters with a different step, it is necessary to install additional rails of the frame.

The heater slabs are mounted in two layers with a run for the maximum effect of insulation and the obstacle to the occurrence of cold bridges.

The thickness of the thermal insulation layer depends on the region of residence and is calculated according to the tables of the average daily temperature, the duration of the heating season, and the minimum temperature indicators of the area.

On the inside of the room, to reduce the moisture -transmitted, vapor barrier is mounted using a stapler. In the quality of the vapor barrier, it is good to use a foil film. It should be the shiny side. The film is laid in the overlap, the joints must be glued with double -sided tape. After the film, it is necessary to nail the rails of the crate for installing the ventilation clearance. The fins are installed on the rails.

Mineral wool excellent insulation and sound insulator will protect against external noise and will save money both during the heating season and in the summer heat. It is easy to install, during operation it requires a minimum number of tools and circulation skills. Positive reviews of consumers around the world guaranteed the success of this product.